Self-healing polyurethane waterproof coating and preparation method thereof

A polyurethane waterproofing and coating technology, applied in polyurea/polyurethane coatings, wax coatings, coatings, etc., can solve the problems of weak waterproof coating strength and inability to be used in combination, and achieve high solid content, good self-healing properties, and adhesion powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

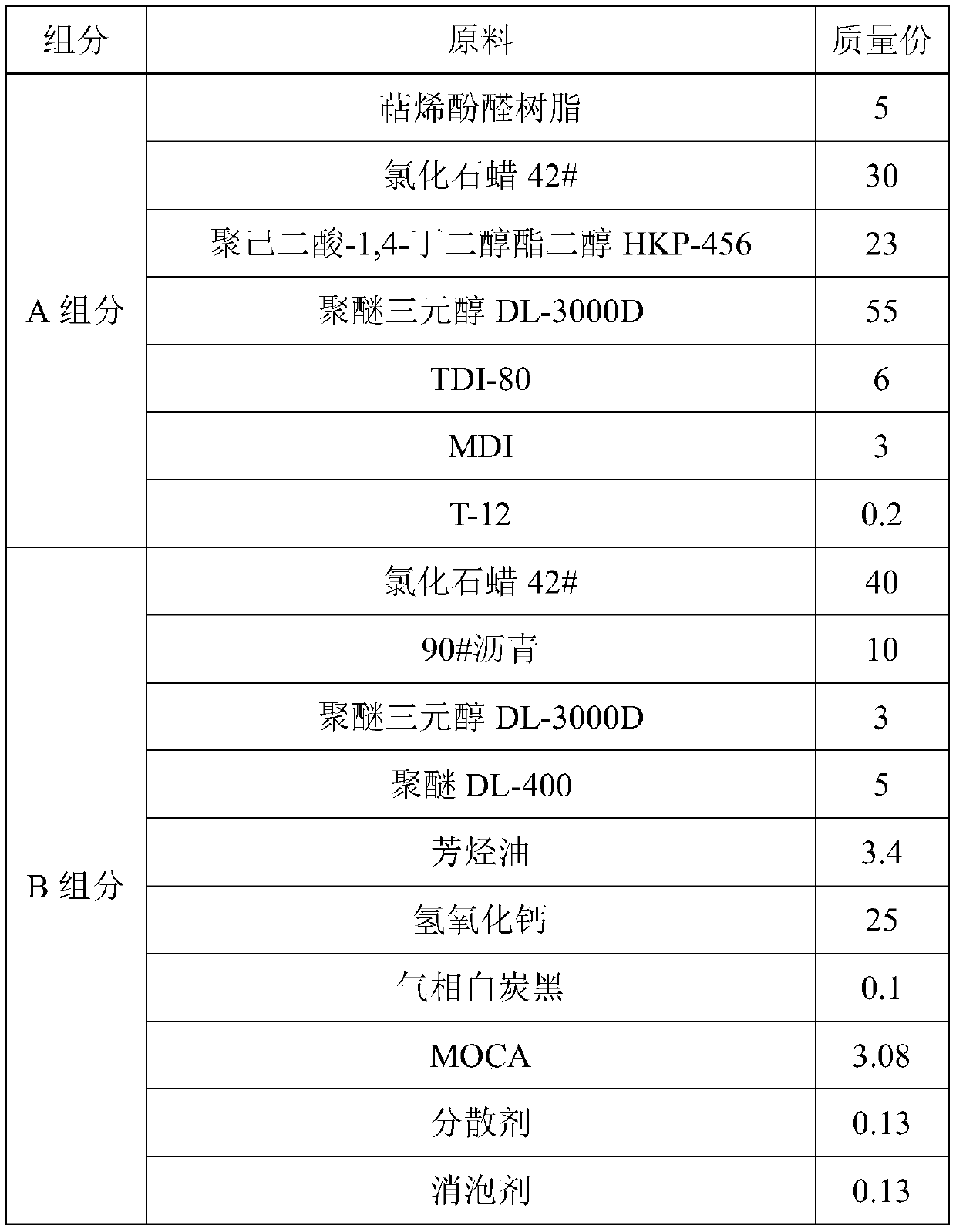

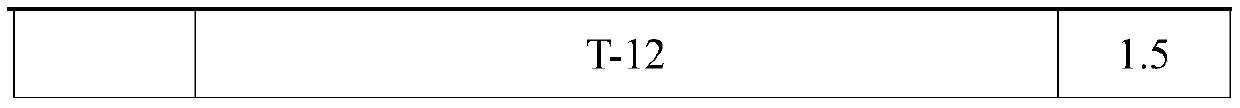

[0058] See Table 1 for the proportions of the raw materials of the self-healing polyurethane waterproof coating in this example.

[0059] The raw material composition of table 1 embodiment 1 self-healing polyurethane waterproof coating

[0060]

[0061]

Embodiment 2

[0063] Table 2 shows the raw material component ratio of the self-healing polyurethane waterproof coating in this example.

[0064] The raw material composition of table 2 embodiment 2 self-healing polyurethane waterproof coating

[0065]

Embodiment 3

[0067] The proportions of the raw materials of the self-healing polyurethane waterproof coating in this example are shown in Table 3.

[0068] The raw material composition of table 3 embodiment 3 self-healing polyurethane waterproof coating

[0069]

[0070]

[0071] The preparation method of the self-healing polyurethane waterproof coating of embodiments 1-3 is as follows:

[0072] Preparation process of component A: According to the compositions in Tables 1 to 3, add terpene phenolic resin, chlorinated paraffin, poly-1,4-butanediol adipate diol HKP-456, and polyether triol accurately. DL-3000D was heated to (115±2)℃, and vacuumed to (-0.095~-0.1)MPa. After 2 hours, the vacuum was stopped. When the temperature dropped to 70℃, TDI-80 and MDI were added accurately, and the temperature was increased to 80°C, react for 2h, when the temperature is lowered to 70°C, add catalyst T-12, react for 30min, cool down to 60°C and vacuumize to (-0.095~-0.1)MPa, and discharge after 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com