Method and device for producing prestressed concrete cylinder pipe by surfactant

A technology of concrete pipe and prestressed steel, which is applied in the direction of strengthening forming, etc., to achieve the effect of enhancing bond strength, high strength and enhancing protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

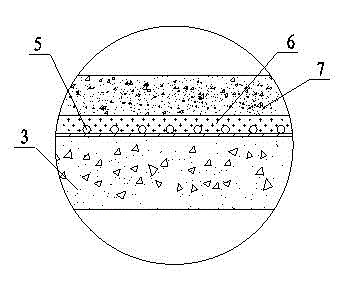

[0023] After winding the circular prestressed high-strength steel wire on the outer surface of the tube core, a layer of interface agent with a thickness of 2.0mm is sprayed on it to carry out the interface between the metal and non-metal materials. After treatment, use a roller jet machine to spray a protective layer of dry hard cement mortar with a compressive strength of 48MPa and a thickness of 25mm.

[0024] Cement 20%

[0025] Waterborne epoxy resin 2%

[0026] Epoxy curing agent 3%

[0027] ≥80 mesh rubber powder 1%

[0028] Quartz sand with a diameter of 1-4mm 30%

[0029] ZD aliphatic water reducer 1%

[0030] water 43%

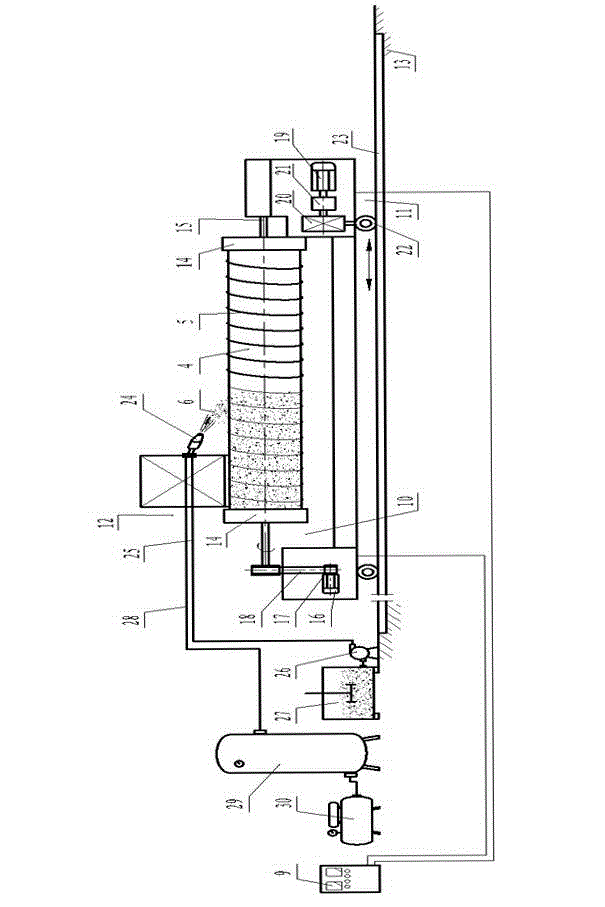

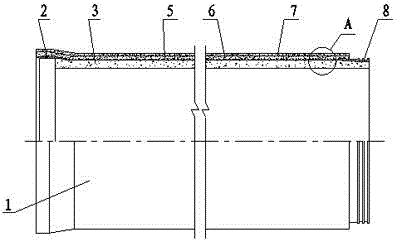

[0031] Depend on figure 1 -3 represents an embodiment of an interface agent spraying equipment for producing prestressed steel cylinder concrete pipes using interface agents according to the present invention: an interface agent injection equipment for producing prestressed steel cylinder concrete pipes using interface agents, which includes pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com