Oil filter adhesive

A technology for oil filters and adhesives, applied in the direction of adhesives, adhesive types, non-polymer adhesive additives, etc., can solve the problem of reduced bond strength between filter element and end cover, shortened service life, and colloidal inadequacy Density and other problems, to achieve the effect of improving carrying capacity, enhancing stability, and clear transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

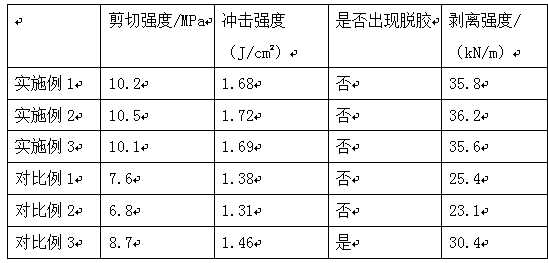

Examples

Embodiment 1

[0021] An oil filter adhesive, the components by weight are as follows: 3 parts of sulfonated modified graphite powder / silica powder composite, 15 parts of silane-modified epoxy resin, 5 parts of butyl rubber, diaminodiphenylmethane 1 part, 0.5 part of bis(2-ethylhexyl) phthalate, 1 part of silane coupling agent KH-550, 0.4 part of initiator, 0.3 part of stabilizer, and 0.4 part of emulsifier.

[0022] As preferably, wherein said initiator is any one in ammonium persulfate, potassium persulfate, azobisisoheptanonitrile, and said stabilizer is calcium / zinc composite stabilizer, barium / focal composite stabilizer, barium / zinc composite stabilizer, Any one of the zinc composite stabilizers, and the emulsifier is any one of the emulsifier OS, the emulsifier OP, and the emulsifier BP.

[0023] As preferably, wherein the preparation method of the sulfonated modified graphite powder / silicon powder composite is as follows:

[0024] 1) Add 4 parts of sodium hexametaphosphate to 30 time...

Embodiment 2

[0034] An oil filter adhesive, the components by weight are as follows: 3.5 parts of sulfonated modified graphite powder / silica powder composite, 20 parts of silane-modified epoxy resin, 7 parts of butyl rubber, diaminodiphenylmethane 1.5 parts, 0.7 parts of bis(2-ethylhexyl) phthalate, 1.2 parts of silane coupling agent KH-550, 0.5 parts of initiator, 0.4 parts of stabilizer, and 0.5 parts of emulsifier.

[0035] As preferably, wherein said initiator is any one in ammonium persulfate, potassium persulfate, azobisisoheptanonitrile, and said stabilizer is calcium / zinc composite stabilizer, barium / focal composite stabilizer, barium / zinc composite stabilizer, Any one of the zinc composite stabilizers, and the emulsifier is any one of the emulsifier OS, the emulsifier OP, and the emulsifier BP.

[0036] As preferably, wherein the preparation method of the sulfonated modified graphite powder / silicon powder composite is as follows:

[0037] 1) Add 4.5 parts of sodium hexametaphosph...

Embodiment 3

[0047] An oil filter adhesive, the components by weight are as follows: 4 parts of sulfonated modified graphite powder / silica powder composite, 25 parts of silane modified epoxy resin, 8 parts of butyl rubber, diaminodiphenylmethane 2 parts, 1 part of bis(2-ethylhexyl) phthalate, 1.5 parts of silane coupling agent KH-550, 0.7 parts of initiator, 0.5 parts of stabilizer, and 0.6 parts of emulsifier.

[0048] As preferably, wherein said initiator is any one in ammonium persulfate, potassium persulfate, azobisisoheptanonitrile, and said stabilizer is calcium / zinc composite stabilizer, barium / focal composite stabilizer, barium / zinc composite stabilizer, Any one of the zinc composite stabilizers, and the emulsifier is any one of the emulsifier OS, the emulsifier OP, and the emulsifier BP.

[0049] As preferably, wherein the preparation method of the sulfonated modified graphite powder / silicon powder composite is as follows:

[0050] 1) Add 5 parts of sodium hexametaphosphate to 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com