Combination of polyurethane modified epoxy resin and modified secondary amine delayed-hardening agent as primer of polyurea elastomer

A technology of polyurethane modification and polyurea elastomer, which is applied in the direction of polyurea/polyurethane coating, preparation of organic compounds, coating, etc. It can solve problems such as insufficient adhesion, peeling off, peeling of polyurea layer, etc., and achieve high-strength adhesion Excellent structural performance, good construction performance, and good environmental adaptability

Inactive Publication Date: 2012-02-15

固克节能科技股份有限公司

View PDF5 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] In the past, in the application of polyurea, everyone thought that there was no need for a primer system. As a result, after a period of use, there were insufficient adhesion and peeling off. Later, people realized this problem bu

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

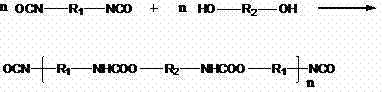

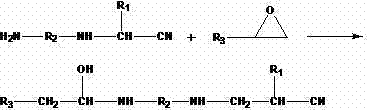

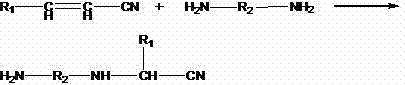

The invention relates to a combination of a polyurethane modified epoxy resin and a modified secondary amine delayed-hardening agent as a primer of polyurea elastomer. The primer provided by the invention comprises the polyurethane modified epoxy resin as A component and the modified secondary amine delayed-hardening agent as B component, wherein the synthesis route of the A component comprises raw material dehydration, polyurethane prepolymer synthesis and EP grafting copolymerization; the synthesis route of the B component comprises Michael addition and monoepoxide addition. With the curing rate of A: B being 6: 1, the primer can be used after aging for 5-10 minutes. Applied to coat polyurea elastomer as a primer, the combination provided by the invention has good system adaptability and superstrong adhesive property; and after the polyurea elastomer is sprayed on the surface of a sandblasting steel matrix in construction, the adhesive strength can reach over 10Mpa and the peeling strength can reach more than 50kN/m.

Description

technical field [0001] The invention relates to a primer for polyurea elastomers, in particular to a polyurethane modified epoxy resin combined with a modified secondary amine delayed curing agent as a primer for polyurea elastomers. Background technique [0002] Spray polyurea elastomer is a type of elastomer compound formed by the reaction of isocyanate component and amino-terminated compound component. It is a solvent-free and environmentally friendly coating technology developed in the past ten years. Due to its excellent physical and chemical properties, excellent manufacturability and environmental protection, it fully demonstrates its unparalleled superiority over traditional coating technology and has been developed rapidly, so it is widely used in construction, shipbuilding, water conservancy, transportation, machinery, chemical industry, mining, Fields such as environmental protection and entertainment have shown strong vitality, especially in the fields of hig...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09D175/02C09D7/12C08G18/58C08G18/42C08G18/10C07C253/30

Inventor 肖良嘉李百奎汪斌吴银河胡洧冰

Owner 固克节能科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com