Moulding processing technology for reinforced concrete airtight door and reinforced concrete airtight door

A reinforced concrete, forming and processing technology, applied in door leaves, sealing devices, door/window accessories, etc., can solve the problems of inaccurate assembly, low sealing effect of door leaves, etc., and achieve precise assembly, good sealing effect, and high-strength adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention will be described in further detail below in conjunction with the accompanying drawings.

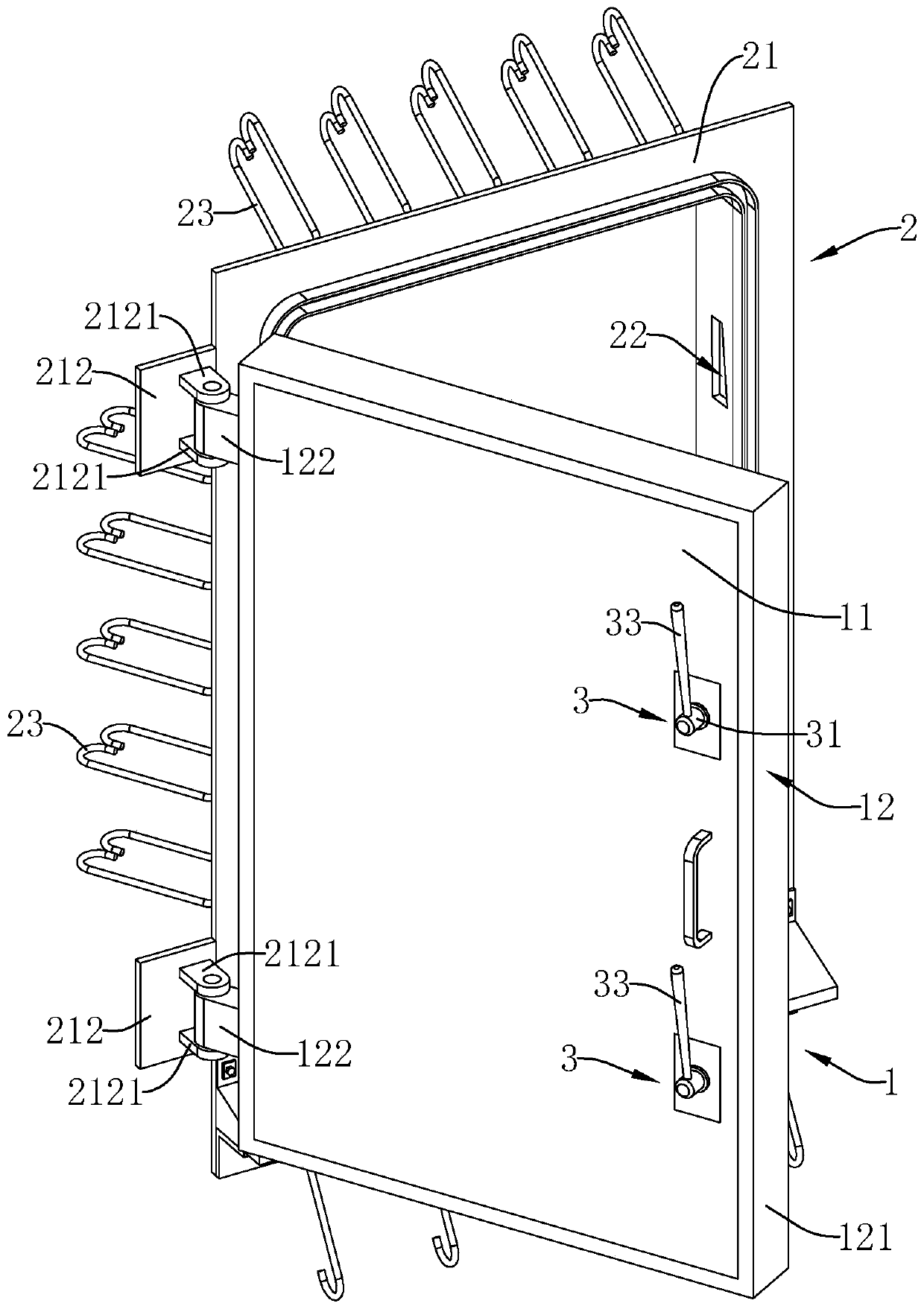

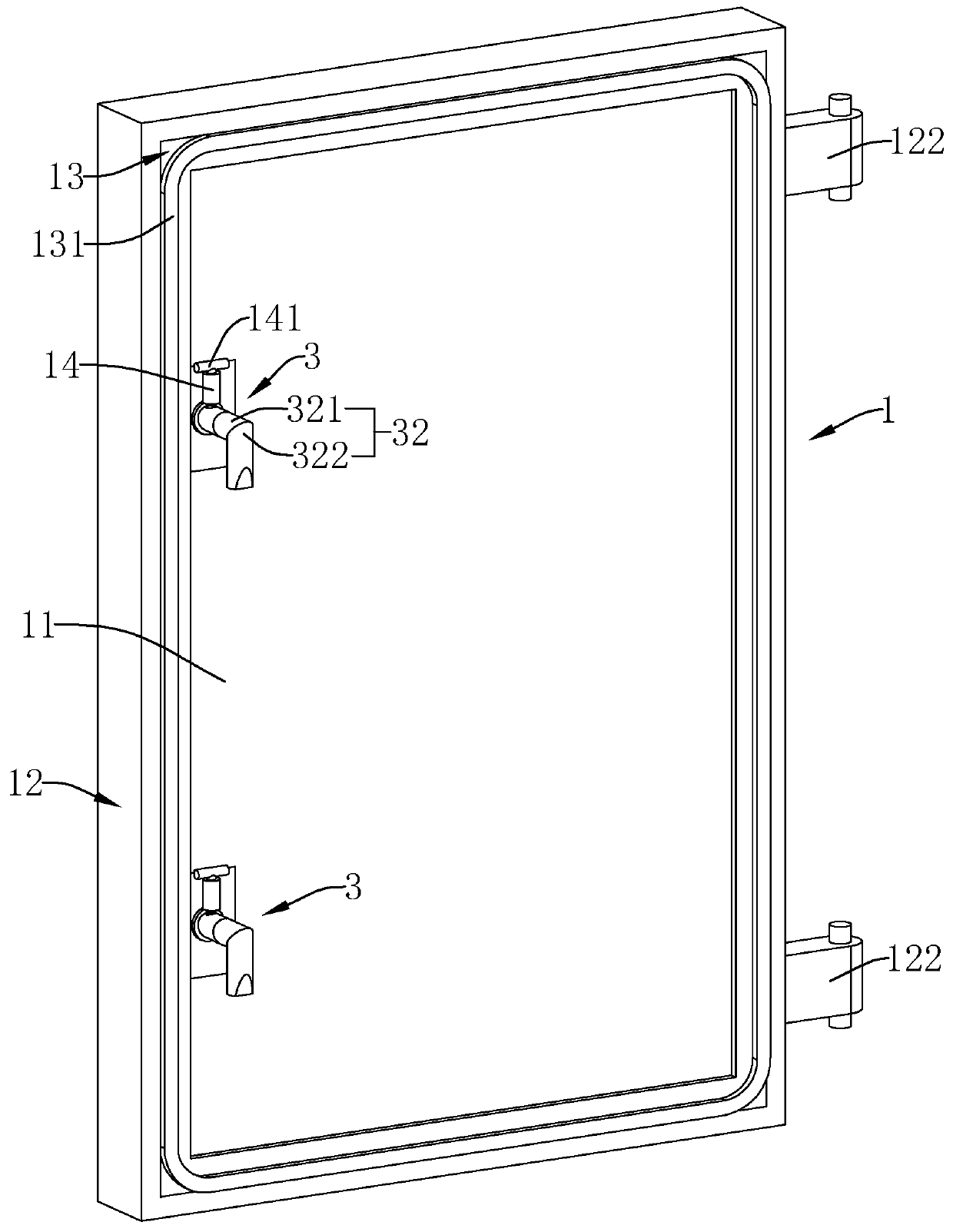

[0063] Such as figure 1 Shown is a reinforced concrete airtight door disclosed by the present invention, which includes a door leaf 1 and a door frame 2 that are hinged and used in cooperation with each other. The door leaf 1 can rotate relative to the door frame 2 to realize the opening and closing of the door leaf 1 .

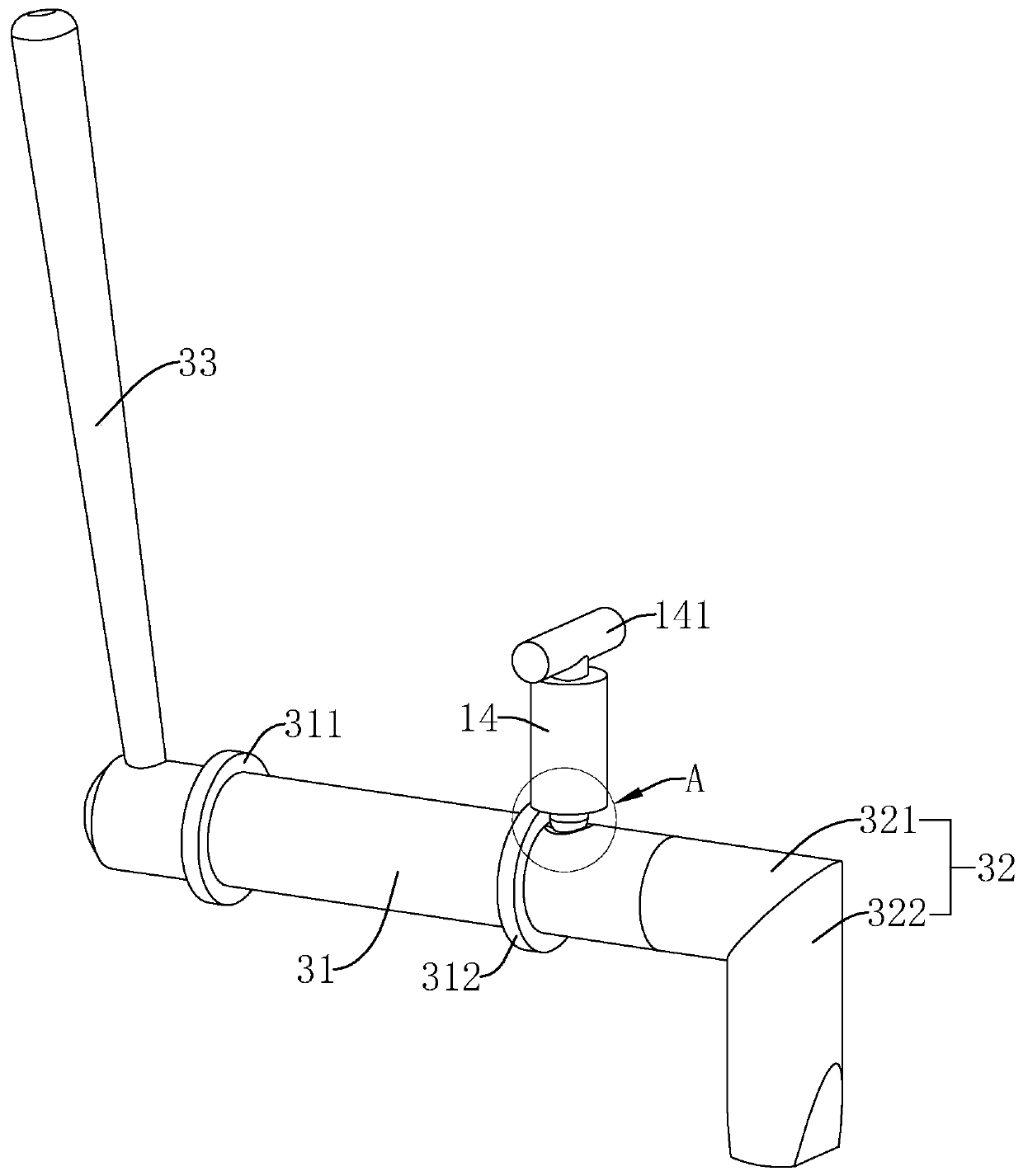

[0064] The door leaf 1 includes a door body 11 made of concrete pouring and a frame 12 covering the periphery of the door body 11 . The door leaf 1 has a rectangular shape as a whole, and the frame 12 is enclosed by four channel steels 121 welded together. A pair of hinge ears 122 are fixedly provided on the outer side of the frame 12 in the length direction, and the two hinge ears 122 are respectively located at the upper and lower ends of the door leaf 1 . A pair of locks 3 are provided on the door body 11 on a side away from the hinge ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com