Motion based stripping dry adhesion mechanism and implementation method

A realization method and technology of dry adhesion, which is applied in the field of bionic dry adhesion, can solve the problems of dry adhesion surface structure damage, increase external force, weaken the gripping strength of mechanism adhesion, etc., achieve high-efficiency movement peeling, and the principle is simple and reliable , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in combination with schematic diagrams.

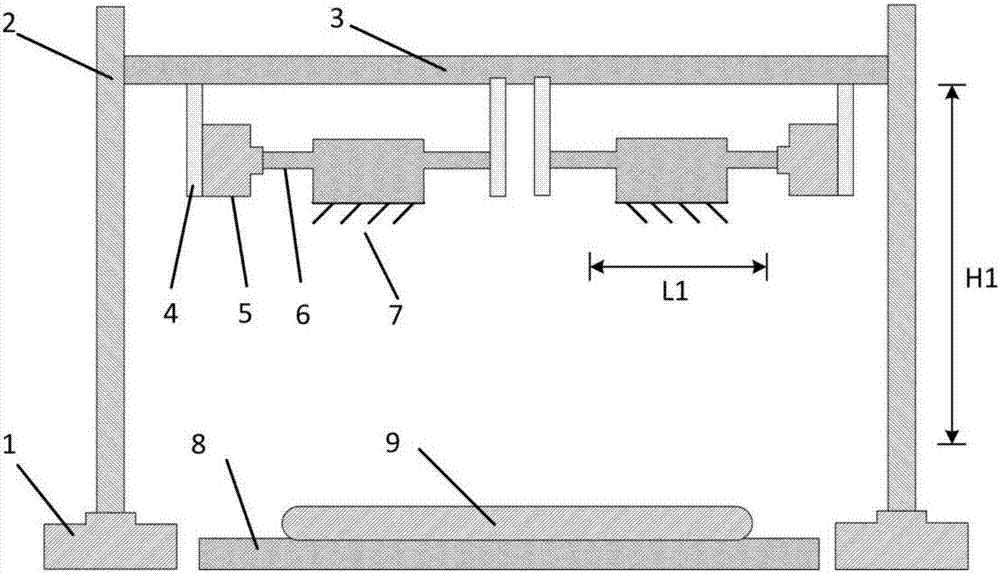

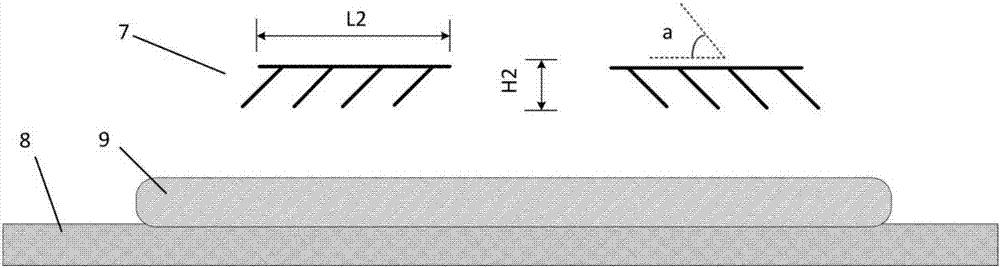

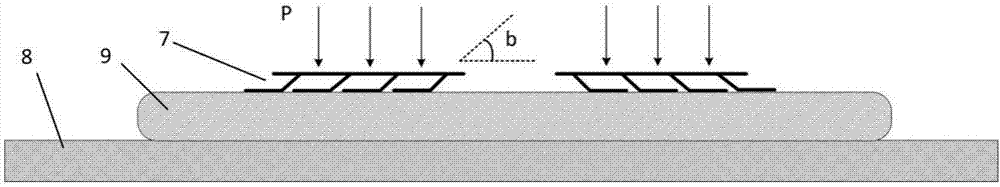

[0018] Such as figure 1 As shown, a dry adhesion mechanism based on motion peeling includes two dry adhesion structures 7 composed of inclined sheet structures. side, each dry adhesion structure 7 is installed on the slider of the horizontal ball screw 6, and the horizontal ball screw 6 is driven by the horizontal motor 5 to realize the horizontal left and right movement of the dry adhesion structure 7; the horizontal motor 5 is connected by the bracket 4 On the beam 3, both ends of the beam 3 are installed on the sliders of the vertical ball screw 2, and the vertical ball screw 2 is driven by the vertical motor 1, and the vertical movement of the beam 3 can be realized under the drive of the vertical motor 1; The adhered object 9 is placed on the horizontal platform 8 below the attached structure 7 , the movement stroke of the mechanism in the vertical direction is H1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com