Coal blending method for preparing high-activity high-strength coke

A high-strength, high-activity technology, used in coke ovens, petroleum industry, etc., can solve the problems of increased coal blending costs, and achieve the effects of reducing coking costs, improving coke quality, and high iron oxide content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

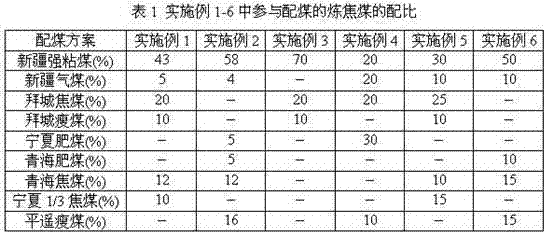

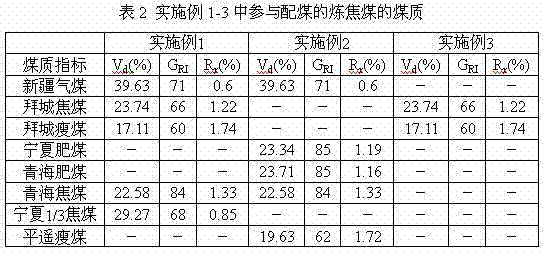

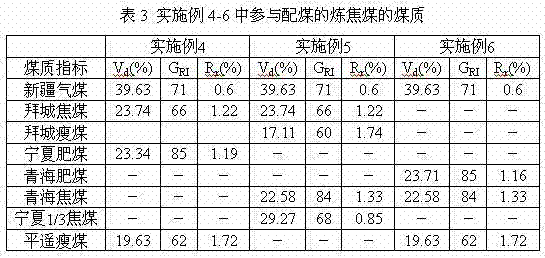

[0039] A coal blending method for preparing high-activity and high-strength coke, including the step of mixing coking coals participating in coal blending. In terms of weight percentage, the coking coal participating in coal blending includes 20-70% of Xinjiang strong caking coal, and the balance is One or more combinations of coking coal, lean coal, fat coal, gas coal, and 1 / 3 coking coal;

[0040] The Xinjiang strong caking coal meets the following index requirements:

[0041] ①Industrial analysis index: air-dry basis moisture M ad 0.8-1.5% by weight, dry basis ash A d 8-10% by weight, dry basis volatile V d The weight percentage is 20-35%;

[0042] ② Sulfur index: sulfur S ad The weight percentage is 0.3-0.5%;

[0043] ③Adhesive index: Adhesive index G RI It is 95-105, and the maximum value of Kiel's fluidity lgMF is 2.0-4.5;

[0044] ④Indicator of coalification degree: average reflectance R of vitrinite r 1.0-1.5%;

[0045] ⑤Ash component index: dry basis ash cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com