Longquan celadon jasper green glaze, jasper green Longquan celadon and preparation method thereof

A green dragon spring, celadon technology, applied in clay products, other household appliances, household utensils, etc., can solve the problems of low firing temperature, unbearable, unsuitable for Longquan celadon, etc., achieve uniform color, increase opacity, richness glaze effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

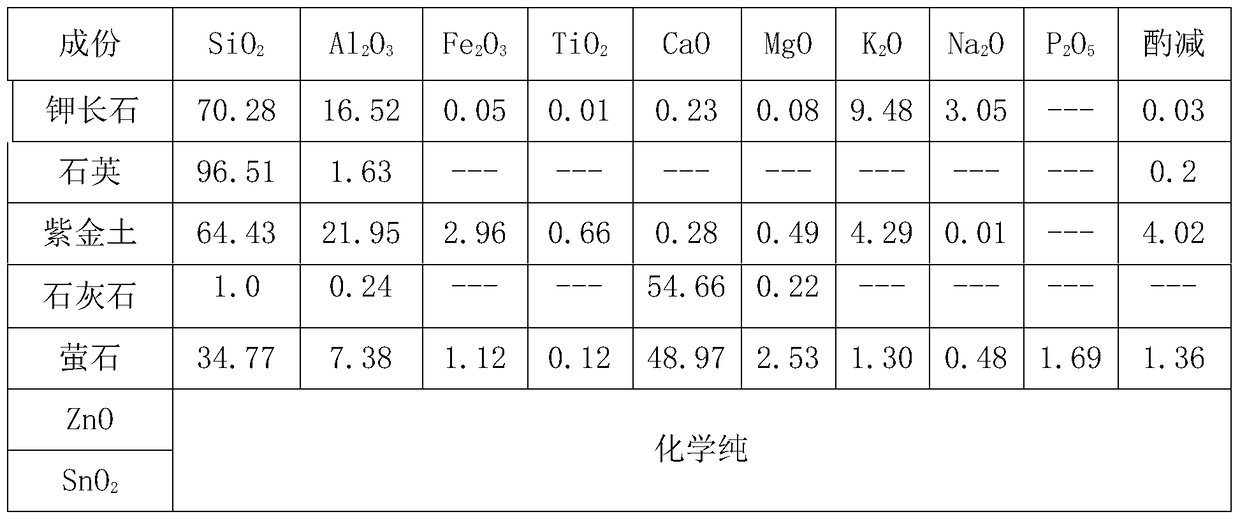

Embodiment 1

[0040] Embodiment 1: a kind of Longquan celadon jasper green glaze, according to its total amount is 100% weight percent, it is made of the glaze material of following components: potassium feldspar 40%, quartz 15%, purple gold soil 20% , Limestone 10%, Fluorite 8%, ZnO 4%, SnO 2 3%. Among them, ZnO is ZnO powder calcined at 1250-1280°C before batching. After calcining, it can reduce the shrinkage of the glaze during the firing process, reduce defects such as air bubbles and pinholes, increase the density of the glaze and improve the performance of the glaze.

Embodiment 2

[0041] Embodiment 2: a kind of Longquan celadon jasper green glaze, according to its total amount is 100% weight percent, it is made of the glaze material of following components: potassium feldspar 35%, quartz 18%, purple gold soil 20% , Limestone 11%, Fluorite 9%, ZnO 3.5%, SnO 2 3.5%. Among them, ZnO is ZnO powder calcined at 1250-1280°C before batching.

Embodiment 3

[0042] Embodiment 3: a kind of Longquan celadon jasper green glaze, according to its total amount is 100% weight percent, it is made of the glaze material of following components: potassium feldspar 42%, quartz 17%, purple gold soil 18% , Limestone 10%, Fluorite 6.5%, ZnO 4%, SnO 2 2.5%. Among them, ZnO is ZnO powder calcined at 1250-1280°C before batching.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com