High-strength quick-solidifying refractory adhesive

A refractory adhesive and adhesive technology, applied in the direction of adhesives, inorganic adhesives, etc., can solve the problems of poor cohesion, poor quick-setting, and difficulty in gunning, and achieve a smooth, smooth and good surface. Volume stability and thermal stability, the effect of fast setting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

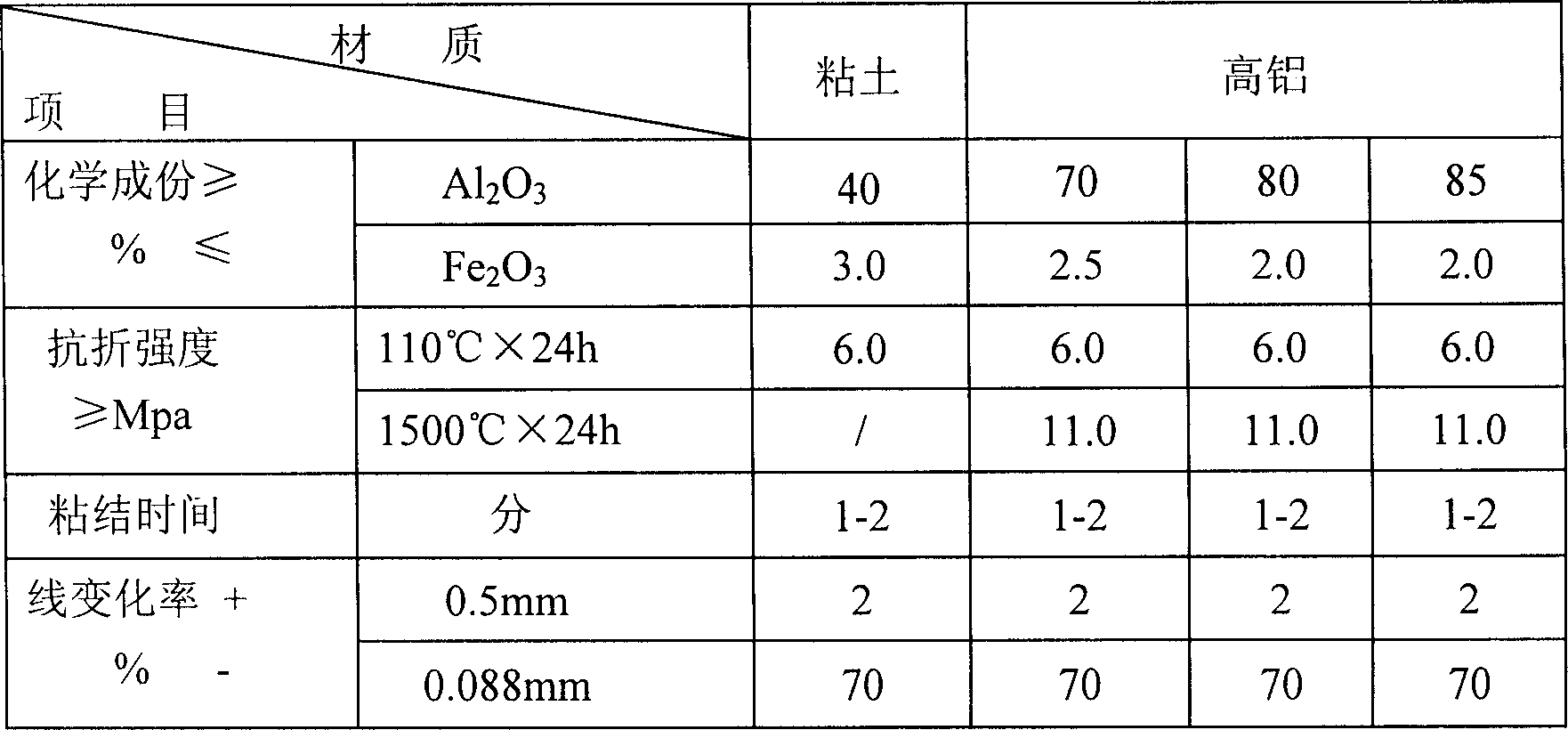

[0019] In Example 1, 50 parts of high alumina powder (Al 2 O 3 ≥70%, Fe 2 O 3 ≤2%), 5 parts of Guangxi mud (Al 2 O 3 ≥35%, Fe 2 O 3 ≤0.9%), 5 parts of superfine powder (particle size2 O 3 ≥80%, Fe 2 O 3 ≤1.5%), put 1 part of sodium hexametaphosphate into a mixer and mix well, then add 39 parts of water glass and mix evenly. The resulting adhesive is thicker and can be used for coke oven refractory repair.

Embodiment 2

[0020] In Example 2, 35 parts of high aluminum powder (Al 2 O 3 ≥70%, Fe 2 O 3 ≤2%), 10 parts of Guangxi mud (Al 2 O 3 ≥35%, Fe 2 O 3 ≤0.9%), 5 parts of superfine powder (particle size2 O 3 ≥80%, Fe 2 O 3 ≤1.5%), 1 part of sodium hexametaphosphate, 1 part of sodium tripolyphosphate, 3 parts of silicon powder into the mixer and mix well, then add 45 parts of water glass, stir evenly, the resulting binder is relatively thin and can be used for coke Spraying of refractory parts of the furnace.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com