Ground floor plastering gypsum

A technology for plastering gypsum and bottom layer, applied in the field of bottom layer plastering gypsum, can solve the problems that affect the popularization and use of bottom layer plastering gypsum, the product performance is greatly affected, and the price of fine quartz sand is high, and the shrinkage cracking is suppressed, the construction is convenient and fast, and the setting retardation effect is achieved. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

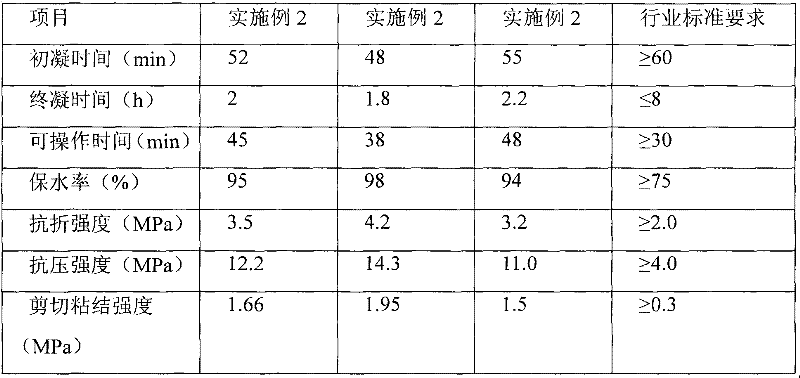

Examples

Embodiment 1

[0021] The dosage of each component: 300kg of desulfurized building gypsum, 700kg of aeolian sand, 1.8kg of water-soluble polyvinyl alcohol, 4kg of calcium-based bentonite, 2kg of HPMC7000 hydroxypropyl methylcellulose, and 2kg of animal protein glue.

[0022] Mix with mixing equipment to make a base plaster.

[0023] When the bottom plaster gypsum of the present invention is applied to plastering mortar, it only needs to add water with 25-30% of the mass of the bottom plaster plaster and stir evenly to prepare the plastering mortar, and then the wall surface construction can be carried out.

Embodiment 2

[0025] Amount of each component

[0026] Desulfurization building gypsum 400kg, aeolian sand 600kg, water-soluble polyvinyl alcohol 1.5kg, calcium-based bentonite 4kg, HPMC7000 hydroxypropyl methylcellulose 1.5kg, animal protein glue 3kg.

[0027] Mix with mixing equipment to make a base plaster.

[0028] When the bottom plaster gypsum of the present invention is applied to plastering mortar, it only needs to add water with 25-30% of the mass of the bottom plaster plaster and stir evenly to prepare the plastering mortar, and then the wall surface construction can be carried out.

Embodiment 3

[0030] Amount of each component

[0031] Desulfurization building gypsum 300kg, aeolian sand 700kg, redispersible latex powder composed of vinyl acetate and ethylene copolymer powder 2kg, calcium-based bentonite 4kg, HPMC7000 hydroxypropyl methylcellulose 2kg, animal protein glue 2kg.

[0032] Mix with mixing equipment to make a base plaster.

[0033] When the bottom plaster gypsum of the present invention is applied to plastering mortar, it only needs to add water with 25-30% of the mass of the bottom plaster plaster and stir evenly to prepare the plastering mortar, and then the wall surface construction can be carried out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com