Novel gypsum retarder and preparation method thereof

A gypsum retarder and a new technology are applied in the field of new gypsum retarder and its preparation, which can solve problems such as nitrogen oxide emission, achieve the effects of low cost, realize resource utilization, and solve disposal problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Add 150 parts of penicillin mycelium powder, 0.25 part of disodium hydrogen phosphate, 0.38 part of sodium hydroxide, 0.07 part of polydimethylsiloxane and 350 parts of water into the reactor to modify the penicillin mycelium, The modification temperature was 40°C and the modification time was 5 hours to obtain a mixture; after the modification was completed, 11 parts of alkaline calcium-based bentonite, 0.04 parts of potassium sorbate and 0.01 part of β-phenylethanol were added to the mixture, and after mixing evenly, the A new type of gypsum retarder in the form of solid powder is made by spray drying.

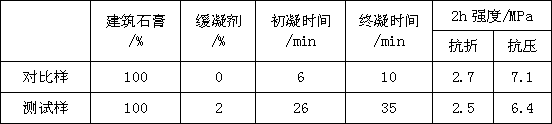

[0019] The retarder prepared in this example was added to 100 parts of building gypsum, and the water-to-material ratio was 0.65, and the setting time and strength performance tests were carried out. At the same time, building gypsum without adding retarder was used as a comparison.

[0020]

Embodiment 2

[0022] Add 165 parts of penicillin mycelium powder, 0.30 part of disodium hydrogen phosphate, 0.45 part of sodium hydroxide, 0.06 part of polydimethylsiloxane and 410 parts of water into the reactor to modify the penicillin mycelium, The modification temperature was 50°C and the modification time was 3 hours to obtain a mixture; after the modification was completed, 15 parts of alkaline calcium-based bentonite, 0.05 parts of potassium sorbate and 0.02 parts of β-phenylethanol were added to the mixture, and after mixing evenly, the A new type of gypsum retarder in the form of solid powder is made by spray drying.

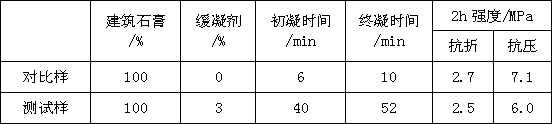

[0023] The retarder prepared in this example was added to 100 parts of building gypsum, and the water-to-material ratio was 0.65, and the setting time and strength performance tests were carried out. At the same time, building gypsum without adding retarder was used as a comparison.

[0024]

Embodiment 3

[0026] Add 180 parts of penicillin mycelium powder, 0.4 part of disodium hydrogen phosphate, 0.6 part of sodium hydroxide, 0.05 part of polydimethylsiloxane and 440 parts of water into the reactor to modify the penicillin mycelium, The modification temperature was 45°C, and the modification time was 4 hours to obtain a mixture; after modification, 18 parts of alkaline calcium-based bentonite, 0.06 parts of potassium sorbate and 0.03 parts of β-phenylethanol were added to the mixture, and after mixing evenly, the A new type of gypsum retarder in the form of solid powder is made by spray drying.

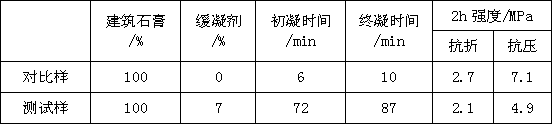

[0027] The retarder prepared in this example was added to 100 parts of building gypsum, and the water-to-material ratio was 0.65, and the setting time and strength performance tests were carried out. At the same time, building gypsum without adding retarder was used as a comparison.

[0028]

[0029] It can be seen from the above three examples that the novel gypsum retarder prepare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com