Advanced treatment method of concentrated sulfuric acid waste liquor

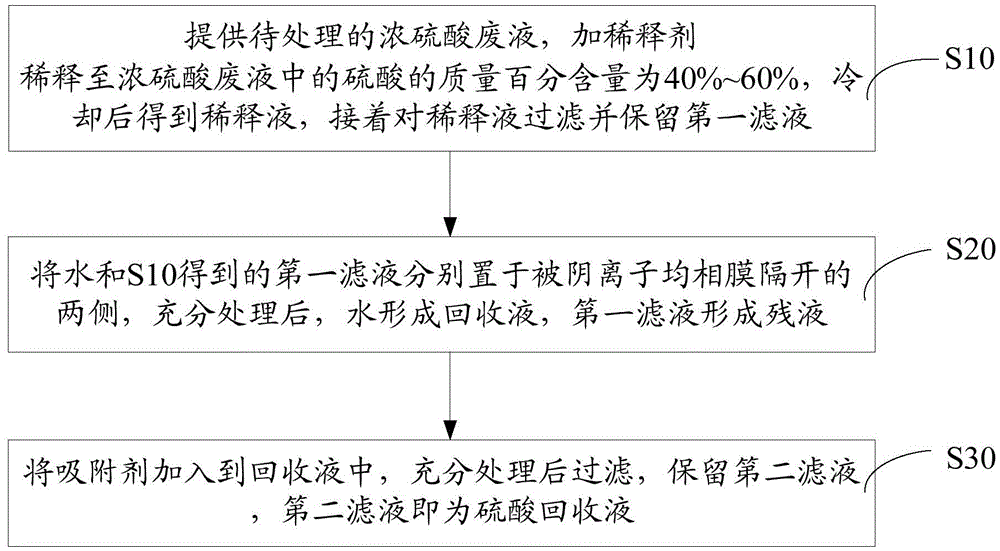

A technology of advanced treatment and concentrated sulfuric acid, applied in filtration treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of huge waste landfill fees and wastewater treatment fees, waste of sulfuric acid resources, etc., to reduce costs and process Simplicity and the effect of improving recycling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Provide concentrated sulfuric acid waste liquid to be treated. The sulfuric acid content in the concentrated sulfuric acid waste liquid is 80.2%, the characteristic COD content is 138g / L, and the iron ion content is 3.59g / L.

[0051]Take 10L of the above-mentioned concentrated sulfuric acid waste liquid, add 7L of diluent to the buffer tank for dilution, obtain the diluted liquid after cooling, and filter the diluted liquid with a sand core filter and a security filter in turn to obtain the first filtrate. The sulfuric acid content in the first filtrate was 50.6%, the characteristic COD content was 12.9 g / L, and the iron ion content was 1.9 g / L. The diluent is the raffinate obtained in the previous treatment, and its sulfuric acid content is 8.3%.

[0052] Adjust the flow rate of the first filtrate of the diffusion dialyzer to be 14mL / min, and the flow rate of tap water to be 15mL / min. After the first filtrate is separated and treated in the diffusion dialyzer for 3 ho...

Embodiment 2

[0056] Provide concentrated sulfuric acid waste liquid to be treated. The sulfuric acid content in the concentrated sulfuric acid waste liquid is 80.2%, the characteristic COD content is 138g / L, and the iron ion content is 3.59g / L.

[0057] Take 10L of the above-mentioned concentrated sulfuric acid waste liquid, add 7L of diluent to the buffer tank for dilution, obtain the diluted liquid after cooling, and filter the diluted liquid with a sand core filter and a security filter in turn to obtain the first filtrate. The diluent is the raffinate in Example 1.

[0058] Adjust the flow rate of the first filtrate of the diffusion dialyzer to be 14mL / min, and the flow rate of tap water to be 15mL / min. After the first filtrate is separated and treated in the diffusion dialyzer for 3 hours, the water will form a recovered liquid, and the first filtrate will form a raffinate, and the outlet The flow rate of the recovered liquid was 15.3 mL / min, and the flow rate of the raffinate was 13...

Embodiment 3

[0062] Provide concentrated sulfuric acid waste liquid to be treated. The sulfuric acid content in the concentrated sulfuric acid waste liquid is 80.2%, the characteristic COD content is 138g / L, and the iron ion content is 3.59g / L.

[0063] Take 10L of the above-mentioned concentrated sulfuric acid waste liquid, add 7L of diluent to the buffer tank for dilution, obtain the diluted liquid after cooling, and filter the diluted liquid with a sand core filter and a security filter in turn to obtain the first filtrate. The diluent is the raffinate in Example 2.

[0064] Adjust the flow rate of the first filtrate of the diffusion dialyzer to be 12mL / min, and the flow rate of tap water to be 13mL / min. After the first filtrate is separated and treated in the diffusion dialyzer for 3 hours, the water will form a recovered liquid, and the first filtrate will form a raffinate, and the outlet The flow rate of the recovered liquid was 13.2 mL / min, and the flow rate of the raffinate was 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com