Industrial-grade garbage classification method and device

A garbage sorting and garbage technology, applied in the direction of sorting, etc., can solve the problems of poor operability and effect, not industrial grade, weak operability, etc., to save direct economic costs, reduce tree felling, and reduce land pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for classifying industrial-grade garbage, specifically comprising the following steps:

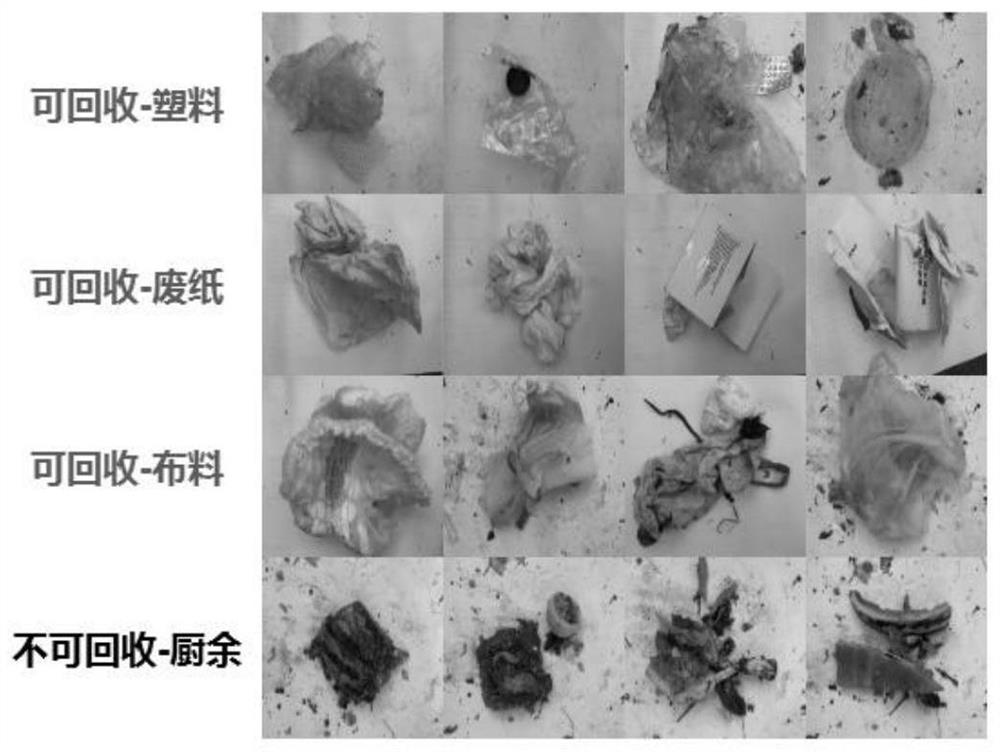

[0024] (1) Collect garbage sorting images from the garbage environment, and establish a garbage sorting image database; in the sorting image database, there are but not limited to 8 categories of garbage labels, of which 5 are recyclable and 3 are non-recyclable, specifically: recyclable-waste Paper, Recyclable-Plastic, Recyclable-Glass, Recyclable-Metal, Recyclable-Cloth, Non-Recyclable-Food Waste, Non-Recyclable-Hazardous, Non-Recyclable-Other.

[0025] (2) The pre-processing device disperses the garbage, adopts the image recognition model to identify the dispersed garbage images, compares them with the images in the classified image database, and realizes the classification of garbage; the present invention selects 3 representative classic images The recognition models are Vgg16, GoogleNet and AlexNet. All three are classic models of image recognition, which have good e...

Embodiment 2

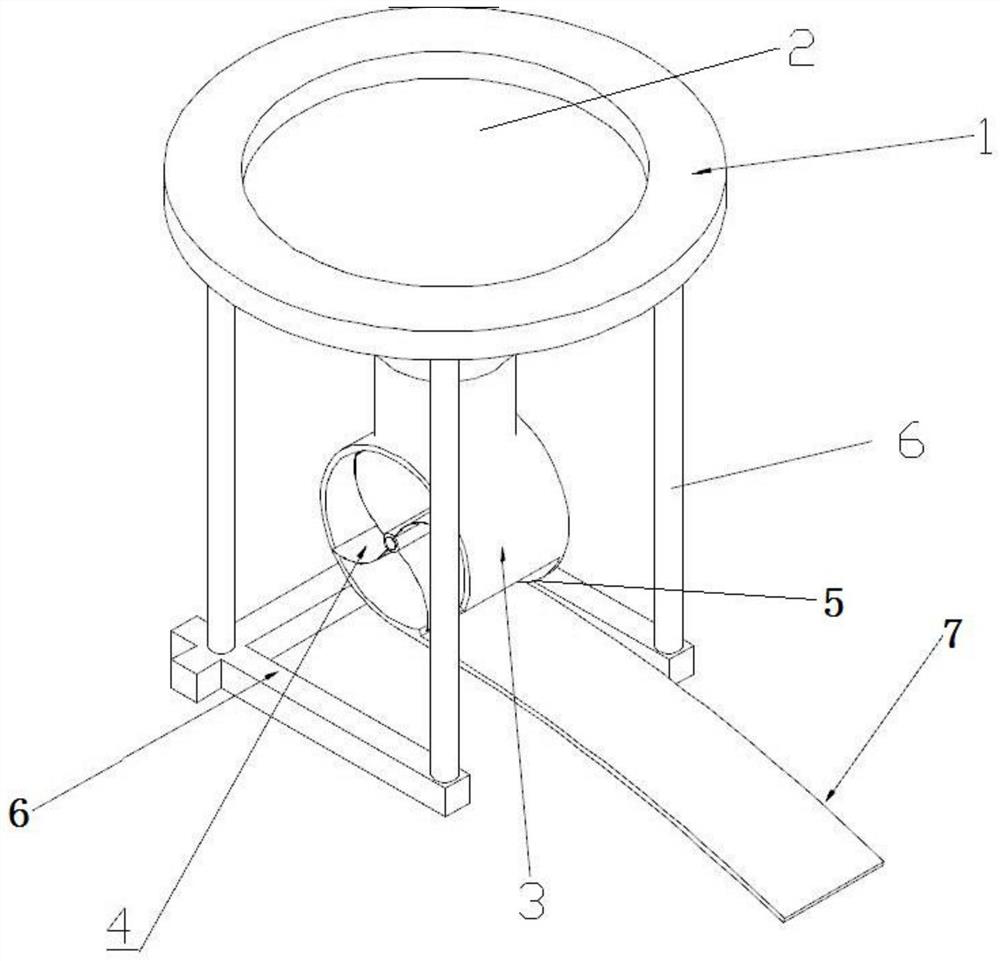

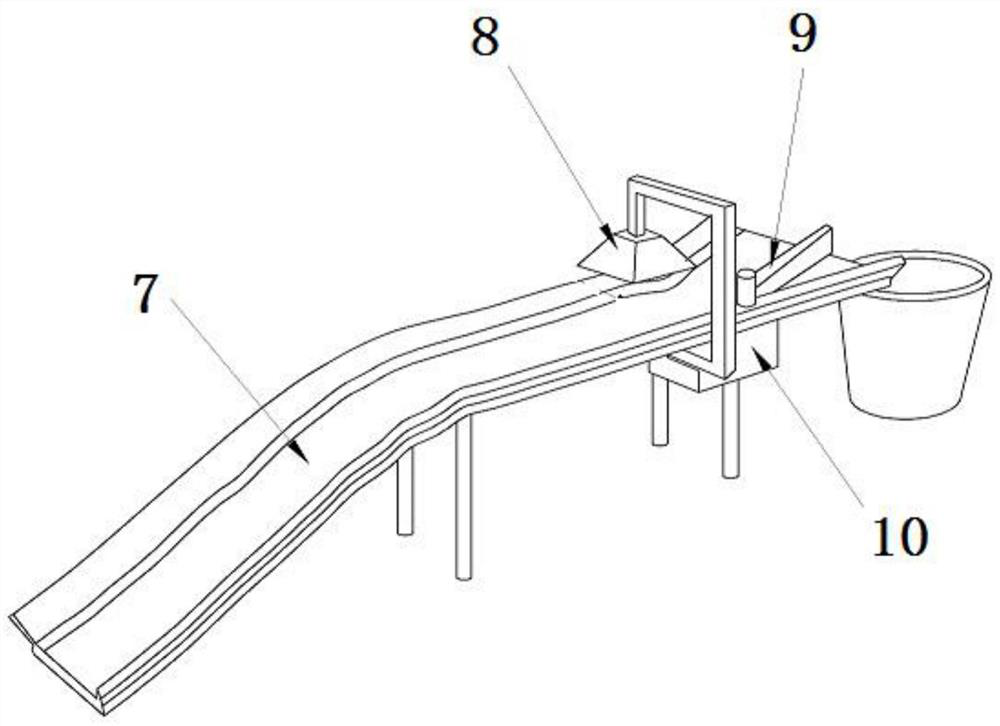

[0039] Further, the device used in the industrial-grade garbage sorting method described in this embodiment includes a garbage disperser 1, a bracket 6, a conveyor belt 7, a camera 8, a garbage sorting board 9, and a controller 10, and the garbage disperser 1 is fixed on the bracket 6 Above, the garbage disperser 1 includes a garbage inlet 2, a dispersing chamber 3, a rotating blade 4, and a garbage outlet 5. The garbage inlet 2 is funnel-shaped, and a garbage dispersing chamber 3 is arranged under the garbage inlet, and a rotating blade is arranged in the garbage dispersing chamber 3. 4. The rotating blade 4 is connected to the dispersion motor through a shaft; one side of the dispersion chamber 3 is provided with a garbage outlet 5, and a conveyor belt is provided at the garbage outlet 5, and a camera 8 is arranged above the conveyor belt 7, and the camera 8 is connected to the controller 10, and the controller 10 is connected with the sorting motor, and the sorting motor is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com