Water-resistant gypsum base wall repair material

A technology of gypsum-based and repairing materials, applied in the field of water-resistant gypsum-based wall repairing materials, which can solve the problems of short setting time, large strength loss of gypsum hardened body, poor water resistance of gypsum products, etc., and achieve reasonable setting time and volume stability Excellent, the effect of reducing the landfill occupation of solid waste and the impact on the ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

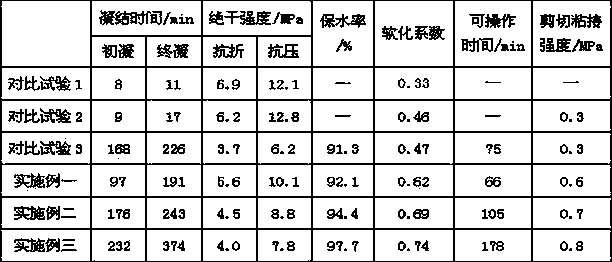

Examples

Embodiment 1

[0020] Example 1: Add 5 parts of waste penicillin residue powder to 100 parts of NaOH aqueous solution with a pH of 13.0, soak and modify at 60°C for 60 minutes, after modification is completed, perform solid-liquid separation to obtain modified penicillin waste residue filtrate Add 250 parts of hydroxylated polyphenylene microsphere emulsions with a solid content of 20% to a certain batch of modified penicillin waste slag filtrate with a solid content of 1 part, mix well and obtain composite auxiliary agent A through spray drying.

[0021] Mix 5.1 parts of composite additive A, 100 parts of desulfurized building gypsum, and 10 parts of manganese slag powder (with a specific surface area of 476m 2 / kg), 5 parts of 42.5 strength grade ordinary Portland cement, 0.2 parts of hydroxypropyl methylcellulose, 0.3 parts of naphthalene-based sulfonate water reducer, etc. are mixed evenly in proportion by weight, and the water-solid ratio 0.6, the test block was cured for 28 days unde...

Embodiment 2

[0022] Example 2: Add 10 parts of waste penicillin residue powder to 100 parts of NaOH aqueous solution with a pH of 13.6, soak and modify at 70°C for 110 minutes, after the modification is completed, perform solid-liquid separation to obtain the modified penicillin waste residue filtrate Add 133.3 parts of hydroxylated polyphenylene microsphere emulsions with a solid content of 20% to a certain batch of modified penicillin waste slag filtrate with a solid content of 1 part, mix well and obtain composite auxiliary agent A through spray drying.

[0023] Mix 8.3 parts of composite additive A, 100 parts of desulfurized building gypsum, and 15 parts of manganese slag powder (the specific surface area is 453m 2 / kg), 7 parts of 42.5 strength grade composite Portland cement, 0.4 parts of hydroxypropyl methylcellulose, 0.5 parts of naphthalene sulfonate water reducer, etc., mixed evenly in proportion by weight, the water-solid ratio 0.6, the test block was cured for 28 days under sta...

Embodiment 3

[0024] Example 3 Add 15 parts of waste penicillin residue powder to 100 parts of NaOH aqueous solution with a pH of 14.0, soak and modify at 80°C for 150 minutes, after the modification is completed, perform solid-liquid separation to obtain the modified penicillin waste residue filtrate Add 100 parts of hydroxylated polyphenylene microsphere emulsion with a solid content of 20% to a certain batch of modified penicillin waste slag filtrate with a solid content of 1 part, mix well and obtain composite auxiliary agent A through spray drying.

[0025] Mix 10.5 parts of composite additive A, 100 parts of desulfurized building gypsum, and 20 parts of manganese slag powder (with a specific surface area of 433m 2 / kg), 10 parts of 32.5 strength grade slag portland cement, 0.6 parts of hydroxypropyl methylcellulose, 0.7 parts of naphthalene sulfonate water reducer, etc., mixed evenly in proportion by weight, the water-solid ratio 0.6, the test block was cured for 28 days under stand...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com