Light and environment-friendly leveling putty and construction method thereof

An environmentally friendly and lightweight technology, applied in the direction of filling slurry, etc., can solve the problems of lack of raw materials for construction waste, damage to soil structure, and surface subsidence, and achieve the effects of solving the shortage of production resources, good compatibility, and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

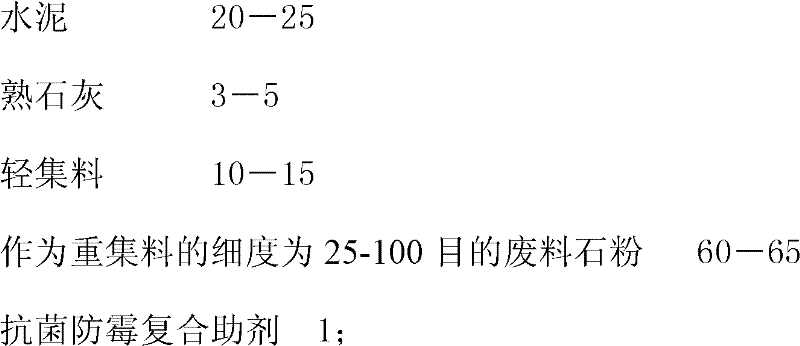

Method used

Image

Examples

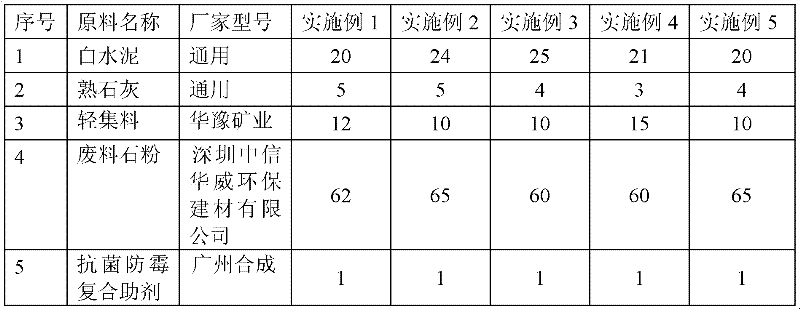

Embodiment 1

[0032]The production process of the lightweight environment-friendly leveling putty using construction waste stone powder of the present invention is as follows:

[0033] According to the weight shown in Example 1 in Table 1, white cement, slaked lime, light aggregate, waste stone powder and antibacterial and anti-mildew composite auxiliary agent are taken, and these components are mixed, and evenly stirred by a machine, to obtain the use building of this embodiment. Lightweight and environmentally friendly leveling putty made of waste stone powder, packed in paper bags or in bulk.

[0034] Take 100 kg of the above-mentioned lightweight environmental protection leveling putty, add 30 kg of water to dilute, stir mechanically or manually until the mixture is uniform, and reach the viscosity (empirical viscosity) suitable for mechanical spraying or manual construction, then mechanized spraying can be carried out.

[0035] Perform performance testing according to national standard...

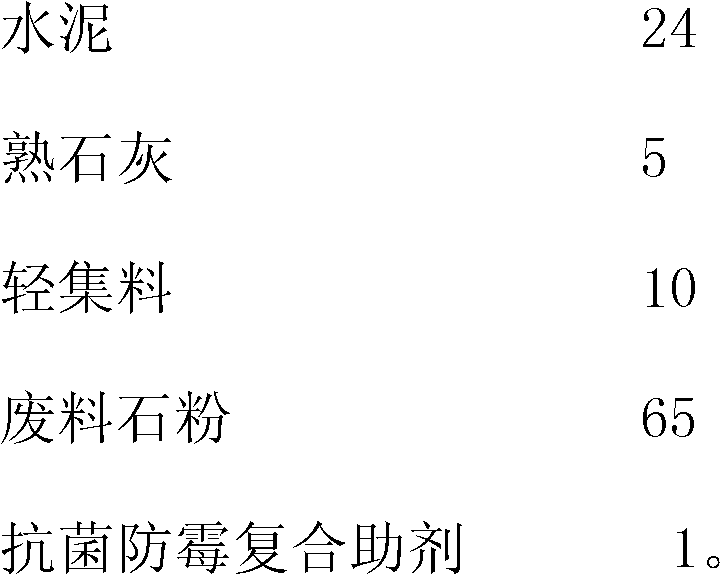

Embodiment 2

[0037] Get each component according to each component weight in embodiment 2 shown in table 1, and repeat the production process described in embodiment 1 (only each component weight changes) to obtain light-weight environmental protection leveling putty; Repeat embodiment 1 described The construction method, dilution weight ratio is putty: water=100: 35, and carry out performance test according to the standard described in embodiment 1, test result is as shown in the corresponding data of embodiment 2 in table two.

Embodiment 3

[0039] Get each component according to each component weight in embodiment 3 shown in table 1, and repeat the production process described in embodiment 1 (only each component weight changes) to obtain light-weight environmental protection leveling putty; Repeat embodiment 1 described The construction method, dilution weight ratio is putty: water=100: 40, and carry out performance test according to the standard described in embodiment 1, test result is as shown in the corresponding data of embodiment 3 in table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com