Soil-phase-free oil-based drilling fluid

An oil-based drilling fluid, soil-free technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of easy sticking downhole, poor tripping, easy to induce lost circulation, etc. Loss of lost circulation, easy on-site operation and maintenance, good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] 1) Preparation of compound emulsifier G326-HEM: Weigh 60% rosin, 20% cyclohexane and 20% 3# white oil according to the weight percentage, and take ethanol whose weight is 2~3 times the weight of rosin acid; in the reaction kettle Add ethanol and abietic acid in sequence in proportion, stir fully until the abietic acid is completely dissolved in ethanol and heat; when the temperature of the reaction kettle reaches 60°C~80°C, add cyclohexylamine dropwise at a uniform speed within 0.5h~1h, Stir at r / min~120 r / min and keep warm for 4h~8h; continue to heat to 90°C~100°C to distill ethanol, add 3# white oil, stir for 0.5h, and get this soil-free oil-based drilling fluid Use emulsifier G326-HEM.

[0011] 2) Preparation of fluid loss reducer G328: Weigh 100g of humic acid and place it in a 250 mL three-neck flask, weigh 50g of octadecylamine into a 200mL beaker, dissolve it with 50mL of absolute ethanol, then pour it into a three-necked flask, and heat to reflux 40 min; dist...

Embodiment 2

[0019] According to the preparation method of Example 1, under the same oil-water ratio (80 / 20), white oil and diesel oil were used as the base oil of the system respectively, and the properties of soil-free oil-based drilling fluids prepared with three different base oils were tested. , the test results are shown in Table 2.

[0020] Table 2 Properties of soil-free oil-based drilling fluids formulated with different base oils

[0021]

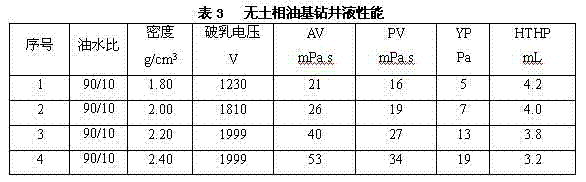

Embodiment 3

[0023] 1) Referring to Example 1, compound emulsifier G326-HEM and fluid loss control agent G328 were prepared.

[0024] 2) Preparation of soil-free oil-based drilling fluid: prepare 50 cubic meters (O / W: 90 / 10) of soil-free oil-based drilling fluid, clean and prepare two mixing tanks. Use a pump to pump Saraline 185V, which is used for 45 m3 gas oil production, into No. 1 tank, and add 1500kg of compound emulsifier G326-HEM, 1500kg of fluid loss reducer G328, and 1000kg of lime according to the pre-calculated amount. After the lime is added, fully stir for 3-4 hours until all oil-soluble components are completely dissolved.

[0025] Pump 5 cubic meters of clean water into No. 2 tank, add 2000kg of CaCl 2 . Under the strong stirring of special equipment such as drilling fluid gun, the CaCl 2 The brine was slowly added to the oil phase. It is best to stir the drilling fluid through the 1.27cm drilling fluid gun nozzle under the pump pressure above 3.45MPa. If the pump pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com