Oil-based drilling fluid suitable for high-water-sensitivity collapsible stratum as well as preparation method and application of oil-based drilling fluid

An oil-based drilling fluid, Minyi technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as rheological thickening, shale strength reduction, pore pressure increase, etc., and achieve strong electrical stability performance, inhibit hydration expansion, and reduce the effect of high temperature and high pressure filtration loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0067] The present invention also provides a method for preparing an oil-based drilling fluid suitable for highly water-sensitive and easily collapsed formations described in the above technical solution, comprising the following steps:

[0068] Add high-efficiency emulsifier, alkalinity regulator, fluid loss reducer, nano-blocking agent and organic soil to the oil phase in sequence to obtain the oil phase mixture;

[0069] The water phase is added to the oil-phase mixed liquid for emulsification, and then a weighting material is added to obtain the oil-based drilling fluid suitable for highly water-sensitive and easily collapsed formations.

[0070] In the invention, the high-efficiency emulsifier, the alkalinity regulator, the fluid loss reducer, the nano plugging agent and the organic soil are sequentially added into the oil phase to obtain the oil phase mixed liquid.

[0071] In the present invention, the high-efficiency emulsifier is preferably added to the oil phase for ...

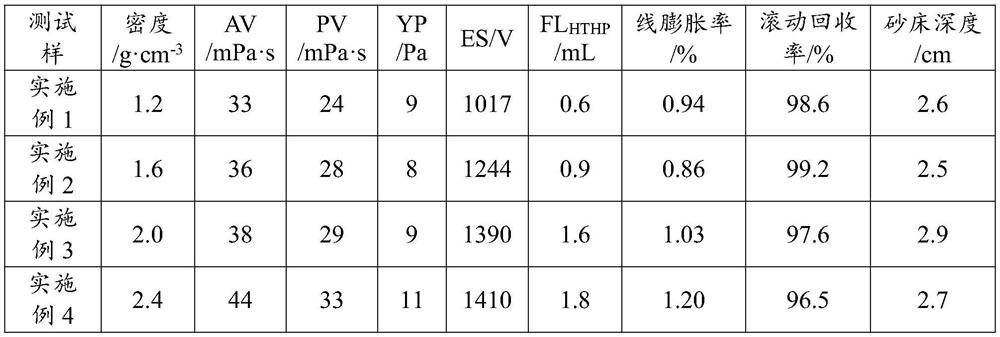

Embodiment 1

[0079] (1) The preparation method of high-efficiency emulsifier is as follows:

[0080] Add 40 parts by weight of trimer acid, 30 parts of diethanolamine and 20 parts of NaOH catalyst into a three-necked flask, raise the temperature to 180°C for acylation reaction, keep the temperature down to 90°C after 8 hours of constant temperature reaction, and continue to add 10 parts of dimer acid, Stir for 30 minutes to mix evenly, add 20 parts of fatty alcohol polyoxyethylene ether dropwise, and react for 8 hours to obtain the high-efficiency emulsifier 1.

[0081] (2) The preparation method of nano-blocking agent is as follows:

[0082] Add 35 parts by weight of styrene, 15 parts of isobutyl acrylate, 10 parts of Span80, and 100 parts of water into a three-necked flask, pass in nitrogen gas, stir evenly, then raise the temperature to 80°C, and simultaneously add 1 part of initiator ammonium persulfate and 25 parts of methacrylic acid, stirred for 4 hours to cause emulsion aggregatio...

Embodiment 2

[0095] (1) The preparation method of high-efficiency emulsifier is as follows:

[0096] Add 30 parts by weight of trimer acid, 25 parts of diethanolamine and 18 parts of NaOH catalyst into a three-necked flask, raise the temperature to 200°C for acylation reaction, keep the temperature down to 120°C after 6 hours of constant temperature reaction, and continue to add 15 parts of dimer acid, Stir for 20 minutes to mix evenly, add 30 parts of fatty alcohol polyoxyethylene ether dropwise, and react for 7 hours to obtain the high-efficiency emulsifier 2.

[0097] (2) The preparation method of nano-blocking agent is as follows:

[0098] Add 45 parts by weight of styrene, 18 parts of isobutyl acrylate, 7 parts of Span80, and 100 parts of water into a three-necked flask, pass in nitrogen gas, stir evenly, and then raise the temperature to 60°C. At the same time, dropwise add 2 parts of initiator ammonium persulfate and 20 parts of methacrylic acid, stirred for 4 hours to cause emulsi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com