Staged floatation method for separating low-grade calcite-barite-fluorite type ore

A step-by-step flotation, low-grade technology, which is applied in the field of step-by-step flotation for separating low-grade calcite-barite-fluorite-type ores, can solve the problem of low recovery rate of useful minerals, failure of minerals to float, and high content of useful minerals. problem, to achieve the effect of comprehensive recycling, good resistance to hard water, and good sorting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

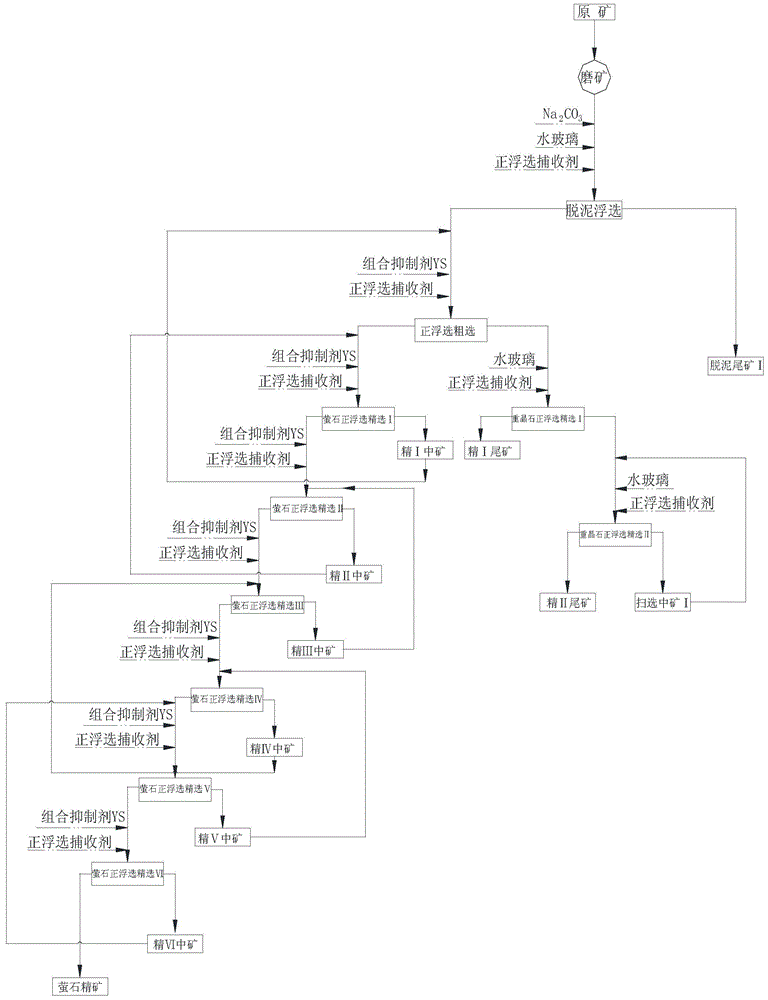

Image

Examples

Embodiment 1

[0028] Embodiment 1, a kind of step-by-step flotation method of separating low-grade calcite-barite-fluorite type ore, its steps are as follows:

[0029] (1) Crush the raw ore of low-grade fluorite ore to -1mm, and feed the crushed material into a ball mill. The part that is ground to -0.074mm accounts for 70% of the total weight of all materials, and then add water to make it with a weight concentration of 20%. Crude pulp;

[0030] (2) Put the raw ore pulp into the flotation equipment, under the condition of stirring speed of 1200rpm, firstly add the regulator sodium carbonate 1500g / t, adjust the pH value of the pulp to 9.5, then add the dispersant water glass 1200g / t, stir, Then add collector CA 300g / t, stir, carry out desliming flotation, and sort out the tailings containing quartz and calcite;

[0031] (3) The mixed coarse concentrate obtained by desliming flotation is subjected to a normal flotation roughing to obtain a fluorite coarse concentrate. During flotation, the ...

Embodiment 2

[0036] Embodiment 2, a kind of step-by-step flotation method of separating low-grade calcite-barite-fluorite type ore, its steps are as follows:

[0037] (1) Crush the raw ore of low-grade fluorite ore to -1mm, and feed the crushed material into a ball mill. The part that is ground to -0.074mm accounts for 95% of the total weight of all materials, and then add water to make it with a weight concentration of 40%. Crude pulp;

[0038](2) Put the raw ore pulp into the flotation equipment, under the condition of stirring speed of 1800rpm, first add the regulator sodium carbonate 2500g / t, adjust the pH value of the pulp to 10.5, then add the dispersant water glass 2000g / t, stir, Then add collector CA 600g / t, stir, carry out desliming flotation, and sort out the tailings containing quartz and calcite;

[0039] (3) The mixed coarse concentrate obtained by desliming flotation is subjected to one positive flotation roughing to obtain fluorite coarse concentrate. During flotation, the ...

Embodiment 3

[0044] Embodiment 3, a kind of step-by-step flotation method of separating low-grade calcite-barite-fluorite type ore, its steps are as follows:

[0045] (1) Crush the raw ore of low-grade fluorite ore to -1mm, and feed the crushed material into a ball mill. The part that is ground to -0.074mm accounts for 75% of the total weight of all materials, and then add water to make it with a weight concentration of 25%. Crude pulp;

[0046] (2) Put the raw ore pulp into the flotation equipment, under the condition of stirring speed of 1400rpm, firstly add the regulator sodium carbonate 1800g / t, adjust the pH value of the pulp to 9.8, then add the dispersant water glass 1500g / t, stir, Then add collector CA400g / t, stir, carry out desliming flotation, and sort out the tailings containing quartz and calcite;

[0047] (3) The mixed coarse concentrate obtained by desliming flotation is subjected to one positive flotation roughing to obtain fluorite coarse concentrate. During flotation, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com