Grinding-aid coupling agent and preparation thereof

A technology of coupling agent and grinding aid, which is applied in chemical instruments and methods, organic chemistry, dyeing physical treatment, etc., can solve the problems of large workshop area, large investment equipment, and large environmental pollution, so as to save investment and improve production Efficiency, the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

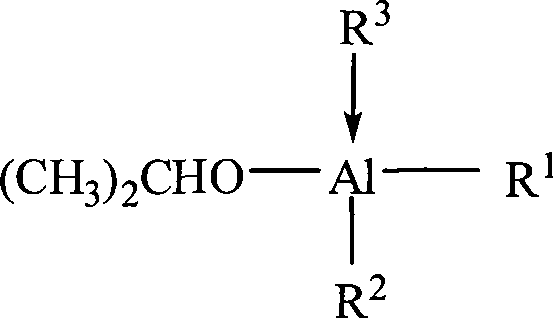

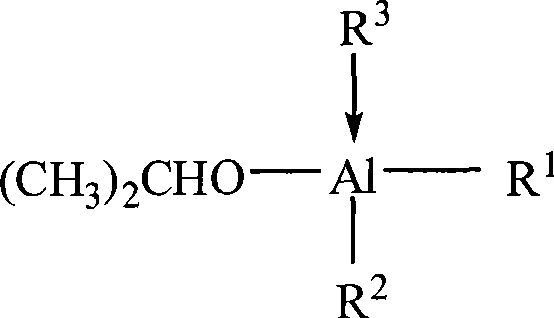

Method used

Image

Examples

Embodiment 1

[0022] Add 30.6 g (0.15 mol) of aluminum isopropoxide to 60 g of liquid paraffin, stir and heat to a temperature of 85° C. to completely dissolve aluminum isopropoxide, add 10 g of octadecyl primary amine, and then add 48.3 g of diisooctyl phosphate ( 0.15mol), stirred and reacted at a temperature of 85-89°C for 55 minutes, then added 62.1g (0.15mol) of naphthenic acid, and continued to stir and reacted for 50 minutes, during which isopropanol and other low-boiling point by-products were removed by vacuum distillation to obtain aluminum Ester coupling agent, cooled to a temperature of 76°C, added 92g of grinding aid oleic acid, and stirred for 20 minutes to obtain 286g of grinding aid coupling agent, which was a light yellow transparent liquid containing 47% of aluminate coupling agent, Abrasive 32%.

Embodiment 2

[0024] In 60g of solvent oil, add 61.2g (0.3mol) of aluminum isopropoxide, stir and heat to a temperature of 85°C to completely dissolve aluminum isopropoxide, add 25g of stearic acid amide, and then add 85.8g (0.3mol) of oleic acid , stirred and reacted at a temperature of 85 to 89°C for 48 minutes, then added 91.2 g (0.3 mol) of dodecylbenzenesulfonic acid, continued to stir and reacted for 50 minutes, during which isopropanol and other low-boiling point by-products were removed by vacuum distillation to obtain Aluminate coupling agent, cooled to a temperature of 76°C, adding 146g of grinding aid ricinoleic acid, and stirring for 20 minutes to obtain 418g of grinding aid coupling agent, which is a light yellow transparent liquid containing 51% of aluminate coupling agent , Grinding aid 35%.

Embodiment 3

[0026] In 40g of xylene, add 20.4g (0.1mol) of aluminum isopropoxide, stir and heat to a temperature of 85°C to completely dissolve aluminum isopropoxide, add 8g of erucamide, and then add 56.8g (0.2mol) of oleic acid, Stir and react at a temperature of 85-89°C for 65 minutes, during which isopropanol and other low-boiling point by-products are removed by distillation under reduced pressure to obtain an aluminate coupling agent, cooled to a temperature of 80°C, adding 49 g of grinding aid naphthenic acid, and stirring In 20 minutes, 157 g of grinding aid coupling agent was obtained, which was a light yellow transparent liquid containing 43% of aluminate coupling agent and 31% of grinding aid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com