Method for recovering barite from lead and zinc tailings

A barite and tailings technology, applied in solid separation, flotation, etc., to achieve the effects of low environmental pollution, low cost of chemicals and processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

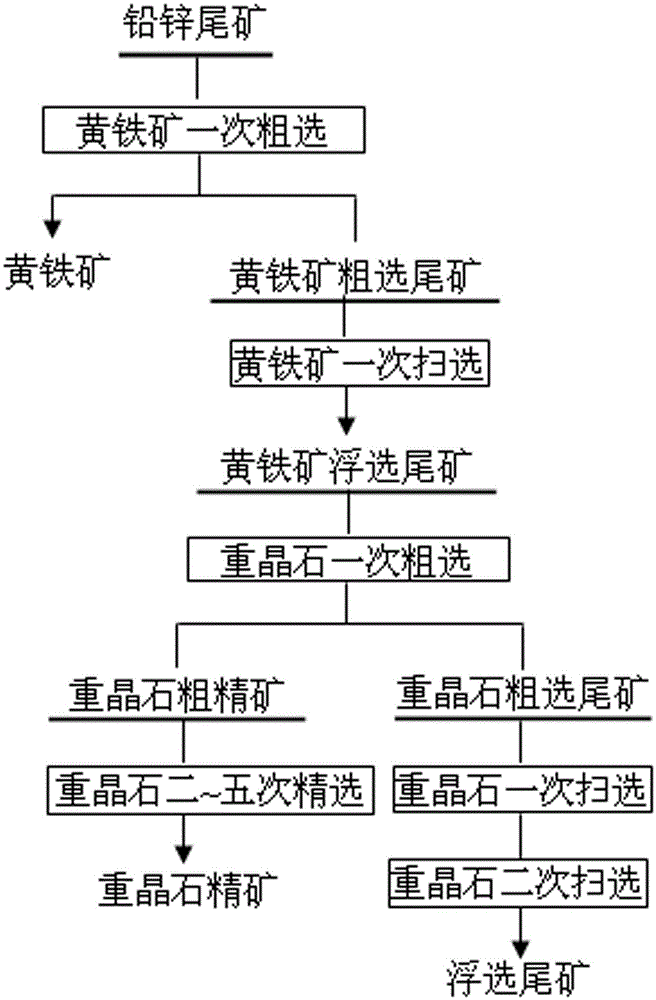

[0021] The content of lead-zinc tailings fineness -0.074mm is 72.58%, the content of dolomite is 60.13%, and the content of barite is 10.25%. Pyrite roughing concentration is 37%, barite roughing concentration is 33%, barite primary concentration is 27%, barite secondary concentration is 26%. According to the doses listed in Table 1 and figure 1 The process operation listed, the final obtained barite concentrate contains BaSO 4 90.85%, BaSO 4 The recovery rate is 70.63%.

Embodiment 2

[0023] The content of lead-zinc tailings fineness -0.074mm is 74.66%, the content of dolomite is 55.25%, and the content of barite is 14.25%. Pyrite roughing concentration is 39%, barite roughing concentration is 35%, barite primary concentration concentration is 29%, barite secondary concentration concentration is 28%, barite secondary concentration concentration is 27%, barite concentration concentration is 27%. The concentration of spar is 26% for four times, and the concentration of barite for five times is 25%. According to the doses listed in Table 1 and figure 1 Listed process operation, the final barite concentrate containing BaSO 4 95.47%, BaSO 4 The recovery rate is 60.84%.

Embodiment 3

[0025] The content of lead-zinc tailings fineness -0.074mm is 73.39%, the content of dolomite is 64.28%, and the content of barite is 13.65%. Pyrite roughing concentration is 36%, barite roughing concentration is 31%, barite primary concentration concentration is 29%, barite secondary concentration concentration is 27%, barite secondary concentration concentration is 26%, barite concentration concentration is 26%. The concentration of crystal stone is 25% for four times. According to the doses listed in Table 1 and figure 1 Listed process operation, the final barite concentrate containing BaSO 4 93.68%, BaSO 4 The recovery rate is 63.57%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com