Tenon jointed artificial reconstructed bamboo furniture

A kind of artificial and bamboo technology, applied in furniture parts, manufacturing tools, connecting components, etc., can solve the problems of no artificial remanufactured bamboo, no artificially remanufactured bamboo furniture patents or non-patent literature, etc., to save natural resources, compressive and bending resistance Good strength and good surface finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Implement the work that the present invention needs to carry out:

[0058] 1. Determination of the physical properties (including compressive strength, flexural strength, flexural modulus, impact toughness, shear strength and hardness, etc.) and technological properties (including bending strength, wear rate and nail holding power).

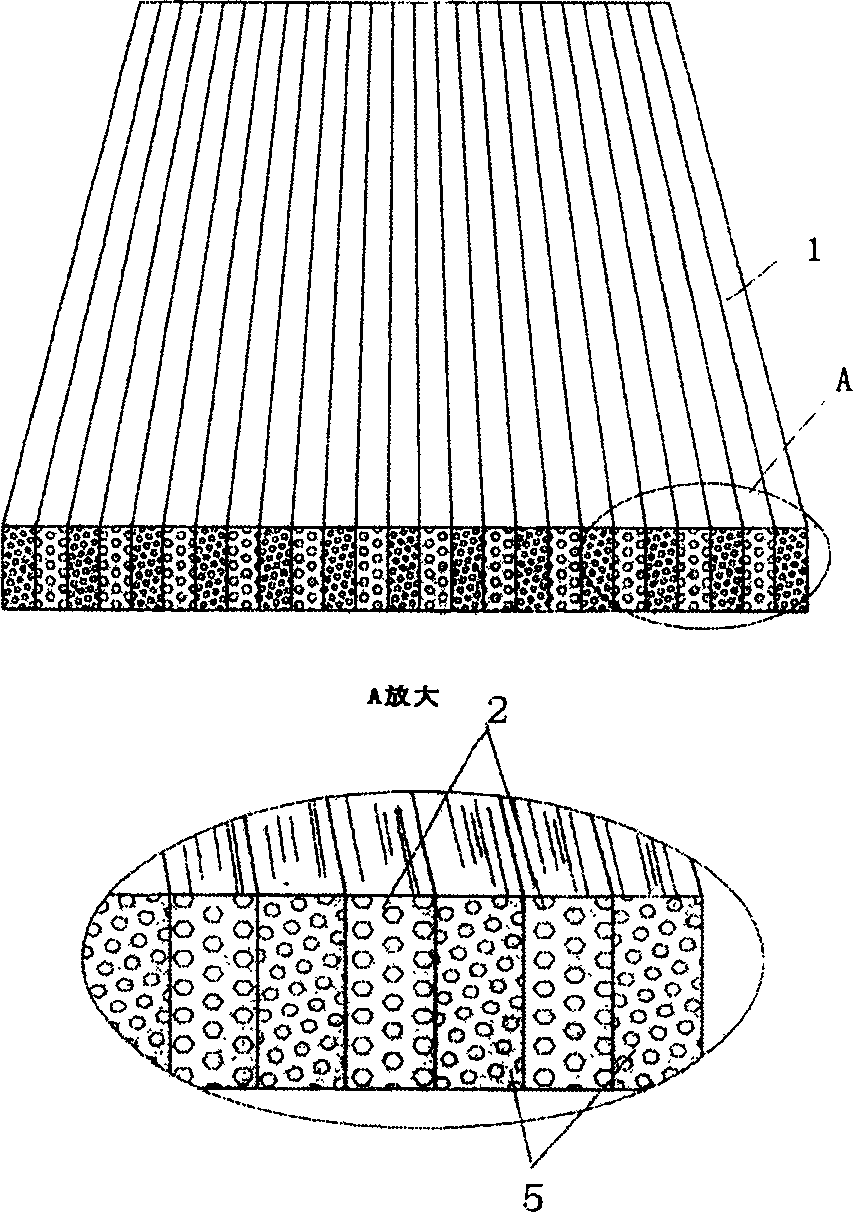

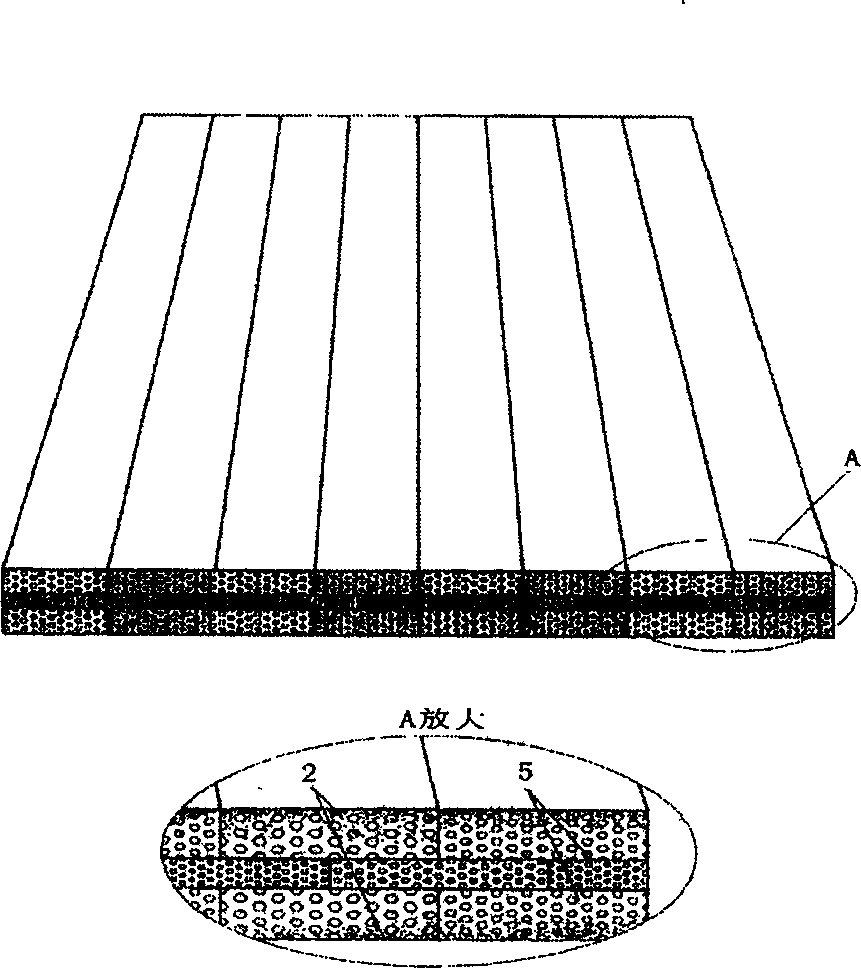

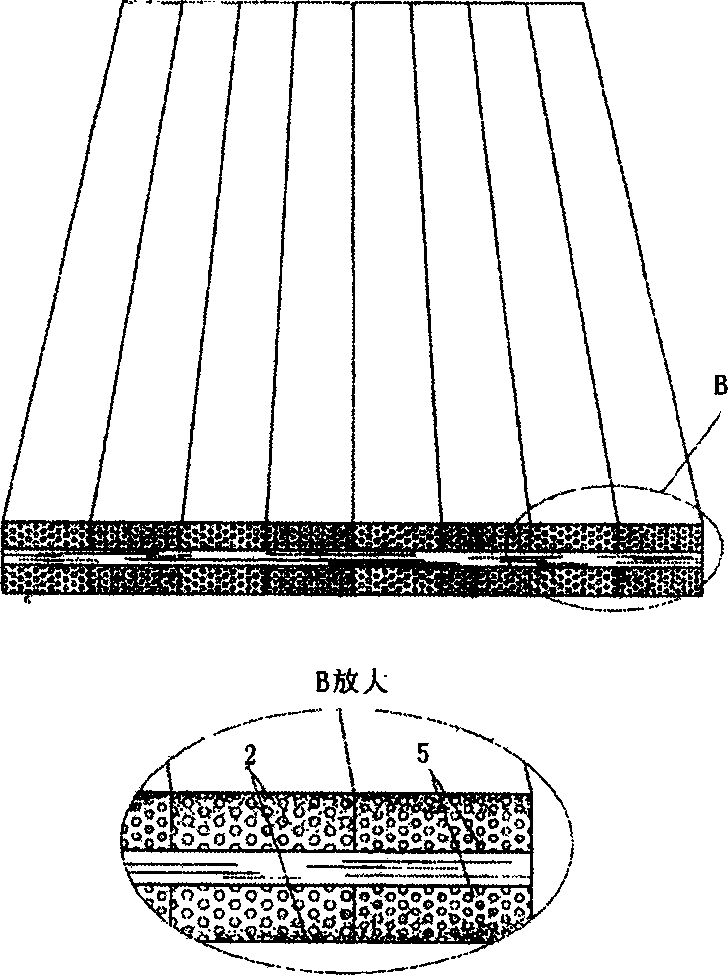

[0059] 2. According to the physical properties, determine the structure of the panels (squares) used for the tenon connection structure of bamboo furniture, the bonding form (flat pressure, side pressure or a combination of the two), and formulate the length, width and thickness series of the panels and squares.

[0060] 3. Determine the applicable tenon joint structure, production process, product quality standards, processing equipment, knives and mold fixtures according to the characteristics of artificially regenerated bamboo.

[0061] The artificially reconstituted bamboo furniture with mortise and tenon connection of the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com