Energy-saving and light quick-setting waterproof mortar for outer wall

A waterproof mortar and quick-setting technology, applied in the field of building waterproof coatings, can solve the problems of high strength of waterproof mortar, weak compressive and flexural strength, long setting time, etc., to improve the problem of shrinkage cracking, good compressive and flexural strength, The effect of excellent construction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

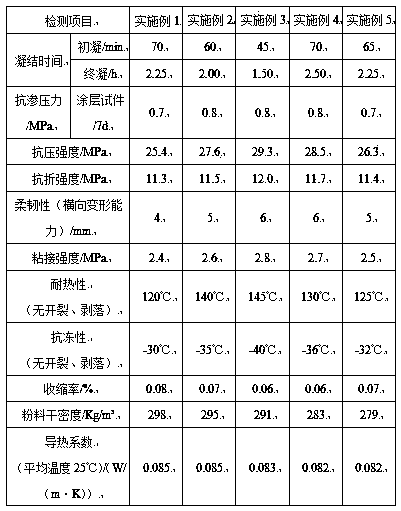

Examples

Embodiment 1

[0044] Example 1 A quick-setting energy-saving lightweight waterproof mortar for exterior walls

[0045] The waterproof mortar includes two components of liquid material and powder material, and its weight ratio is liquid material: powder material = 1:2.77;

[0046] (1) In parts by weight, the liquid material components include: 45 parts of styrene-butadiene emulsion, 0.5 parts of cellulose ether, 54 parts of water, 0.3 parts of defoamer, and 0.2 parts of preservative;

[0047] (2) In parts by weight, the powder components include:

[0048] 30 parts of Portland cement, 15 parts of hollow glass microspheres, 3 parts of fly ash, 50.5 parts of quartz sand, 0.5 parts of cement expansion agent, 0.2 parts of water reducer, 0.2 parts of dispersant, 0.1 part of coagulant, thixotropic 0.5 part of agent;

[0049] The cellulose ether is hydroxyethyl cellulose ether with a viscosity of 1000mPa·s, purchased from Guangdong Longfor Technology Co., Ltd.;

[0050] The Portland cement: the l...

Embodiment 2

[0055] Example 2 A quick-setting energy-saving lightweight waterproof mortar for exterior walls

[0056] The waterproof mortar includes two components of liquid material and powder material, and its weight ratio is liquid material: powder material = 1:3;

[0057] (1) In parts by weight, the liquid material components include: 50 parts of styrene-butadiene emulsion, 0.4 parts of cellulose ether, 48.9 parts of water, 0.4 parts of defoamer, and 0.3 parts of preservative;

[0058] (2) In parts by weight, the powder components include:

[0059] 34 parts of Portland cement, 16 parts of hollow glass microspheres, 4 parts of fly ash, 44.2 parts of quartz sand, 0.6 parts of cement expansion agent, 0.3 parts of water reducing agent, 0.3 parts of dispersant, 0.3 parts of coagulant, thixotropic 0.3 part of agent;

[0060] The cellulose ether is hydroxyethyl cellulose ether with a viscosity of 4000mPa·s, purchased from Guangdong Longfor Technology Co., Ltd.;

[0061] The Portland cement...

Embodiment 3

[0066] Example 3 A quick-setting energy-saving lightweight waterproof mortar for exterior walls

[0067] The waterproof mortar includes two components of liquid material and powder material, the weight ratio of which is liquid material: powder material = 1:3.3;

[0068] (1) In parts by weight, the liquid material components include: 55 parts of styrene-butadiene emulsion, 0.4 parts of cellulose ether, 44 parts of water, 0.3 parts of defoamer, and 0.3 parts of preservative;

[0069] (2) In parts by weight, the powder components include:

[0070] 36 parts of Portland cement, 18 parts of hollow glass microspheres, 4 parts of fly ash, 40.1 parts of quartz sand, 0.8 parts of cement expansion agent, 0.3 parts of water reducing agent, 0.3 parts of dispersant, 0.3 parts of coagulant, thixotropic 0.2 part of dose;

[0071]The cellulose ether is hydroxyethyl cellulose ether with a viscosity of 5000mPa·s, purchased from Guangdong Longfor Technology Co., Ltd.;

[0072] The Portland cem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com