Aerated concrete composite external wall insulation block without autoclaving and production method thereof

A technology of aerated concrete and external wall insulation boards, applied in insulation, building components, ceramic molding machines, etc., can solve problems such as organic insulation materials, poor adhesion of cement mortar, weak oxidation resistance, etc., and achieve Significant thermal insulation performance, strong fire performance, and strong oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] (1) Raw material ratio of aerated concrete:

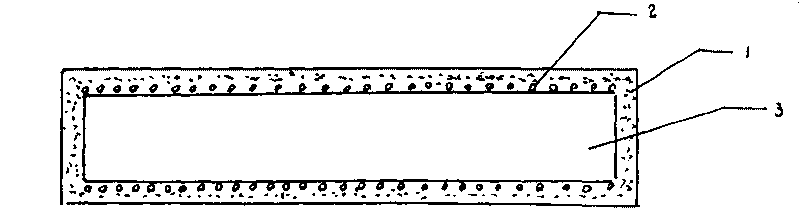

[0047] High alumina cement: lime: fly ash: water glass = 0.3: 0.2: 0.45: 0.05, then add water and stir according to the water-to-material ratio of 0.59. Wherein the foaming agent (aluminum powder) is used in an amount of 0.15% (percentage by weight) of the total amount of air-entrained concrete materials. The amount of poured air-entrained concrete material should be able to completely wrap the polystyrene board at the end of the gas generation. At this time, the volume of the air-entrained concrete accounts for one-third of the total volume of the steam-free aerated concrete composite external wall insulation board.

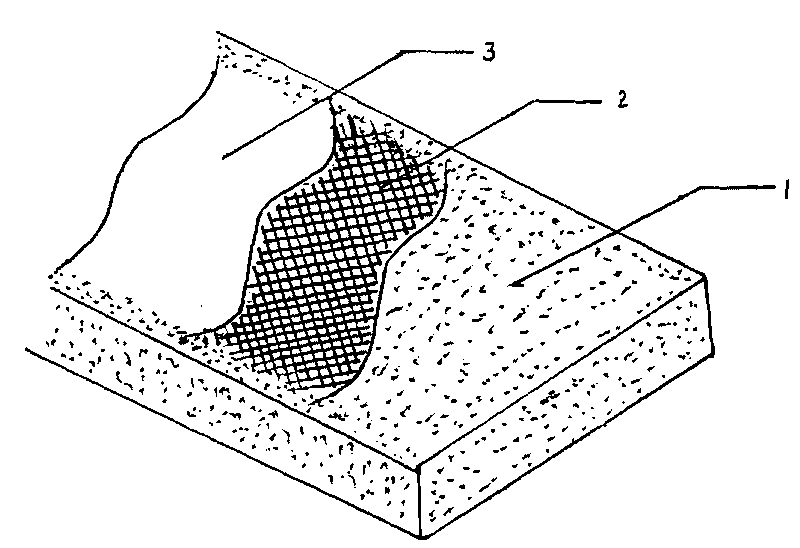

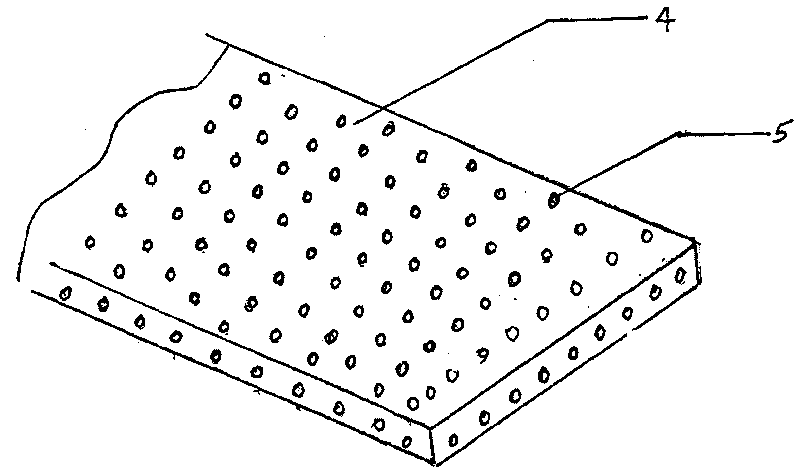

[0048] (2) Iron the six sides with round holes with a diameter of 0.5 to 2 cm and a depth of 0.5 to 2 cm, and fix the polystyrene board with glass mesh cloth on two large surfaces (with a diameter of 1 to 3 cm) standing upright (the large surface is vertical) in the mold. Fixing method: Fix on the positionin...

Embodiment 2

[0051] (1) Raw material ratio of aerated concrete:

[0052] High alumina cement: lime: sand: water glass=0.32: 0.21: 0.42: 0.05 Then add water and stir according to the water-material ratio of 0.56. Wherein the consumption of foaming agent (aluminum powder) is 0.16% (percentage by weight) of the total amount of materials. The amount of poured material should be able to completely wrap the polystyrene board at the end of the gas generation. At this time, the volume of the air-entrained concrete accounts for one-third of the total volume of the non-steamed aerated concrete composite external wall insulation board.

[0053] (2) Fix the six-sided polystyrene board with round holes with a diameter of 0.5 to 2 cm and a depth of 0.5 to 2 cm and two large surfaces fixed (with a diameter of 1 to 3 cm) and glass mesh cloth standing (large surface vertical) On a bracket that can keep a gap of 2-3 cm between the polystyrene board and the bottom and four sides of the mold, the length of t...

Embodiment 3

[0056] (1) Raw material ratio of aerated concrete:

[0057] High alumina cement: lime: fly ash: gypsum = 0.31: 0.22: 0.43: 0.04 and then add water and stir according to the water-material ratio of 0.6. Wherein the consumption of foaming agent (aluminum powder) is 0.14% (percentage by weight) of the total amount of materials. The amount of poured material should be able to completely wrap the polyurethane board at the end of the gas generation. At this time, the volume of the air-entrained concrete accounts for one-third of the total volume of the non-steamed aerated concrete composite external wall insulation board.

[0058](2) Fix the six-sided round hole with a diameter of 0.5 to 2 cm and a depth of 0.5 to 2 cm and two large surfaces fixed (hole diameter 1 to 3 cm) of polyurethane board with glass mesh cloth standing (large surface vertical) on the in the mold. Fixing method: Fix on the positioning nails that ensure a 2-3cm gap with the bottom of the mold. At the same tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com