Alkali aggregate reaction inhibitor

A technology of reaction inhibitor and alkali aggregate, applied in the field of concrete auxiliary materials, can solve the problem of insignificant inhibition effect, and achieve the effects of inhibiting alkali aggregate reaction, improving workability, and reducing unit water consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

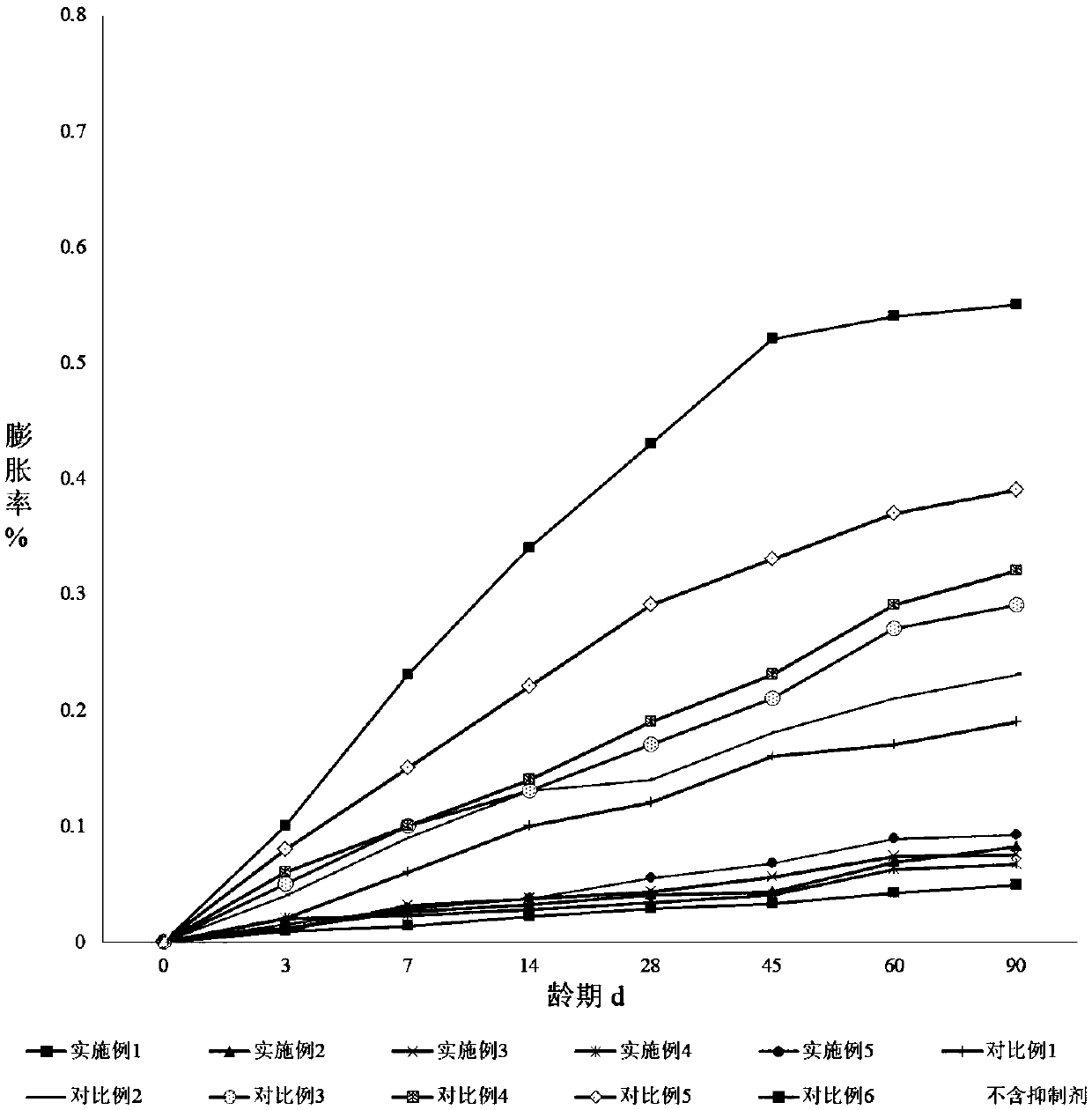

Image

Examples

Embodiment 1

[0032] Follow the steps below to prepare the alkali aggregate inhibitor and prepare the cement mortar:

[0033] (1) Preparation of rice husk ash: In the combustion control box, the heating rate is 50°C / min, the maximum temperature is 460°C, and the combustion of rice husk is controlled for 20 minutes. After burning the rice husk, add 0.06% ethylene glycol , the particle size of the rice husk ash is ground into 30 microns for subsequent use;

[0034] (2) the soybean meal is pulverized to make soybean meal powder with a particle size of 30 microns for subsequent use;

[0035] (3) Dissolving 0.2% quaternary ammonium salt, 0.2% polyoxyethylene ether, 0.2% polyvinyl alcohol and 0.5% lactic acid in water to make an aqueous solution, and prepare cement mortar with the aqueous solution;

[0036] (4) Add 6% rice husk ash, 0.8% soybean meal powder, and 4% lithium carbonate to the cement mortar in sequence.

Embodiment 2

[0038] Follow the steps below to prepare the alkali aggregate inhibitor and prepare the cement mortar:

[0039] (1) Preparation of rice husk ash: In the combustion control box, the heating rate is 40°C / min, the maximum temperature is 500°C, and the combustion of rice husk is controlled for 10 minutes. After burning the rice husk, add 0.1% ethylene glycol , the rice husk ash particle size is ground into 10 microns, for subsequent use;

[0040] (2) the soybean meal is pulverized to make soybean meal powder with a particle size of 10 microns for subsequent use;

[0041] (3) Dissolving 1% quaternary ammonium salt, 0.25% polyoxyethylene ether, 0.75% polyvinyl alcohol and 0.1% lactic acid in water to make an aqueous solution, and prepare cement mortar with the aqueous solution;

[0042] (4) Add 3% rice husk ash, 5% soybean meal powder, and 1% lithium carbonate to the cement mortar in sequence.

Embodiment 3

[0044] Follow the steps below to prepare the alkali aggregate inhibitor and prepare the cement mortar:

[0045] (1) Preparation of rice husk ash: In the combustion control box, the heating rate is 60°C / min, the maximum temperature is 400°C, and the combustion of rice husk is controlled for 30 minutes. After burning the rice husk, add 0.01% ethylene glycol , the rice husk ash particle size is ground into 50 microns, for subsequent use;

[0046] (2) the soybean meal is pulverized to make soybean meal powder with a particle size of 50 microns for subsequent use;

[0047] (3) Dissolving 0.01% quaternary ammonium salt, 0.01% polyvinyl alcohol and 2% lactic acid in water to make an aqueous solution, and prepare cement mortar with the aqueous solution;

[0048] (4) Add 8% rice husk ash, 0.3% soybean meal powder, and 1% lithium carbonate to the cement mortar in sequence.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com