Concrete and preparation method thereof

A concrete and mixture technology, applied in the field of concrete and its preparation, can solve the problems of poor concrete performance and achieve the effects of improved impact resistance, simple operation, and high crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

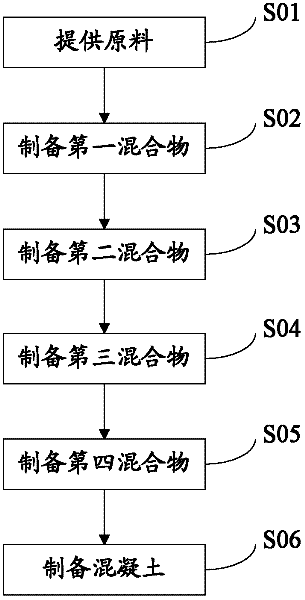

[0060] see figure 1 , figure 1 Show the concrete preparation method flowchart of the embodiment of the present invention, comprise the steps:

[0061] Step S01, providing raw materials:

[0062] Take the following components:

[0063] cementitious material,

[0064] River sand, the mass ratio of the river sand to the cementitious material is 1~1.3:1,

[0065] Water, the mass ratio of described water and gelling material is 0.12~0.22: 1,

[0066] superplasticizer, the mass ratio of the superplasticizer to the gelling material is 0.006~0.08:1,

[0067] mixed graded steel fibers, the volume ratio of the steel fibers to the concrete is 0.005-0.03:1,

[0068] Mixed and graded polypropylene fibers, the volume ratio of the polypropylene fibers to the concrete is 0.0015-0.012:1;

[0069] Step S02, preparing the first mixture:

[0070] mixing the river sand, steel fibers, and polypropylene fibers to obtain a first mixture;

[0071] Step S03, preparing the second mixture:

[0...

Embodiment 1

[0116] The proportion of the modified active powder concrete of the embodiment of the present invention, which is environmentally friendly, cost-effective and multi-graded is as follows:

[0117] Concrete material (cement and multi-gradation composite material) dosage: cement (P.O 42.5) 525kg, silica fume: 105kg, fly ash: 126kg, 95 grade slag powder: 126kg, limestone powder: 105, superfine slag powder: 84kg

[0118] The mass of river sand with particle size up to 1.25mm continuous gradation: 1258kg

[0119] Mixed steel fiber (volume ratio, accounting for the total volume ratio of concrete): copper-plated steel fiber 105kg, end-hook steel fiber 52.5kg.

[0120] Mixed polypropylene fiber (accounting for concrete volume percentage): fine polypropylene fiber 1.12kg, coarse polypropylene fiber 8kg

[0121] Superplasticizer: 21kg

[0122] Water quality: 156kg

[0123] The preparation method of the modified active powder concrete with environmental protection, high cost performanc...

Embodiment 2

[0131] The proportion of an environmentally friendly, cost-effective and multi-graded modified active powder concrete is as follows:

[0132] Concrete material (cement and multi-component graded composite material) dosage: cement (P.O42.5) 420kg, silica fume: 105kg, fly ash: 52.5kg, 95 grade slag powder: 105kg, limestone powder 210kg Fine slag powder: 157kg

[0133] Aggregate is continuous graded river sand with particle size up to 1.25mm: 1258kg

[0134] Mixed steel fiber (volume ratio, accounting for the total volume ratio of concrete): copper-plated steel fiber 78.5kg, end-hook steel fiber 78.5kg.

[0135] Mixed polypropylene fiber (accounting for concrete volume percentage): fine polypropylene fiber 1.45kg, coarse polypropylene fiber 9.3kg

[0136] Superplasticizer: 21kg

[0137] Water-binder ratio: 176.5kg

[0138] The preparation method of the modified active powder concrete with environmental protection, high cost performance and multi-gradation in the embodiment of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com