Energy-saving gas stove

A gas stove and gas technology, applied in the field of gas stoves, can solve the problems of heat consumption, high temperature, waste gas overflow, etc., and achieve the effects of improving combustion efficiency, thermal efficiency, and thermal efficiency.

Active Publication Date: 2010-09-08

GUANGDONG DEHE TECH CO LTD

View PDF5 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The air preheater of the above-mentioned device needs to obtain heat from the burner, so it needs to consume a certain amount of heat energy; at the same time, because the device cannot discharge the exhaust gas such as carbon monoxide and carbon dioxide generated during the combustion of gas in time, the exhaust gas gradually accumulates in the isolation cover. Affects the air supply required for full combustion of the gas, and these exhaust gases will eventually overflow around the isolation enclosure, which will pose a safety hazard to human health

In addition, there is still such a problem in the existing gas stove that the temperature of the pot is easy to be too high when the gas stove burns, and then the food in the pot will produce harmful substances that are not conducive to human health, and even produce a large amount of carcinogens

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

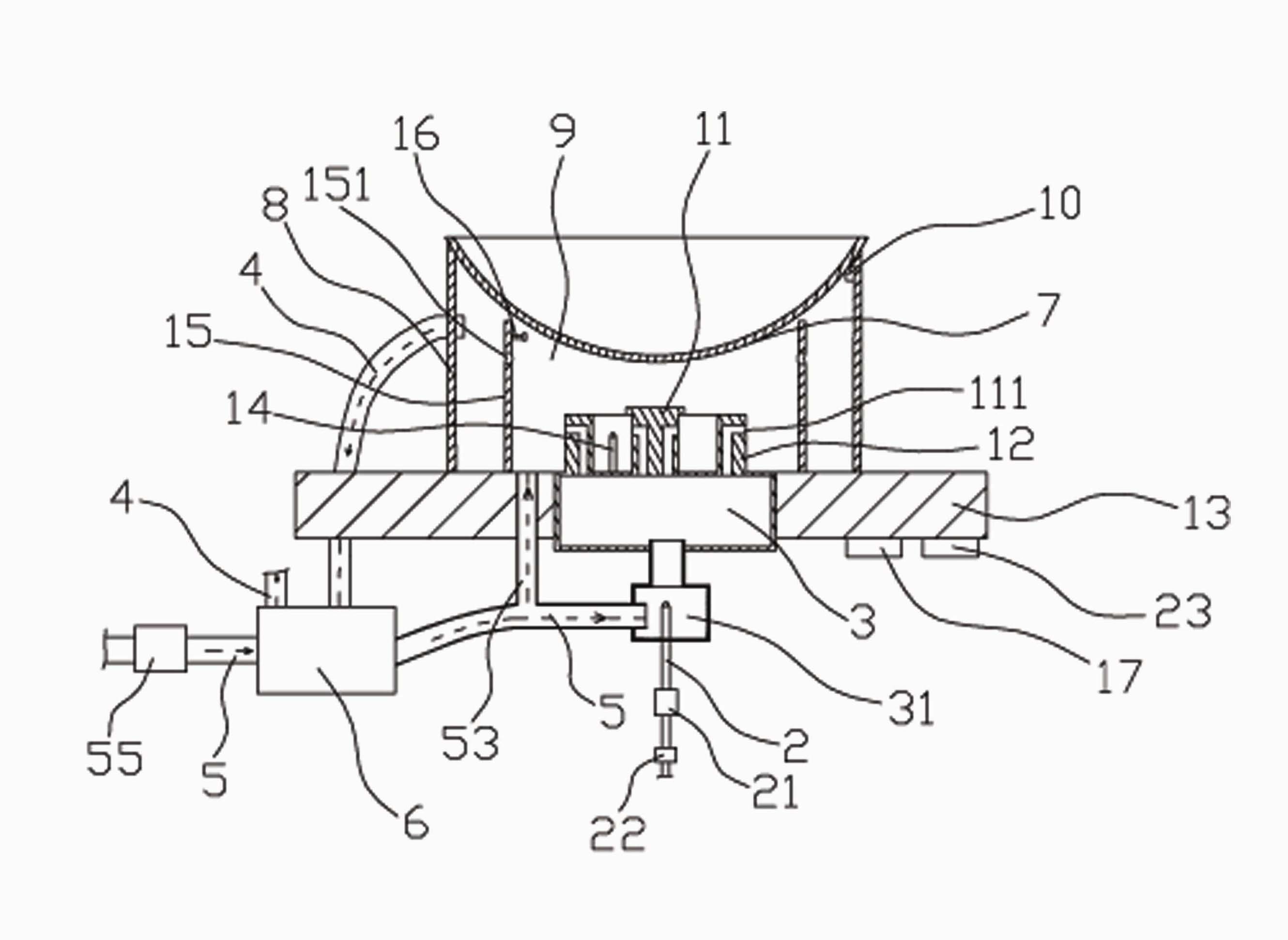

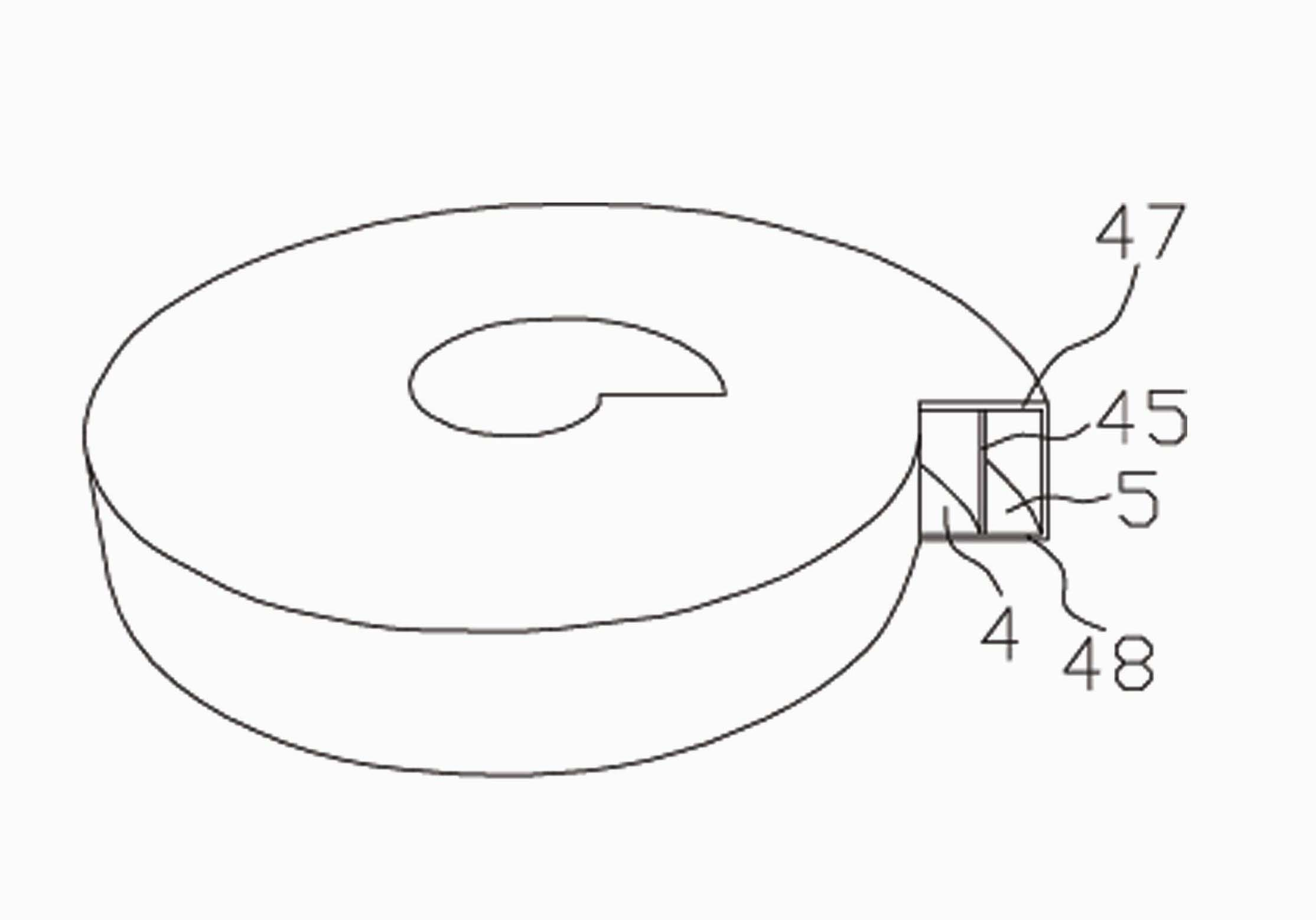

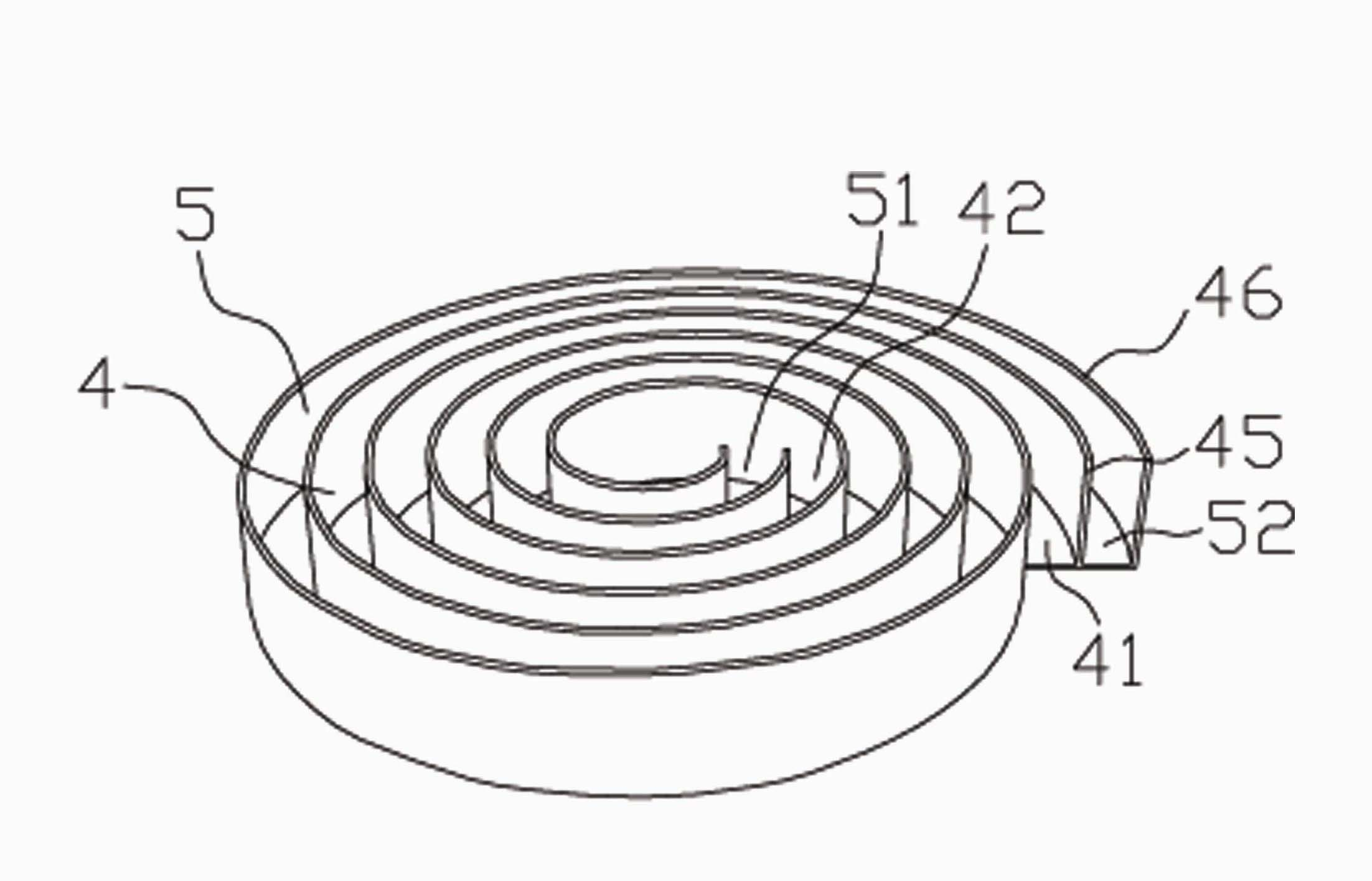

The invention discloses an energy-saving gas stove, which comprises a gas stove body, a combustor, a gas guide pipe and a gas mixing chamber, wherein the gas guide pipe is communicated with the gas mixing chamber and the combustor is communicated with the upper part of the gas mixing chamber. The gas stove additionally comprises an isolation hood, a waste gas exhaust pipe, an air guide pipe and a heat exchange device, wherein the isolation hood isolates combustion hot gas from the outside and the heat exchange device is used for heat exchange between incoming cold air and exhausted hot waste gas. The invention has the advantages that not only the gas is combusted more fully but also the thermal efficiency is effectively improved because heat contained in the waste gas produced during combustion is used for preheating the cold air participating in combustion, and the impact on body health caused by the waste gas is effectively avoided because the waste gas is fully exhausted. Moreover, since the heat generated by the gas in the closed gas combustion chamber is not rapidly dissipated around, the thermal efficiency of the gas stove is promoted.

Description

An energy-saving gas stove technical field [0001] The invention belongs to the technical field of gas stoves, in particular to an energy-saving gas stove that can significantly improve gas combustion efficiency and simultaneously avoid the impact of combustion waste gas on human health. Background technique Traditional gas stove mostly is that low-temperature gas is directly introduced into the burner to burn, because the air participating in combustion is not preheated, it is unfavorable for the complete combustion of gas, causing the burner to be easily carbonized; simultaneously, gas is in the process of burning , the carbon monoxide, carbon dioxide, incompletely burned natural gas and other waste gases produced directly spread around the cooker, seriously affecting the health of users; moreover, the heat energy generated by the combustion of this open traditional gas stove will also spread a lot around, Not only the thermal efficiency is low, but also a lot of energy i...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F24C3/00F24C3/12F24C15/10F23L15/00

CPCY02B40/166Y02B40/00Y02E20/34

Inventor 林水龙

Owner GUANGDONG DEHE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com