Filling and recovering device for low-melting-point alloy

A recovery device and low melting point technology, which is applied in the field of low melting point alloy filling and recovery devices, can solve the problems of low recovery efficiency of low melting point alloys, low energy utilization rate of warm water, increased workload of workers, etc., and achieves a small footprint , good bending deformation and reduced labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

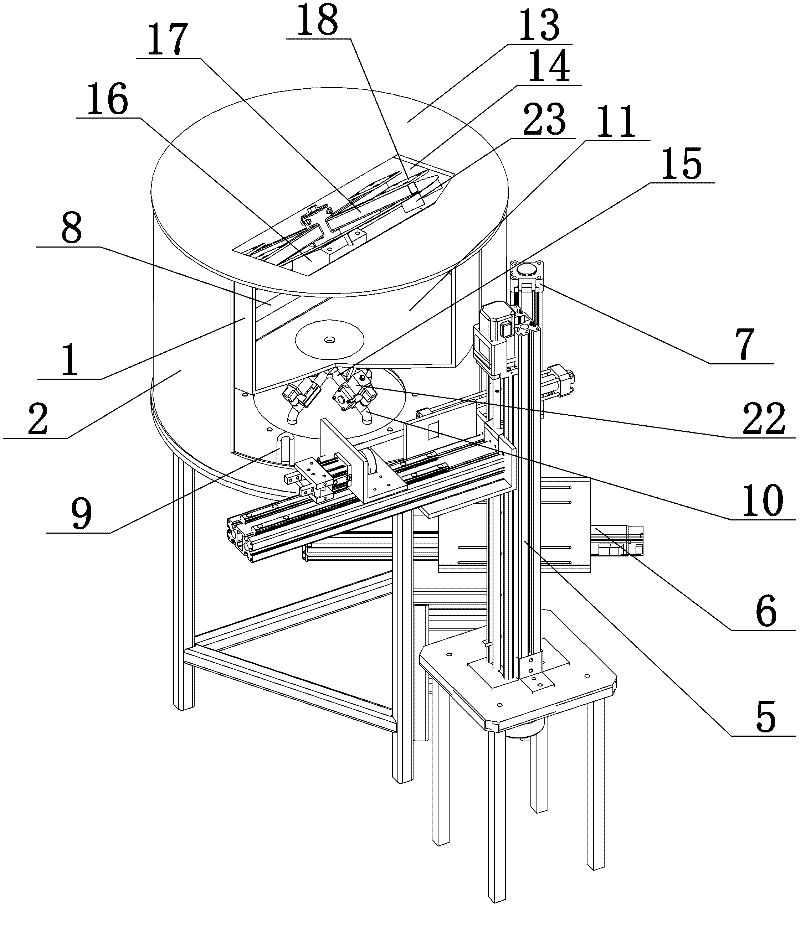

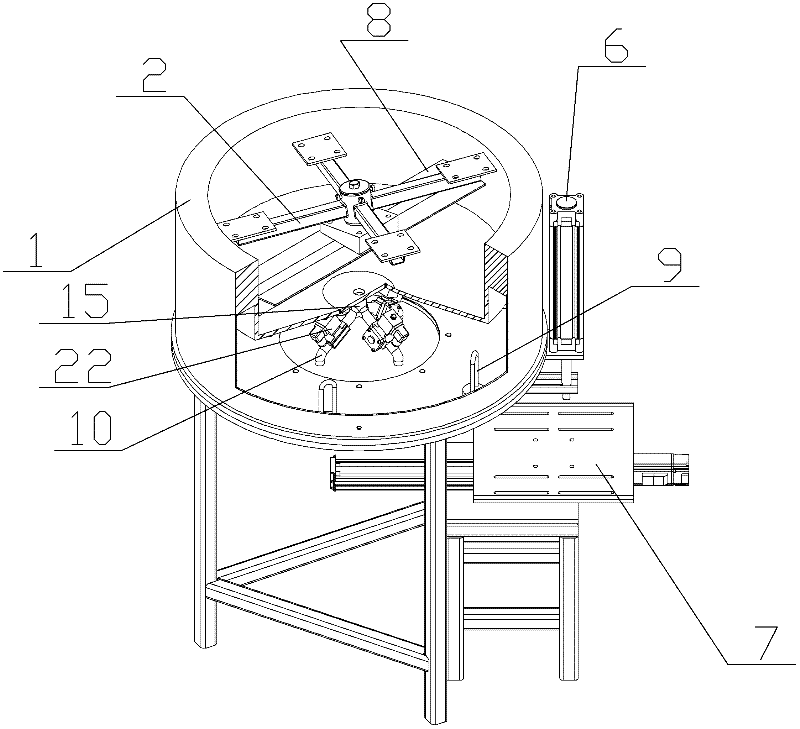

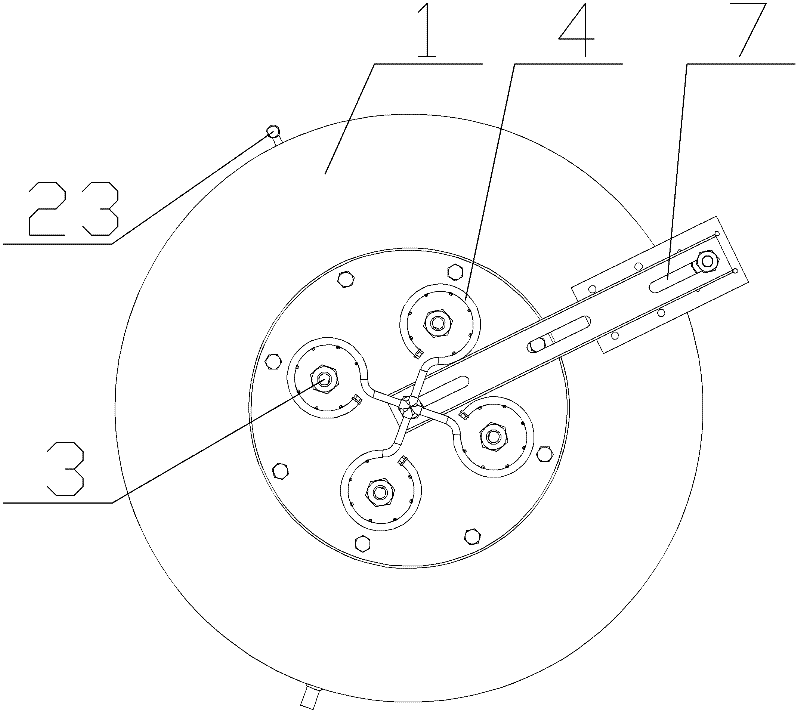

[0038] The present invention will be further described below in conjunction with accompanying drawing.

[0039] The low melting point alloy filling and recovery device of the present invention includes a water tank, a turntable, a gate 3, a cooling nozzle 4, a first manipulator 5 that can take and place workpieces from the turntable, and a second manipulator that can pick and place workpieces from the gate 3 6. The third manipulator 7 that can drive the cooling nozzle 4 to move along the filling direction of the low melting point alloy in the workpiece; the water tank is provided with a mounting seat 8 and a water temperature maintaining unit 9, and the turntable is rotatably connected to the mounting seat 8, and the rotation plane of the turntable is in line with the The horizontal planes intersect; between the gate 3 and the water tank, there is an openable and closable connecting pipe 10 for connecting the gate 3 and the water tank, one end of the connecting pipe 10 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com