Paint powder mixing device

A mixing device and powder technology, applied in mixers, mixers with rotating containers, transportation and packaging, etc., can solve the problem of powder flying around, saving labor consumption, improving uniformity and uniform mixing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

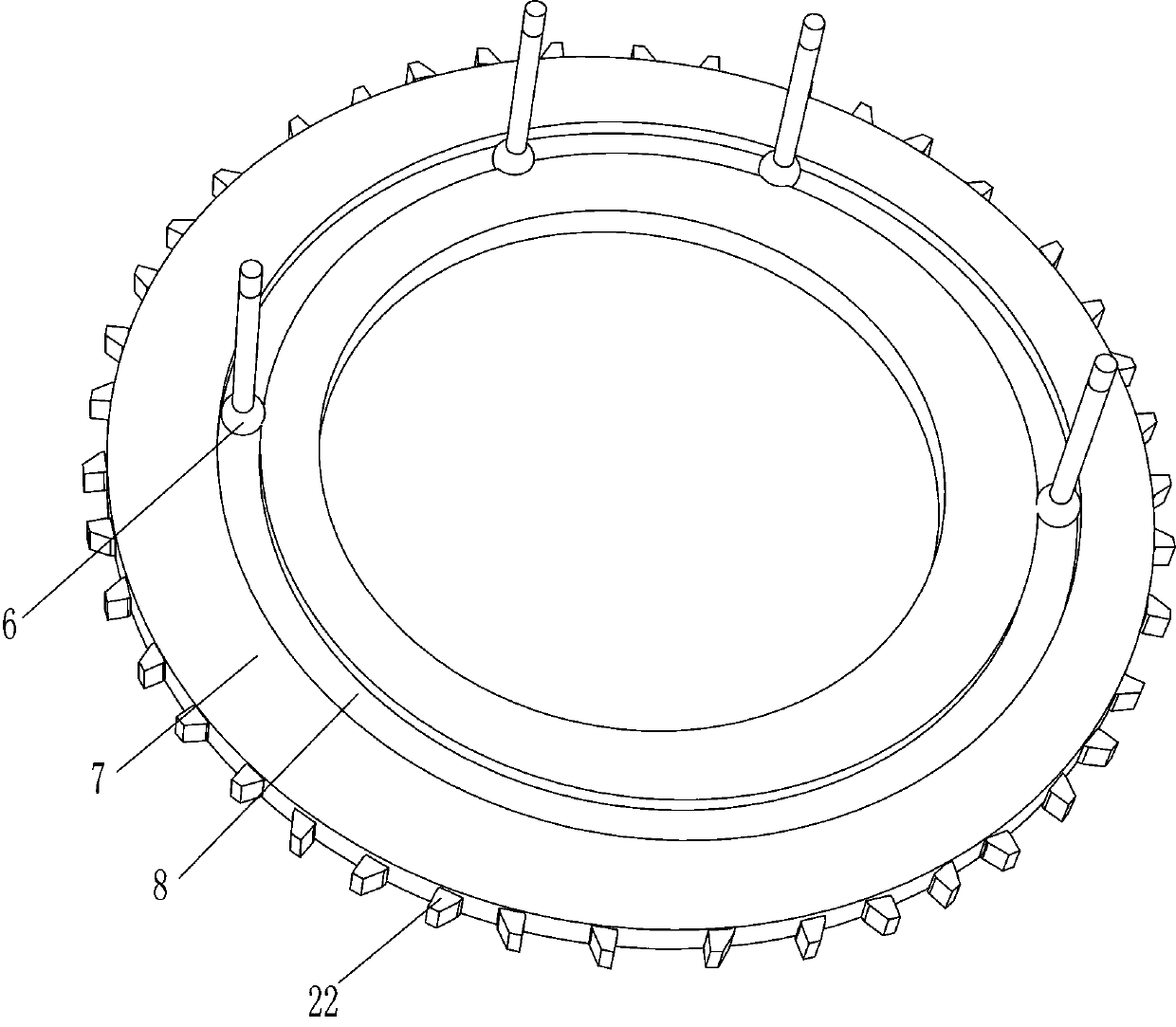

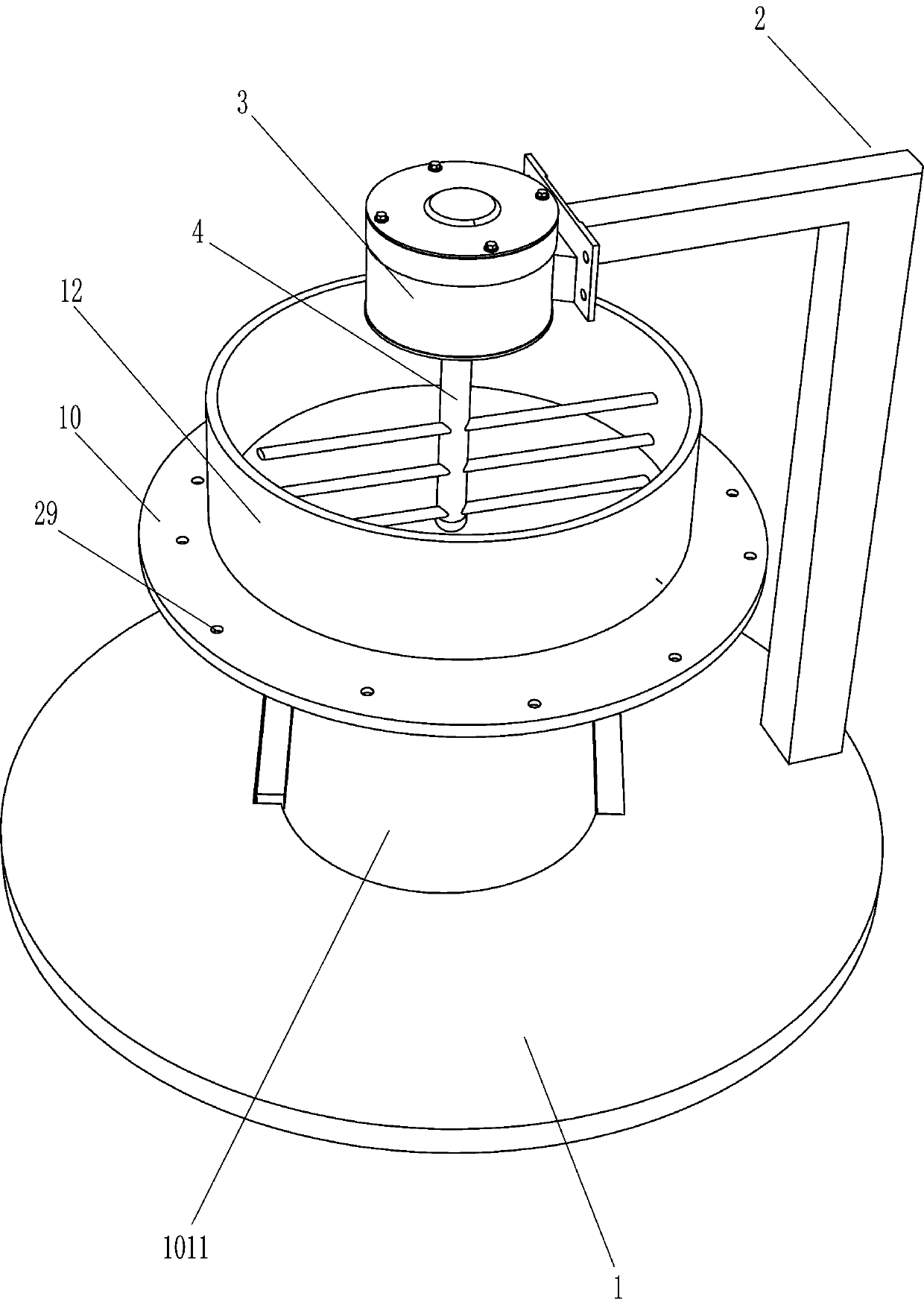

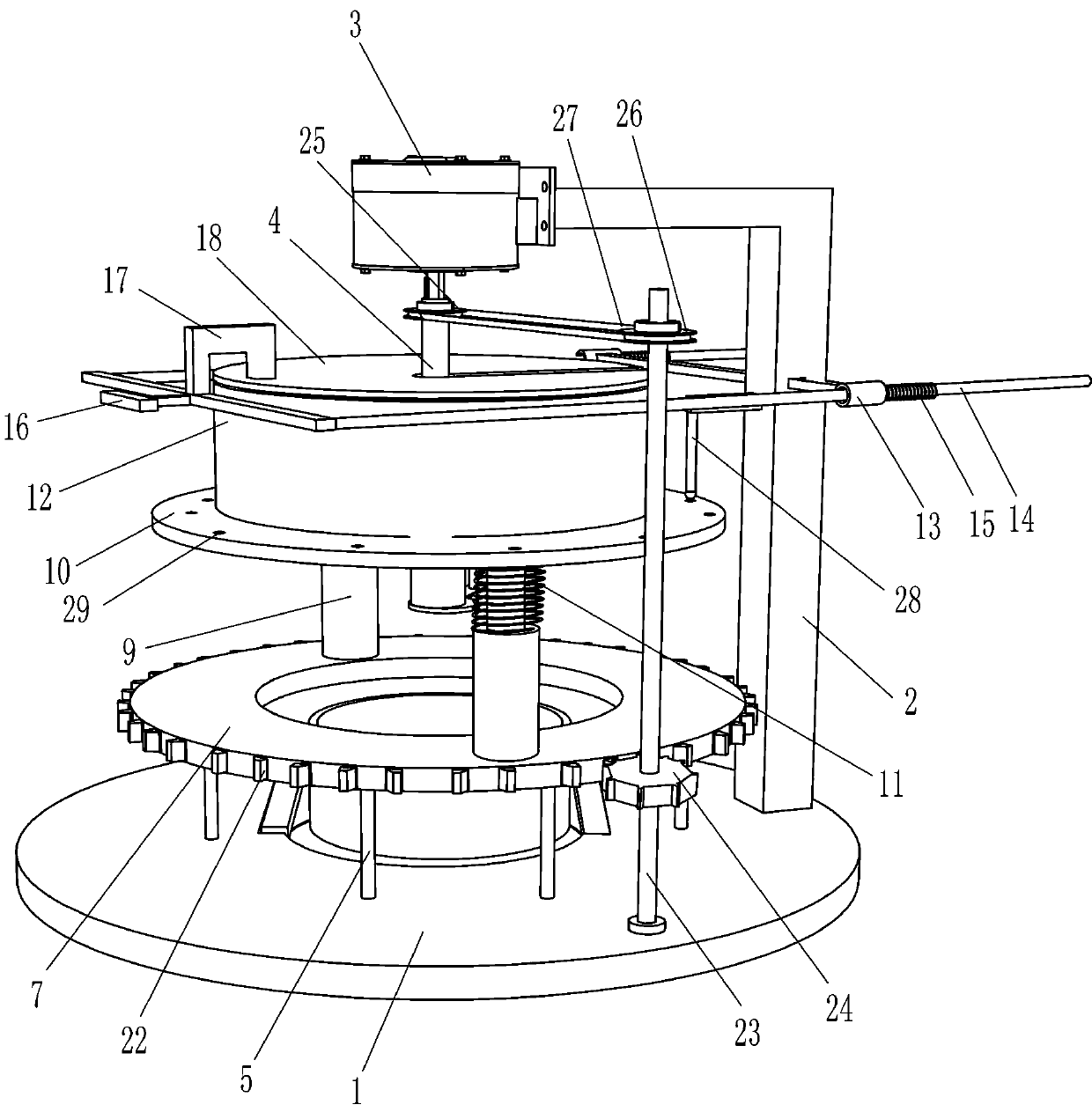

[0022] A paint powder mixing device, such as Figure 1-5 As shown, it includes a bottom plate 1, a mixing component, a material storage component, a closing component, a blanking component and a rotating component. The bottom plate 1 is used to install the entire device, and the mixing component is arranged on the bottom plate 1, which is powered by a motor to rotate and mix materials. The storage component is arranged on the top of the bottom plate 1 for placing the paint powder, the closing component is arranged on the mixing component, and the switch is performed by sliding, and the blanking component is arranged on the storage component, and the material is unloaded by pushing and rotating. The assembly is arranged on the mixing assembly and rotates by means of rotation.

[0023] like figure 1 and 2 As shown, the mixing assembly includes a mounting rod 2, a deceleration motor 3 and a stirring rod 4, the mounting rod 2 is set on the right side of the top of the bottom pla...

Embodiment 2

[0035] On the basis of Example 1, as figure 1 and 3 As shown, a clamping rod 28 is also included. The clamping rod 28 is welded on the upper left side of the installation rod 2. The clamping groove 29 is a circle and is evenly opened on the outside of the top of the placing plate 10. The clamping rod 28 is matched with the clamping groove 29.

[0036] The specific operation process of the above-mentioned embodiment: when the placing plate 10 rotates counterclockwise, the clamping slot 29 is driven to rotate counterclockwise, when the clamping slot 29 is disengaged from the clamping rod 28, the placing plate 10 is pushed to move downward, and the clamping rod 28 is clamped in. When it is in the card slot 29, the placing tray 10 moves upward and resets, so that manual pressing can be performed without manual operation, which improves the automation of the equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com