Suede plastering method for decorative strip of vehicle

A technology of decorative strips and velvet, which is used in vehicle parts, transportation and packaging, and devices for coating liquids on surfaces, etc. It can solve the problems of high risk of bad batches, increase production costs, time-consuming and laborious wiping, etc., and reduce batches. Production risks, reduce power consumption and production costs, avoid flying effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

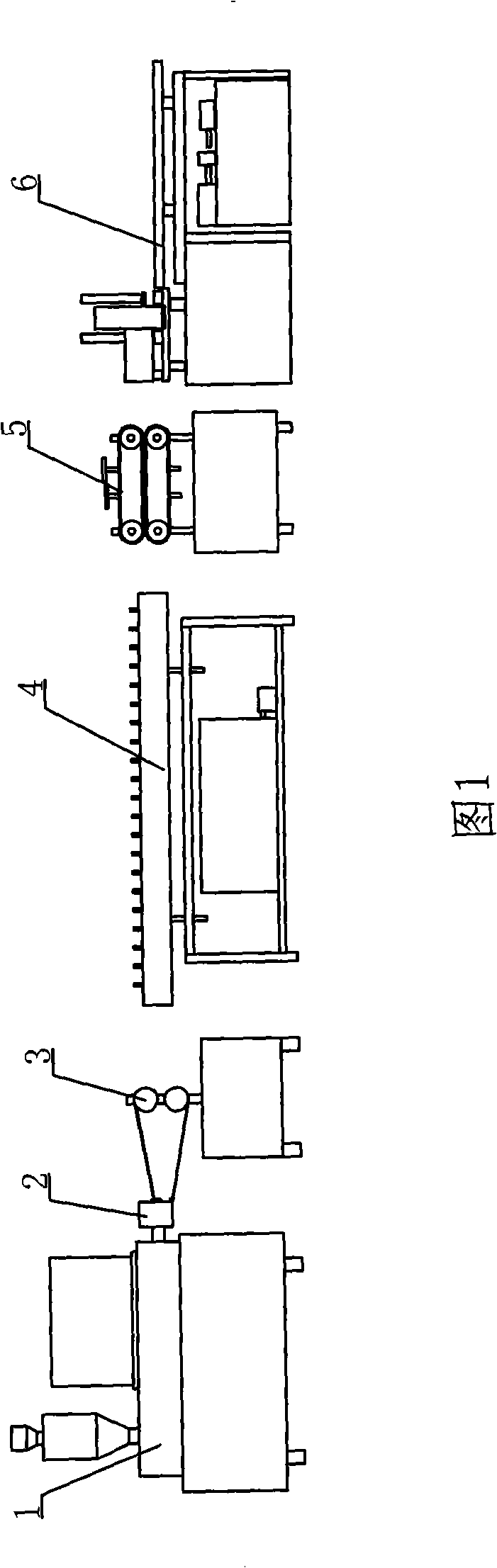

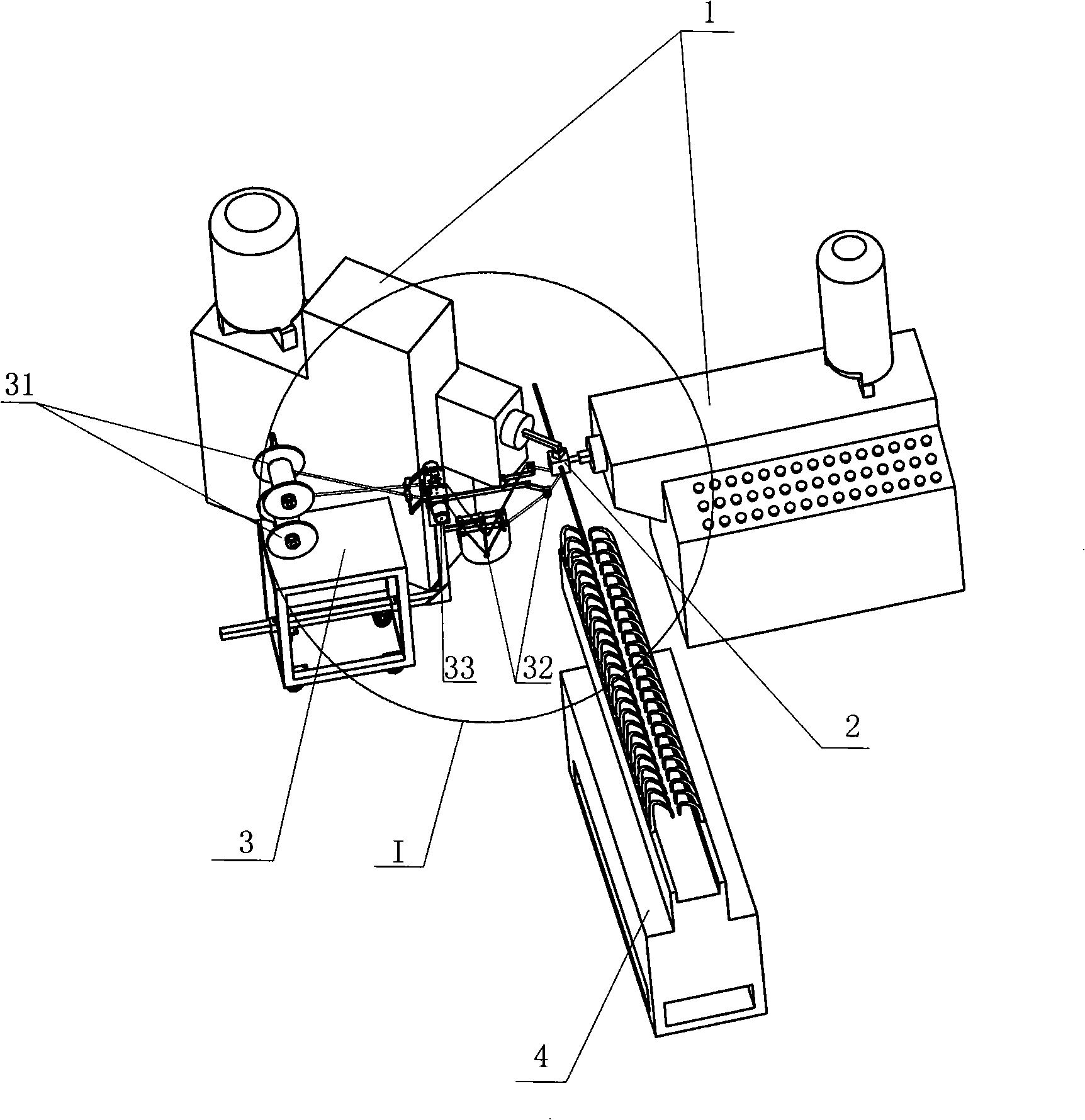

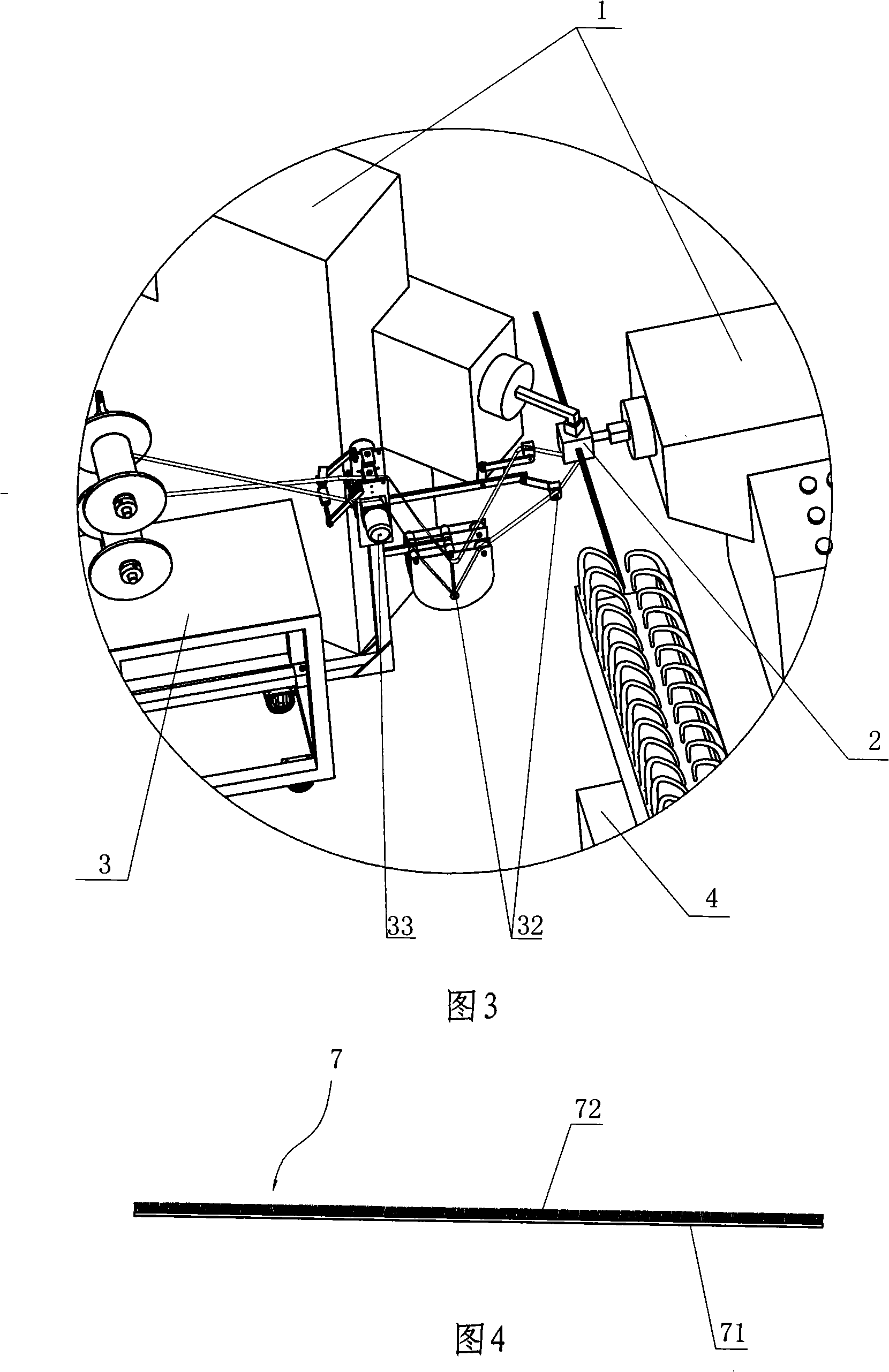

[0021] The invention will be further described in detail below in conjunction with the embodiments of the accompanying drawings.

[0022] As shown in Figures 1 to 6, the vehicle decorative strip body 9 is a water cut with two lips, and all need to be pasted on the two lips, and its method of pasting is as follows: ①. The film 71 that can be thermally bonded to the main body of the decorative strip between ℃ and 190 ℃, in this embodiment, the film is made of polyvinyl chloride (PVC) plastic material, or thermoplastic elastic triphenyl phosphate (TPE), thermoplastic vulcanizate ( TPV), thermoplastic polyurethane resin (TPU) or thermoplastic polyolefin (TPO), the thickness is selected as 0.2mm, of course, 0.1mm or 0.3mm can also be selected, first clean the surface of the film, and then apply glue on the surface of the film;② , and then plant fluff 72 on the surface of the whole film 71 by means of electrostatic flocking; ③, then place the good whole film 71 of the above-mentione...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com