Wood cutting machine

A cutting machine and cutting mechanism technology, applied in the direction of wood processing equipment, sawing equipment, sawing components, etc., can solve the problems of increasing processing procedures, increasing operating costs, and troublesome operation, so as to reduce production costs, save energy, and process convenient effect

Pending Publication Date: 2018-09-14

重庆草衣木食文化传播有限公司

View PDF8 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

After the wood is cut, the surface of the wood needs to be polished and polished. However, the existing cutting equipment can only cut the wood and has a single function. When polishing is required, the wood needs to be transferred to the polishing equipment. and increased operating costs

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0012] The present invention will be described in further detail below by means of specific embodiments:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

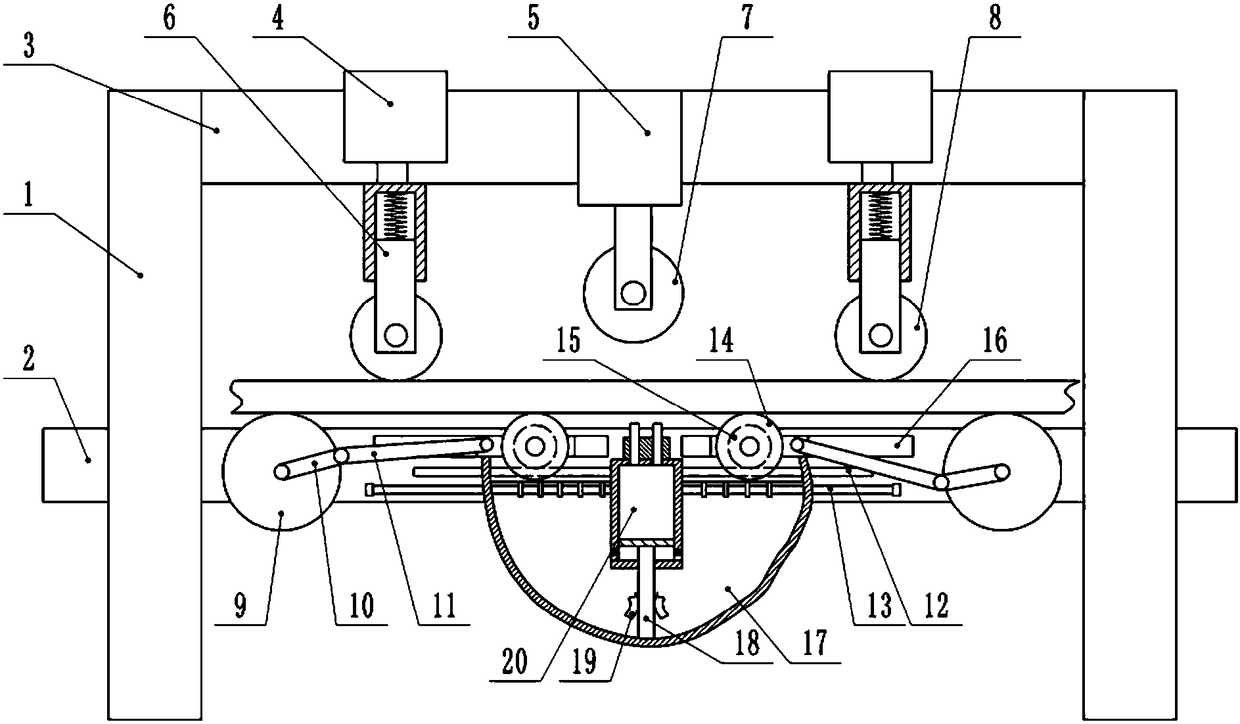

The invention belongs to the technical field of wood processing equipment, and particularly discloses a wood cutting machine. The wood cutting machine comprises a rack and a cutting mechanism, the rack is rotationally provided with two driving rollers and a driven roller, the rack is provided with two sliding grooves, two polishing rollers slide and are rotationally connected between the two sliding grooves, transmission mechanisms are arranged between the driving rollers and the polishing rollers, a collecting bag is connected between the two polishing rollers, a gear rack is connected to therack, gears meshed with the gear rack are arranged on the polishing rollers, two cylinder blocks are fixedly connected to the rack, pistons are arranged in the cylinder blocks, elastic pieces are arranged between the pistons and the top walls of the cylinder blocks, push rods are connected to the lower ends of the pistons, the lower ends of the push rods are fixed to the middle portion of the collecting bag, air blowing openings facing the cutting mechanism are formed in the upper portions of the cylinder blocks, air outlets are formed in the side walls of the lower positions of the cylinderblocks and are provided with filter nets, dust sucking openings are formed in the side walls of the cylinder blocks and are provided with one-way doors. According to the scheme, wood polishing can becarried out while wood cutting is carried out, the number of wood processing procedures is decreased, and the working efficiency is improved.

Description

technical field [0001] The invention belongs to the technical field of wood processing equipment, in particular to a wood cutting machine. Background technique [0002] Wood is an important raw material, which is widely used in various fields such as construction and home decoration. Wood processing is an important technological means. Efficient, fine and automatic wood processing equipment has been actively researched, designed and produced. Among wood processing equipment, wood cutting equipment is being demanded in large quantities. After the wood is cut, the surface of the wood needs to be polished and polished. However, the existing cutting equipment can only cut the wood and has a single function. When polishing is required, the wood needs to be transferred to the polishing equipment. And increased operating costs. Contents of the invention [0003] The object of the present invention is to provide a wood cutting machine capable of polishing wood while cutting wood...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B27B5/24B27B5/29B27B25/02B27G3/00B24B7/28

CPCB24B7/28B27B5/24B27B5/29B27B25/02B27G3/00Y02P70/10

Inventor 朱培钢

Owner 重庆草衣木食文化传播有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com