Automobile sealing strip punching and cutting integrated equipment

An automotive sealing strip, integrated technology, applied in metal processing and other directions, can solve the problems of inability to cut to a fixed length and adjust the hole distance, and achieve the effect of eliminating manual operation, high yield, and avoiding random flying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

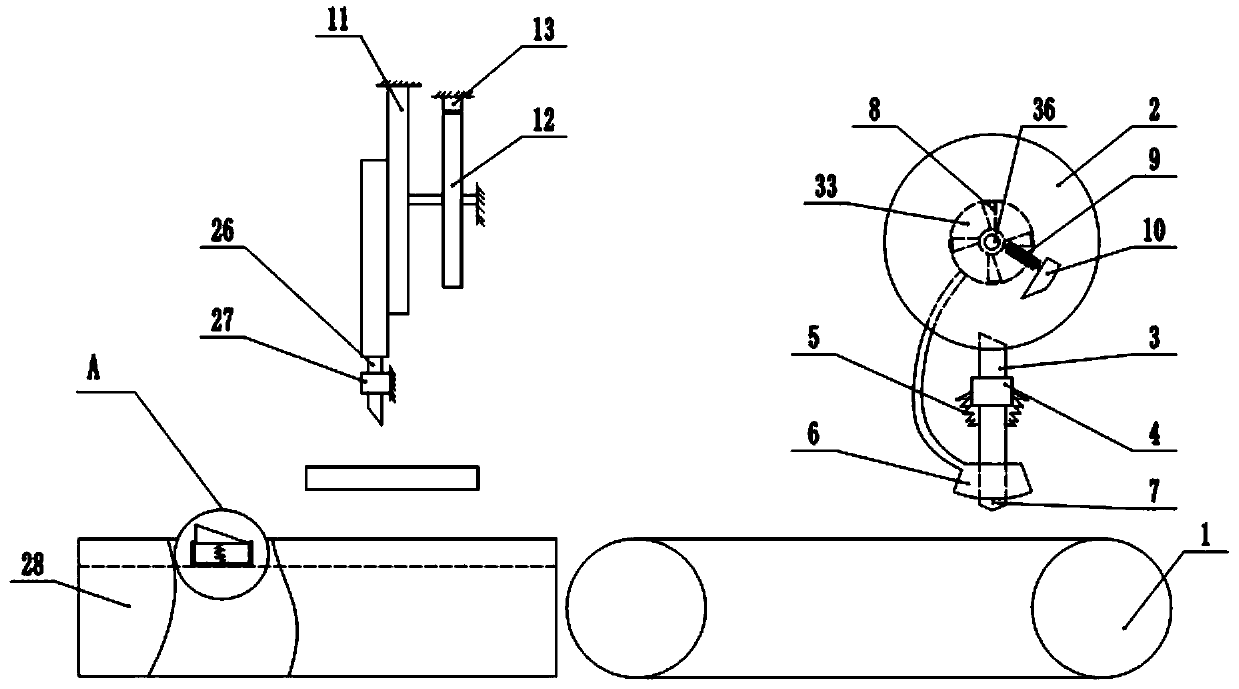

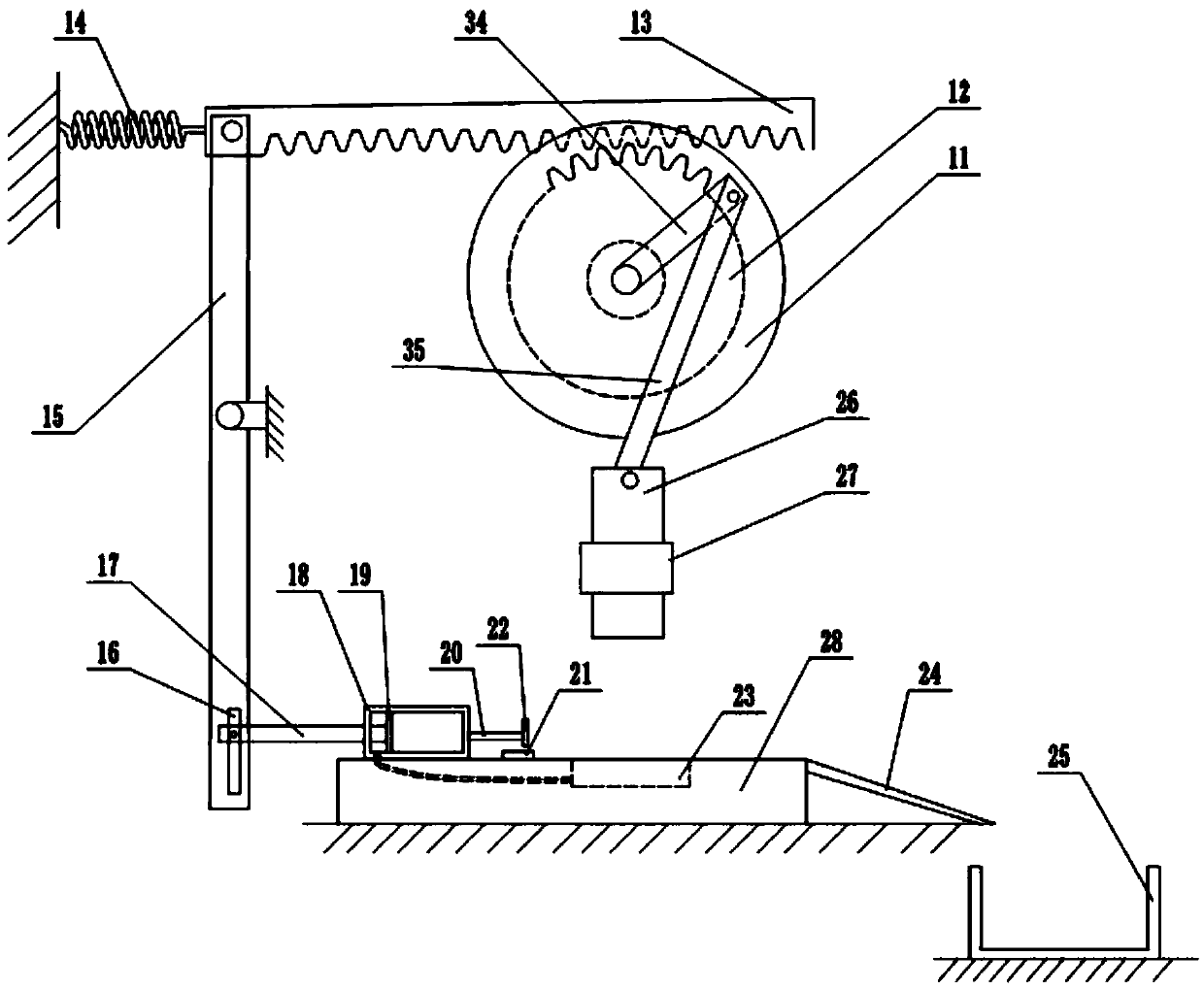

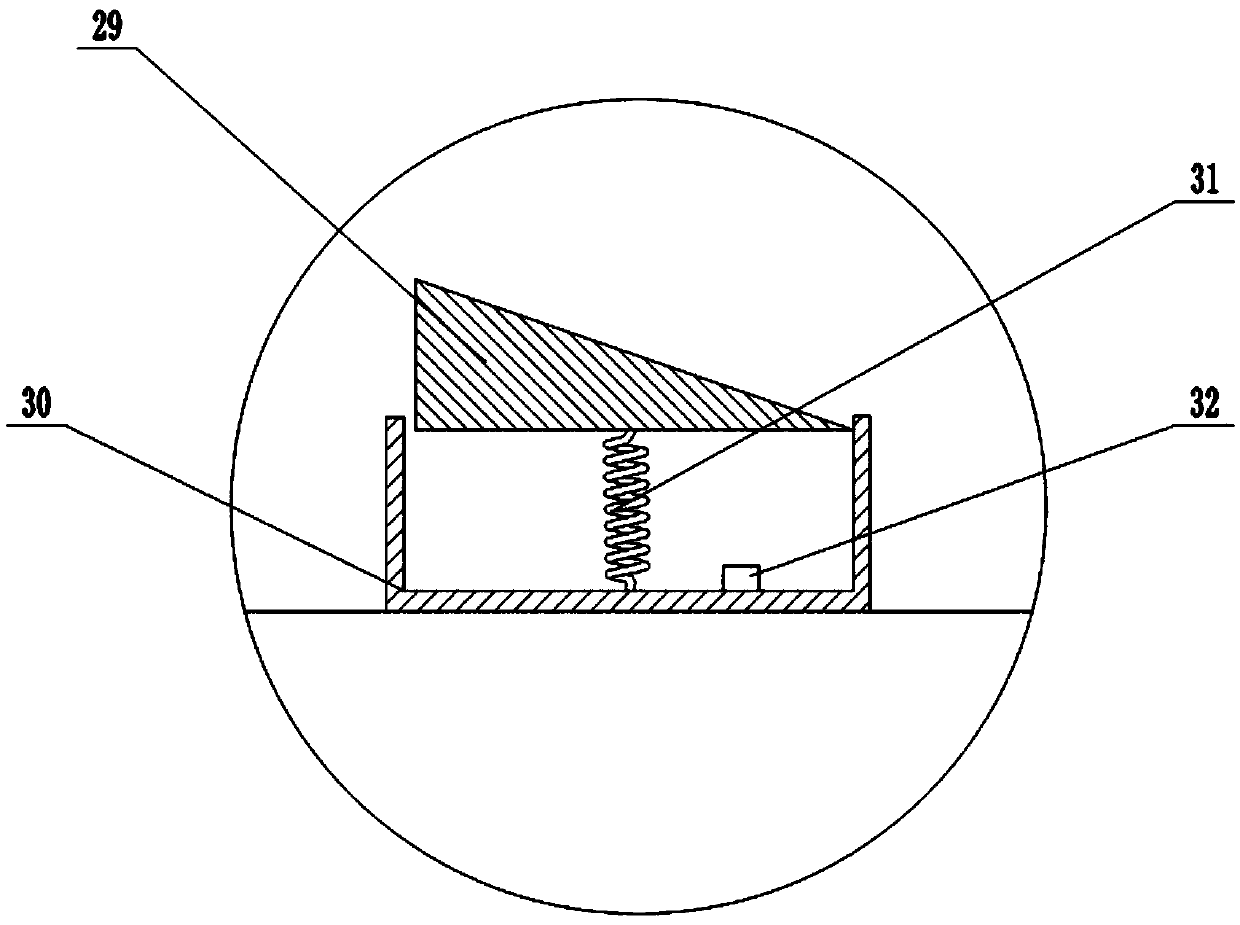

[0032] Place the sealing strip to be processed in the groove of the conveyor belt 1, drive the conveyor belt 1 and the first rotating shaft 36, and during the rotation of the first rotating shaft 36, the wedge 10 is subjected to centrifugal force and gradually moves radially away from the first rotating shaft 36. The direction of a rotating shaft 36 moves, and at the same time the first spring 9 is stretched, the wedge 10 touches the inner wall of the hollow cylinder 2, and squeezes the wedge surface of the wedge rod 3, and the wedge rod 3 is subjected to the extrusion force to vertically Move straight down, the drill bit 7 at the bottom of the wedge bar 3 drills into the sealing strip, and completes the punching operation to the sealing strip.

[0033] The first rotating shaft 36 drives the blade 8 to rotate while rotating, and the rotation of the blade 8 generates air flow, so that in the drilling process, the air flow on the air inlet surface of the blade 8 generates suction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com