Organic fertilizer production line

A production line and organic fertilizer technology, applied to organic fertilizers, mixers, conveyors, etc., can solve the problems of smoke and dust pollution to the surrounding environment, uneven particle size, and damage to the health of on-site workers, so as to reduce the sawdust falling out of the tape , Improve the working environment and avoid the effect of flying around

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

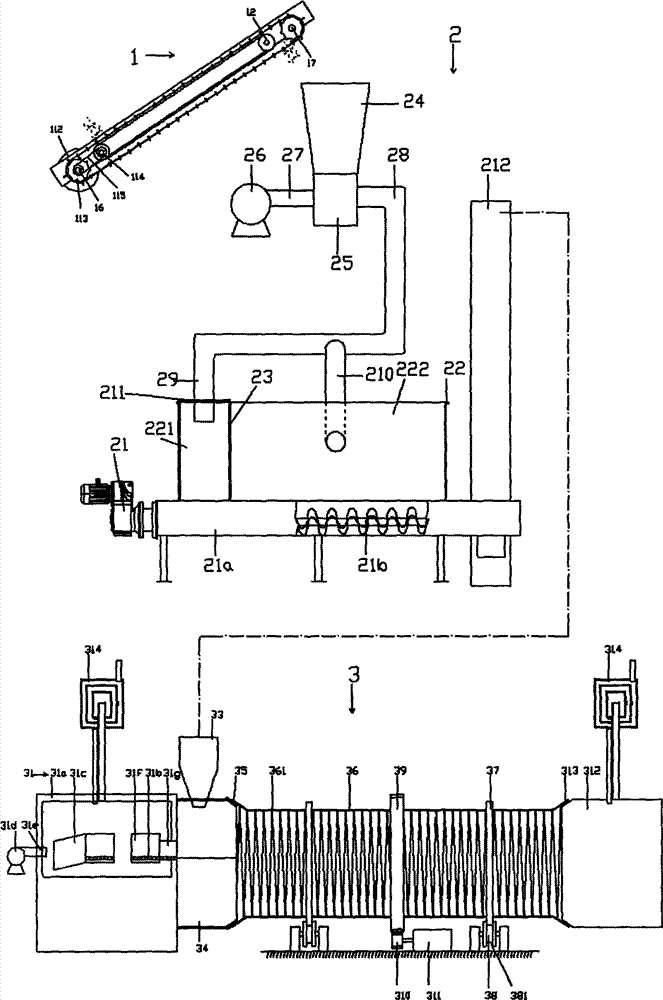

[0032] Example: see Figures 1 to 7 As shown, the organic fertilizer production line is composed of a sawdust lifting conveyor belt 1, a sawdust sludge mixing device 2 and an incineration device 3,

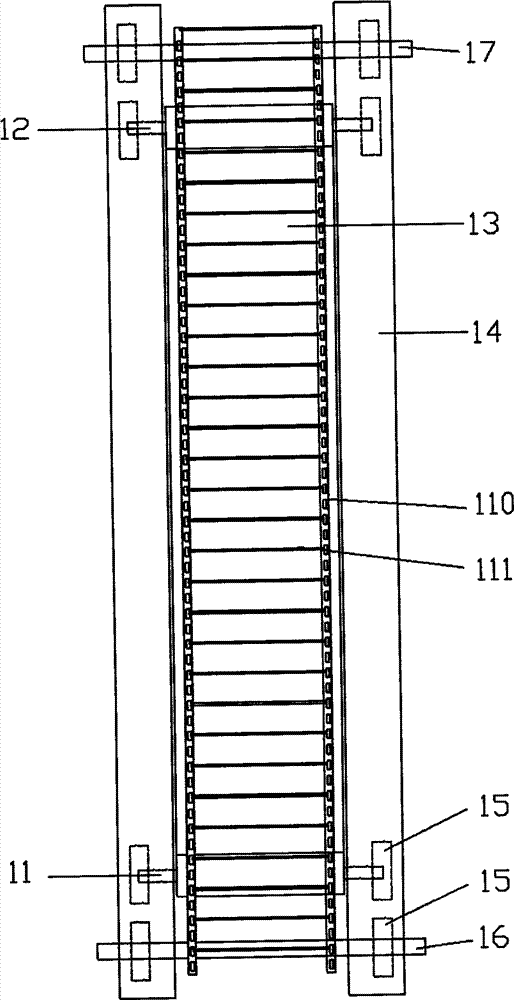

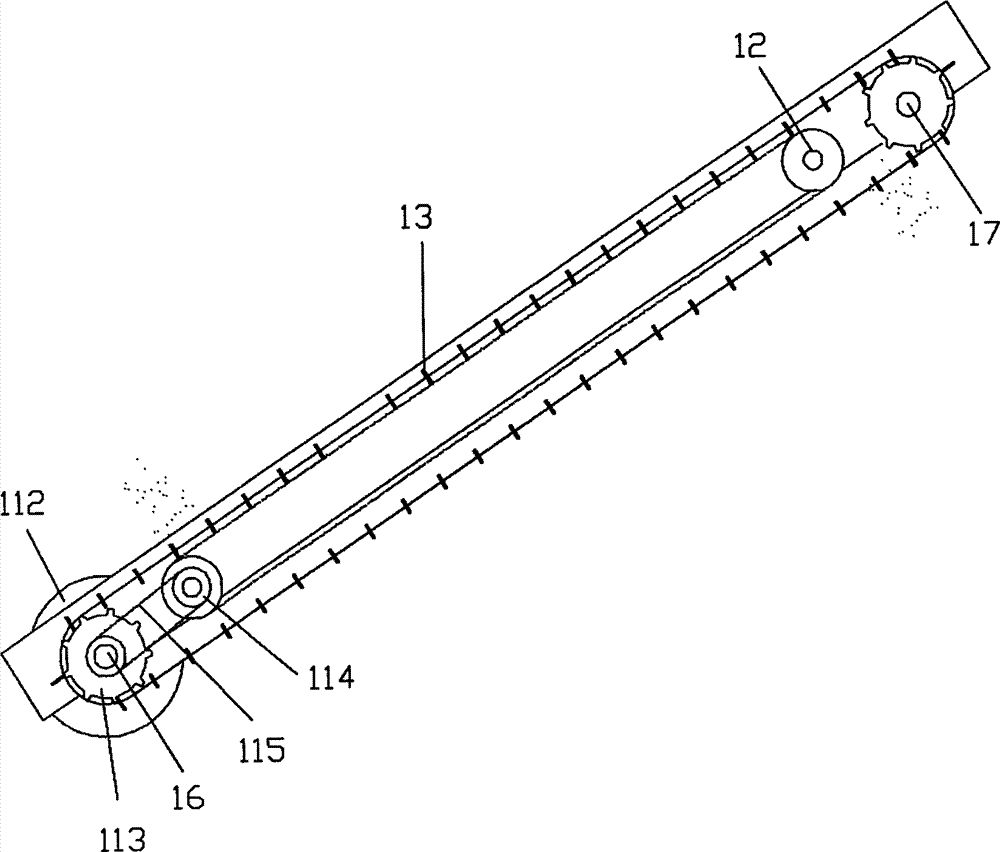

[0033] The structure of the sawdust lifting conveyor belt 1 is that the tape 13 is tensioned on the tape lower roller 11 and the tape upper roller 12, and the two ends of the roller shafts of the tape lower roller 11 and the tape upper roller 12 are installed on the shaft seat 15, and the shaft seat 15 fixed on the baffle 14;

[0034] The two ends of driving shaft 16 and driven shaft 17 are all installed on the shaft seat 15, and shaft seat 15 is fixed on the baffle plate 14, and driving shaft 16 is fixed with driving sprocket 18, and driven shaft 17 is fixed with driven chain Wheel 19, chain 110 is tensioned on driving sprocket 18 and driven sprocket 19, adhesive tape 13 is placed in two chains 110, and scraper 111 is fixed on chain 110, and the bottom of scraper 111 on chain 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com