Simple grinding machine and protective cover mechanism thereof

A technology of protective cover and main board, used in grinding/polishing equipment, grinding/polishing safety device, metal processing equipment, etc., can solve the problem of waste chips splashing out of the grinding machine, etc., to reduce up and down shaking, facilitate transportation, and reduce wear and tear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

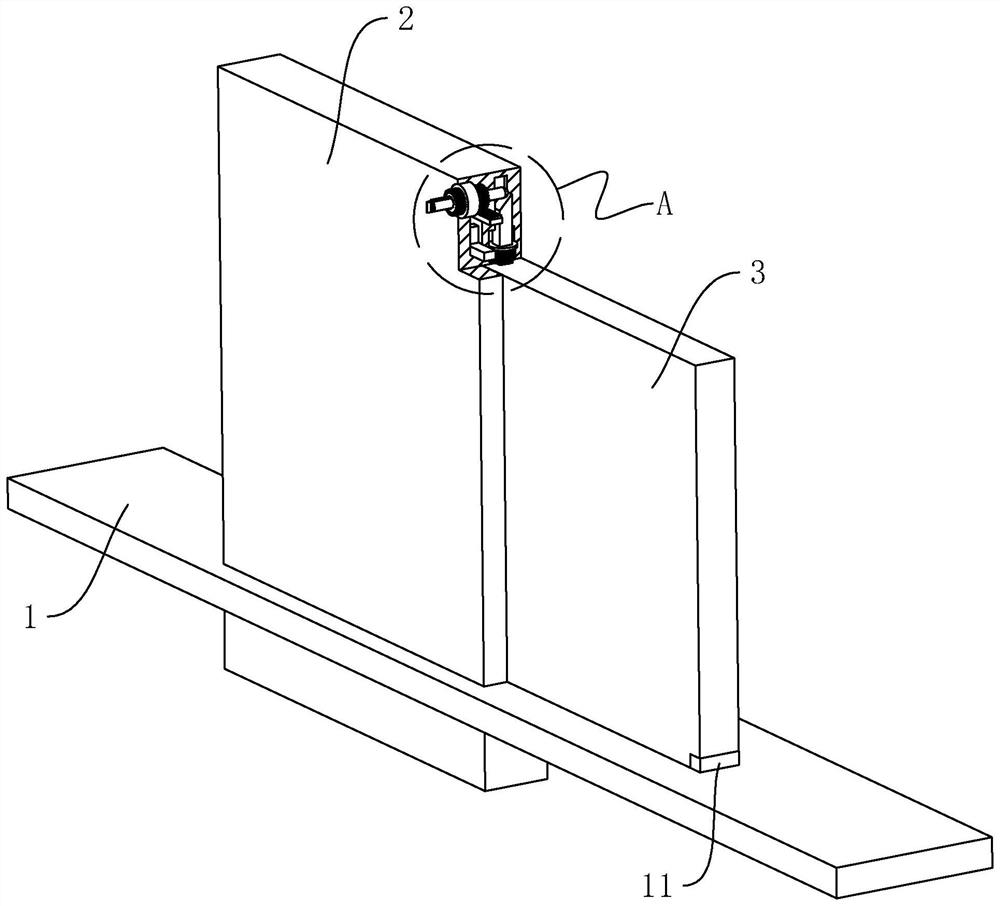

[0041] The following is attached Figure 1-8 The application is described in further detail.

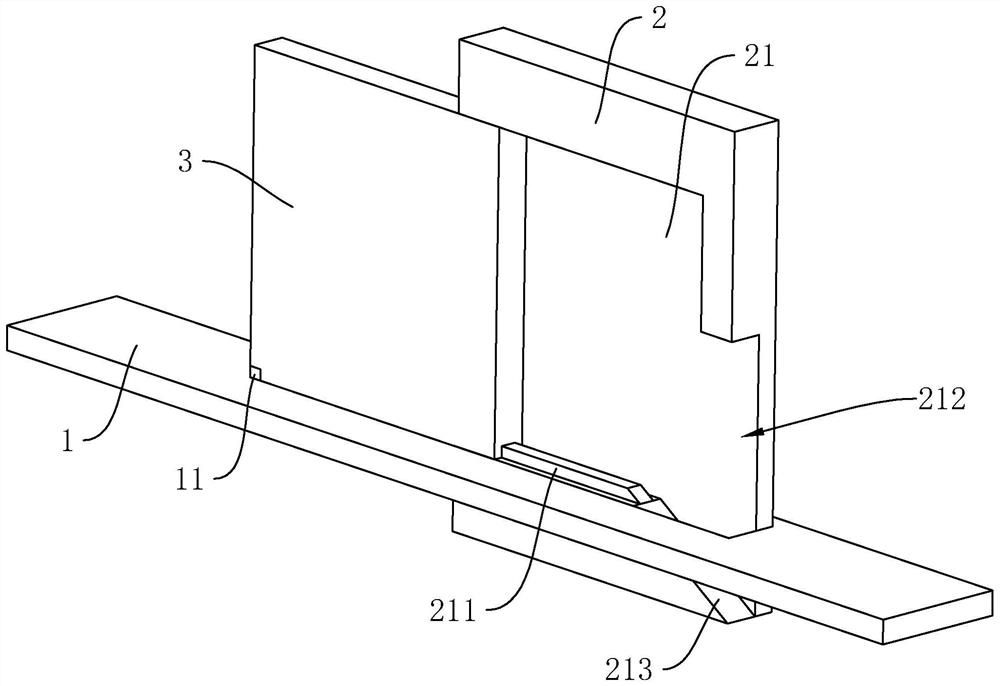

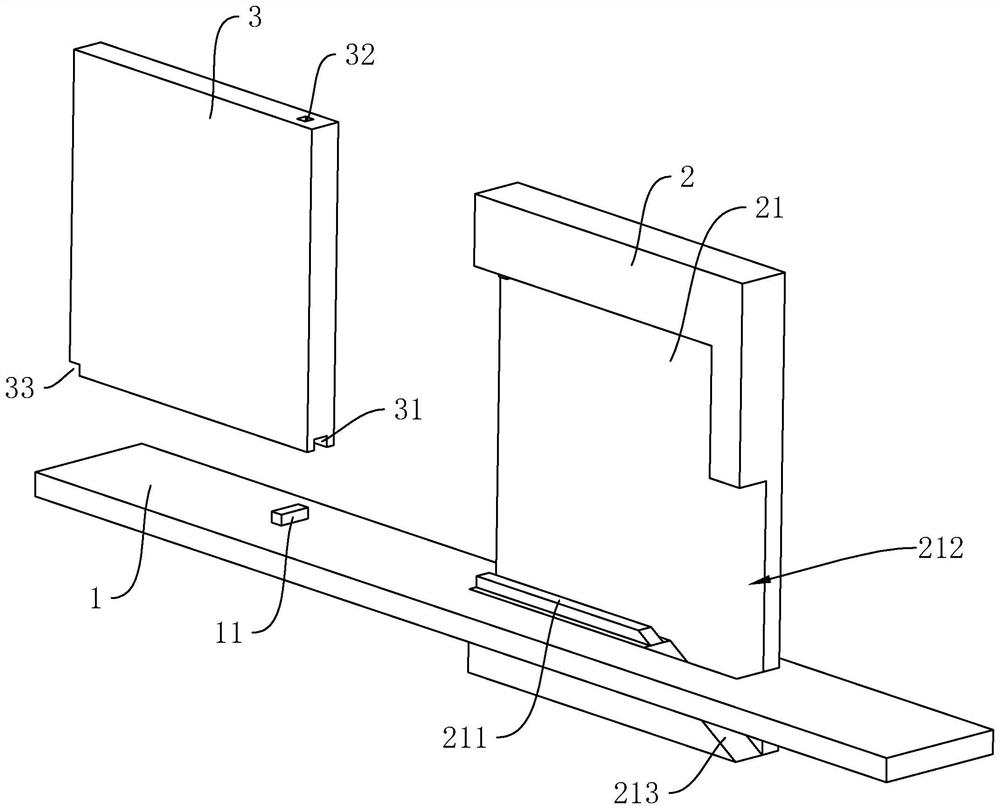

[0042] The embodiment of the present application discloses a protective cover mechanism. see figure 1 , the protective cover mechanism includes a connecting rod 1, a main board 2 and an extension board 3. The connecting rod 1 is used to be installed and fixed on the grinding machine. There is a chute 21 on it, the chute 21 is located on one side of the main board 2, and one end of the chute 21 in the horizontal direction runs through the main board 2, the extension board 3 is slidably connected in the chute 21, and the extension board 3 is slid to extend out or into the motherboard 2.

[0043] see figure 2 , the bottom inner wall of the chute 21 is fixed with a limit protrusion 211, the length direction of the limit protrusion 211 is parallel to the sliding direction of the extension plate 3, the lower end surface of the extension plate 3 is provided with a slideway 31, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com