Handheld polishing device

A handle and fixed body technology, which is applied in the field of hand-held grinding devices, can solve the problems of endangering the health of the staff and the impact of the surrounding environment, and achieve the effects of protecting the health, avoiding flying around, and reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

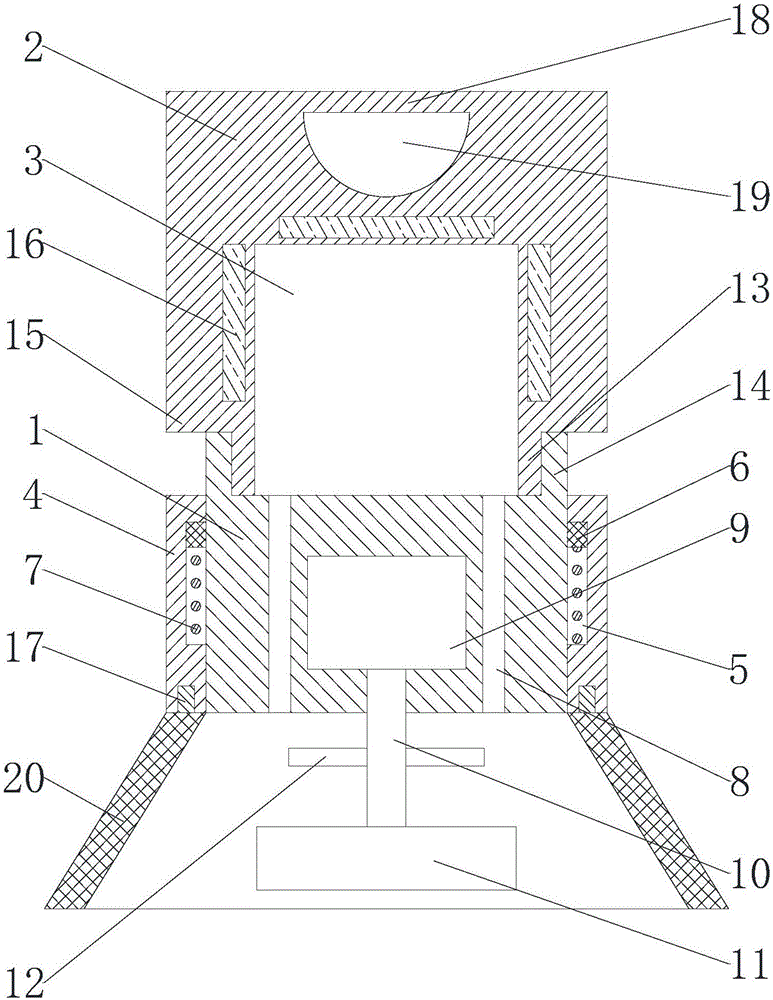

[0028] Such as figure 1 As shown, a hand-held grinding device includes a fixed body 1, a movable cylinder 4 and a collection cylinder 2 with a collection cavity 3, and the movable cylinder 4 is sleeved on the outer surface of the fixed body 1;

[0029] The collection tube 2 is connected to the upper end of the fixed body 1, and the fixed body 1 is provided with a channel 8 that runs through its upper and lower end surfaces and communicates with the collection chamber 3;

[0030] A driving motor 9 is installed in the fixed body 1, and the output end of the driving motor 9 is connected with a rotating shaft 10. a blade 12 positioned above the grinding wheel 11;

[0031] The inner wall surface of the movable cylinder 4 is provided with an annular groove 5, and the outer wall surface of the fixed body 1 is provided with a positioning ring 6 which is located in the annular groove 5 and can move up and down relative to the annular groove 5. The annular groove 5 is provided with an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com