Process for sorbing material using soot

An adsorption material, coal ash technology, applied in chemical instruments and methods, other chemical processes and other directions, can solve the problems of low coal ash adsorption, large increase in waste water sludge volume, etc., achieve high adsorption efficiency, reduce waste water treatment costs, The effect of high market advantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

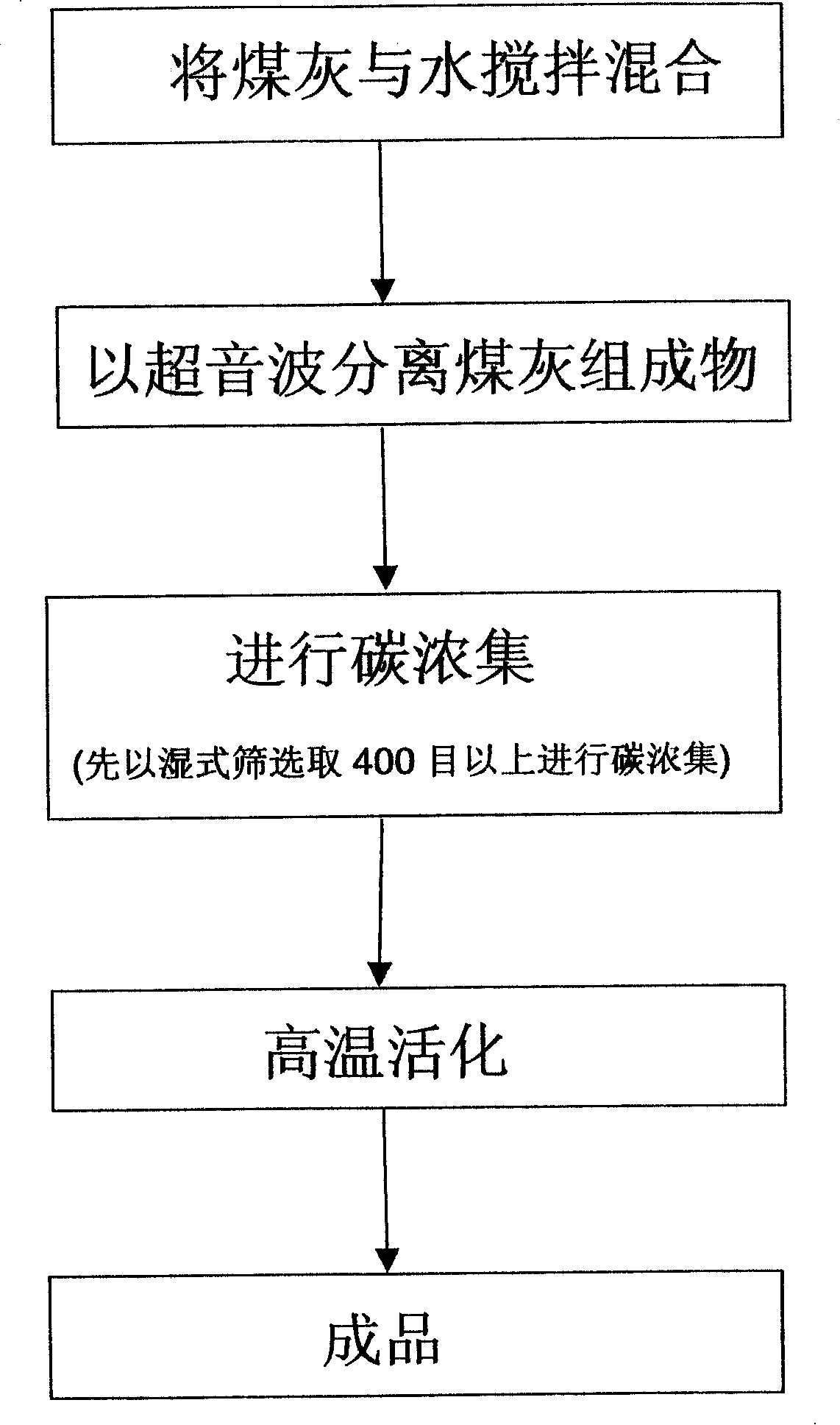

[0027] First, please refer to figure 1 Shown:

[0028] (1) Separation of coal ash components: First, stir and mix coal ash and water (solid-to-liquid ratio = 1g: 20ml), and introduce ultrasonic waves (20KHz) into the mixture to form coal ash components (oxide particles and carbon particles) fully dispersed;

[0029] (2) Carry out carbon concentration treatment: after step (1) ultrasonic treatment, use wet screening again, take out the part of 400 mesh or more, after ultrasonic treatment for 10 minutes, its carbon grade can reach more than 85% (see Table 3), And after 15 minutes, then can obtain the carbon concentrate of carbon grade up to 90.5% (as table 3, can find out the effect of ultrasonic treatment to carbon concentration, preferably time is about 15 minutes, concentrate The carbon grade can be as high as 90.5%).

[0030] Table 3 The effect of ultrasonic treatment on improving the carbon grade of the concentrate

[0031] Ultrasonic treatment time (min)

...

Embodiment 2

[0058] The second possible embodiment of the present invention also includes the steps of ultrasonic treatment to separate coal ash components, carbon concentration treatment and activation of carbon concentration at high temperature, please refer to figure 1 Shown:

[0059] (1) Separation of coal ash components: first, coal ash and water are stirred and mixed, and the mixing ratio is the same as above, and ultrasonic waves are introduced into the mixed solution to cause the coal ash components to be fully dispersed;

[0060] (2) Carry out carbon concentration treatment: after step (1) ultrasonic treatment, then use wet screening to carry out carbon concentration treatment;

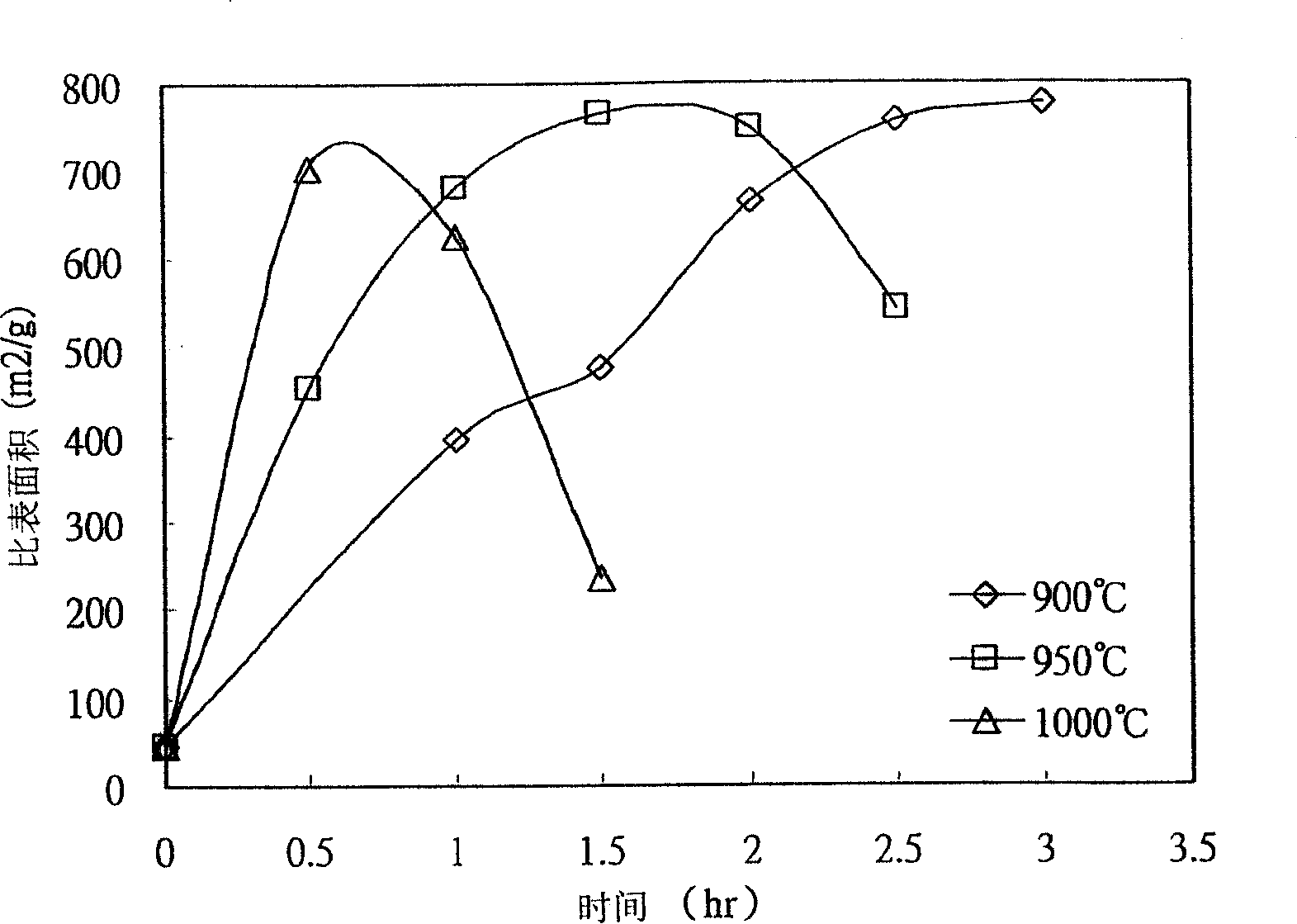

[0061] (3) Activation treatment: the carbon concentrate obtained after step (2) is activated with carbon dioxide, please refer to Figure 4 As shown, the activation treatment in a carbon dioxide (cm / min) atmosphere, the effect of temperature and time on increasing the specific surface area of the prod...

Embodiment 3

[0068] The third feasible embodiment of the present invention also includes the steps of ultrasonic treatment to separate the composition of coal ash, carbon concentration treatment, and high-temperature activation of carbon concentrate. After the above steps are completed, the activated product is subjected to a wet screening step, To further improve the adsorption performance of the product, its implementation steps are:

[0069] (1) Separation of coal ash components: first, the coal ash and water are stirred and mixed, and ultrasonic waves are introduced into the mixed solution to cause the coal ash components to be fully dispersed;

[0070] (2) Carry out carbon concentration treatment: after step (1) ultrasonic treatment, then use wet screening to carry out carbon concentration treatment;

[0071] (3) Activation treatment: the high-temperature activation treatment is carried out on the carbon concentrates wet-screened in step (2);

[0072] (4) Carbon concentration treatme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com