Patents

Literature

50 results about "Handheld ultrasound" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

System and Method for Alignment of Instrumentation in Image-Guided Intervention

InactiveUS20090221908A1Ultrasonic/sonic/infrasonic diagnosticsSurgical needlesUltrasonic sensorSonification

The invention provides systems and methods for aligning or guiding instruments during image-guided interventions. A volumetric medical scan (image data) of a patient may first be registered to patient space data regarding the patient obtained using a tracking device. An ultrasound simulator fitted with position indicating elements whose location is tracked by the tracking device is introduced to the surface of the anatomy of the patient and used to determine an imaginary ultrasound scan plane for the ultrasound simulator. This scan plane is used to reformat the image data so that the image data can be displayed to a user in a manner analogous to a handheld ultrasound transducer by re-slicing the image data according to the location and orientation of the ultrasound simulator. The location of an instrument fitted with position indicating elements tracked by the tracking device may be projected onto the re-sliced scan data.

Owner:PHILIPS ELECTRONICS LTD

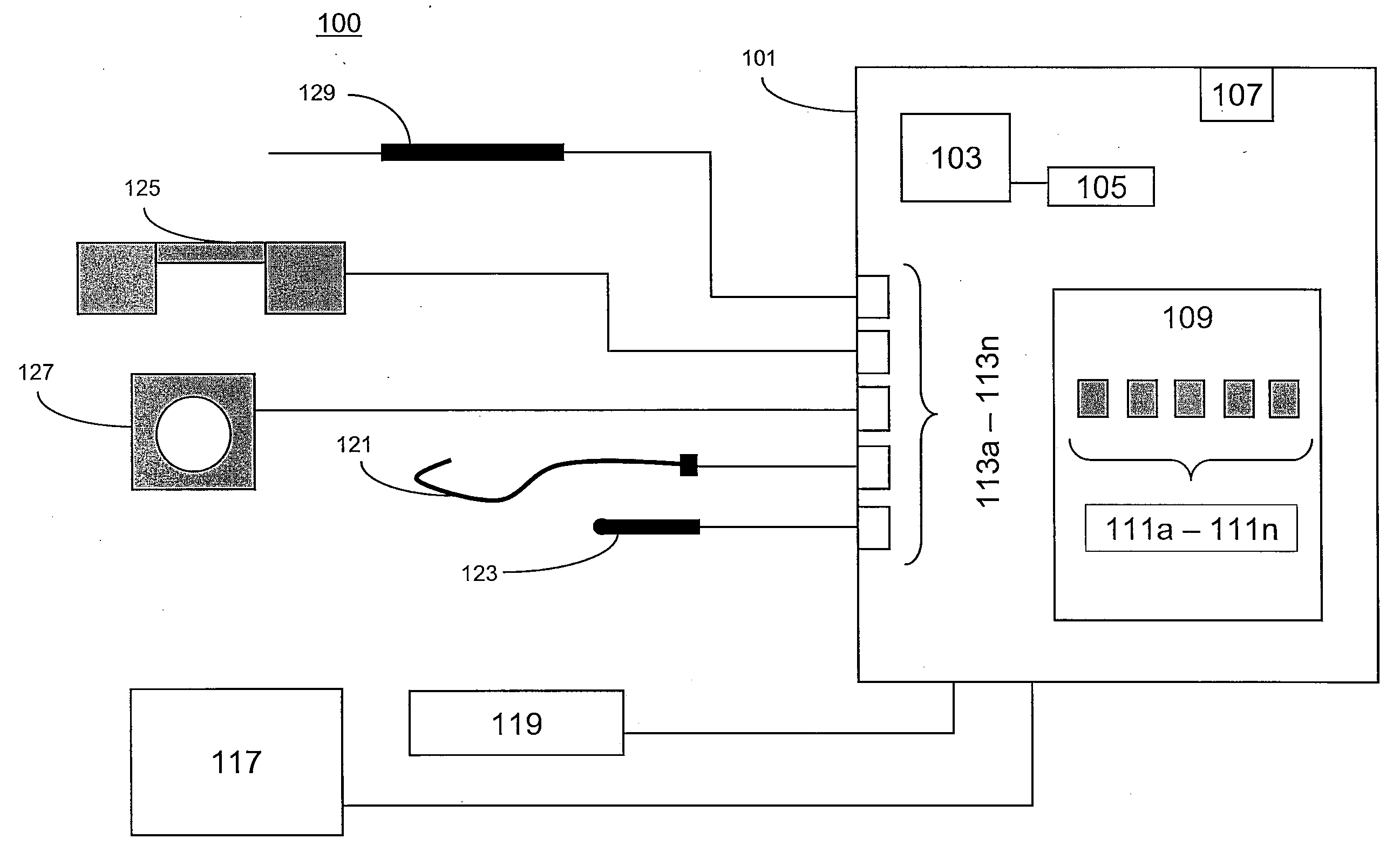

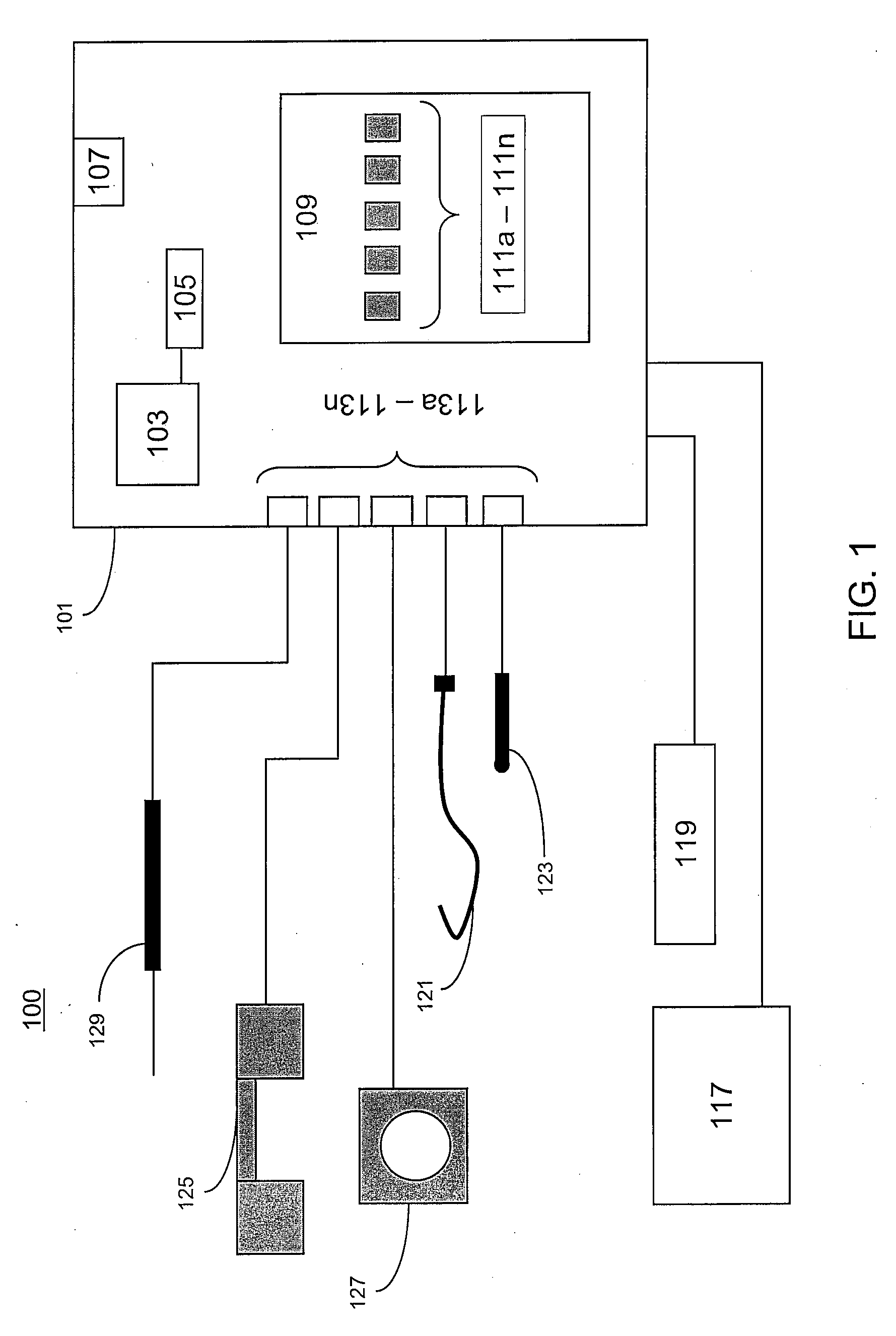

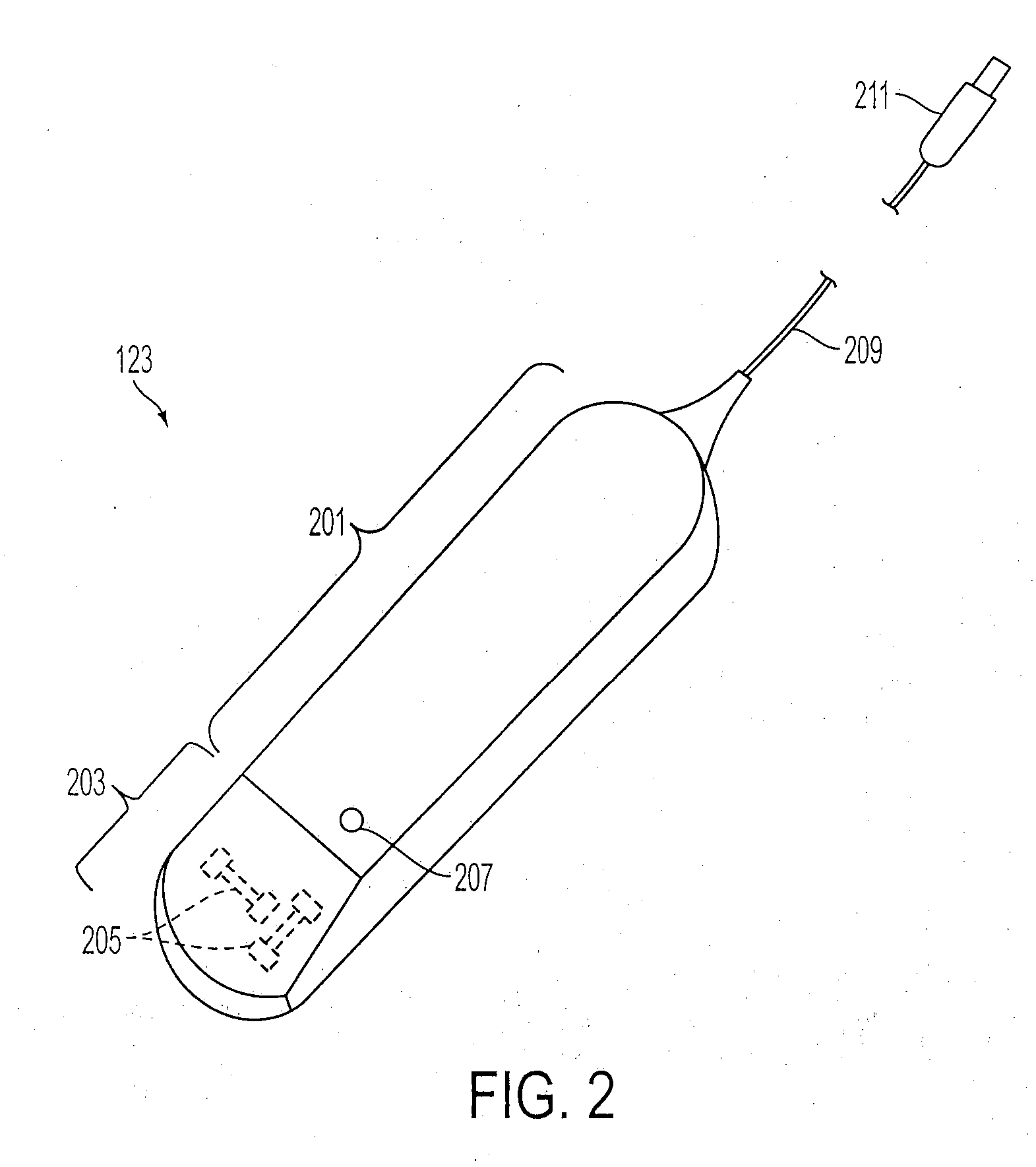

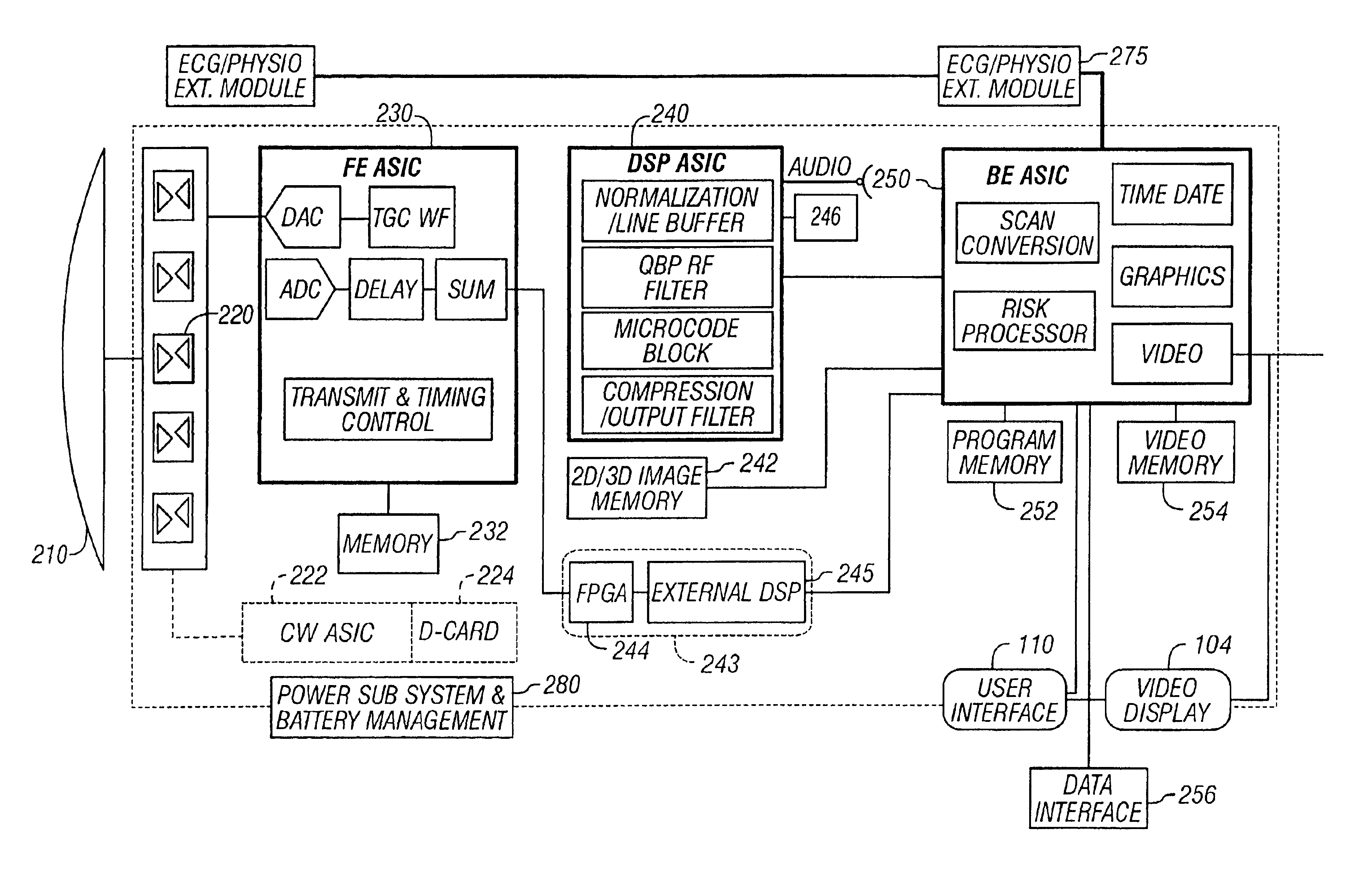

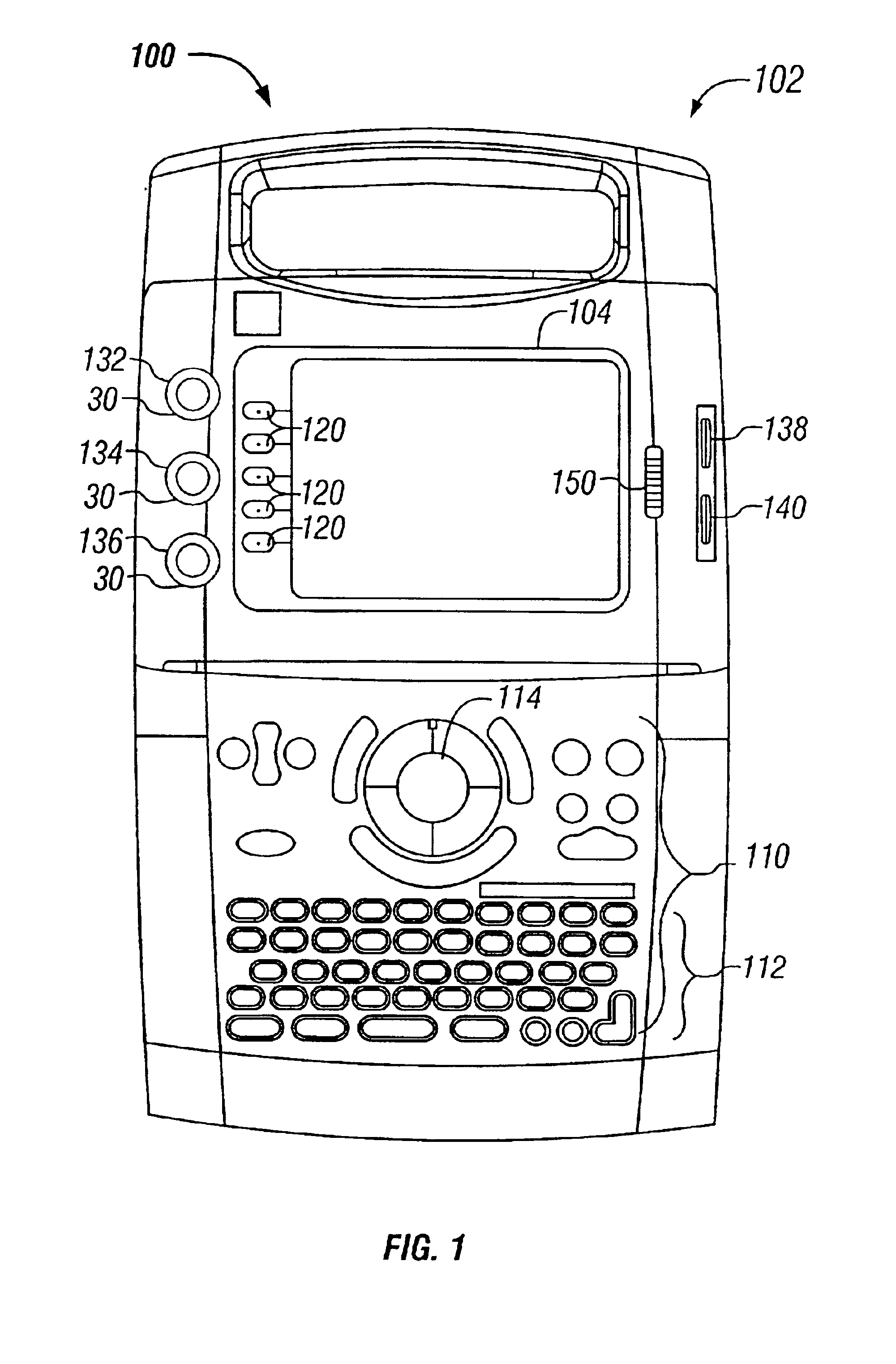

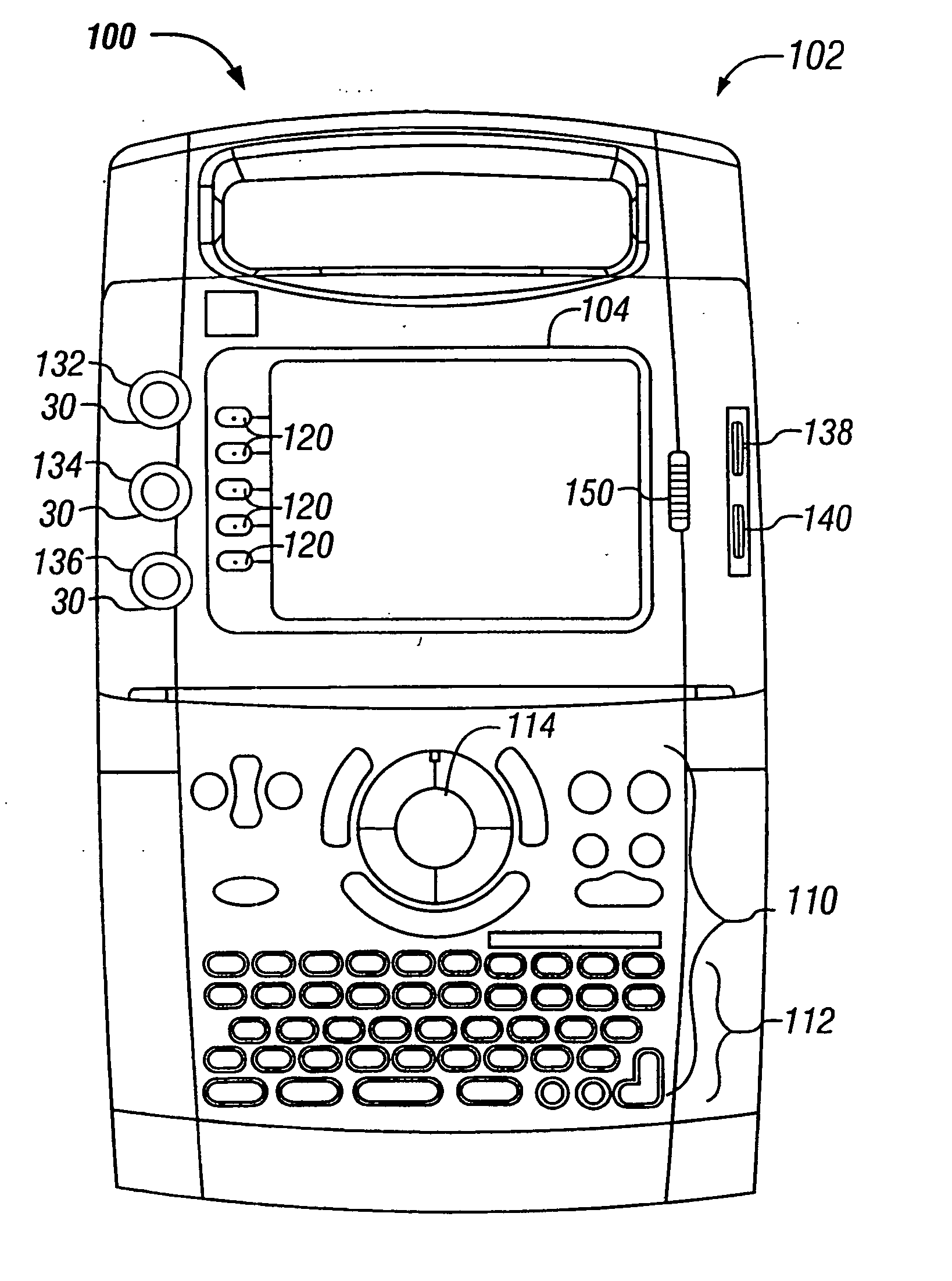

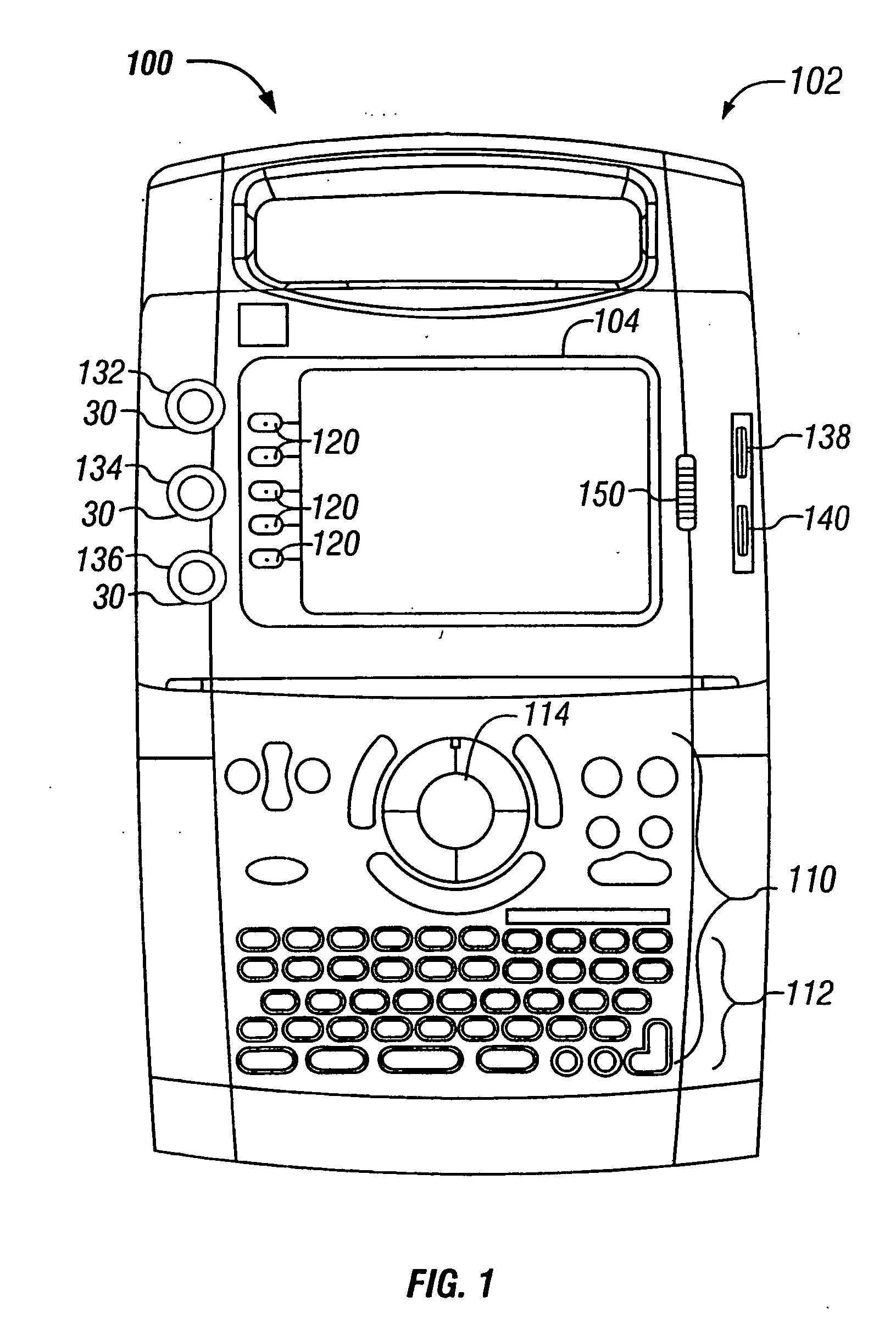

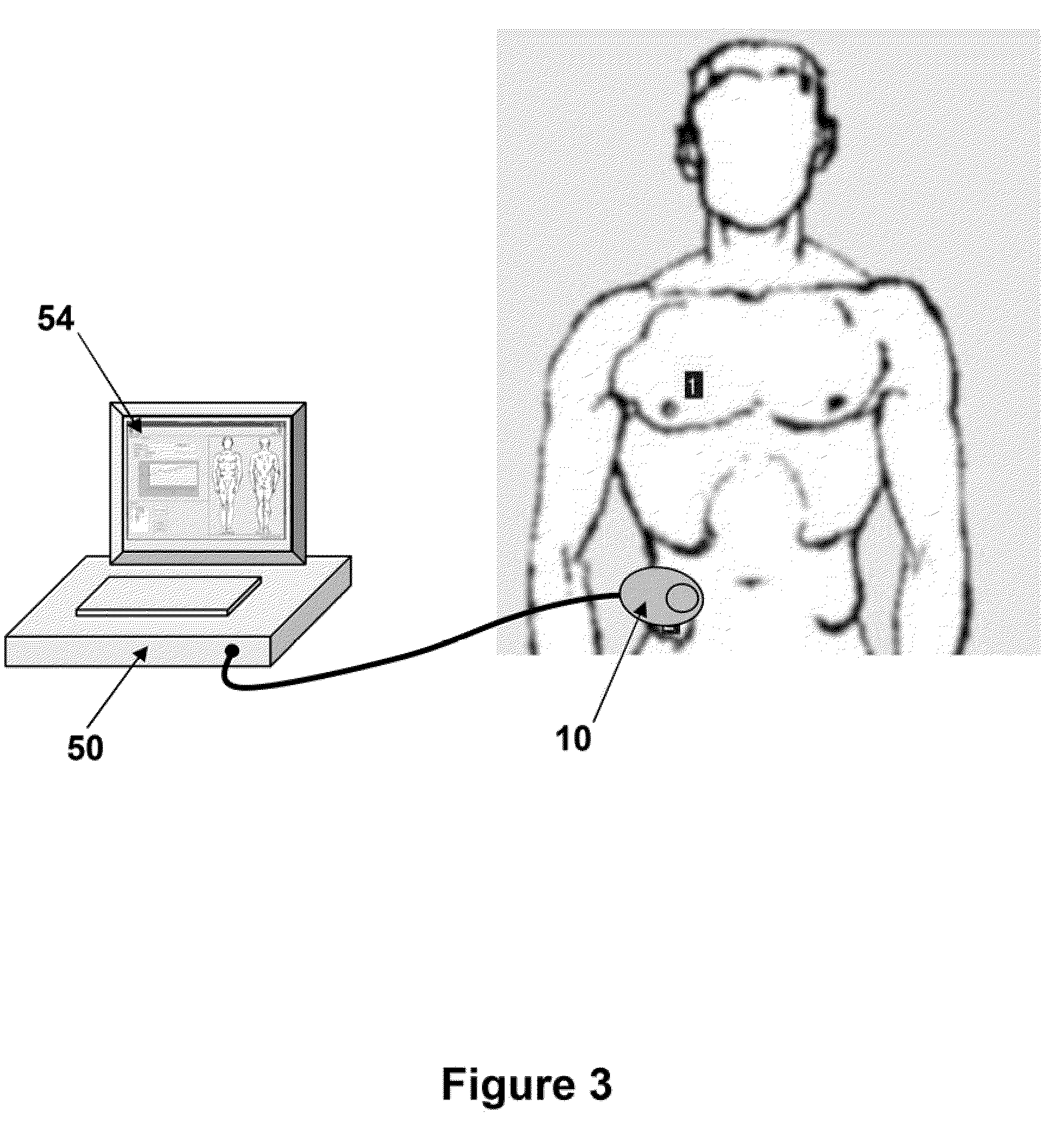

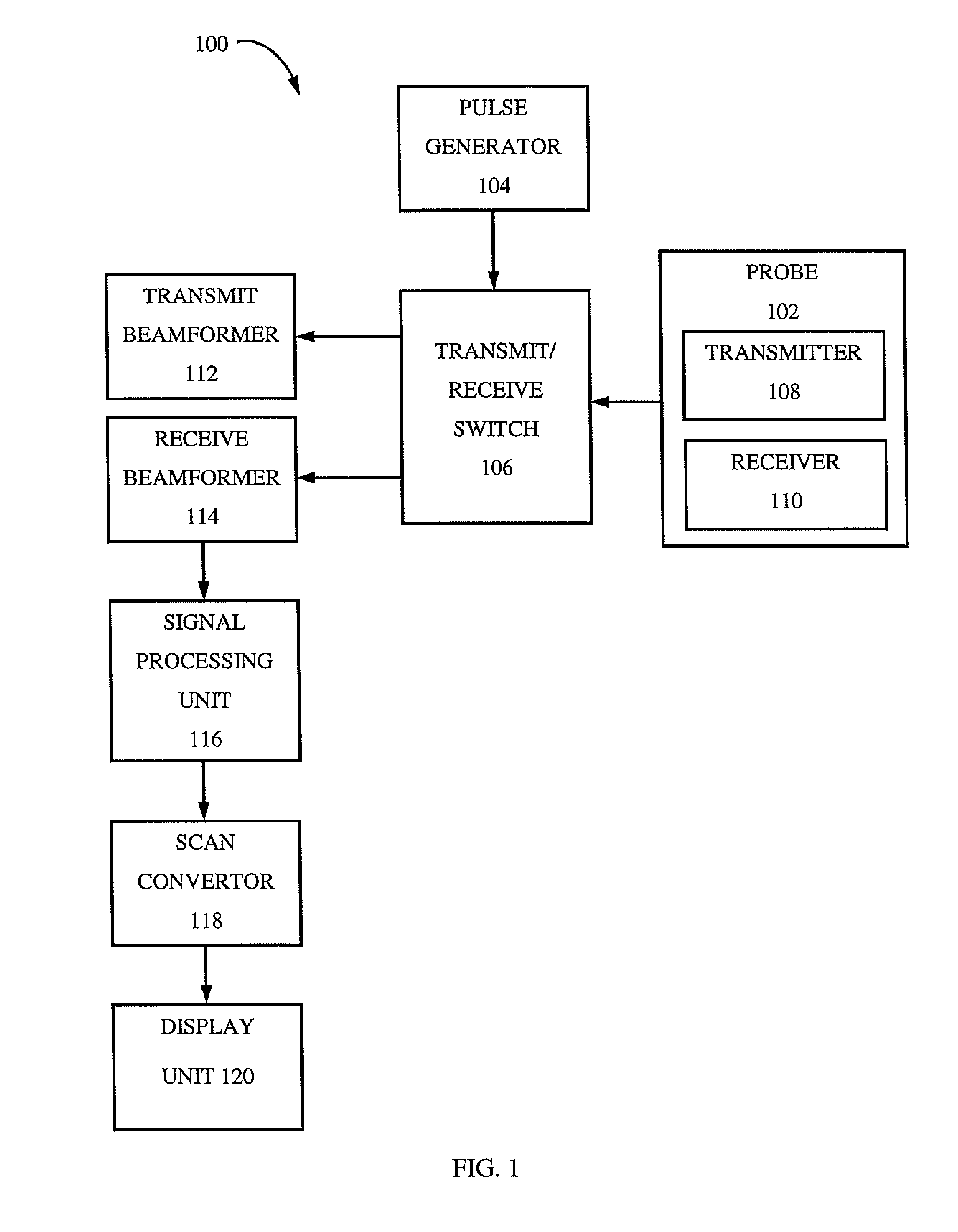

Medical diagnostic ultrasound instrument with ECG module, authorization mechanism and methods of use

InactiveUS6962566B2Restricts modificationImprove distributionElectrocardiographyBlood flow measurement devicesDiagnostic modalitiesColor doppler

A handheld ultrasound instrument is disclosed having enhanced diagnostic modes including pulse / continuous wave Doppler, time-motion analysis, spectral analysis and tissue harmonic imaging. An external electrocardiograph (ECG) recording unit is also disclosed. The ECG unit is adaptable to be used with the handheld ultrasound instrument to provide for ECG monitoring while performing an ultrasound scan in B-mode, Doppler, color Doppler, M-mode, and CW / PW mode. The enhanced handheld ultrasound instrument further includes a security mechanism allowing any combination of the diagnostic modes to be enabled by the manufacturer, and later to enable or disable any one or group of the diagnostic modes. The invention also discloses a method for a manufacturer to maintain a database of handheld ultrasound instrument capabilities after the instruments enter the stream of commerce.

Owner:FUJIFILM SONOSITE

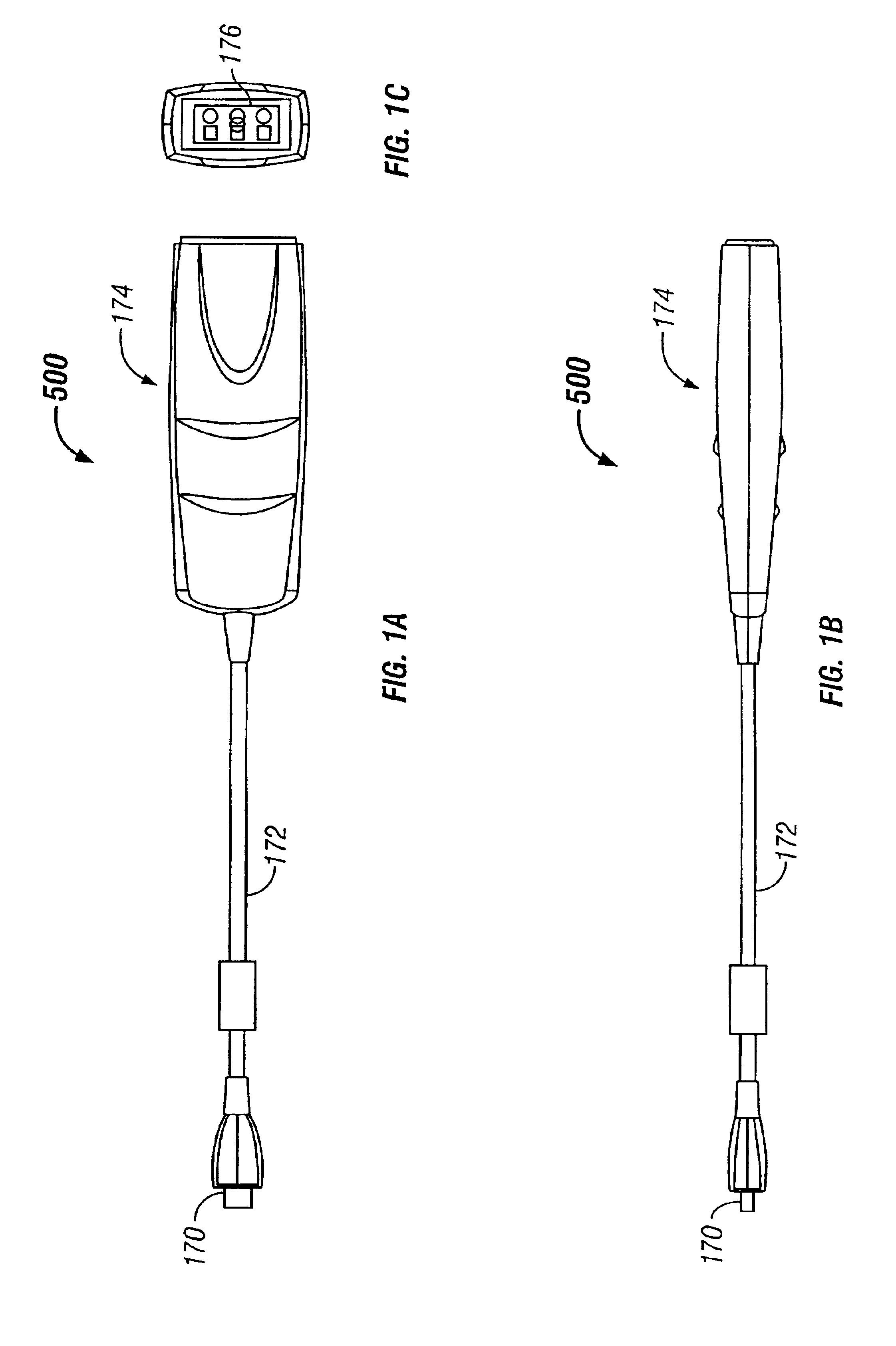

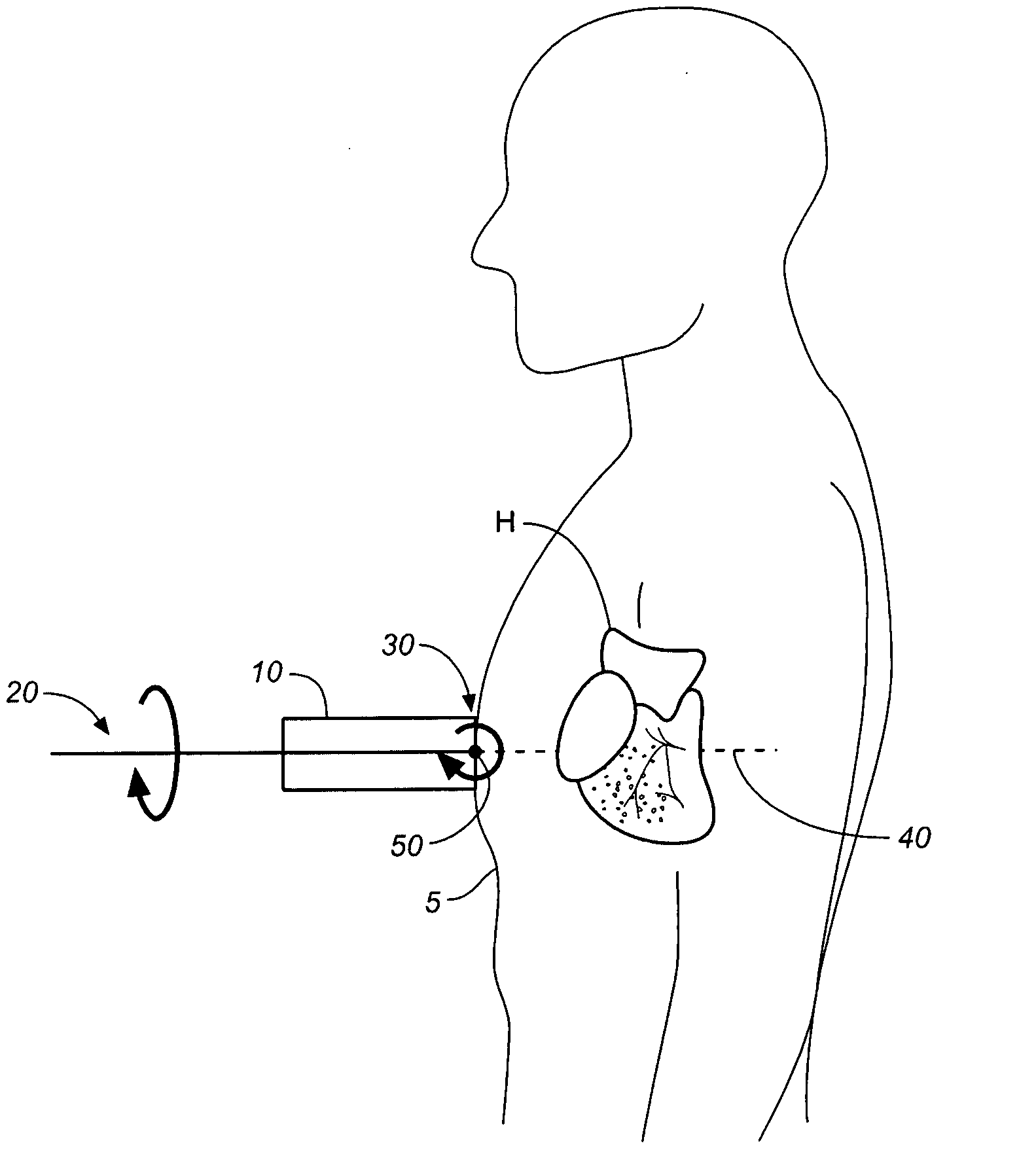

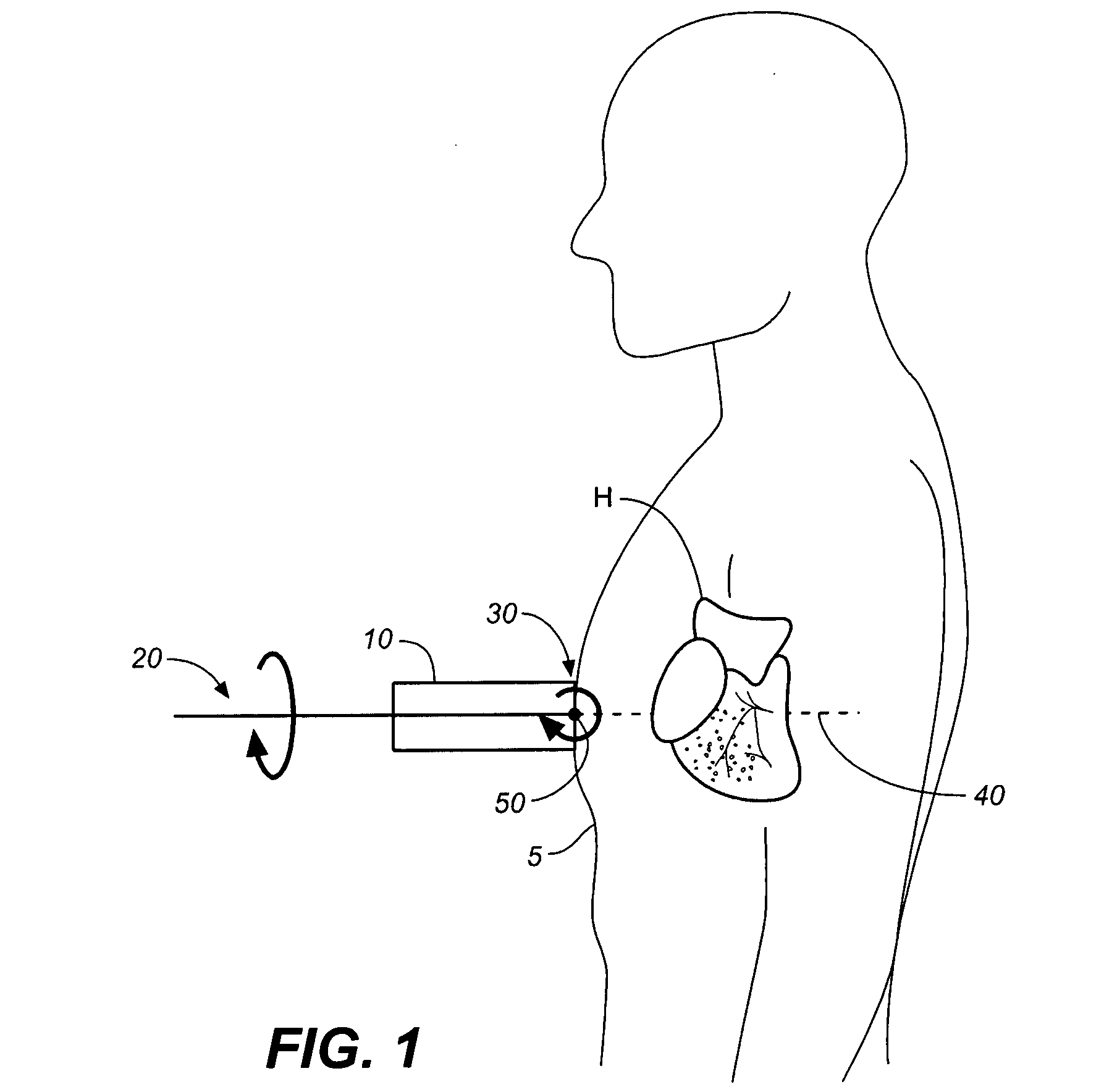

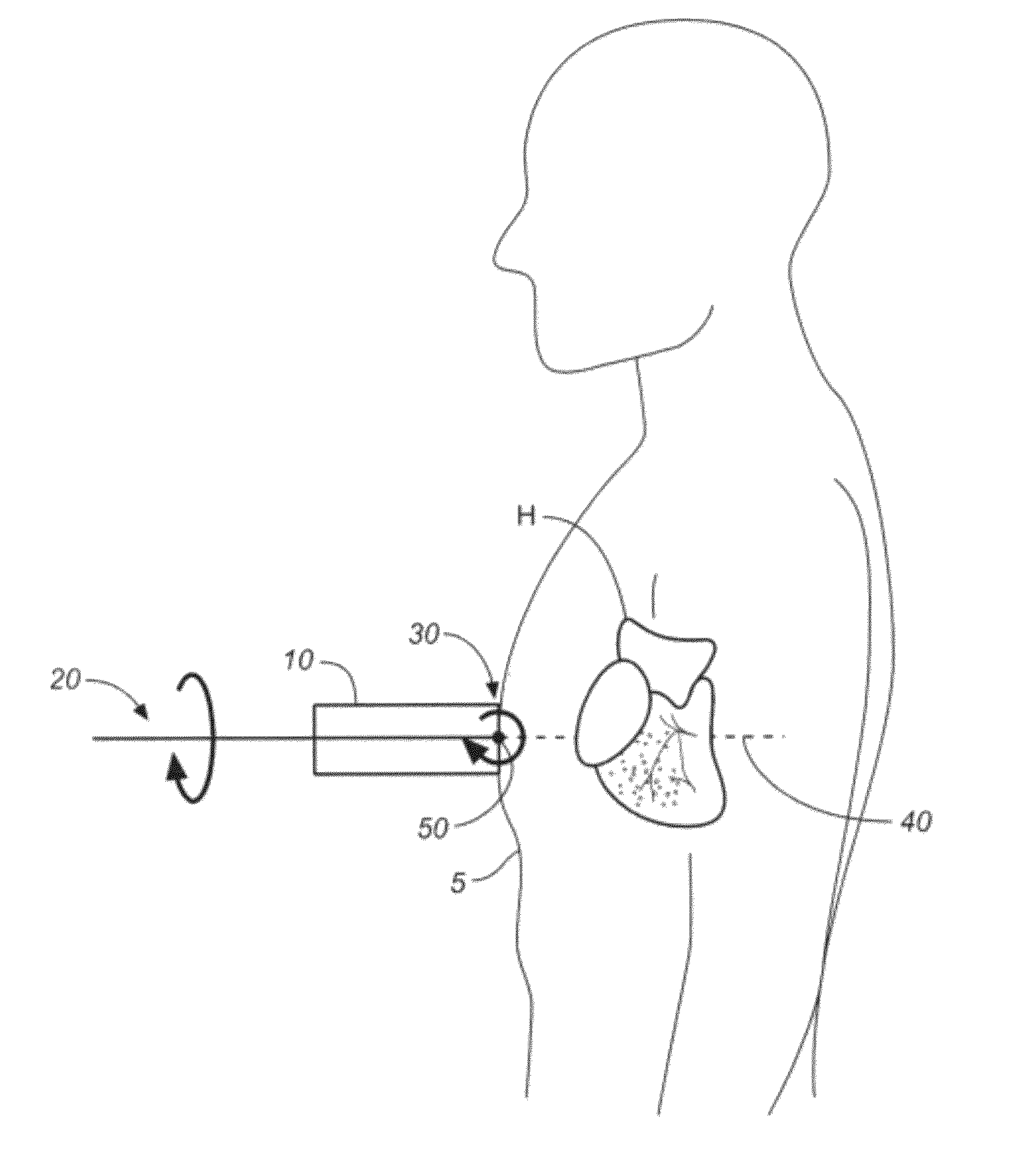

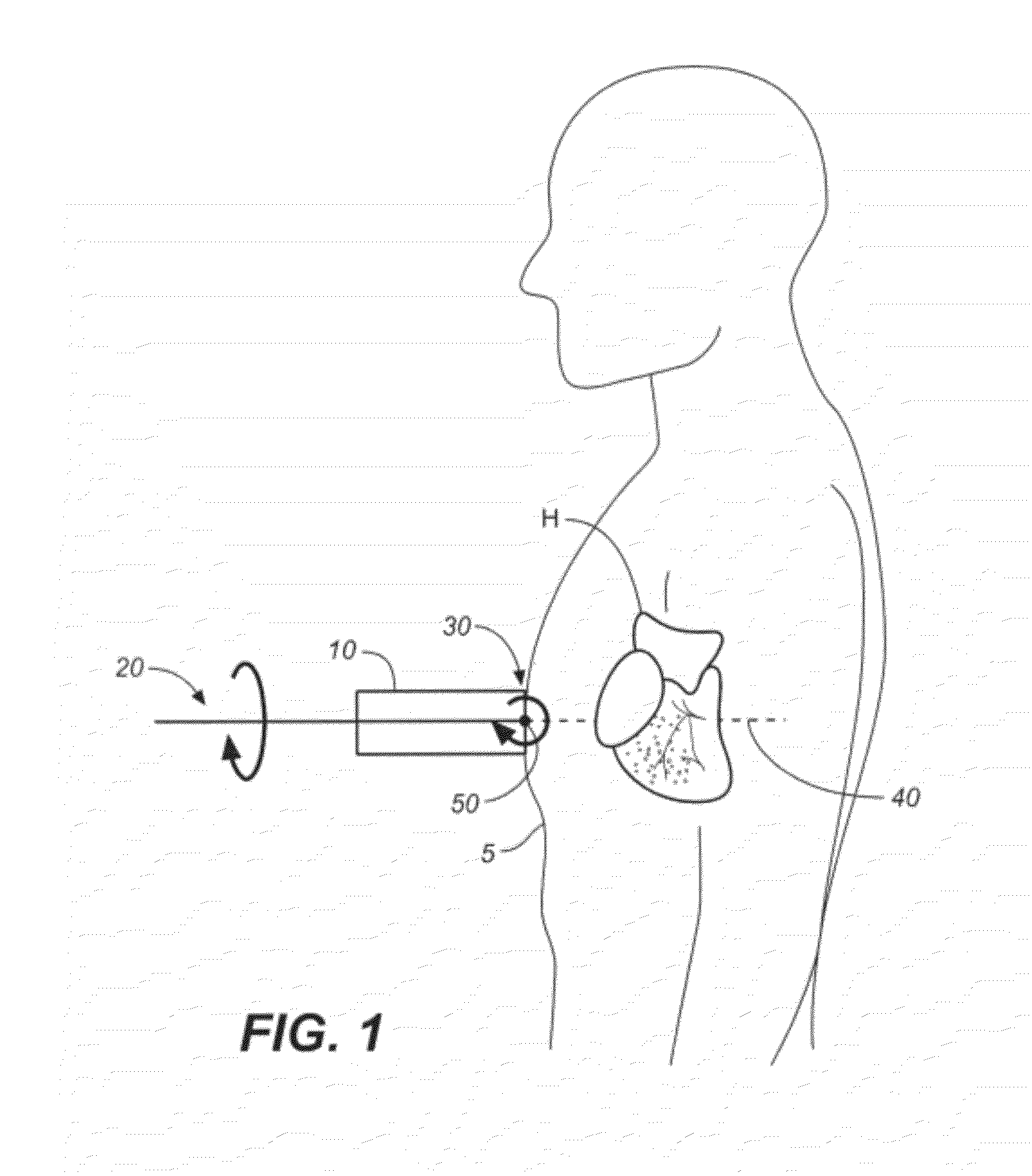

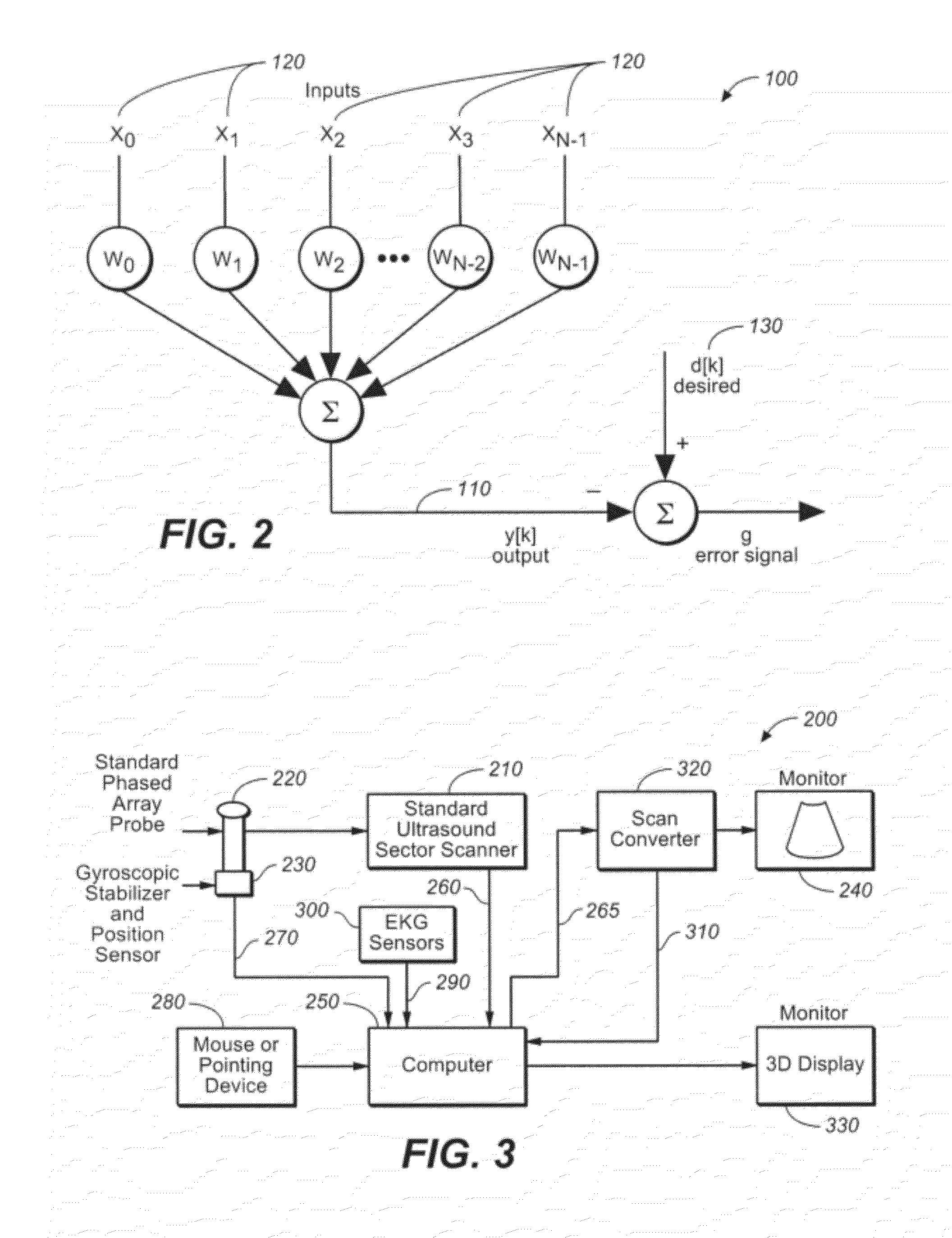

Method and apparatus to visualize the coronary arteries using ultrasound

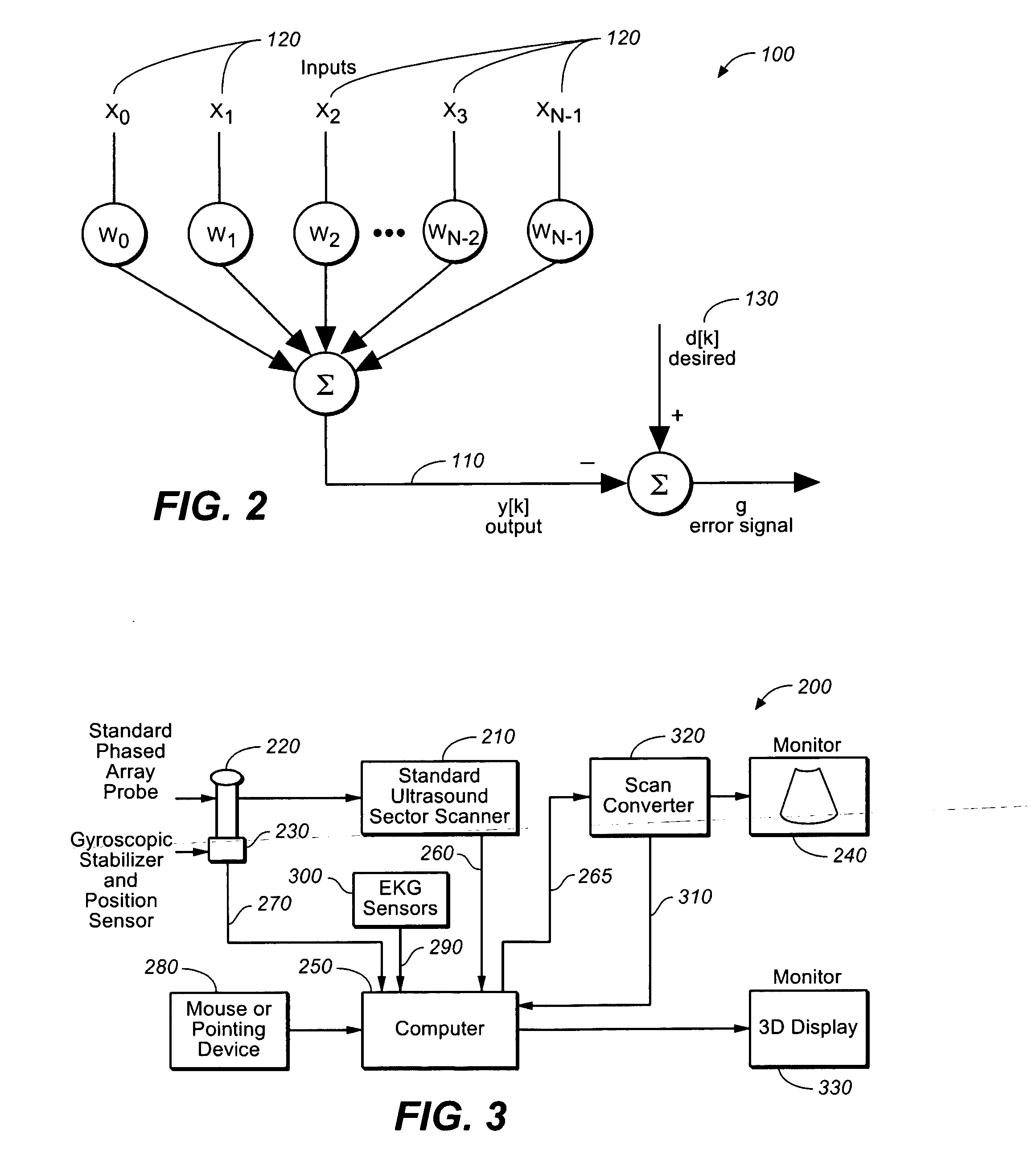

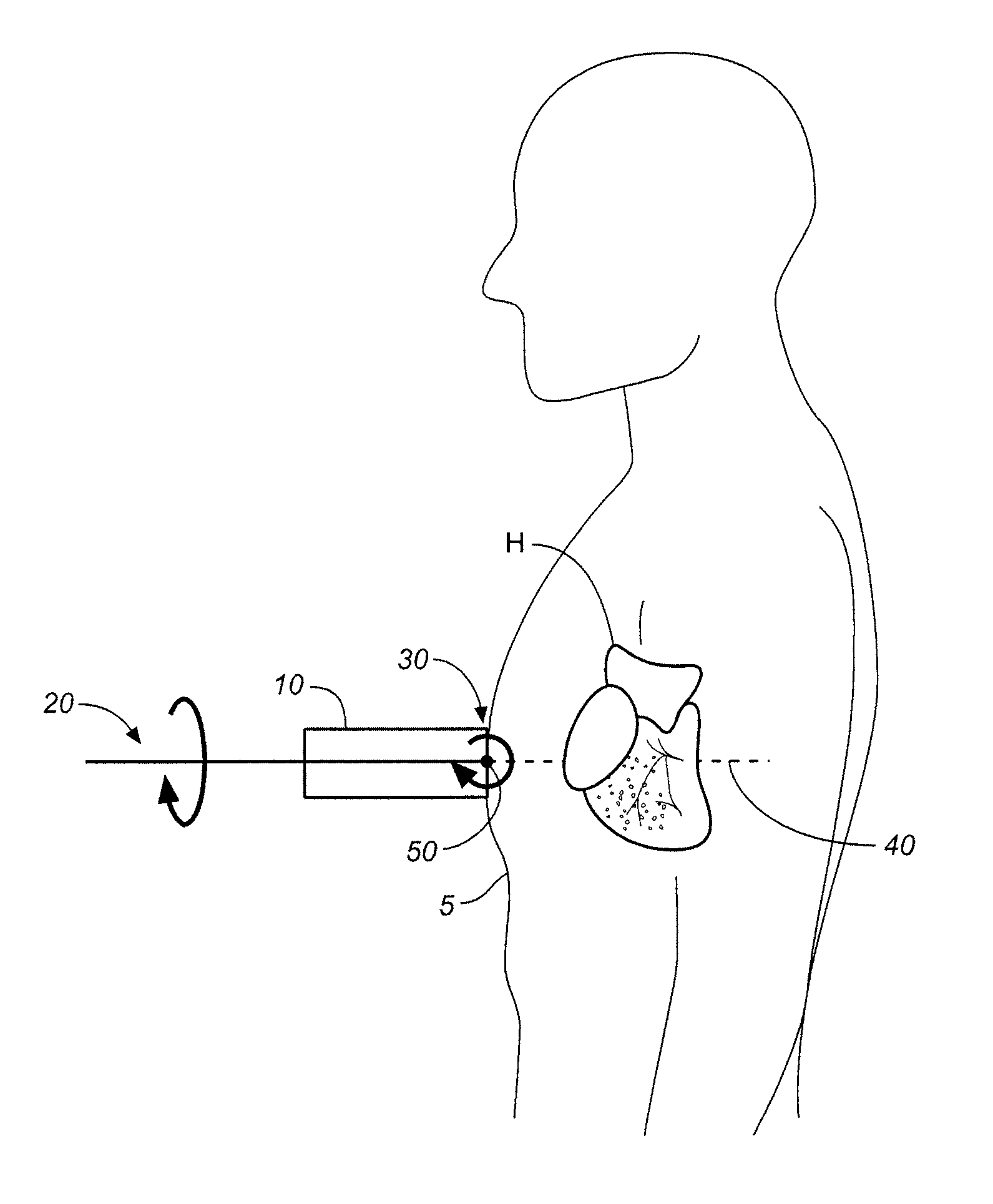

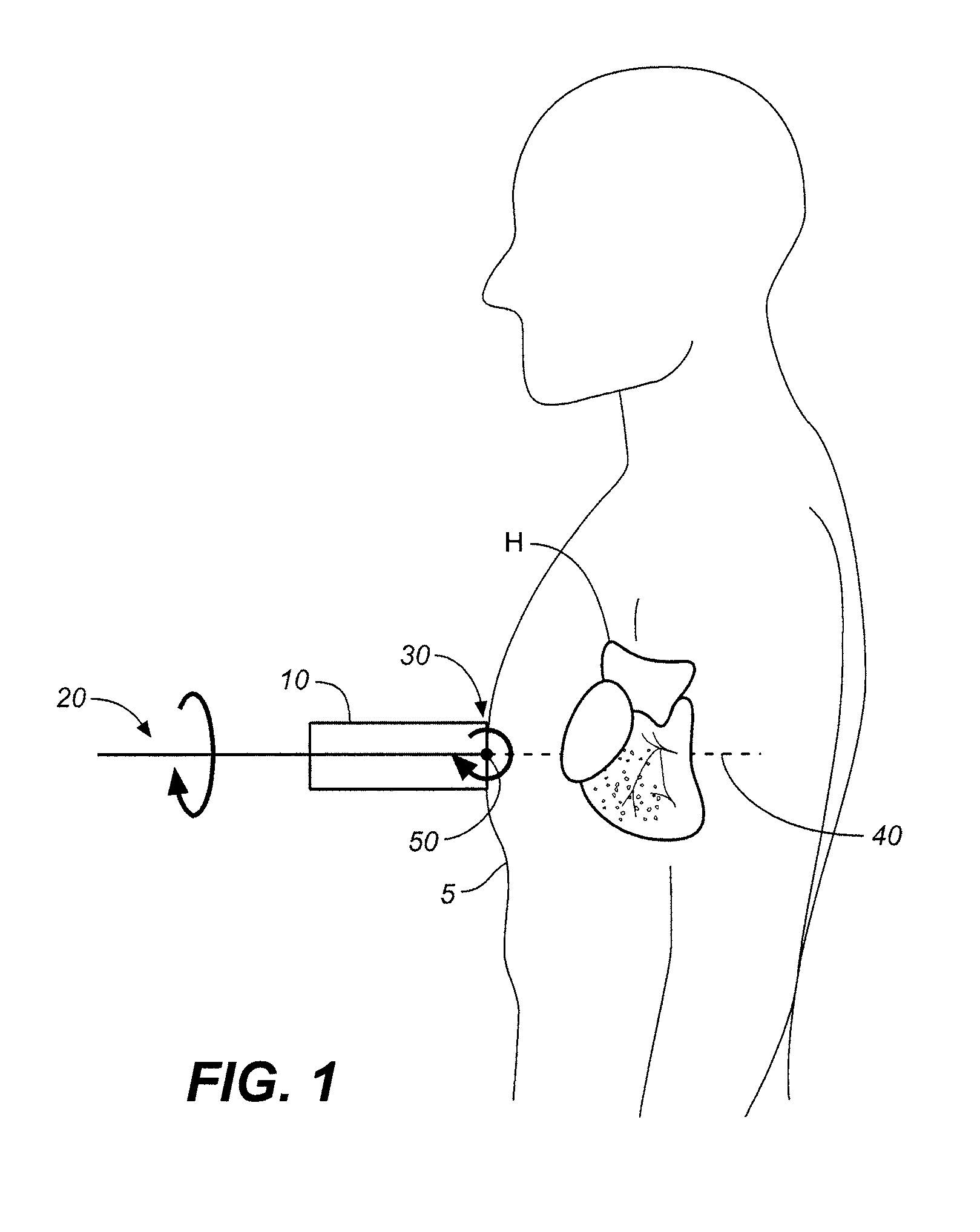

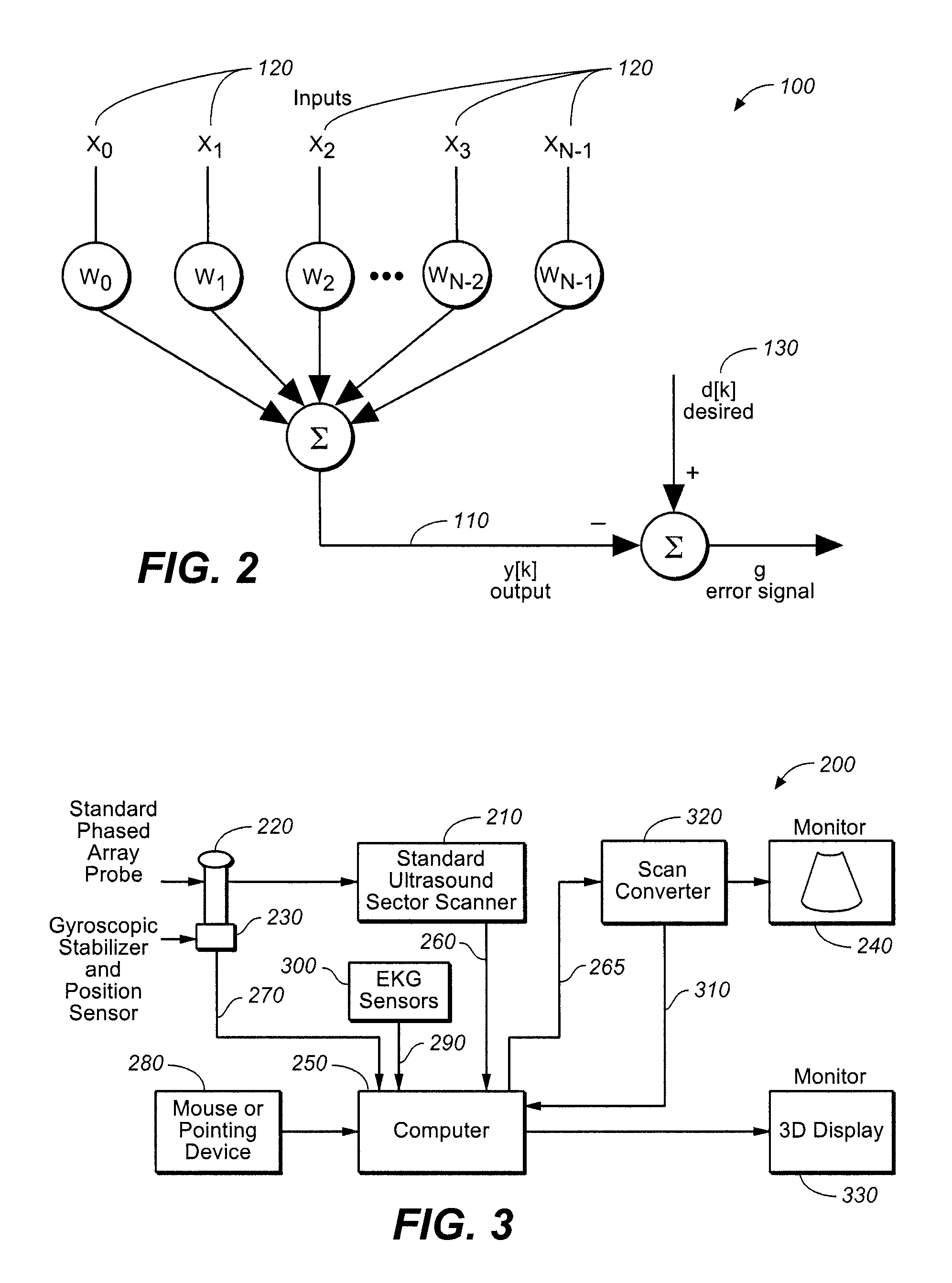

ActiveUS20070238999A1Improved three dimensional imageReduce noiseImage enhancementImage analysisBLOOD FILLEDScreening techniques

A non-invasive screening technique for visualizing coronary arteries which overcomes the problems of visualizing the curved arteries by projecting the three dimensional volume of the arteries onto a two dimensional screen. Blood filled areas, and in particular, the coronary arteries and veins, are highlighted to contrast them with other nearby tissues using non-linear classification and segmentation techniques. Data is gathered as a sequence of 2D slices stored as a 3D volume. Software is employed to interpolate voxels intermediate to the slices. Wiener filtering or LMS spatial filtering can be implemented on each 2D scan to improve lateral resolution and reduce noise prior to the use of the scan data with the classification and segmentation algorithms. A traditional handheld ultrasound probe is employed to enable the technician to locate the area of interest, but a gyroscopic stabilizer is added to minimize unwanted variation on two axes of rotation while scanning through angles on the third axis of rotation.

Owner:MAUI IMAGING

Method and apparatus to visualize the coronary arteries using ultrasound

ActiveUS8105239B2Improved three dimensional imageReduce noiseImage enhancementImage analysisBLOOD FILLEDScreening techniques

A non-invasive screening technique for visualizing coronary arteries which overcomes the problems of visualizing the curved arteries by projecting the three dimensional volume of the arteries onto a two dimensional screen. Blood filled areas such as the coronary arteries and veins, are highlighted to contrast with other nearby tissues using non-linear classification and segmentation techniques. Data is gathered as a sequence of 2D slices stored as a 3D volume. Software interpolates voxels intermediate to the slices. Wiener filtering or LMS spatial filtering can be implemented on each 2D scan to improve lateral resolution and reduce noise prior to the use of the scan data with the classification and segmentation algorithms. A traditional handheld ultrasound probe is employed to enable the technician to locate the area of interest, but a gyroscopic stabilizer is added to minimize unwanted variation on two axes of rotation.

Owner:MAUI IMAGING

Medical diagnostic ultrasound instrument with ECG module, authorization mechanism and methods of use

InactiveUS20060025684A1Restricts modificationRestricts replacementElectrocardiographyBlood flow measurement devicesDiagnostic modalitiesColor doppler

Owner:FUJIFILM SONOSITE

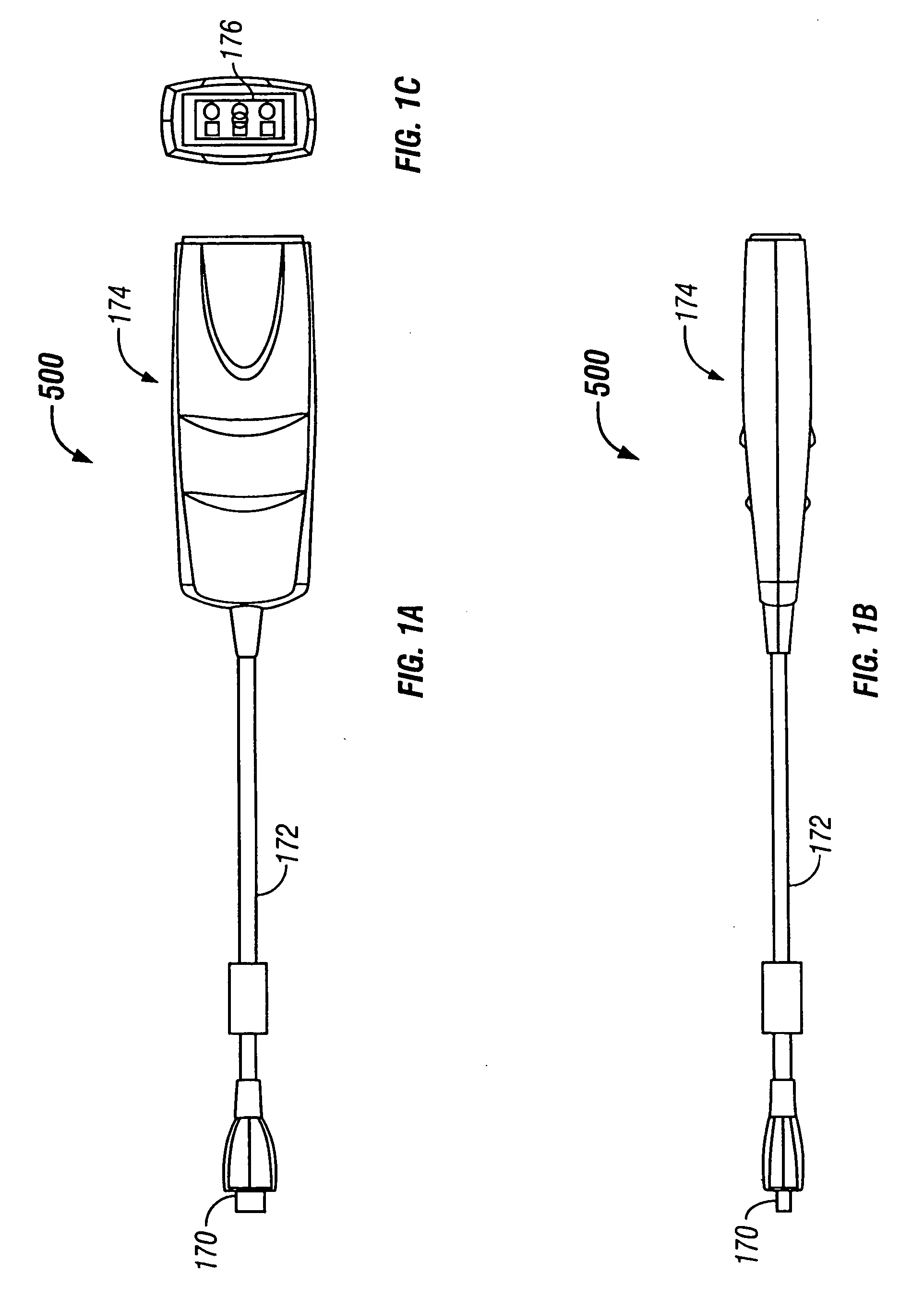

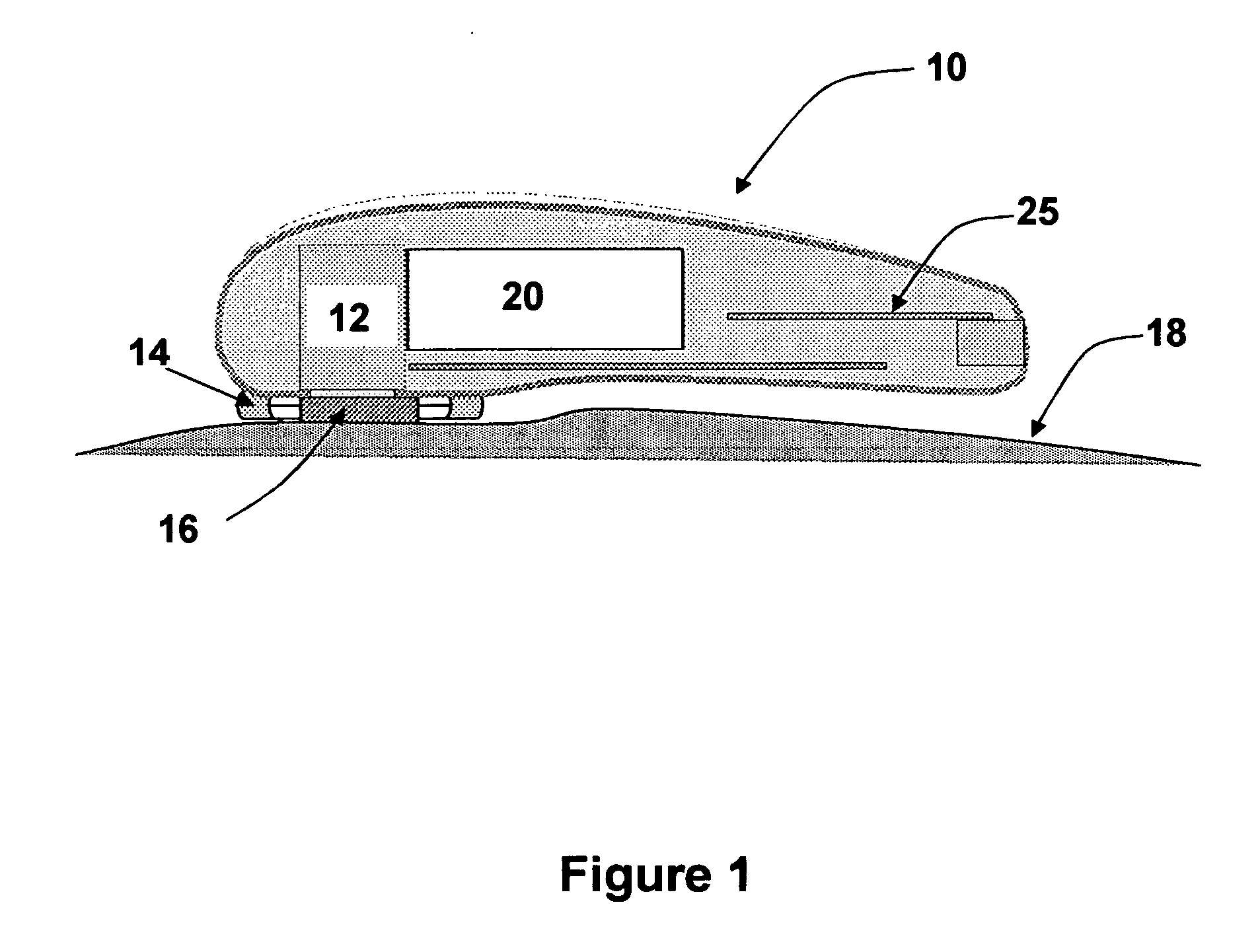

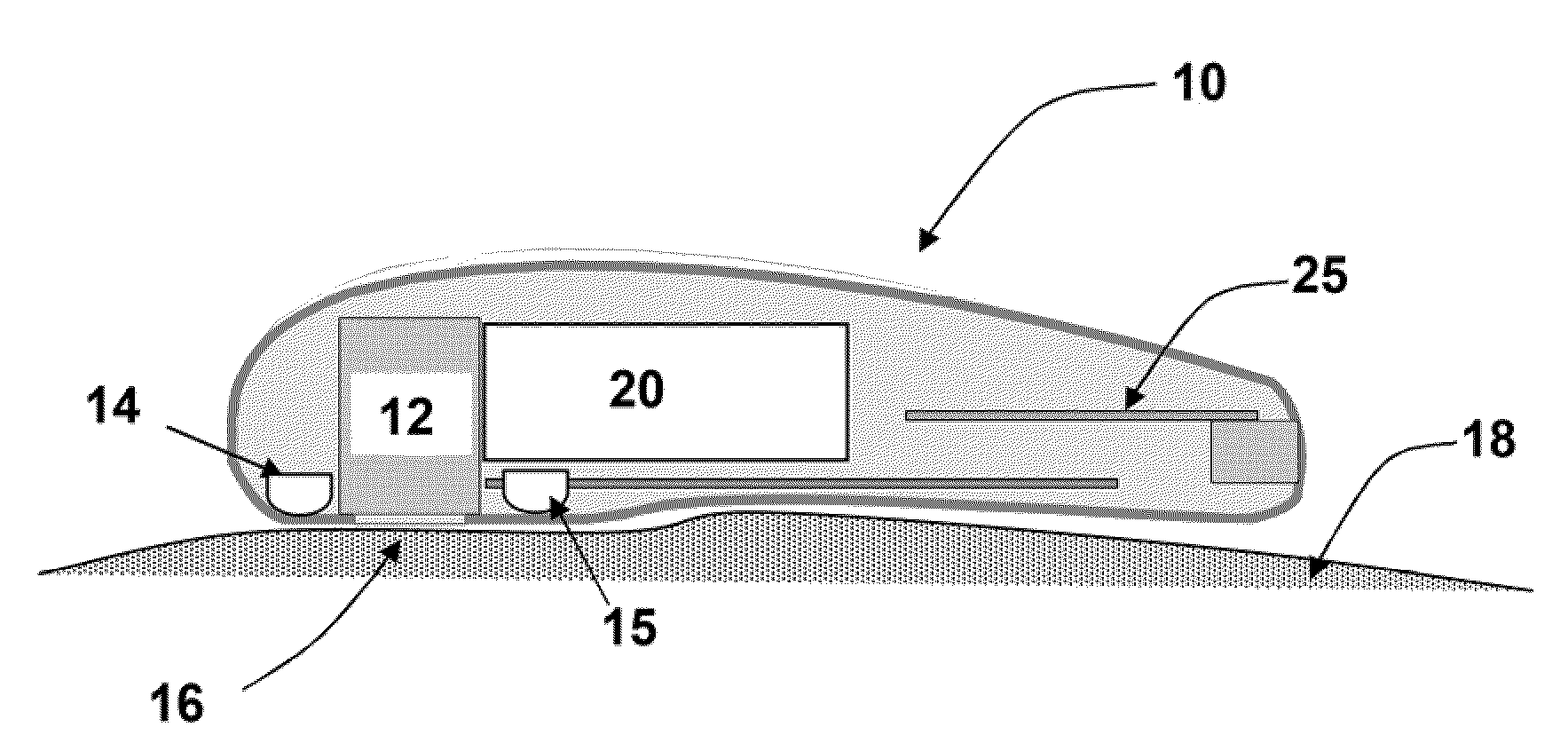

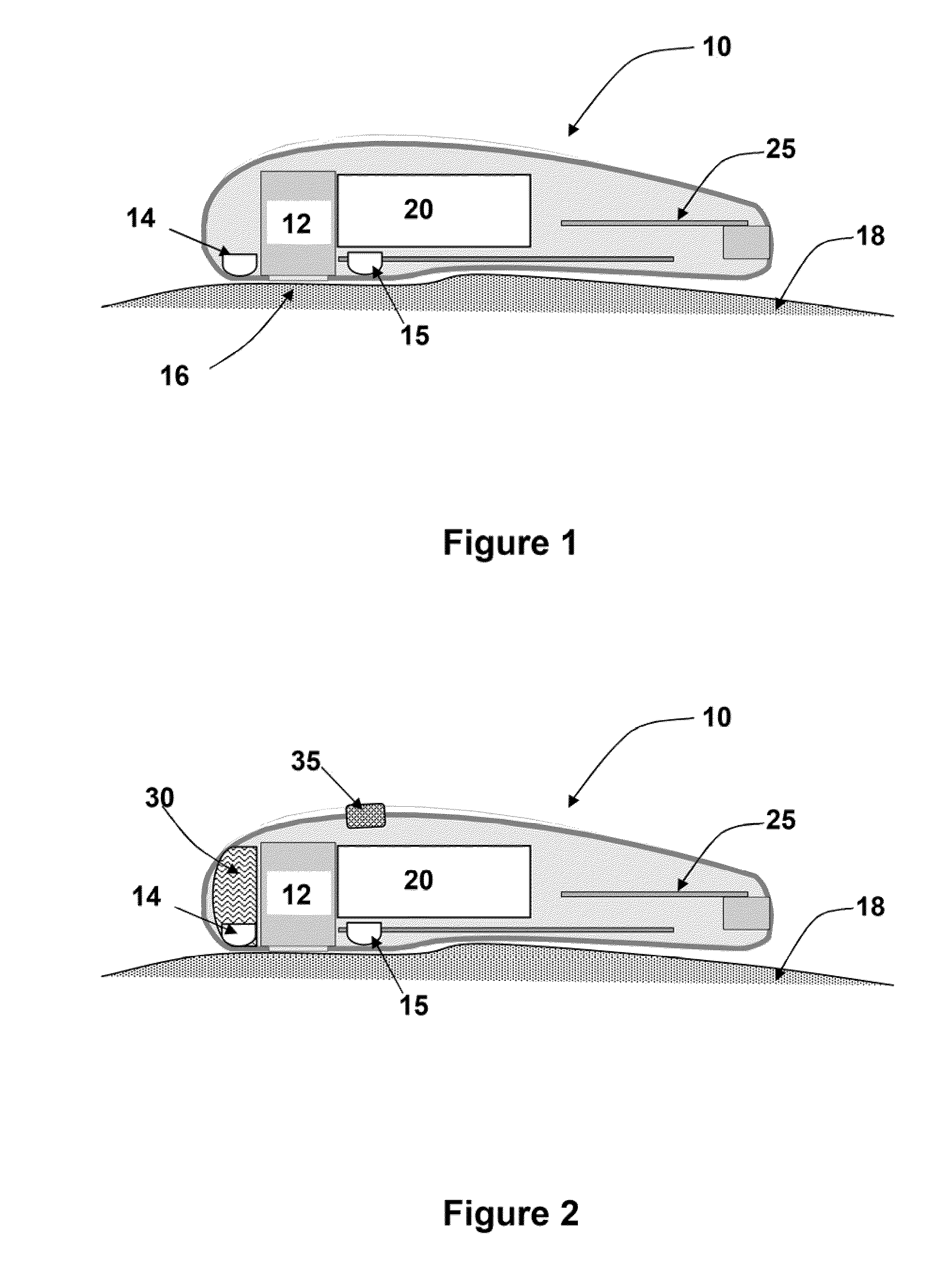

Tissue thickness measurement device

InactiveUS20060184024A1Accurate measurementAccurate distributionUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsMeasurement deviceUltrasonic sensor

A device is described that can be easily used to accurately measure and monitor tissue thickness using ultrasound. The device comprises a remote control and data processing unit, a handheld ultrasound transducer, a display monitor and means for effectively coupling ultrasound to tissue.

Owner:INTELAMETRIX

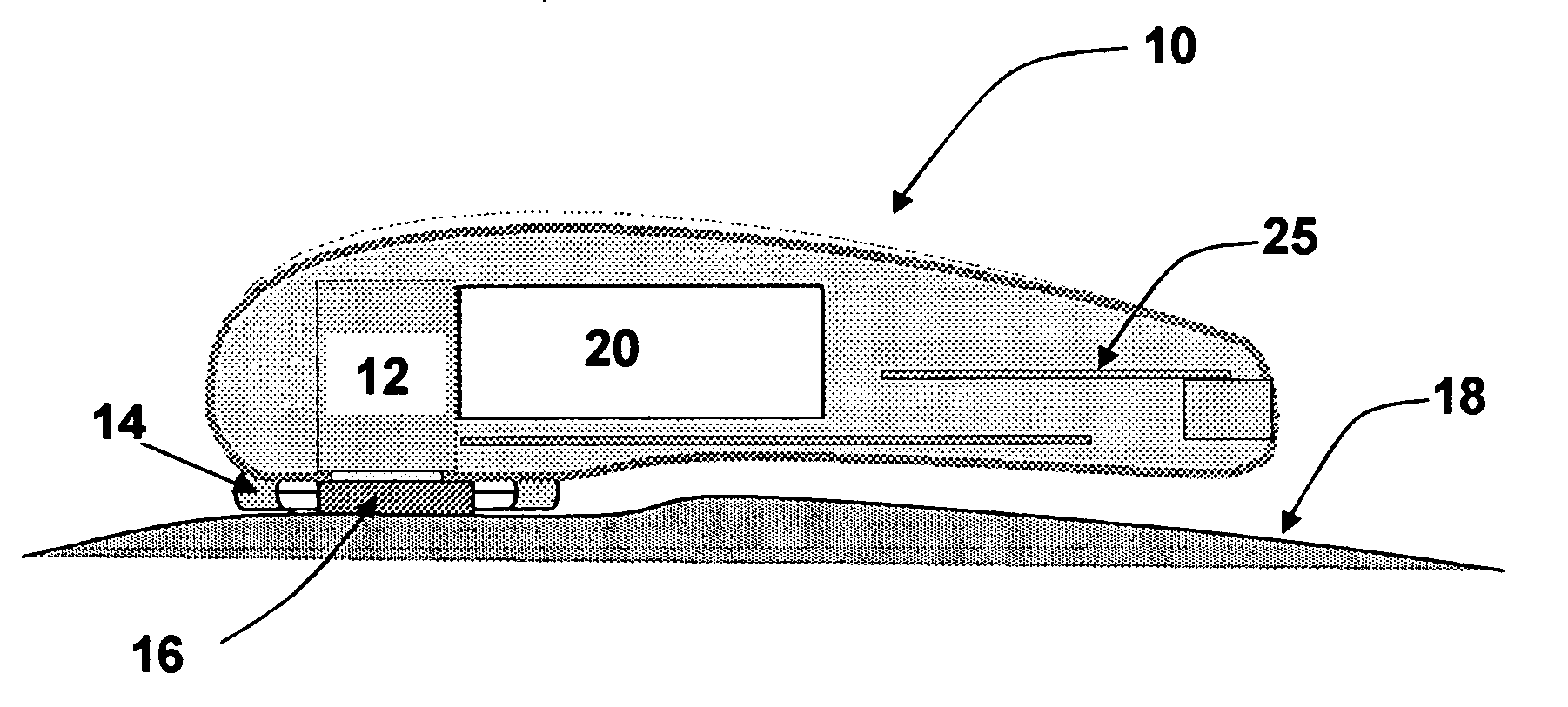

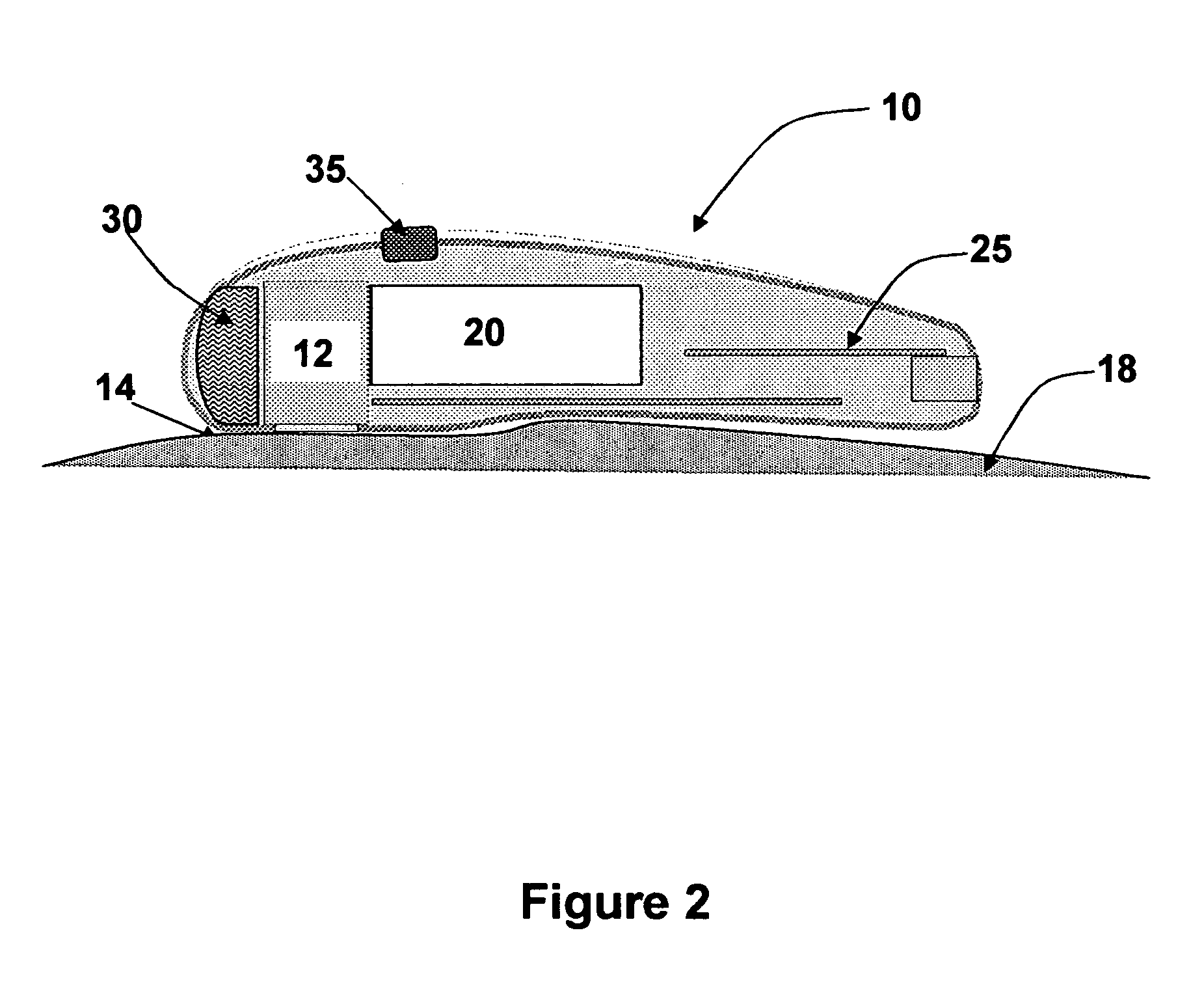

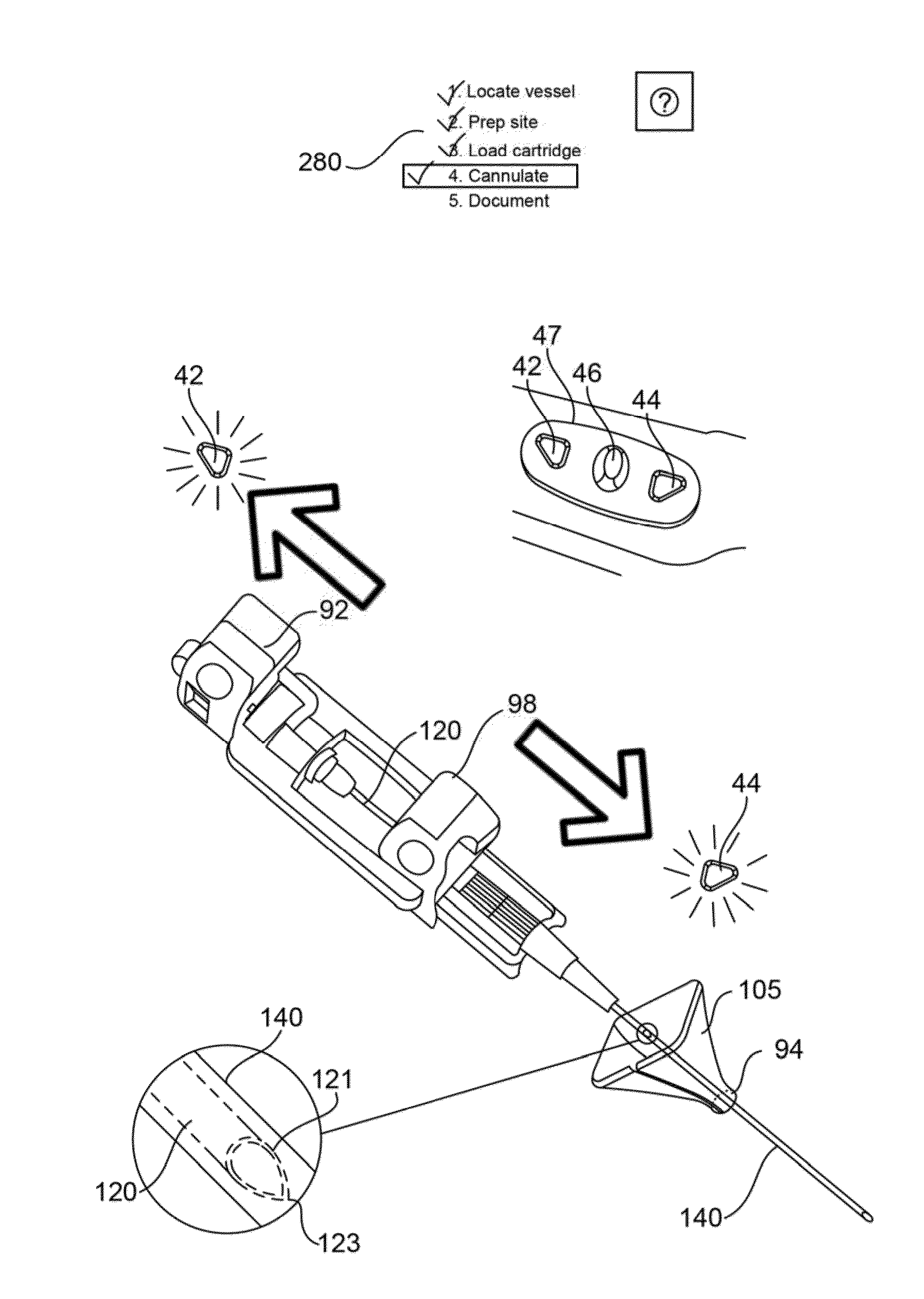

Cartridge for a blood vessel access system and device

A cartridge for use with a blood vessel access system and device. The cartridge includes a slideable needle mount and a slideable cannula mount, the slideable needle mount having a needle in slideable connection with a lumen of a cannula held by the needle mount. The slideable needle mount and the slideable cannula mount are removeably attachable with separate moveable platforms of a needle injector that is pivotally attached to a handheld ultrasound transceiver in signal communication with a computer processing unit connected with a monitor. Upon insonification of a patient's vasculature using the handheld ultrasound transceiver pressed against the surface of the patient, needle injection and subsequent cannulation of a targeted blood vessel appearing on the monitor is accomplished by deploying the needle and cannula from the cartridge via motorization of the moveable platforms that is initiated by the user operating a controller on the device's needle injector.

Owner:VERATHON

Method and Apparatus to Visualize the Coronary Arteries Using Ultrasound

ActiveUS20120116226A1Improved three dimensional imageReduce noiseImage enhancementImage analysisBLOOD FILLEDScreening techniques

A non-invasive screening technique for visualizing coronary arteries which overcomes the problems of visualizing the curved arteries by projecting the three dimensional volume of the arteries onto a two dimensional screen. Blood-filled areas such as the coronary arteries and veins, are highlighted to contrast with other nearby tissues using non-linear classification and segmentation techniques. Data is gathered as a sequence of 2D slices stored as a 3D volume. Software interpolates voxels intermediate to the slices. Wiener filtering or LMS spatial filtering can be implemented on each 2D scan to improve lateral resolution and reduce noise prior to the use of the scan data with the classification and segmentation algorithms. A traditional handheld ultrasound probe is employed to enable the technician to locate the area of interest, but a gyroscopic stabilizer is added to minimize unwanted variation on two axes of rotation.

Owner:MAUI IMAGING

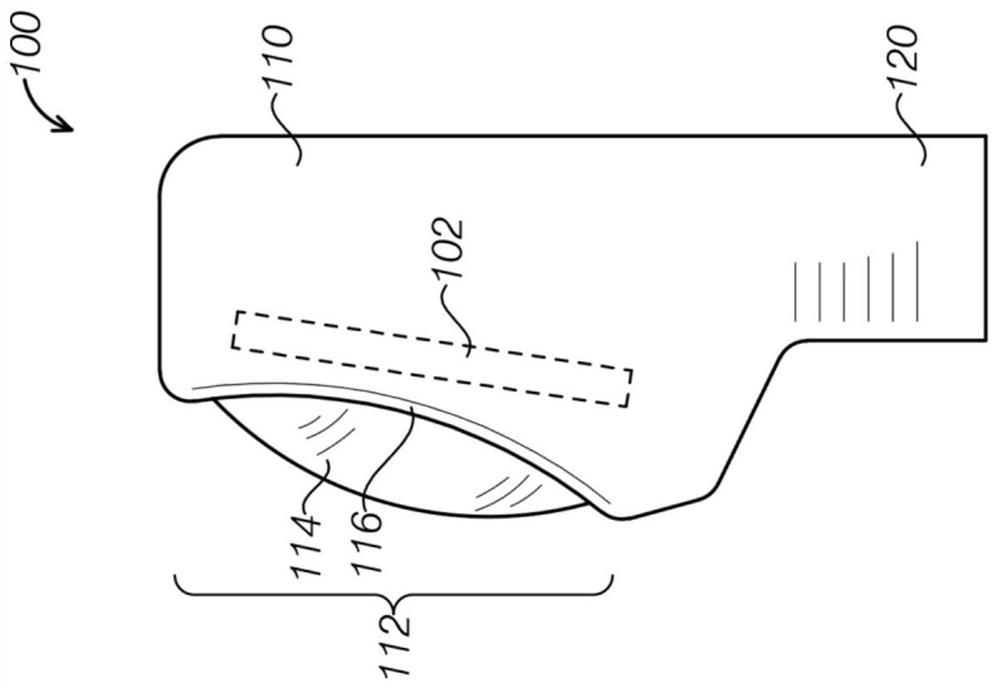

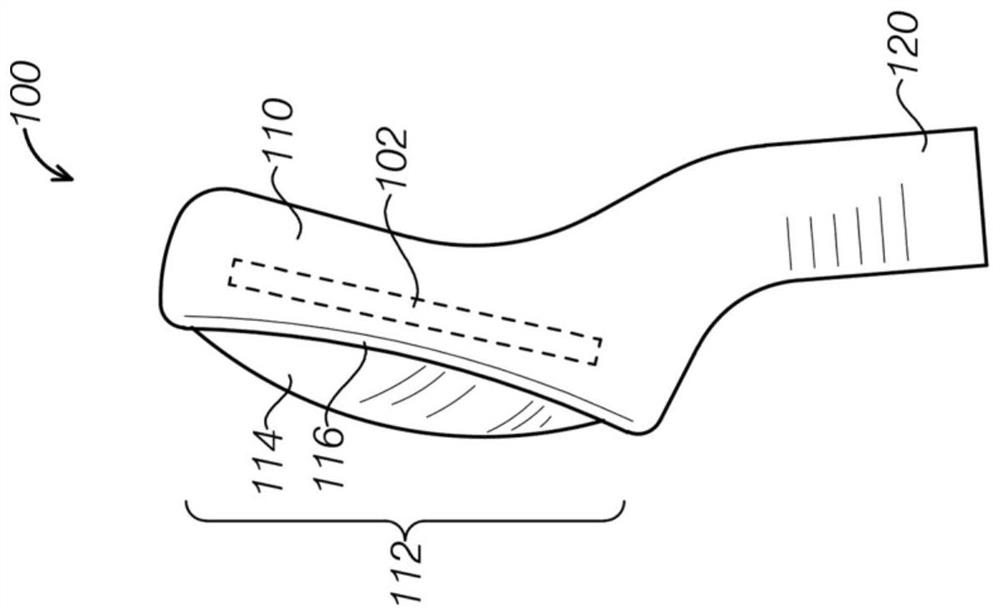

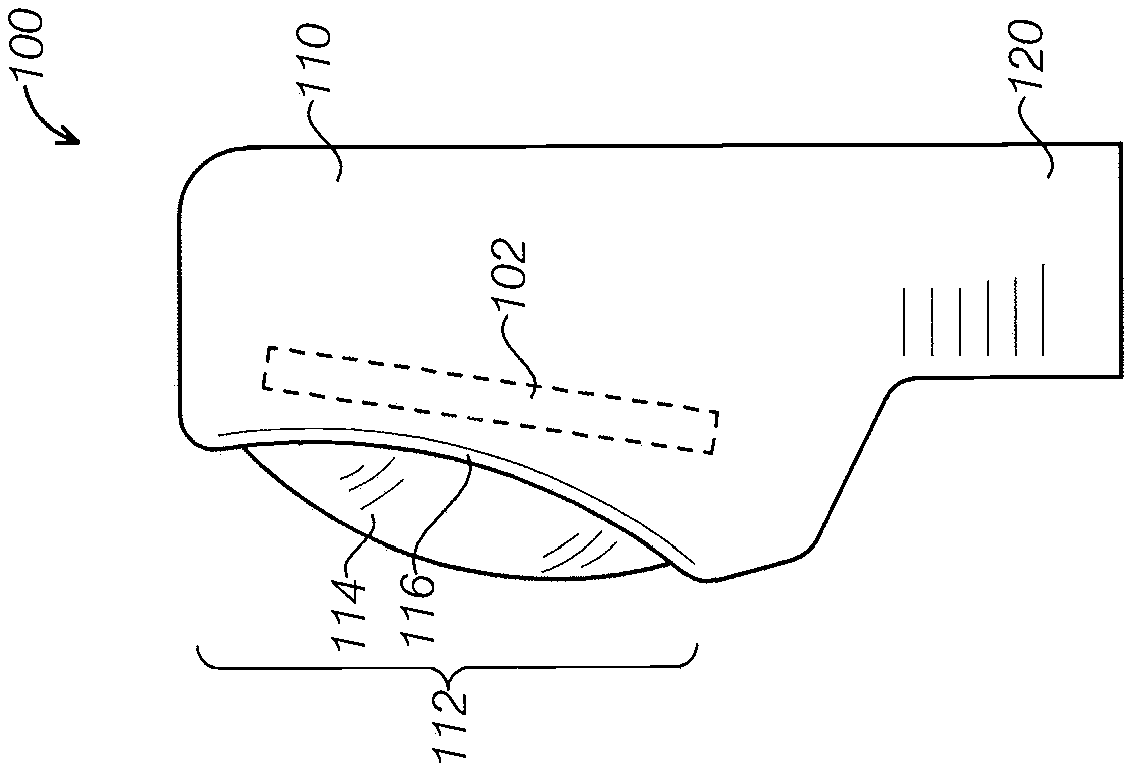

Ultrasound device for vulvovaginal rejuvenation

InactiveUS20190060675A1Increase blood flowReduce drynessUltrasound therapySurgical instrument detailsUltrasound deviceMedicine

A handheld ultrasound device and corresponding methods used for rejuvenating the vulvovaginal area of the user. In general, the handheld ultrasound devices include a device body coupled to an acoustic coupler and a handle. The device body further includes internal components including an ultrasound transducer, an energy delivery element, and circuitry for controlling the ultrasound output. The methods of using the handheld ultrasound device include engaging the tissue in and around the vulvovaginal area with the energy delivery element, applying ultrasound energy to the vulvovaginal tissue from the energy delivery element and through the acoustic coupler, and affecting a measurable parameter associated with vulvovaginal rejuvenation.

Owner:MADORRA INC

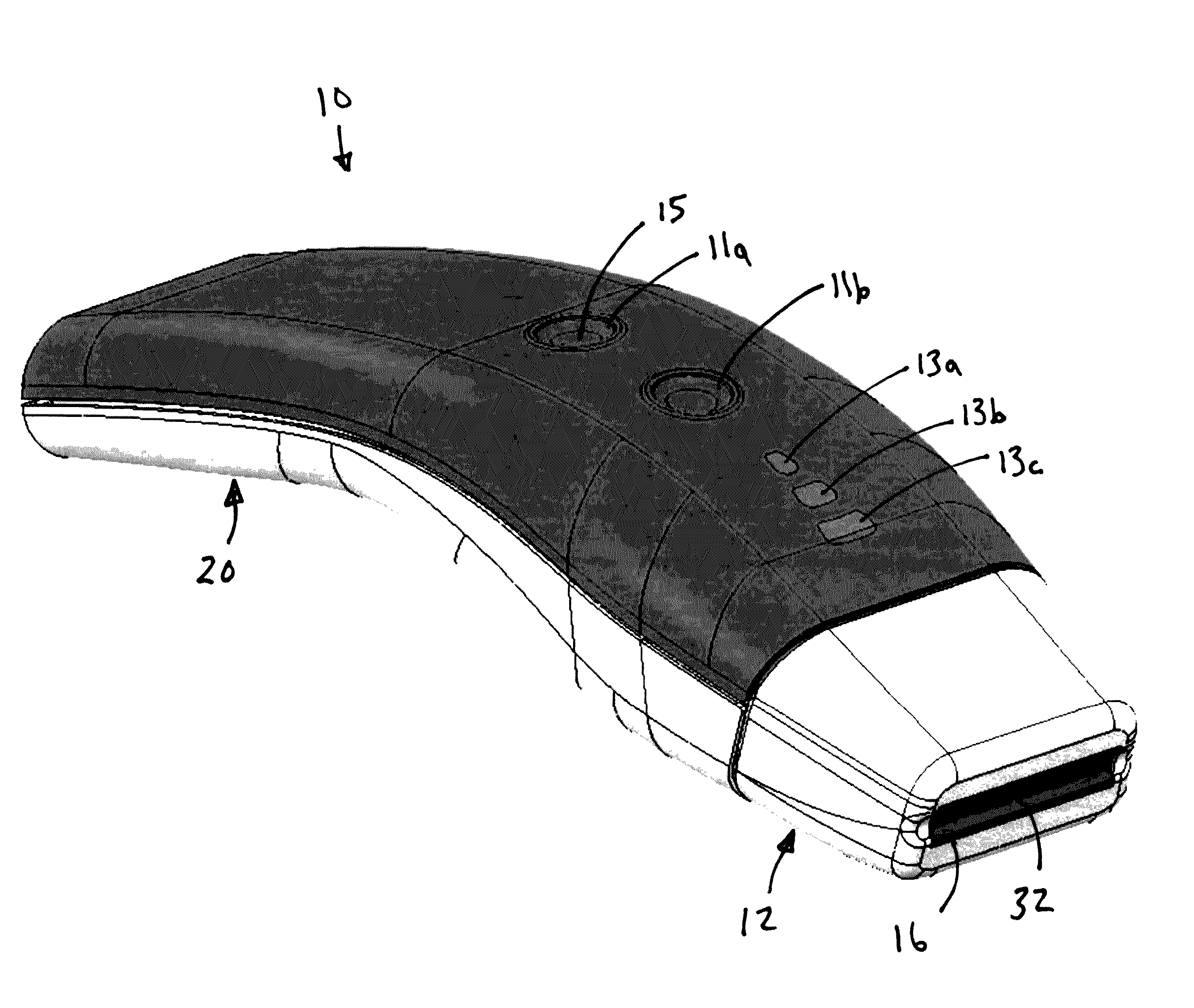

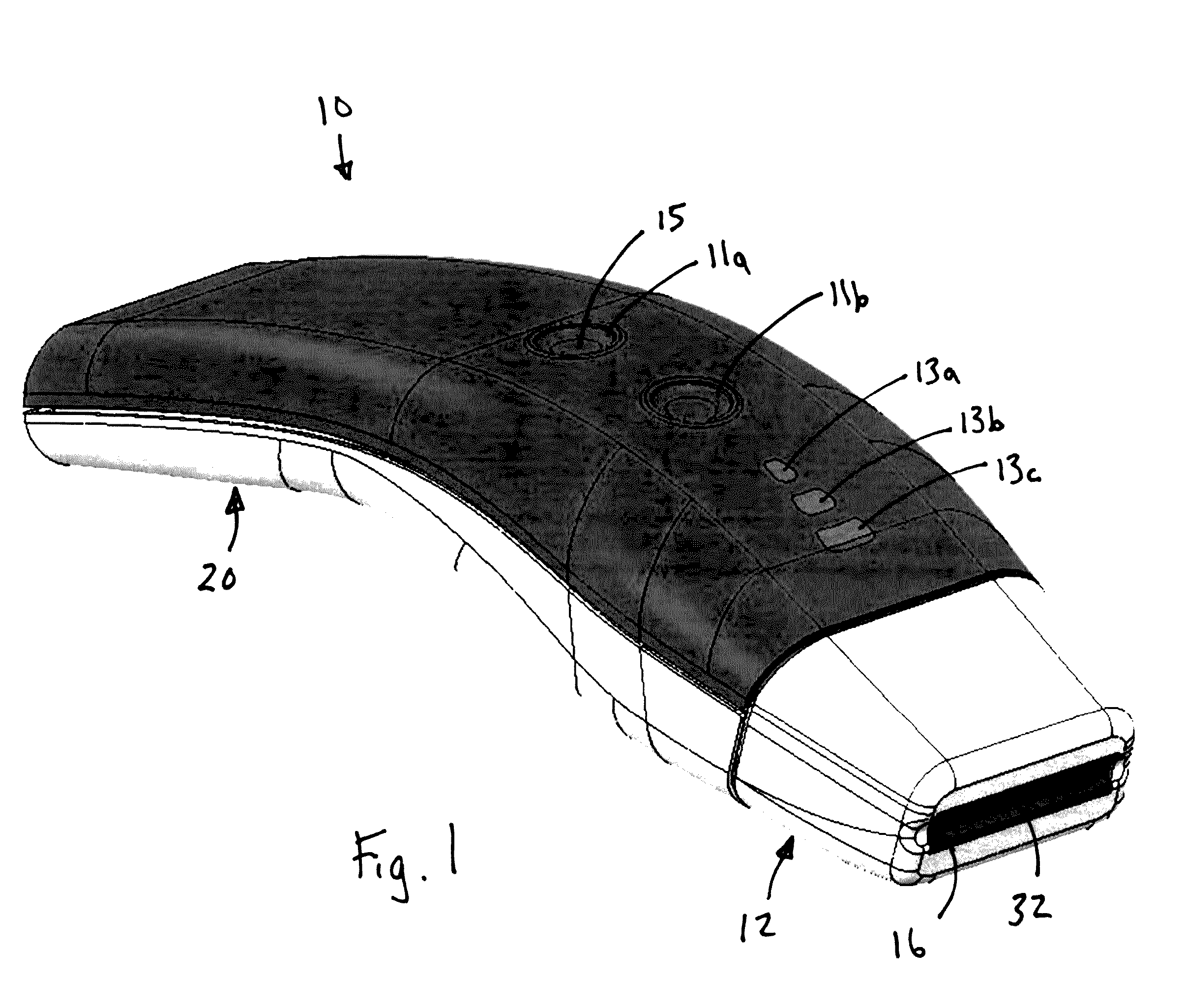

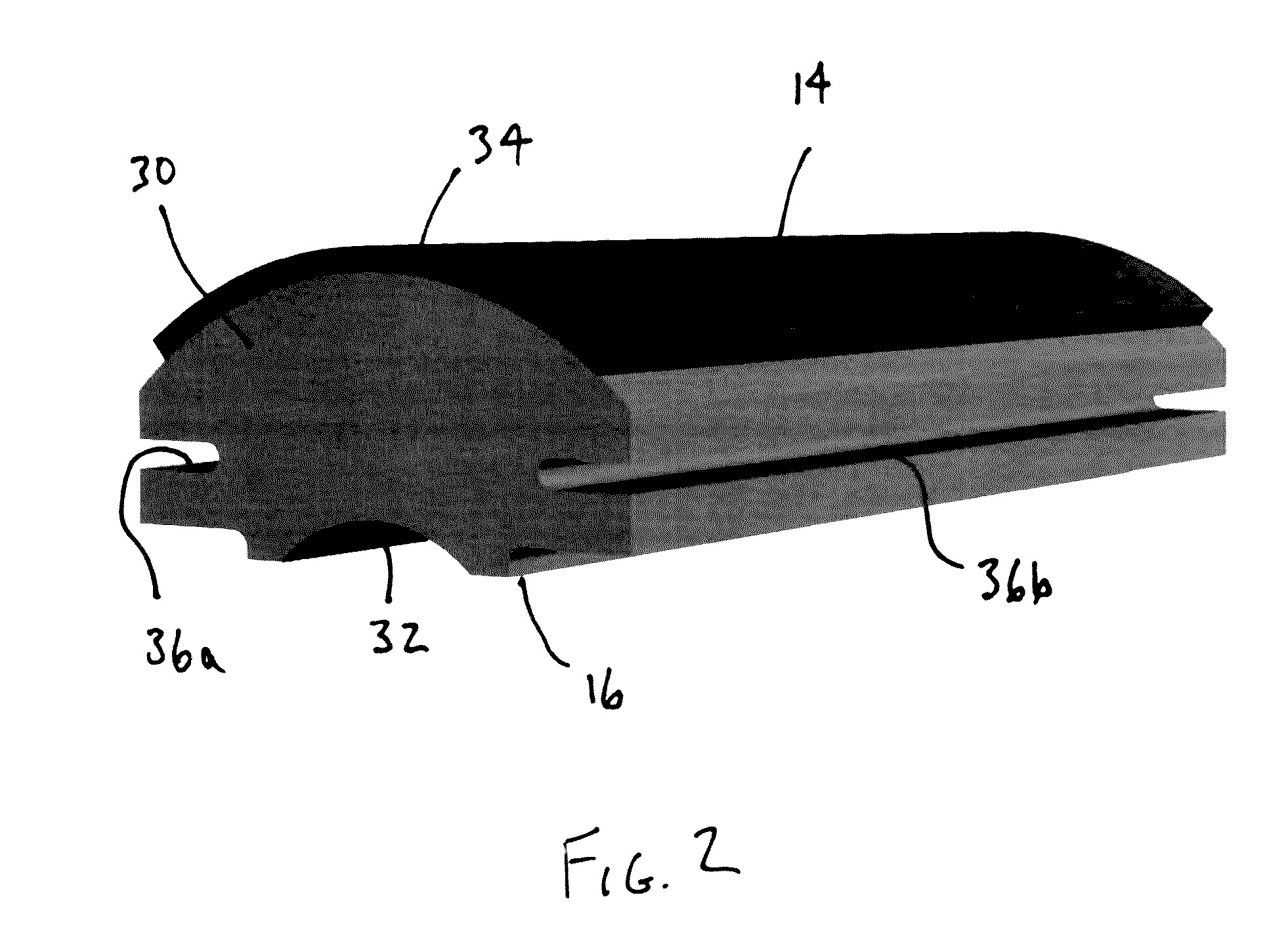

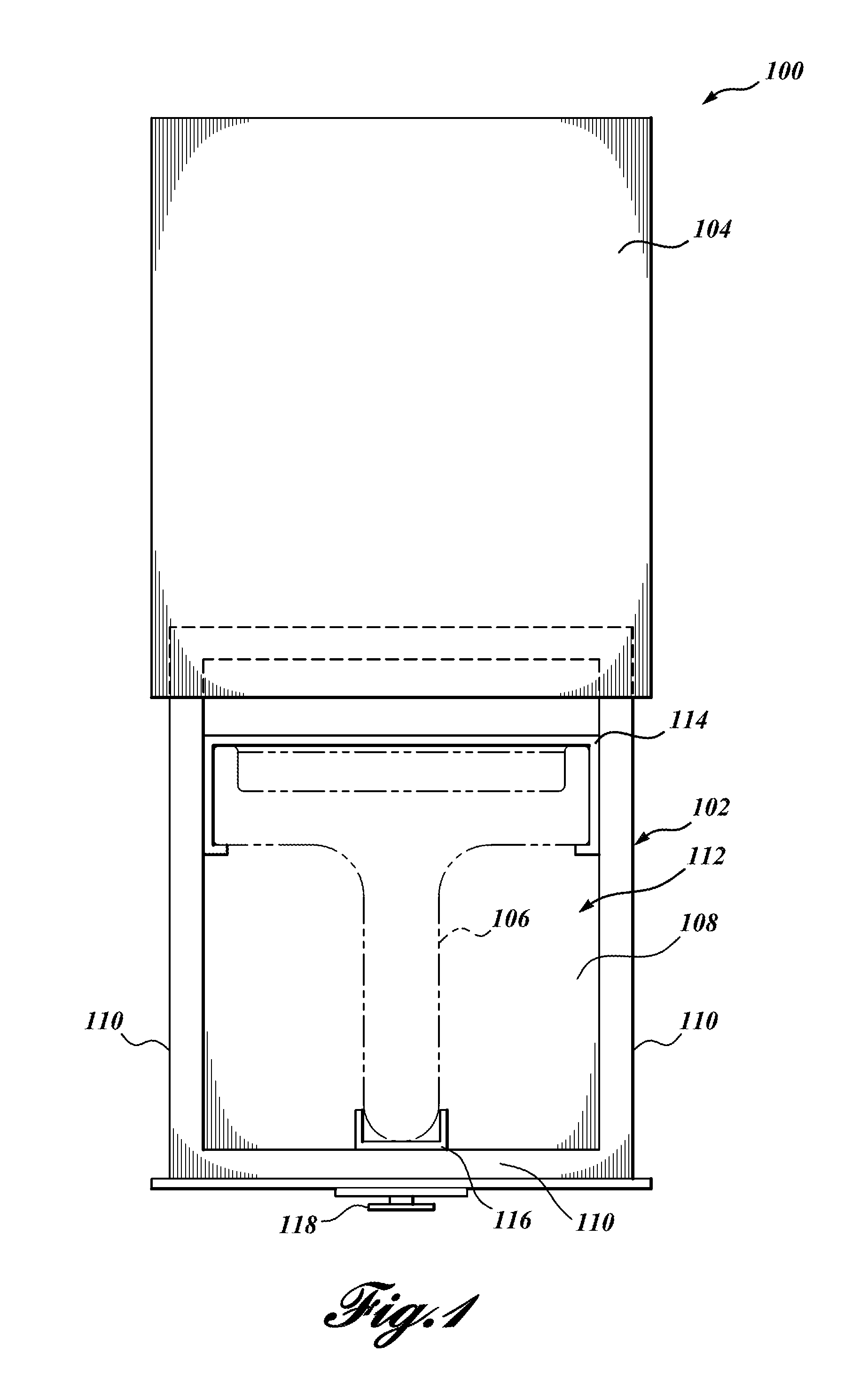

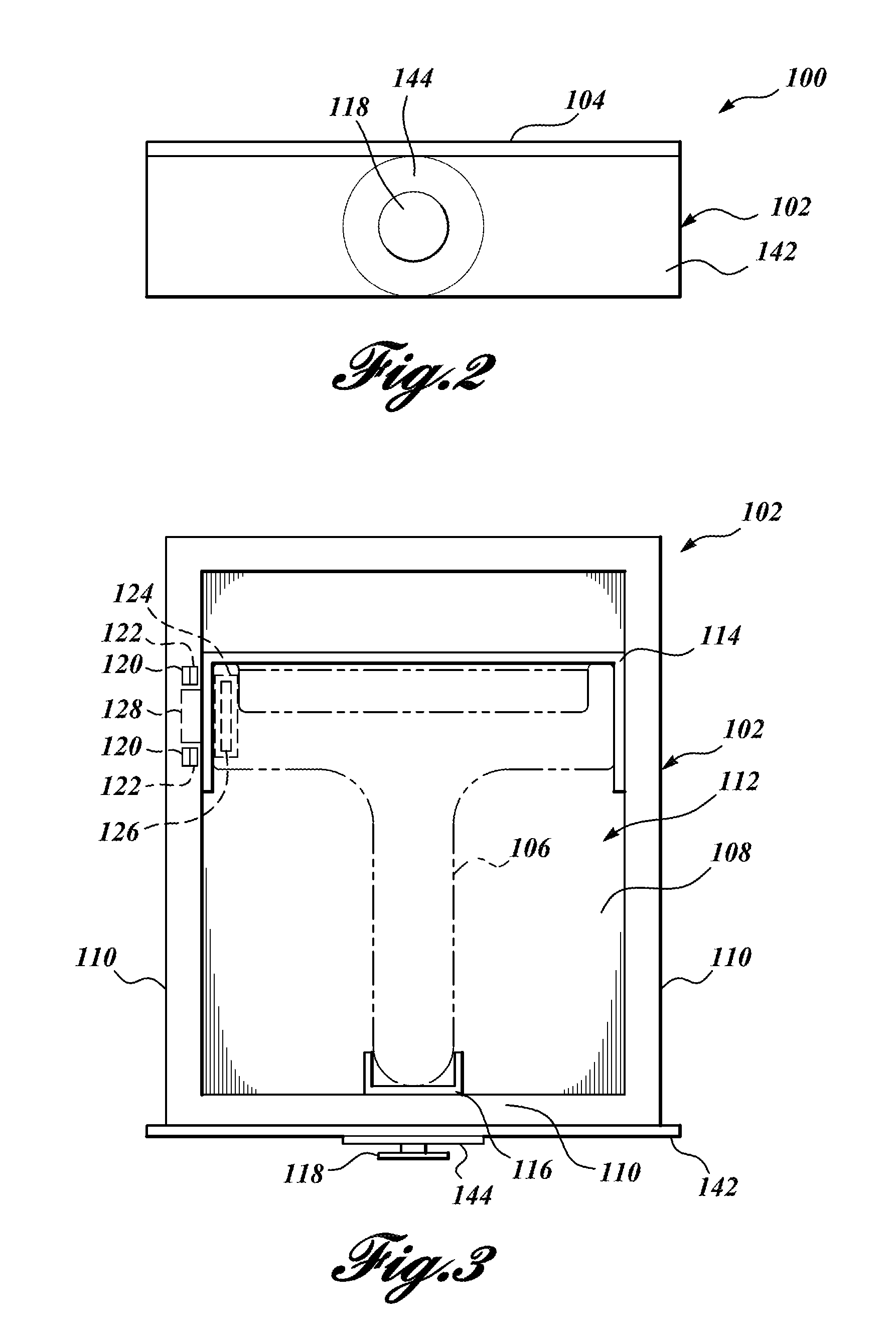

Acoustic module and control system for handheld ultrasound device

ActiveUS20170043189A1Uniformity in acoustic outputImprove overall acoustic uniformityUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyOperating pointAcoustic energy

An acoustic module with a transducer and a solid waveguide. The transducer and waveguide may be curved to focus the acoustic energy along a focal line. The transducer, the top surface of the waveguide and the bottom surface of the waveguide may extend along coaxial curves. The waveguide may include a recess closely receiving the transducer. The waveguide may include an integral skirt that provides a thermal mass. The acoustic module may include a space to accommodate thermal management options. For example, the acoustic module may include a heatsink, an active ventilation system and / or a phase change material. The ultrasound device may include a controller configured to perform a uniformity scan sweep during supply of operating power to the transducer. The uniformity scan sweep can extend through a frequency range that includes the operating point of the acoustic module and does not exceed an acceptable efficiency loss.

Owner:ACCESS BUSINESS GRP INT LLC

Tissue thickness and structure measurement device

InactiveUS20090264756A1Reduce the risk of electric shockCover can be removedUltrasonic/sonic/infrasonic diagnosticsDiagnostic recording/measuringMeasurement deviceUltrasonic sensor

A device is described that can be easily used to accurately measure and monitor tissue thickness and structure using ultrasound. The device comprises a remote control and data processing unit, a handheld ultrasound transducer with an integrated position sensor.

Owner:INTELAMETRIX

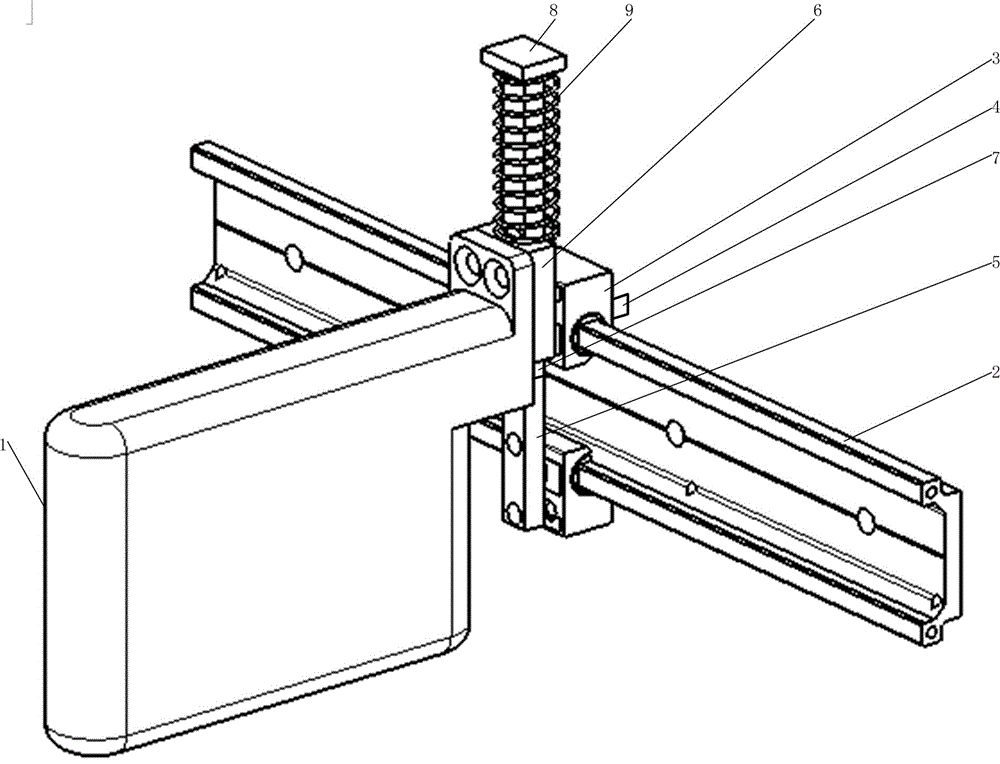

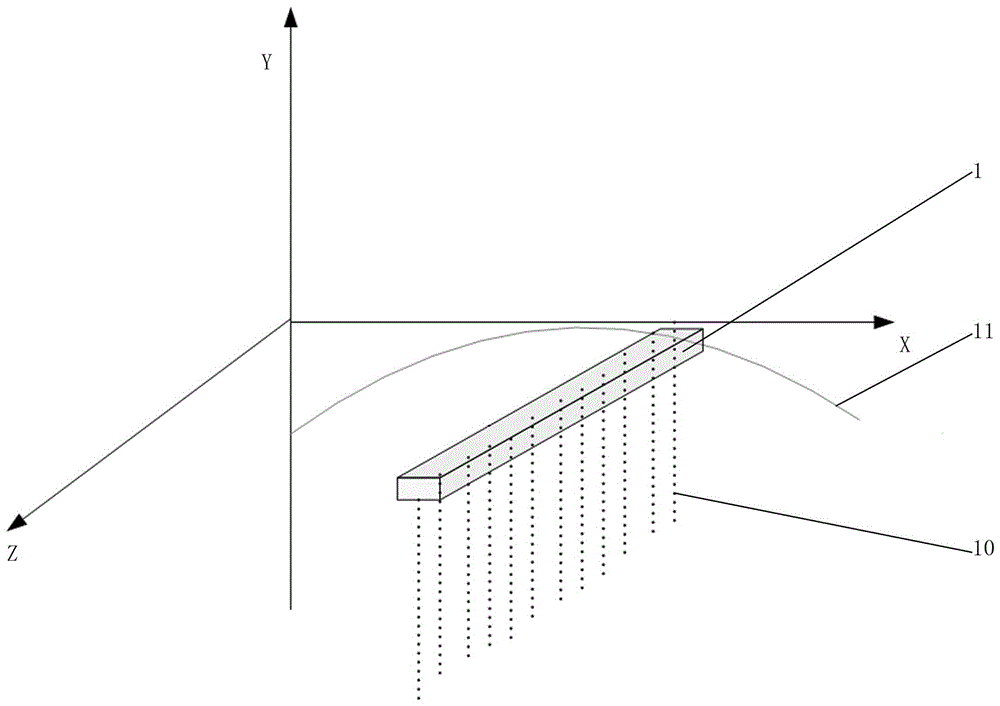

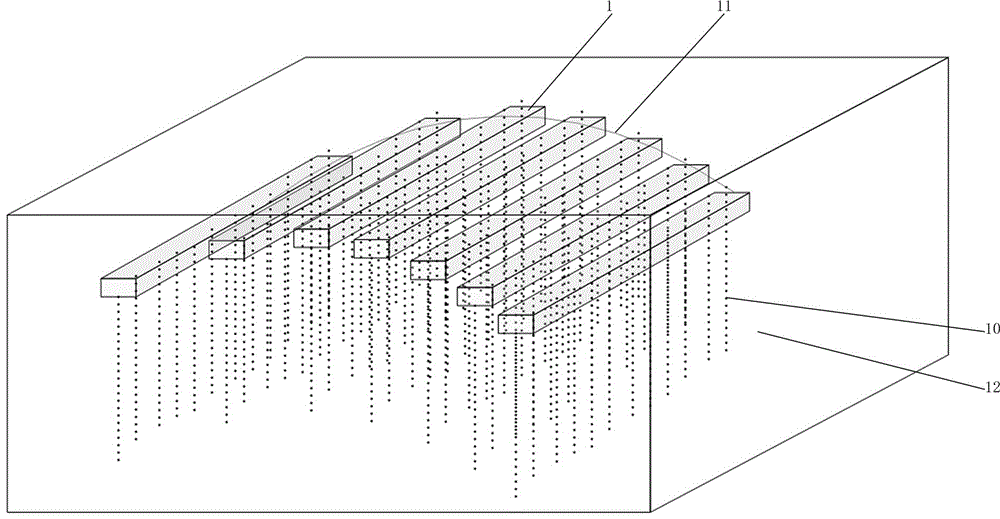

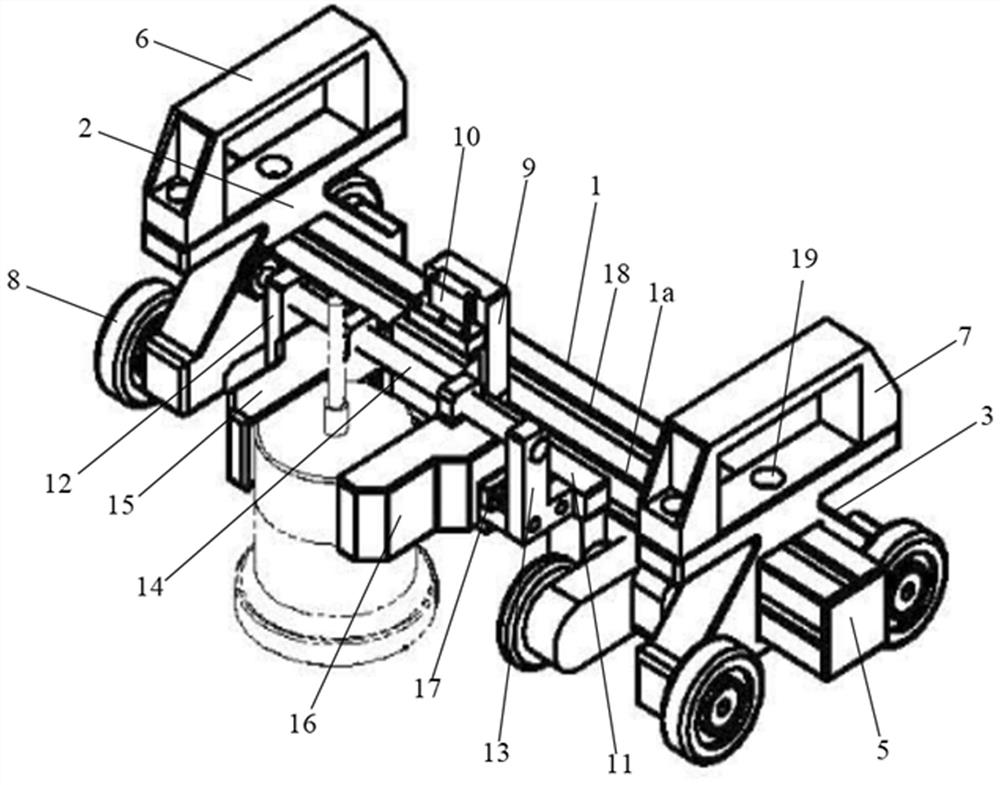

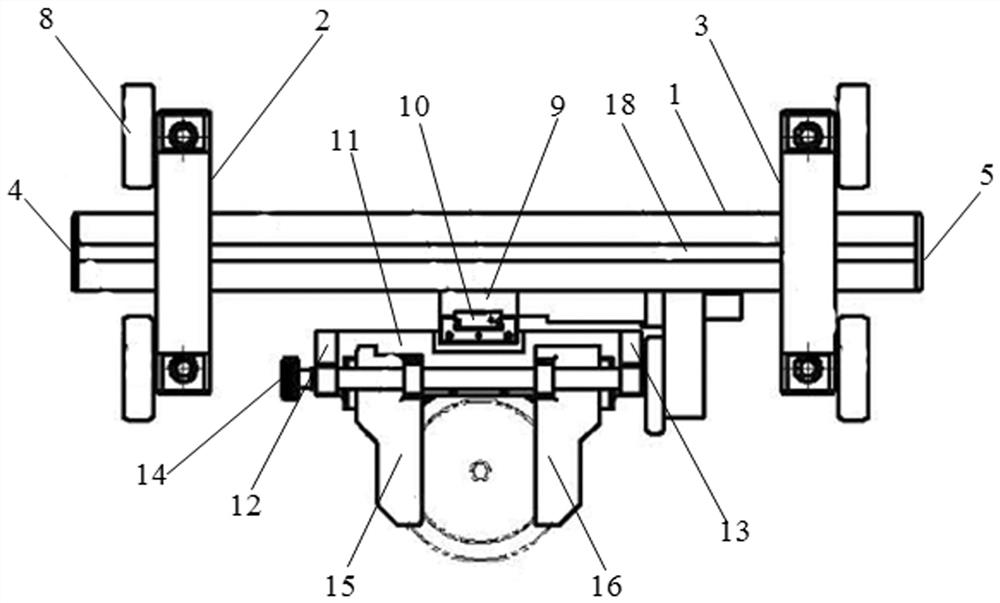

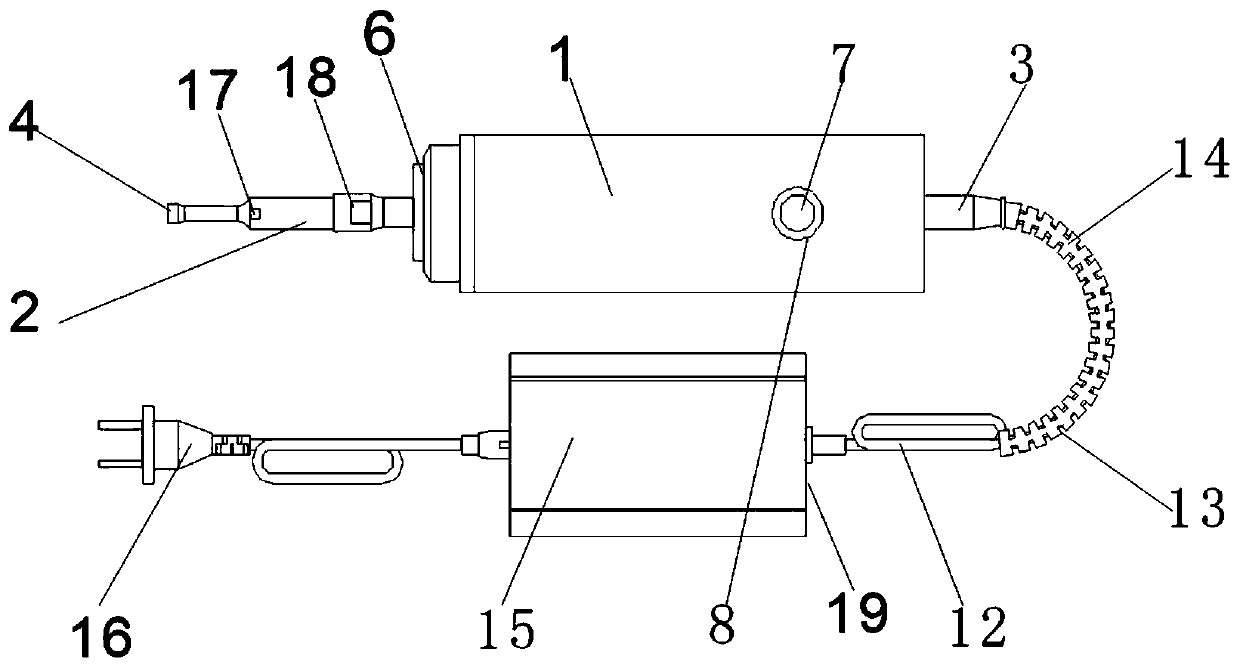

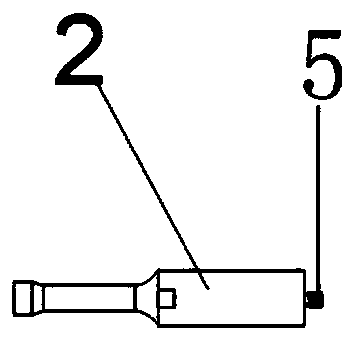

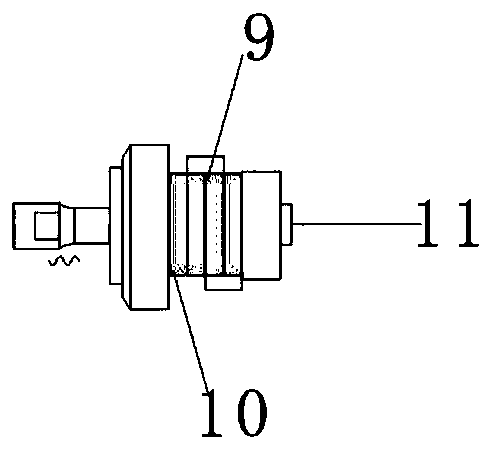

Ultrasonic automatic scanning device and imaging method thereof

InactiveCN106798572AModerate pressureImprove accuracyDiagnostic probe attachmentInfrasonic diagnosticsHandheld ultrasoundEngineering

Provided are an ultrasonic automatic scanning device and an imaging method thereof. The device comprises a housing, a drive, a transverse guide, a transverse slider, a transverse encoder, a longitudinal guide, a longitudinal slider, a longitudinal encoder, a pressure sensor and a spring. The transverse slider is mounted on the transverse guide; the longitudinal guide is mounted on the transverse slider; the longitudinal slider is mounted on the longitudinal guider; the pressure sensor is mounted on the top of the longitudinal guide; the spring is set between the longitudinal slider and pressure sensor; and an ultrasonic probe is mounted on the outer side of the longitudinal slider. Automatic scanning has the advantages of being subject to feedback the pressure of a ultrasonic probe, maintaining a moderate pressure and improving the accuracy of the diagnosis through the pressure sensor; performing pressure to the ultrasonic probe through the spring, having an adaptive function of compression, and being applied to scan the flat or concave-convex parts of the human body. A data reconstruction and a three-dimensional ultrasound volume imaging are performed based on ultrasonic scanning line data and moving trajectory, which solves the difficult problem of three-dimensional ultrasonic volume imaging of handheld ultrasound scanning device.

Owner:SHANTOU INST OF UITRASONIC INSTR CO LTD

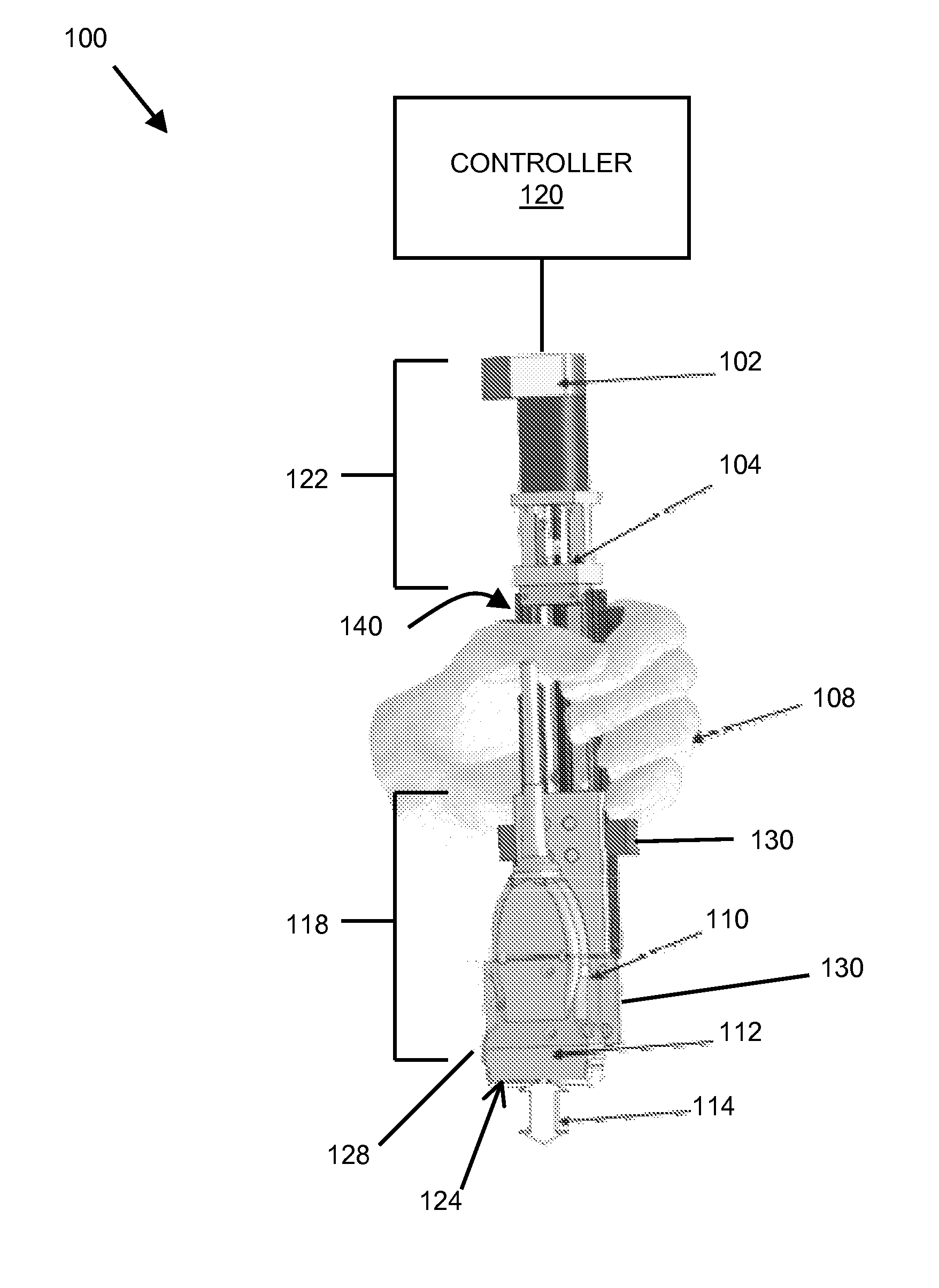

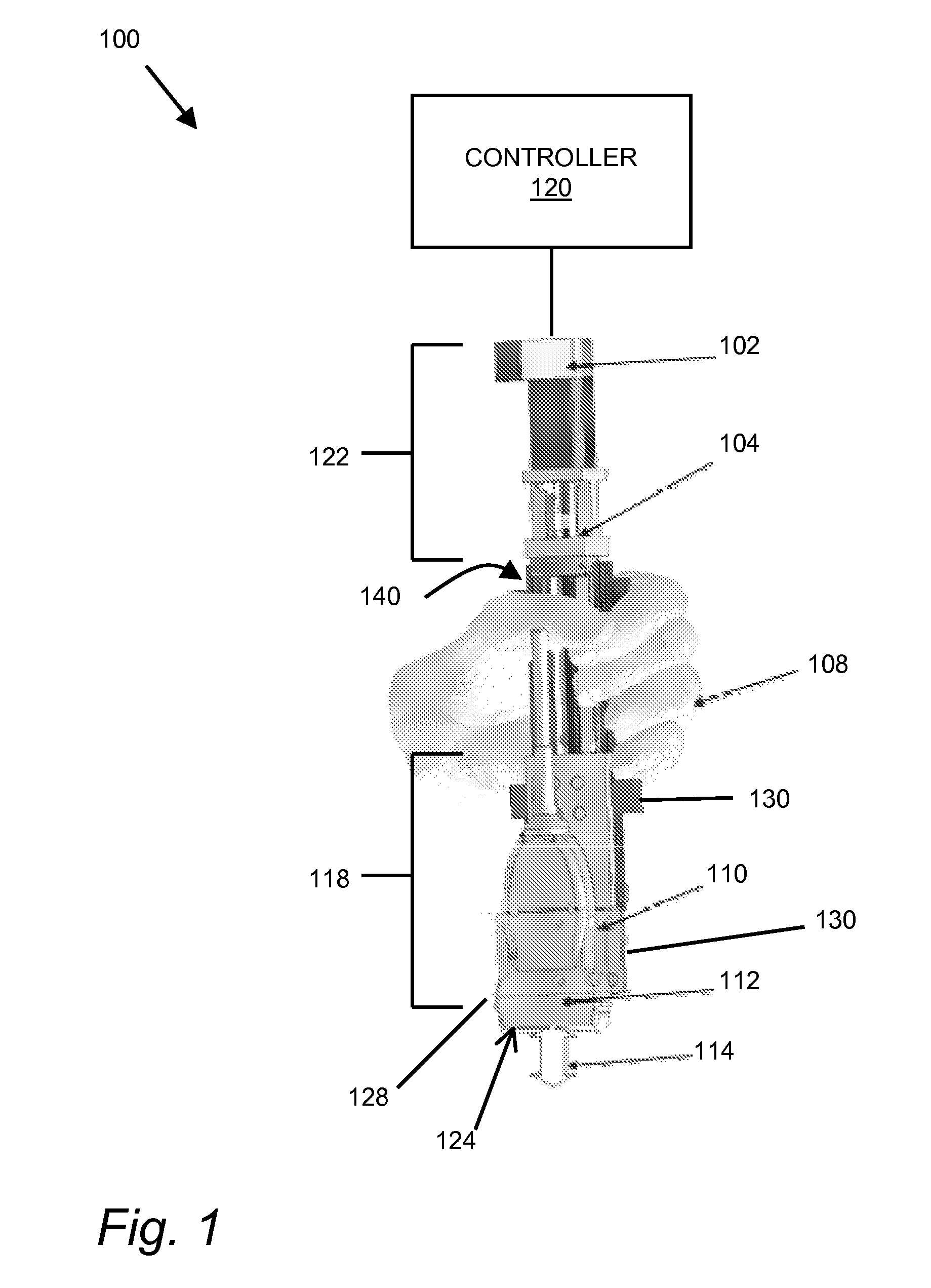

Handheld force-controlled ultrasound probe

InactiveUS20110172541A1Reduce force differencesUltrasonic/sonic/infrasonic diagnosticsMaterial analysis using sonic/ultrasonic/infrasonic wavesHandheld ultrasoundHand held

A handheld ultrasound probe includes force detection and feedback to permit control and / or characterization of applied forces. The probe may, for example, be operated to maintain a substantially constant applied force over a period of use independent of a user's hand position, or to measure applied forces that might contribute to deformation of an imaging subject.

Owner:MASSACHUSETTS INST OF TECH

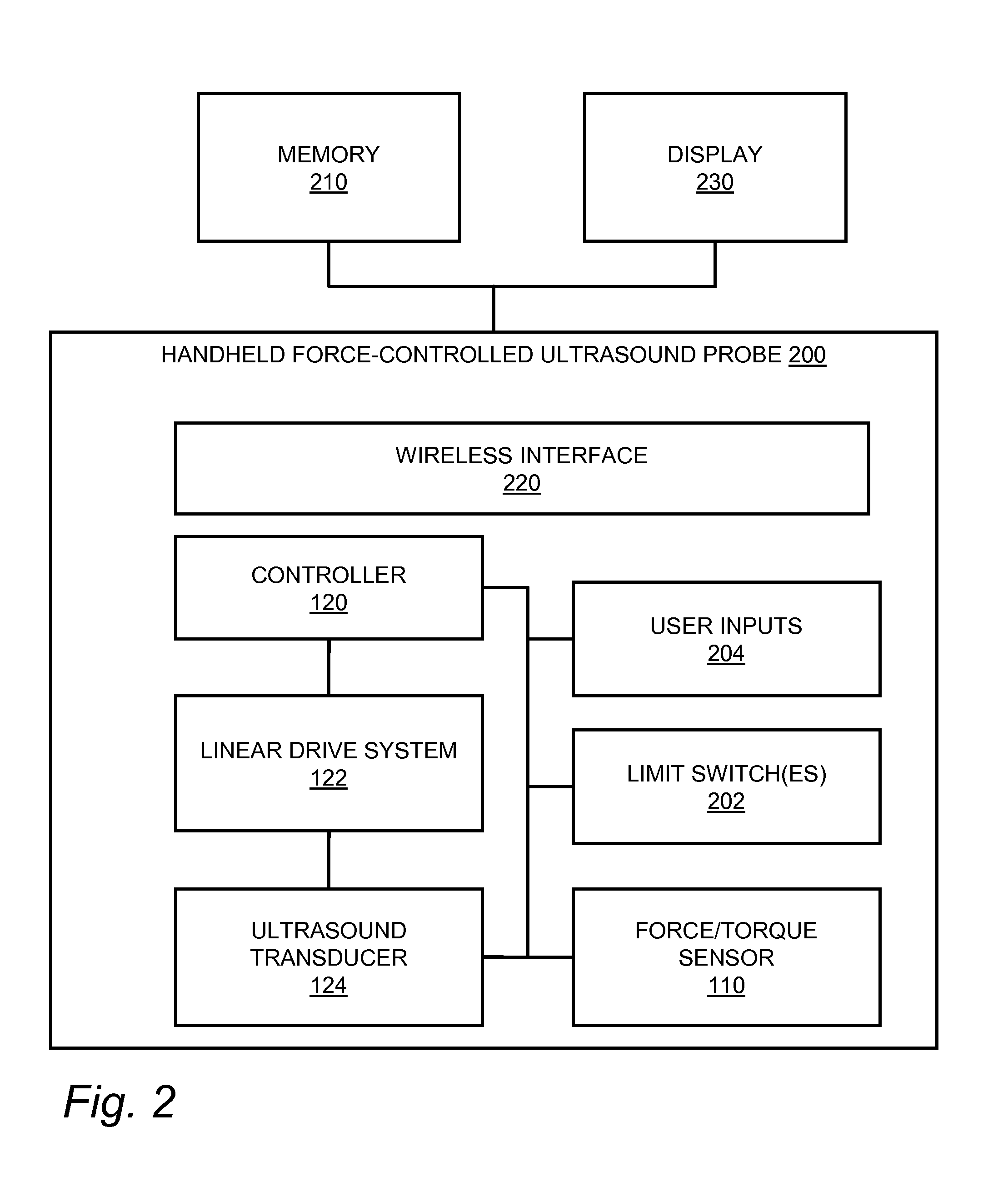

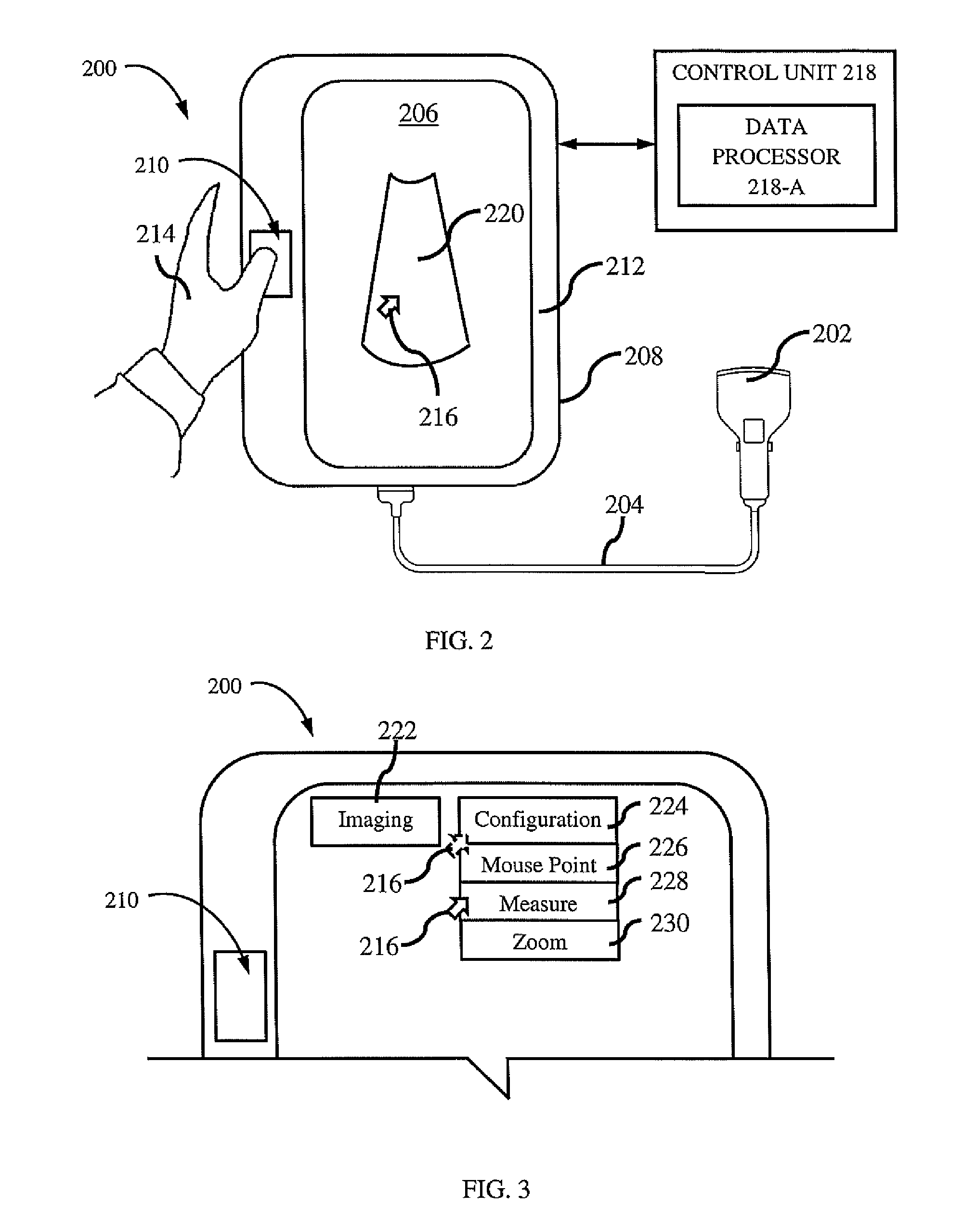

Handheld medical imaging apparatus with cursor pointer control

InactiveUS20160004330A1Input/output for user-computer interactionUltrasonic/sonic/infrasonic diagnosticsUltrasound imagingSonification

A handheld ultrasound imaging apparatus for capturing images of a subject is disclosed. The handheld ultrasound imaging apparatus includes a display for displaying a diagnostic ultrasound image and a plurality of user interface (UI) objects. A housing for holding the display. Further a user input interface is configured in at least one of the display and the housing. The user input interface is operable by a user to control a pointer for providing user input at points on the display to perform one or more activities.

Owner:GENERAL ELECTRIC CO

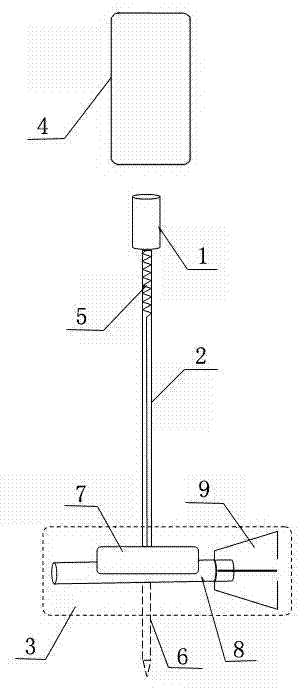

Method and device for handheld ultrasonic measurement of channel flow speed

InactiveCN104502628ANo mechanical wearImprove stabilityTransmission systemsFluid speed measurementHandheld ultrasoundHand held

The invention relates to a method and device for handheld ultrasonic measurement of the channel flow speed, and belongs to the technical field of measurement of the flow speed of river channels or channels. According to the technical scheme, a measuring head (3) comprises an ultrasonic flow speed sensor (7), a flow speed measuring tube (8) and a tail wing (9), wherein the flow speed measuring tube is a tube with the through head end and the through tail end, the ultrasonic flow speed sensor is arranged on the flow speed measuring tube in a matched mode, and the tail wing is arranged on the outer wall of the tail end of the flow speed measuring tube. A host computer (1) comprises a single-chip microcomputer (10), a wireless communication module (11) and a battery (12), wherein the single-chip microcomputer is connected with the wireless communication module and the battery. The host computer is arranged on the upper portion of a measuring rod (2) in a matched mode, and the measuring head is arranged on the lower portion of the measuring rod. According to the method and device for handheld ultrasonic measurement of the channel flow speed, the flow speed sensor is of an ultrasonic type, and is good in stability, the maintenance cost is reduced, the flow speed sensor can work by using the battery, the equipment structure is simplified, and the device for handheld ultrasonic measurement of the channel flow speed can be applied flexibly and conveniently along with continuous improvement of functions of mobile phones and continuous improvement of the data handling capacity.

Owner:张喜

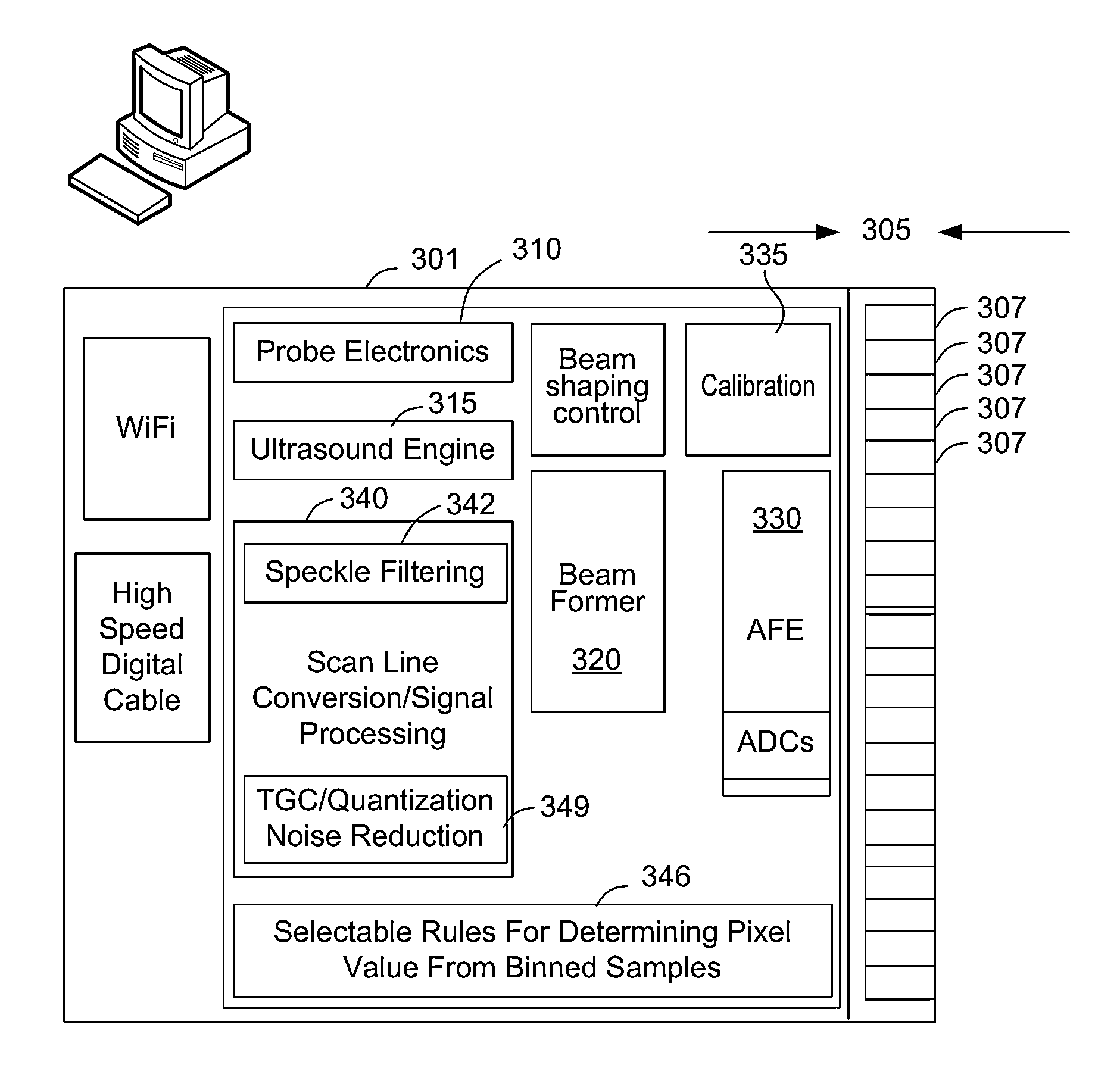

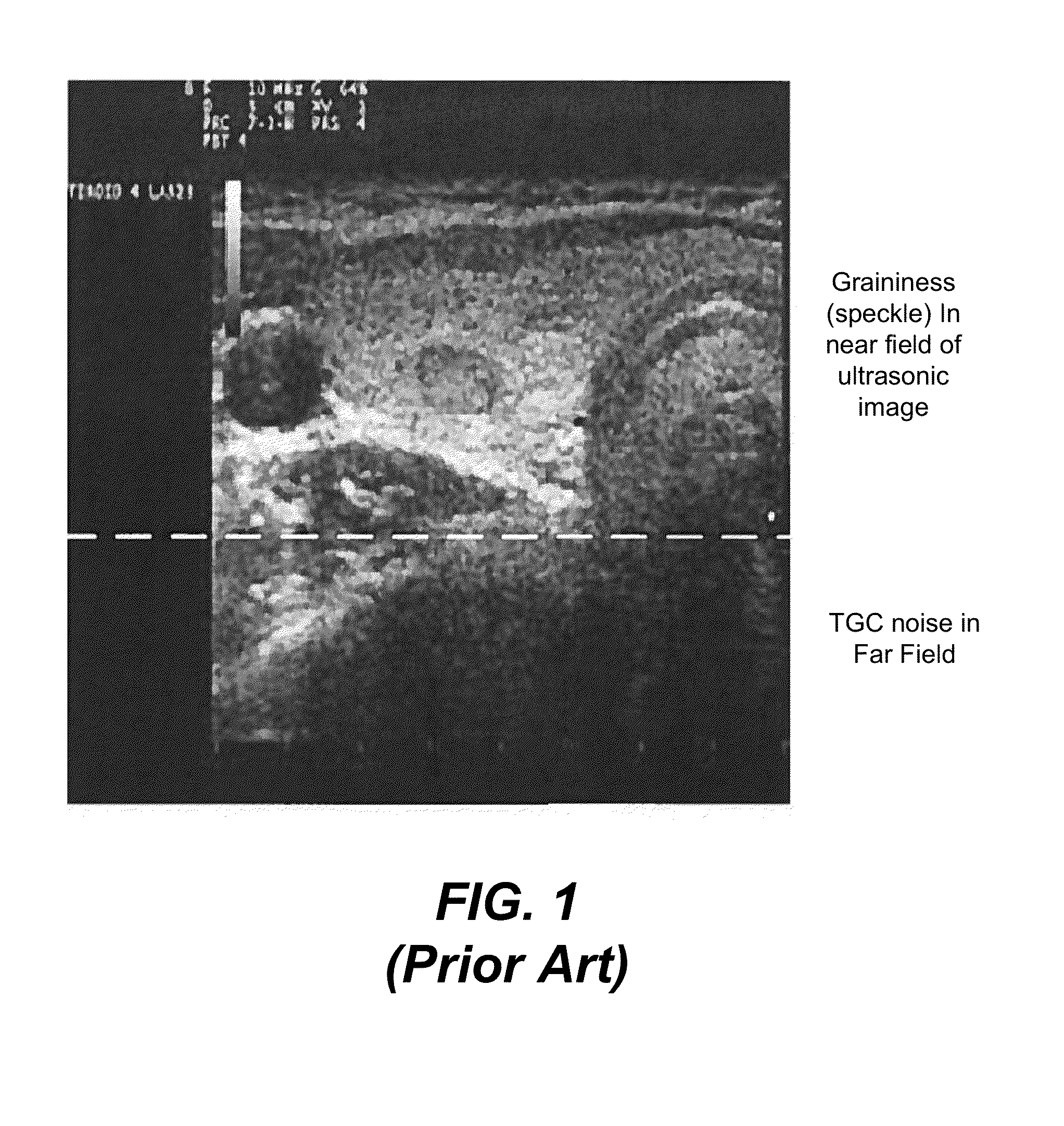

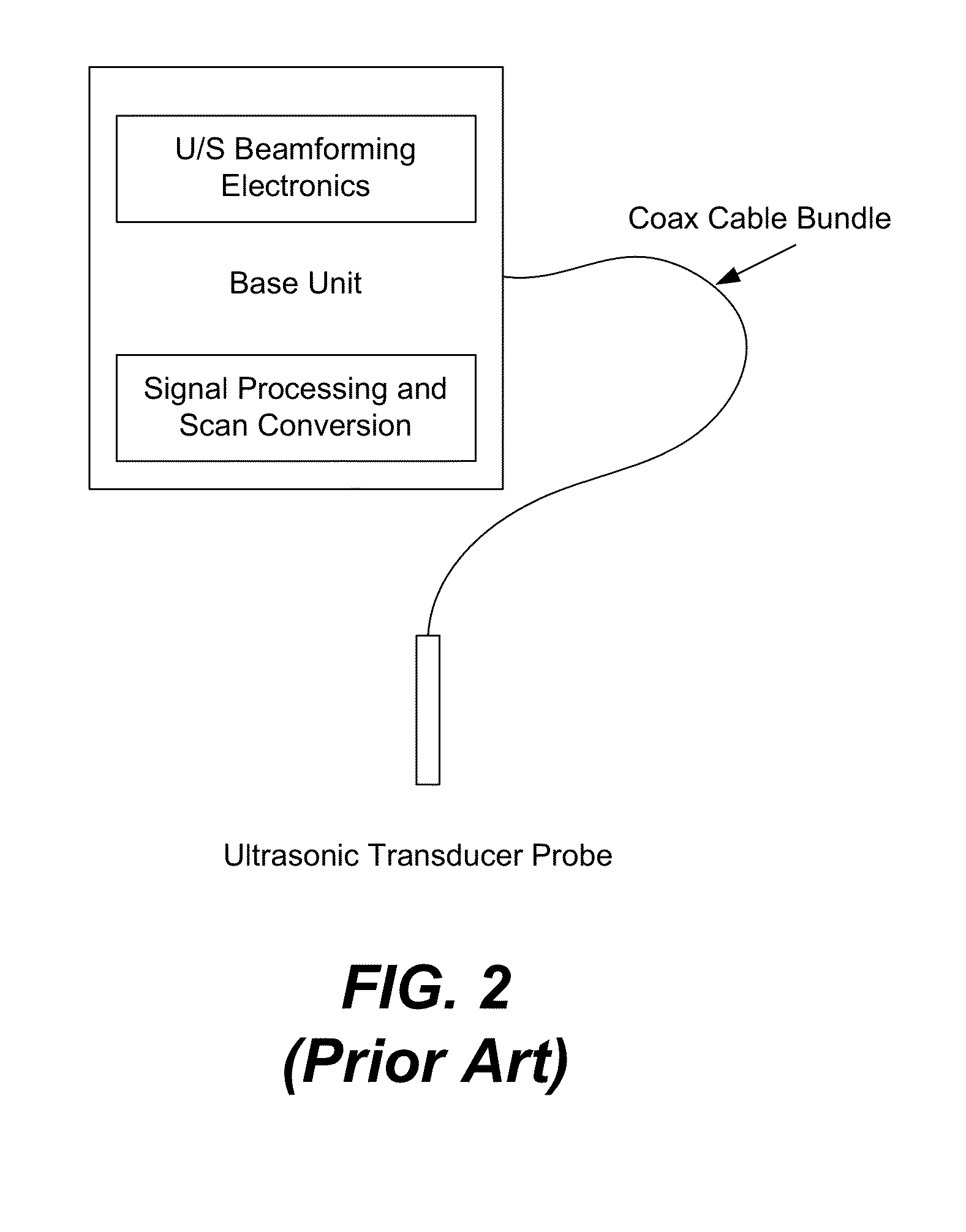

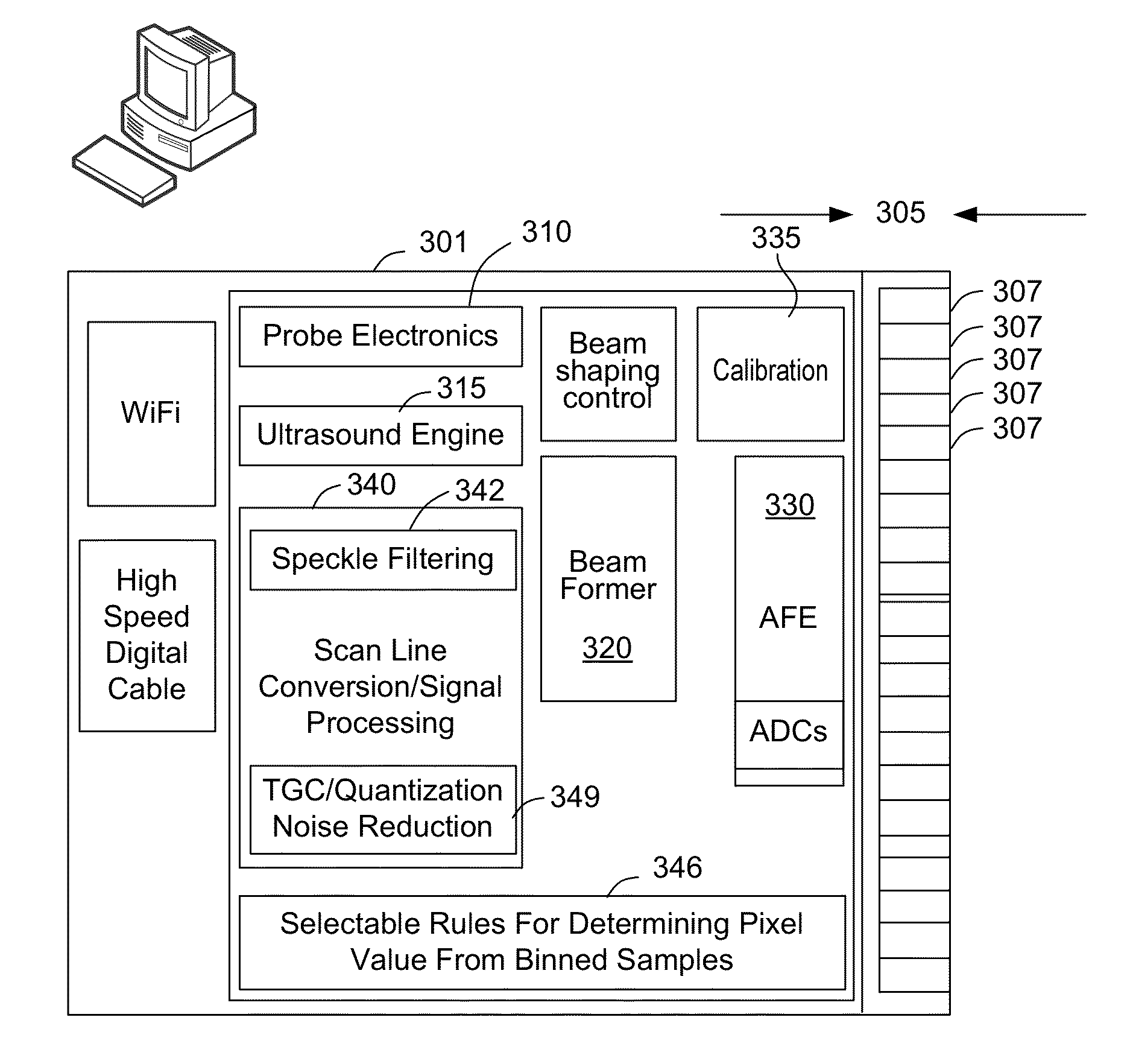

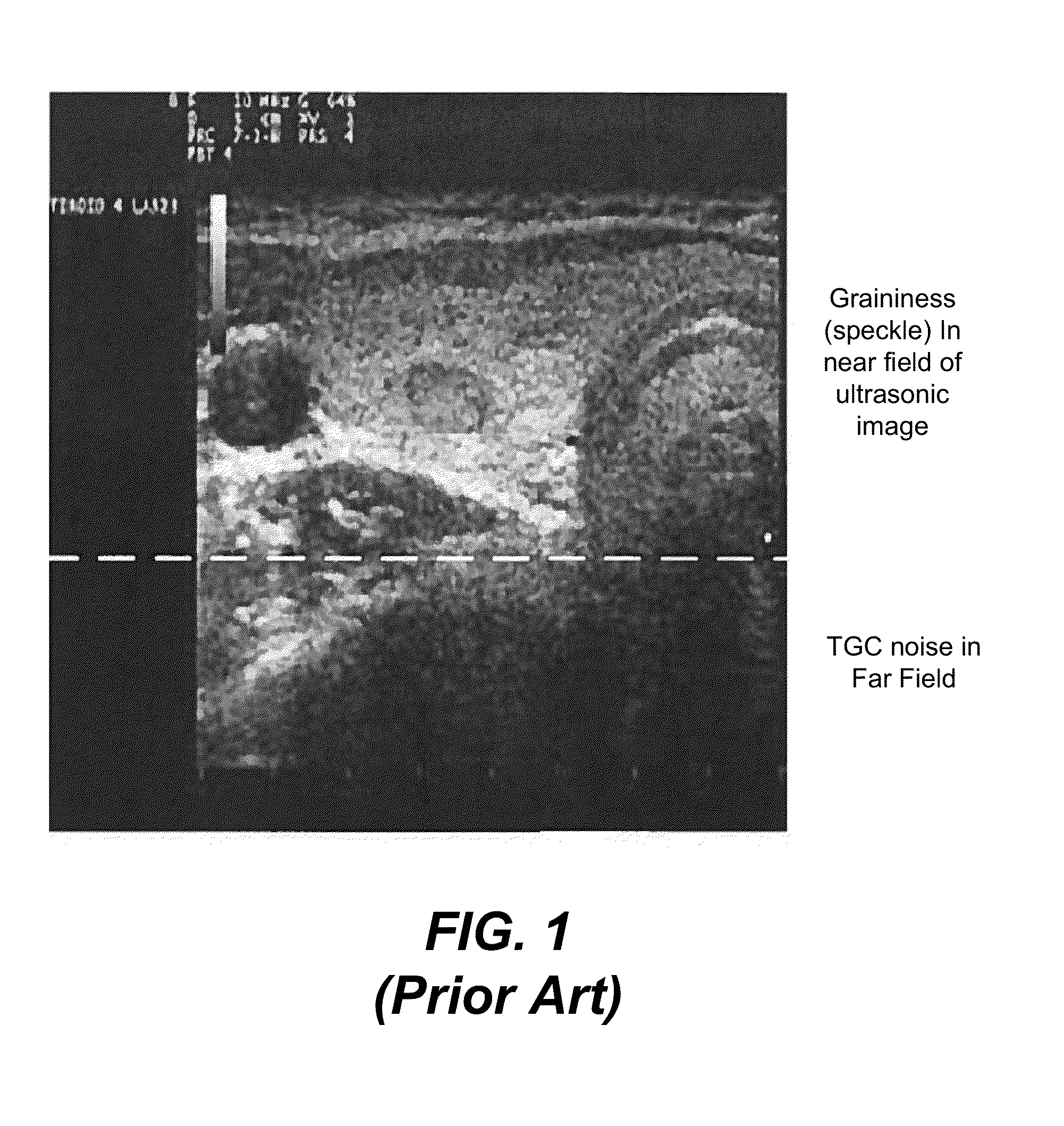

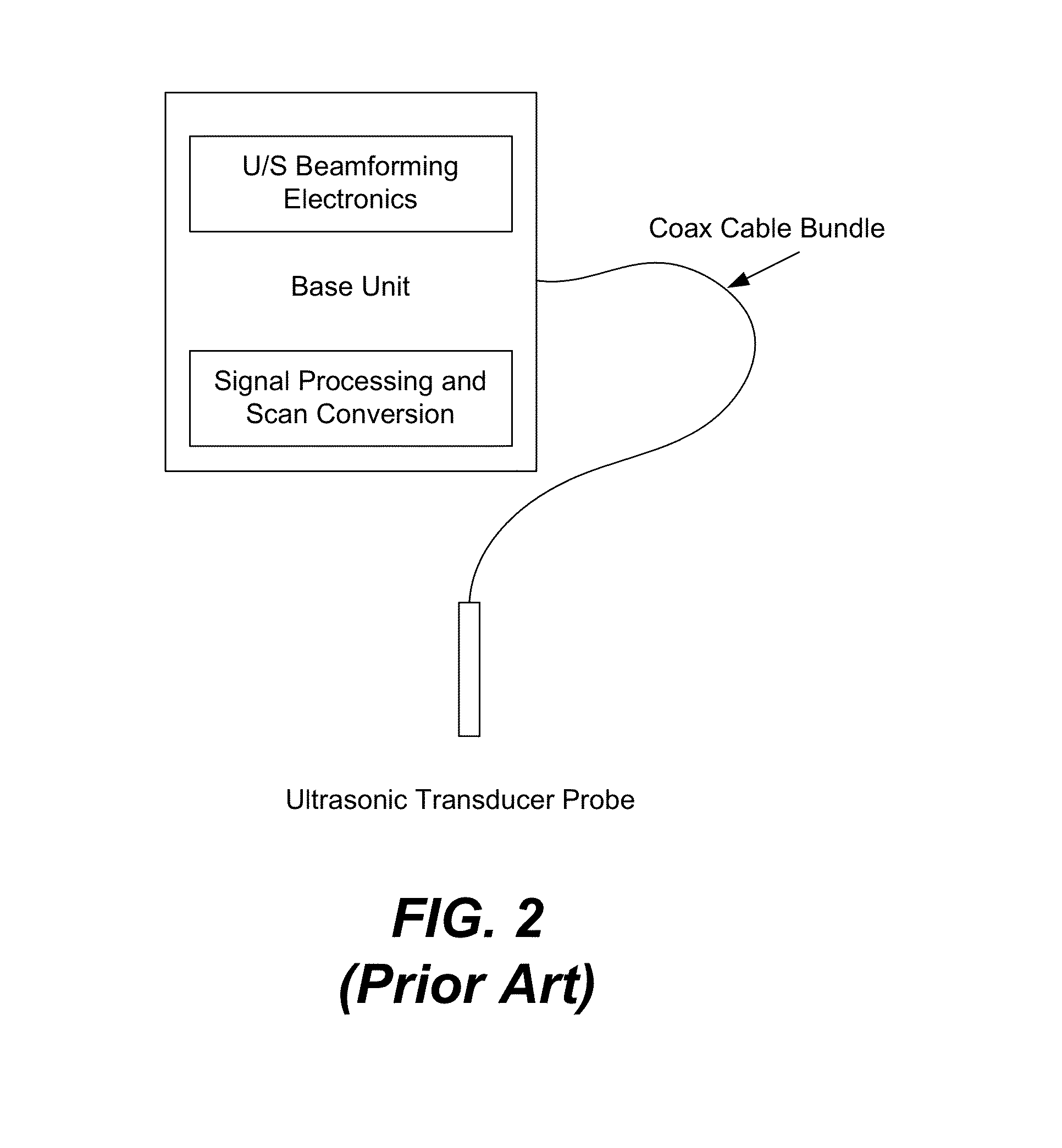

Speckle and noise reduction in ultrasound images

InactiveUS20150094591A1Reduce speckle and time gain compression noiseImprove fluencyOrgan movement/changes detectionMechanical vibrations separationUltrasound imagingSonification

An ultrasound imaging system includes features to reduce speckle and time gain compression noise. A handheld ultrasound system may include beam forming electronics and digital waveform generators to generate the transmitted pulses with fine grained apodization to improve coherence and reduce speckle. Speckle filtering may be included in the ultrasound system. Features to reduce quantization noise and improve the time gain compression response may be provided.

Owner:EAGLEYEMED

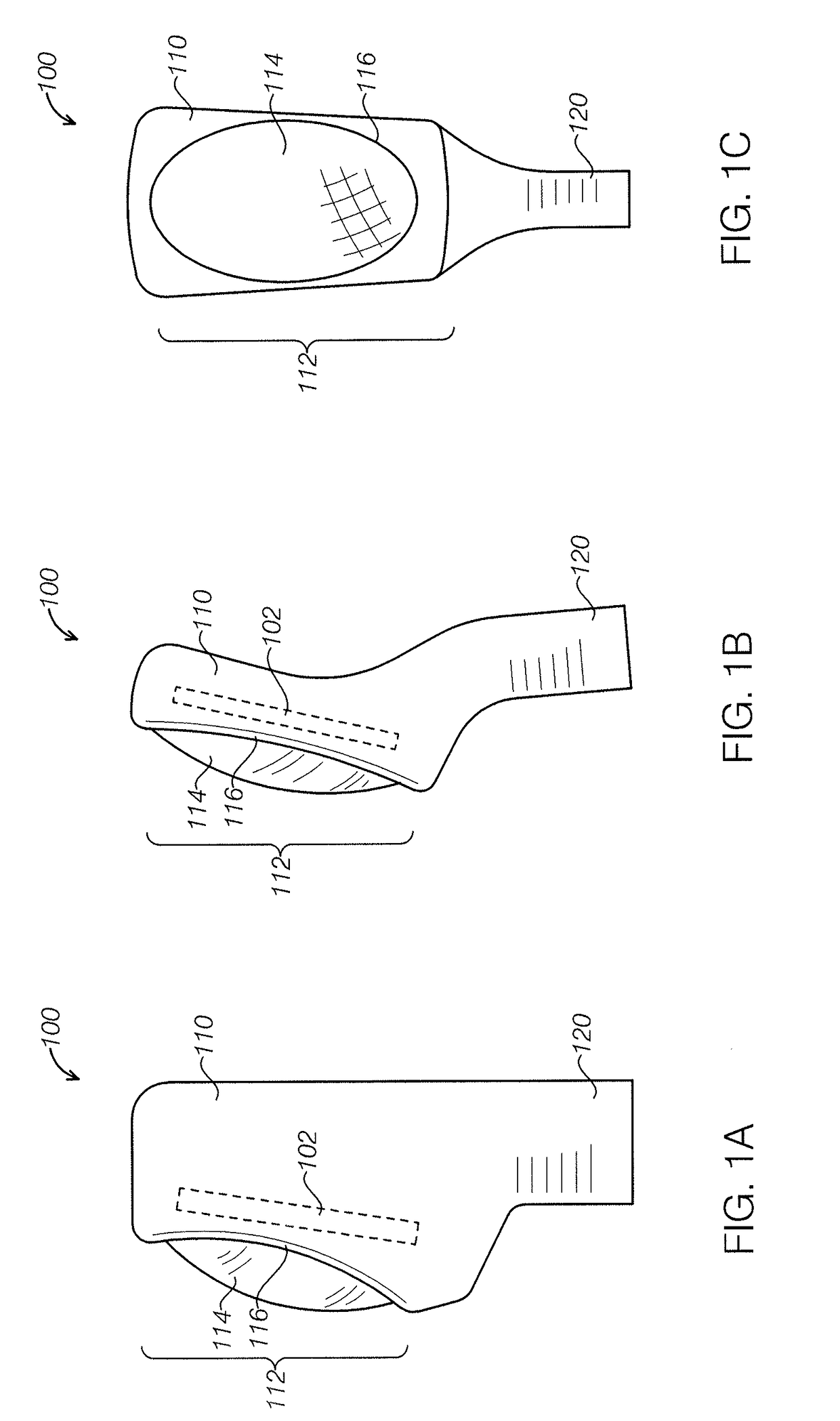

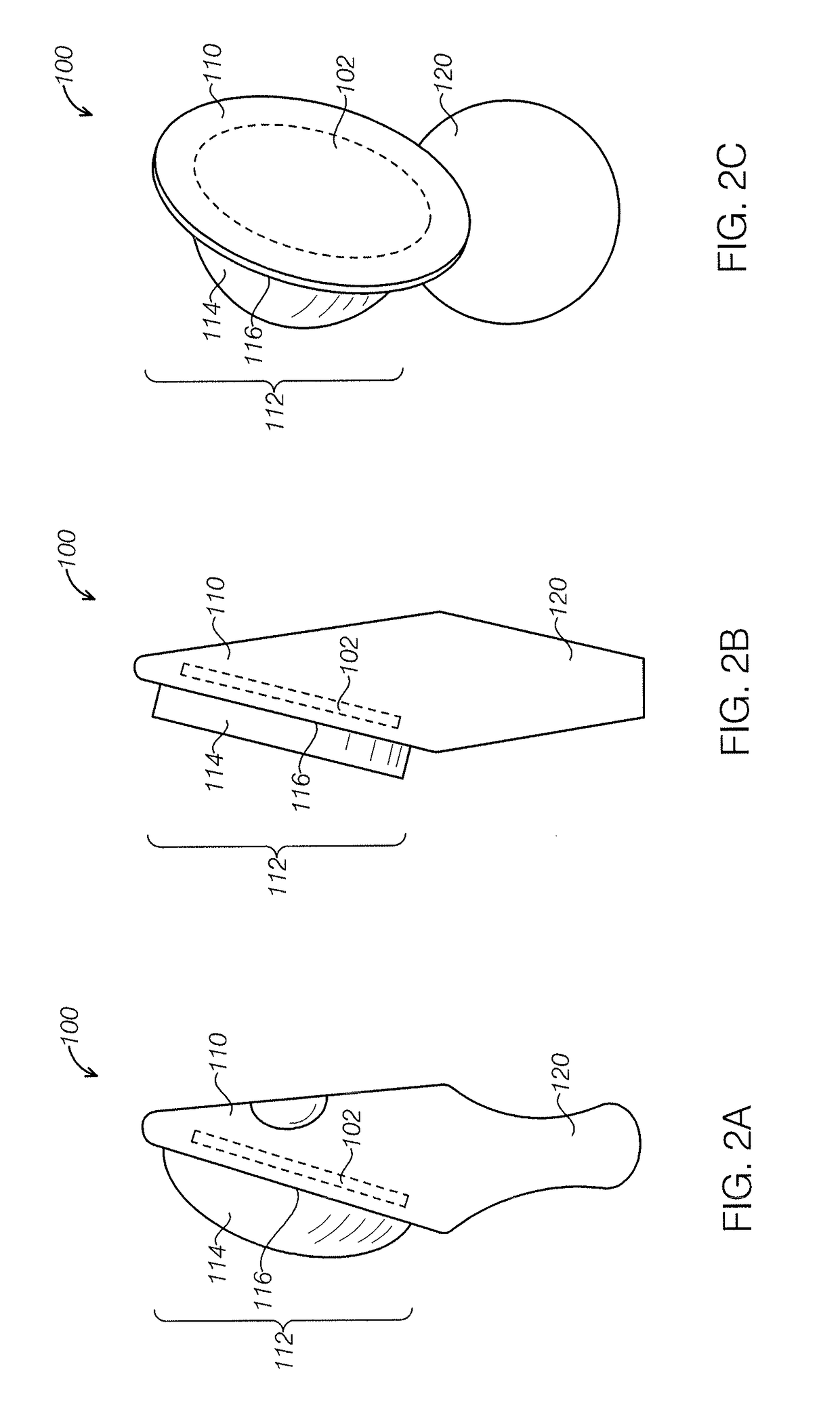

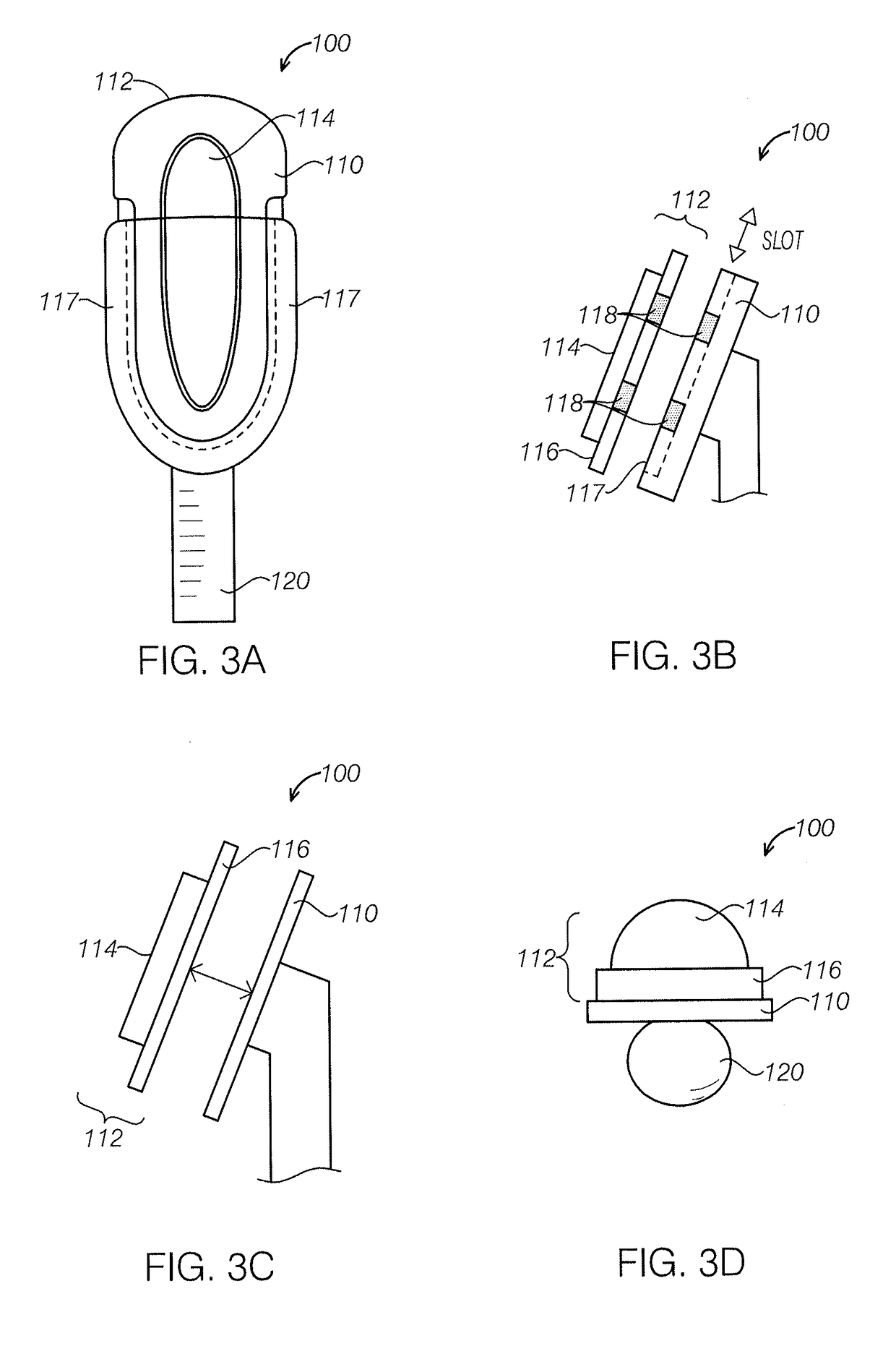

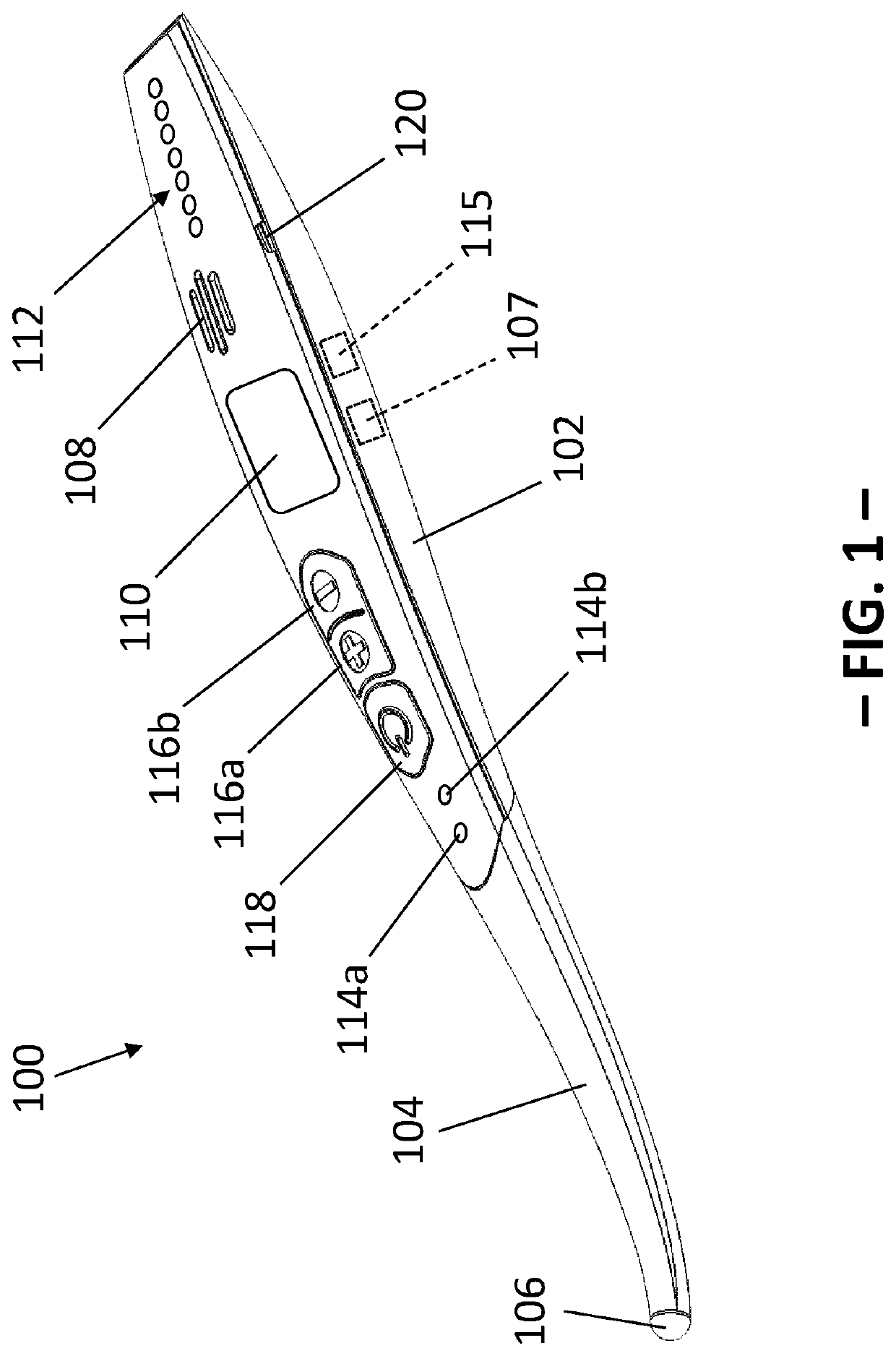

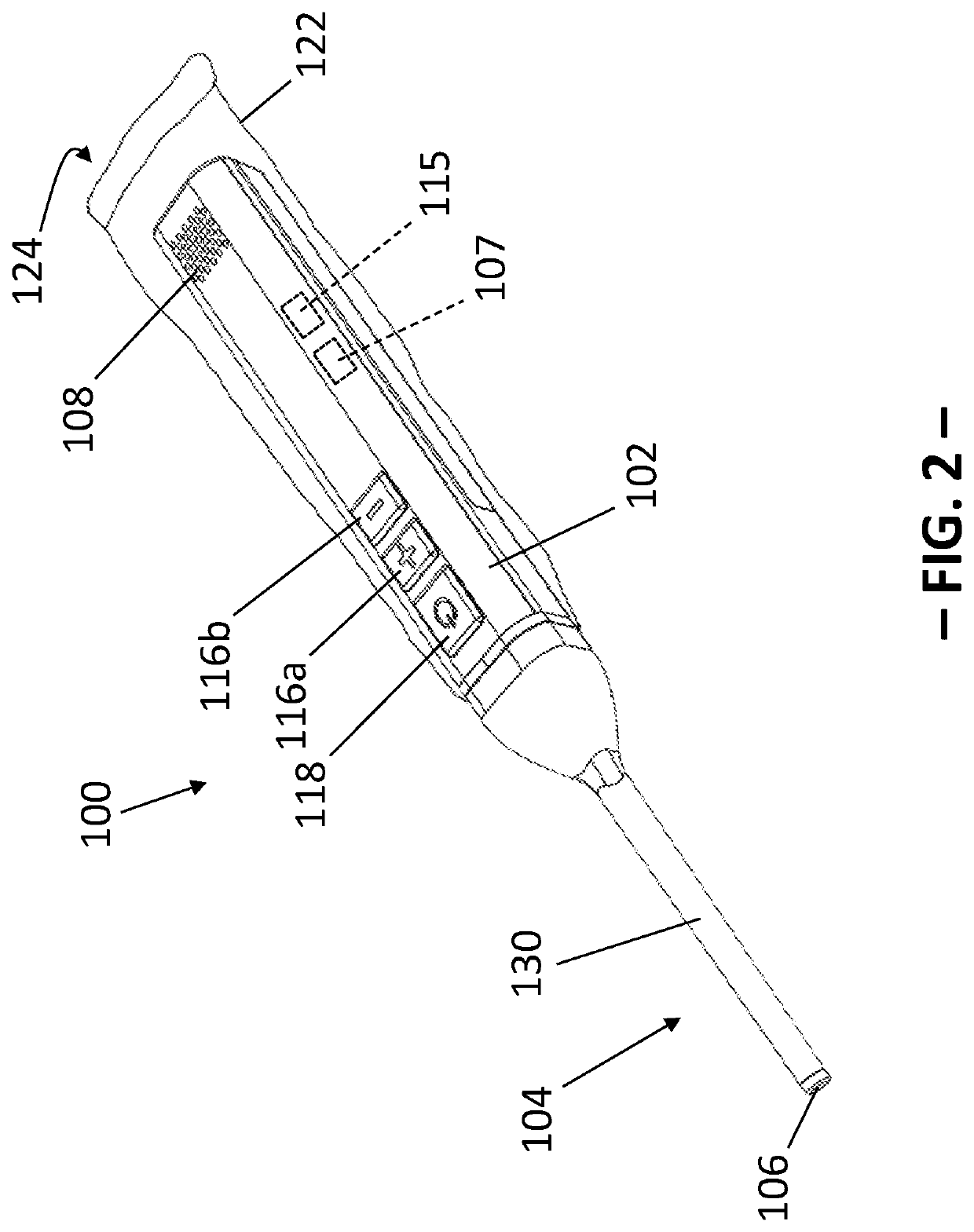

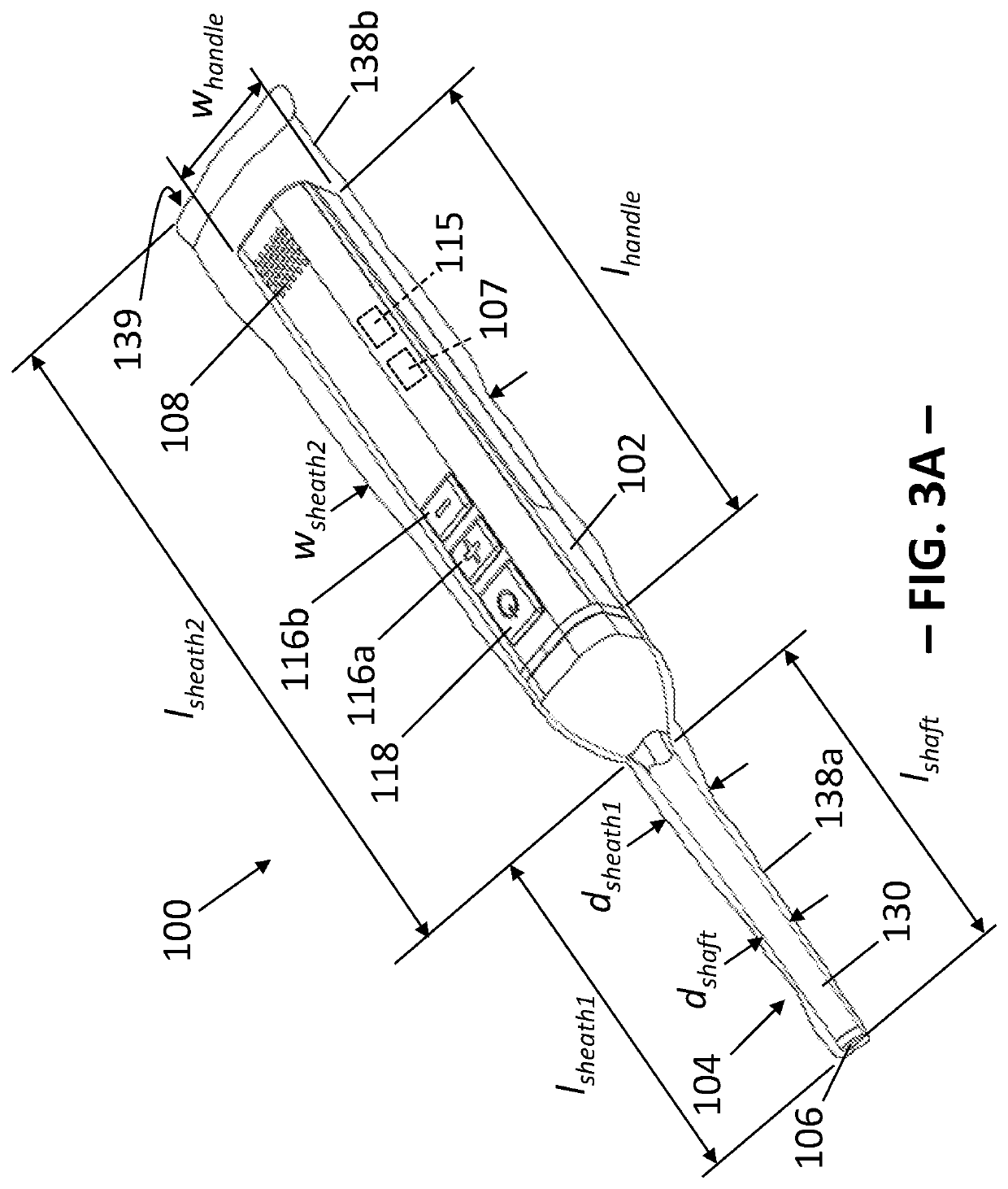

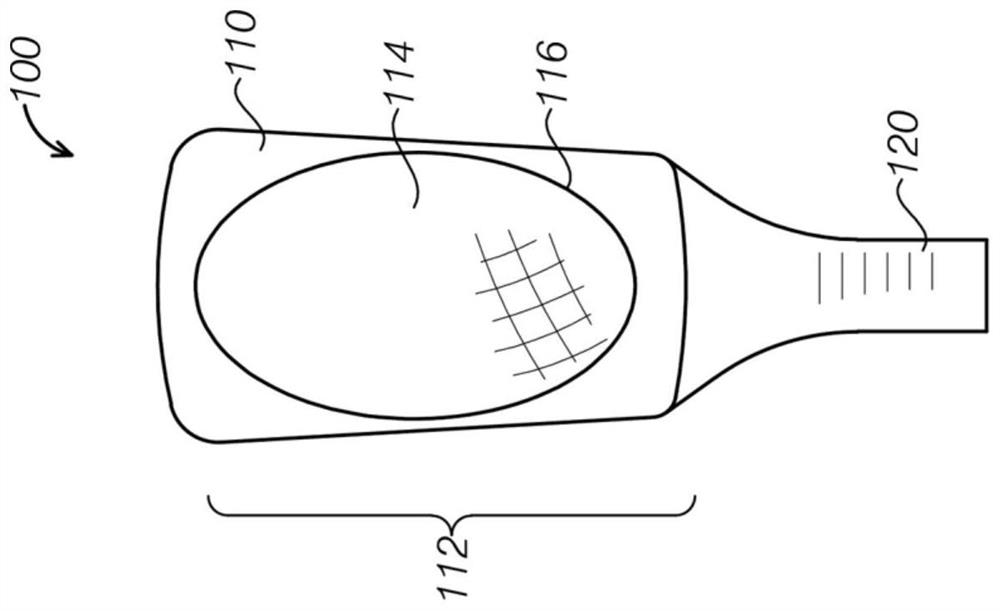

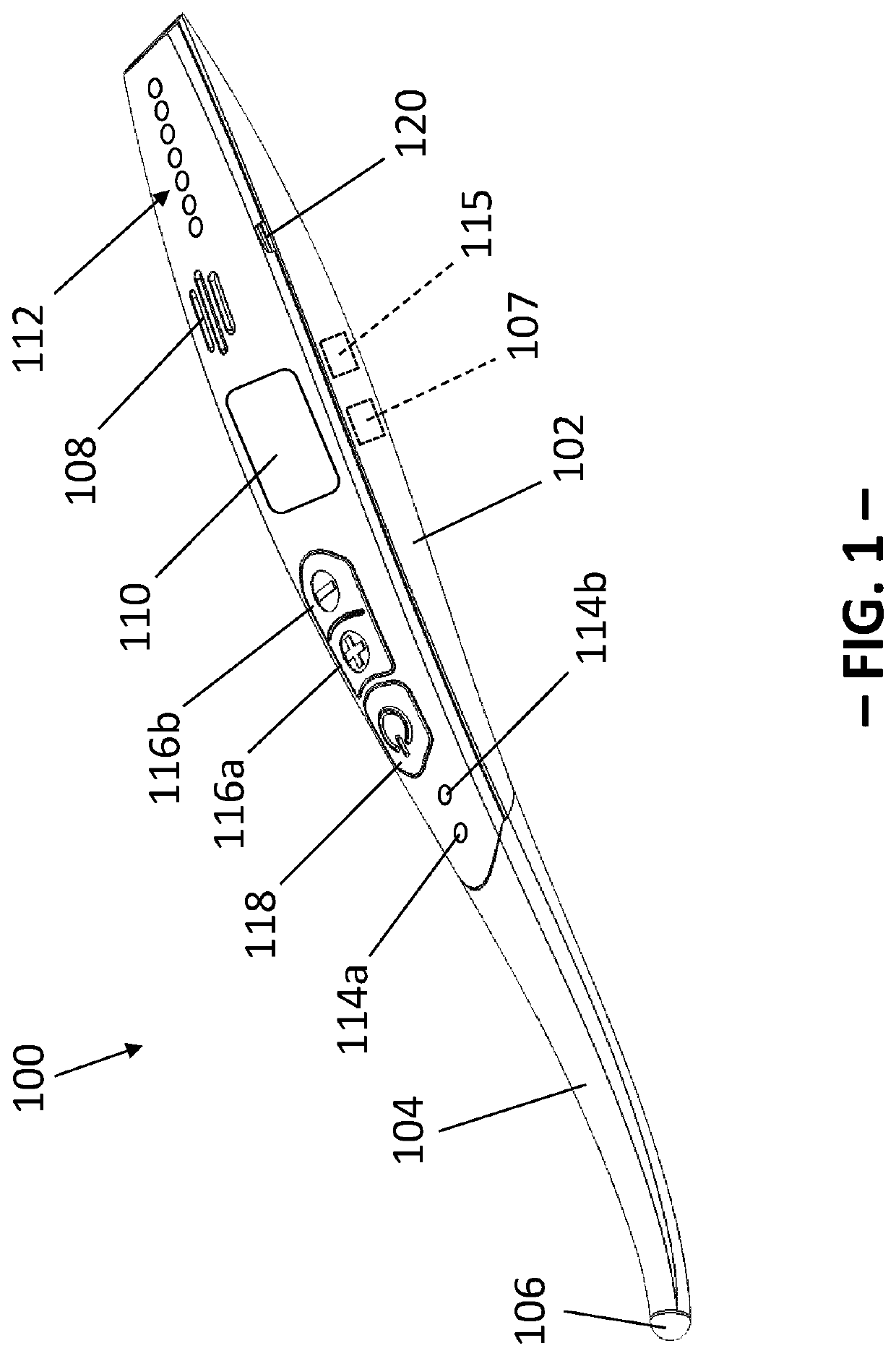

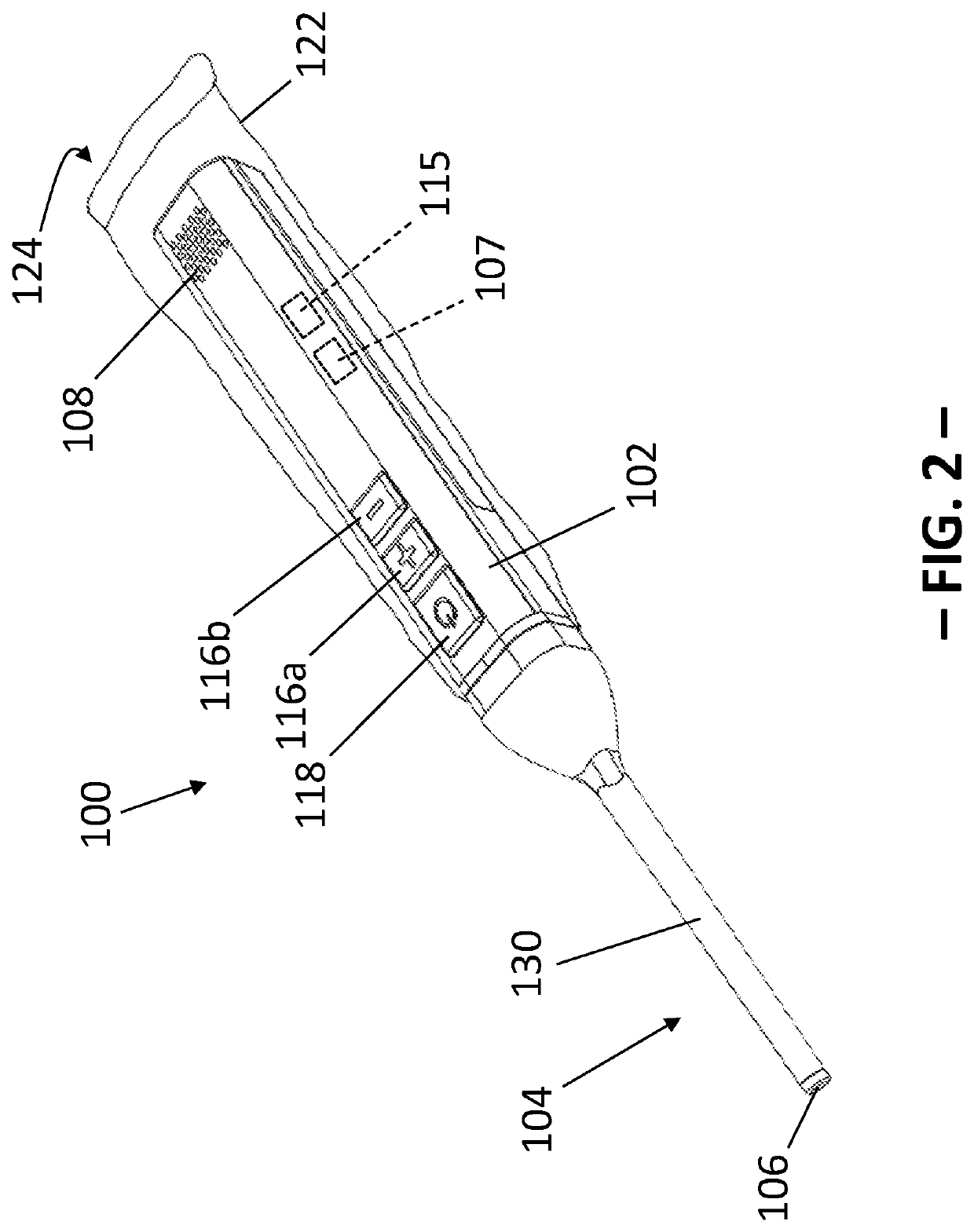

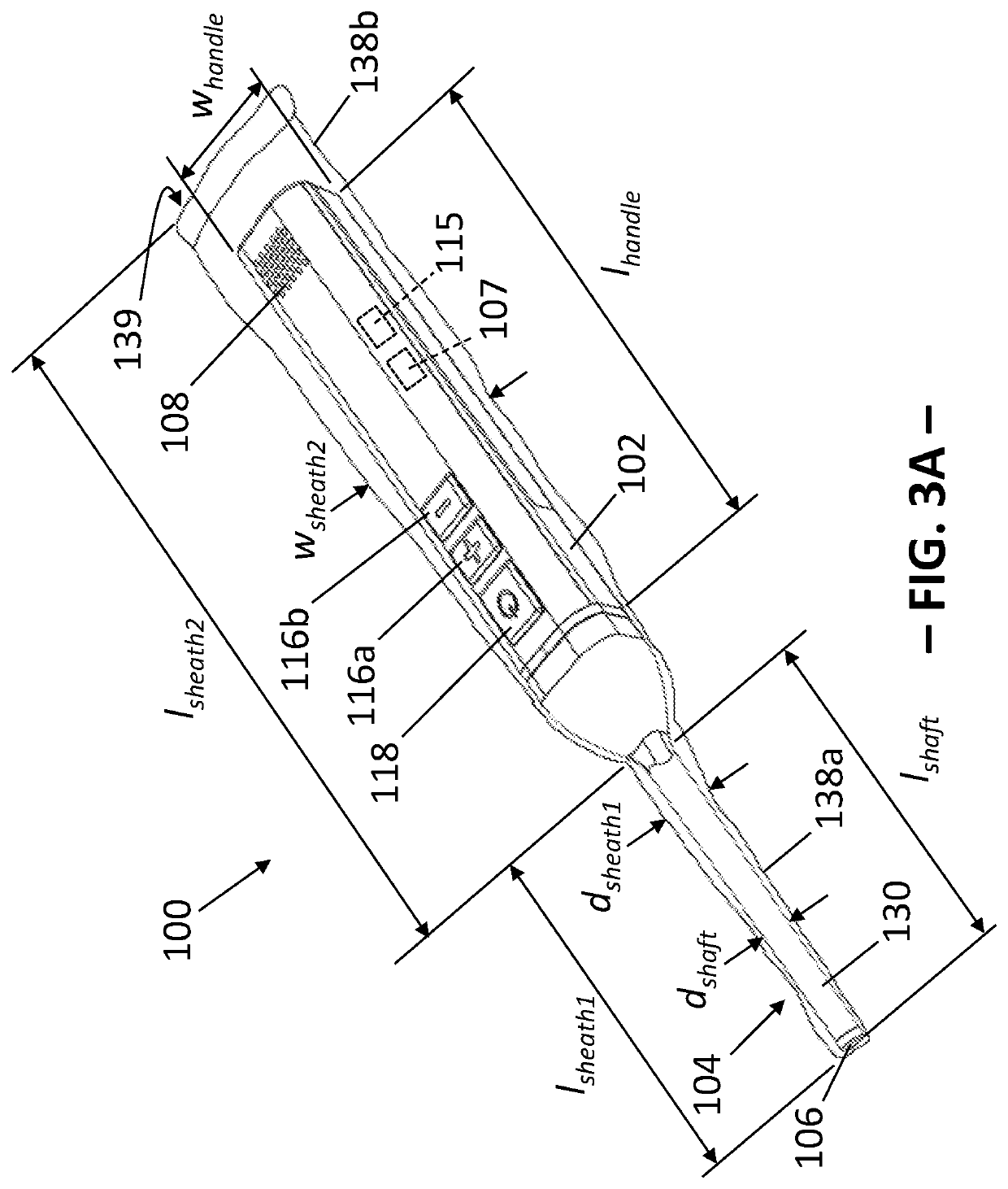

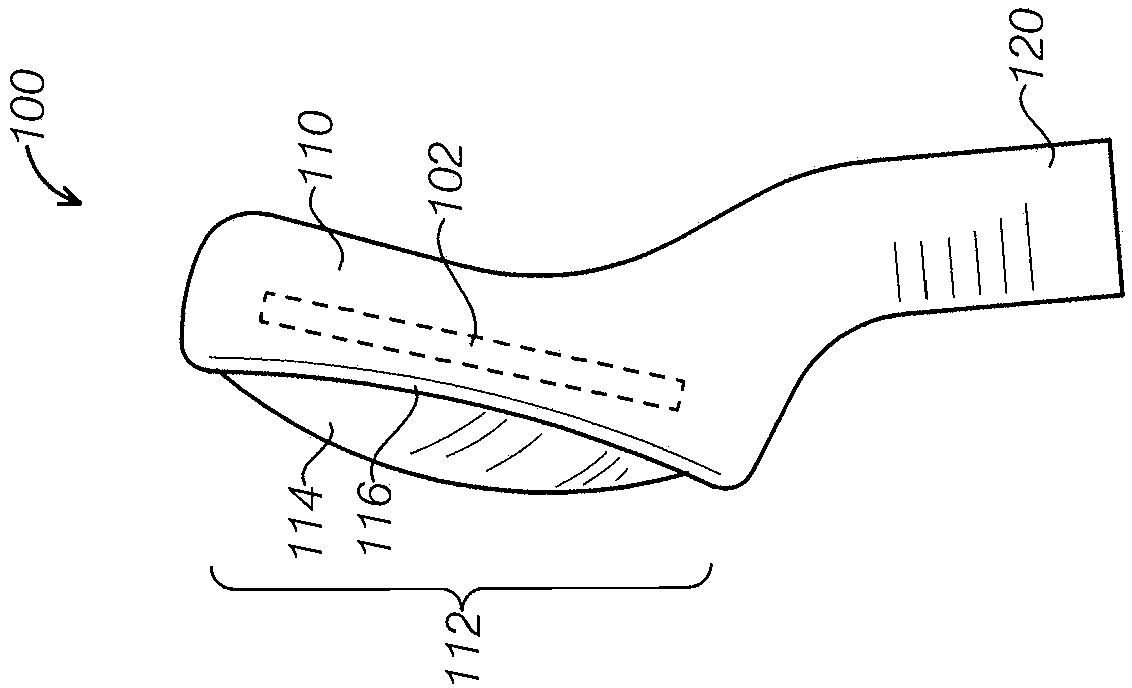

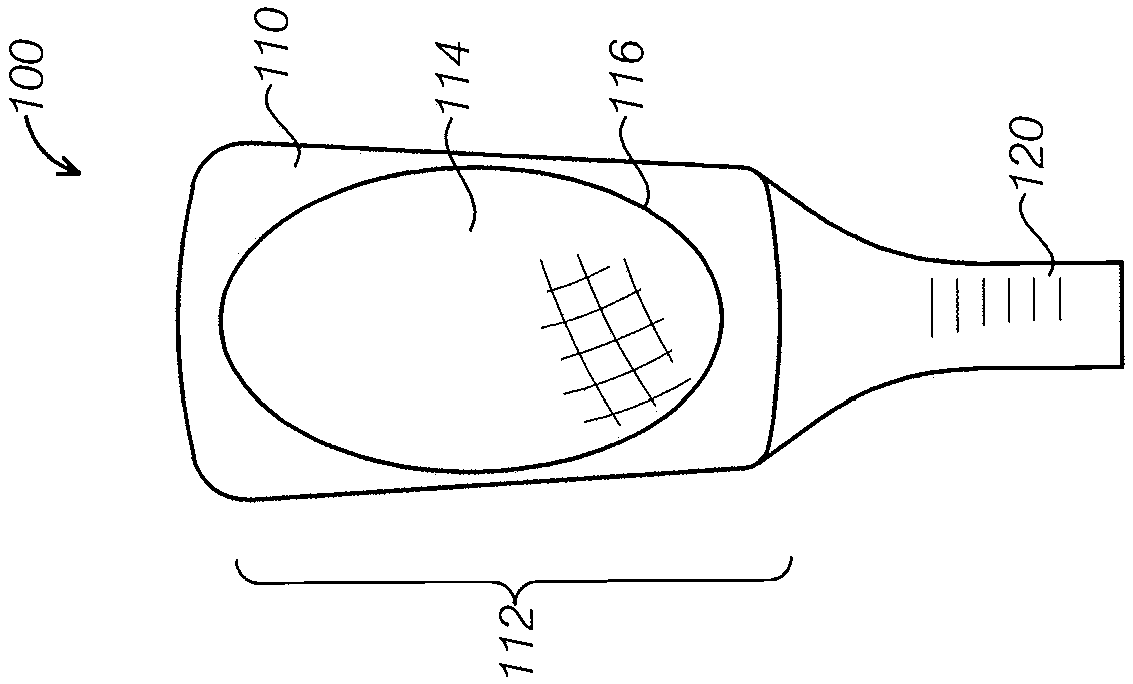

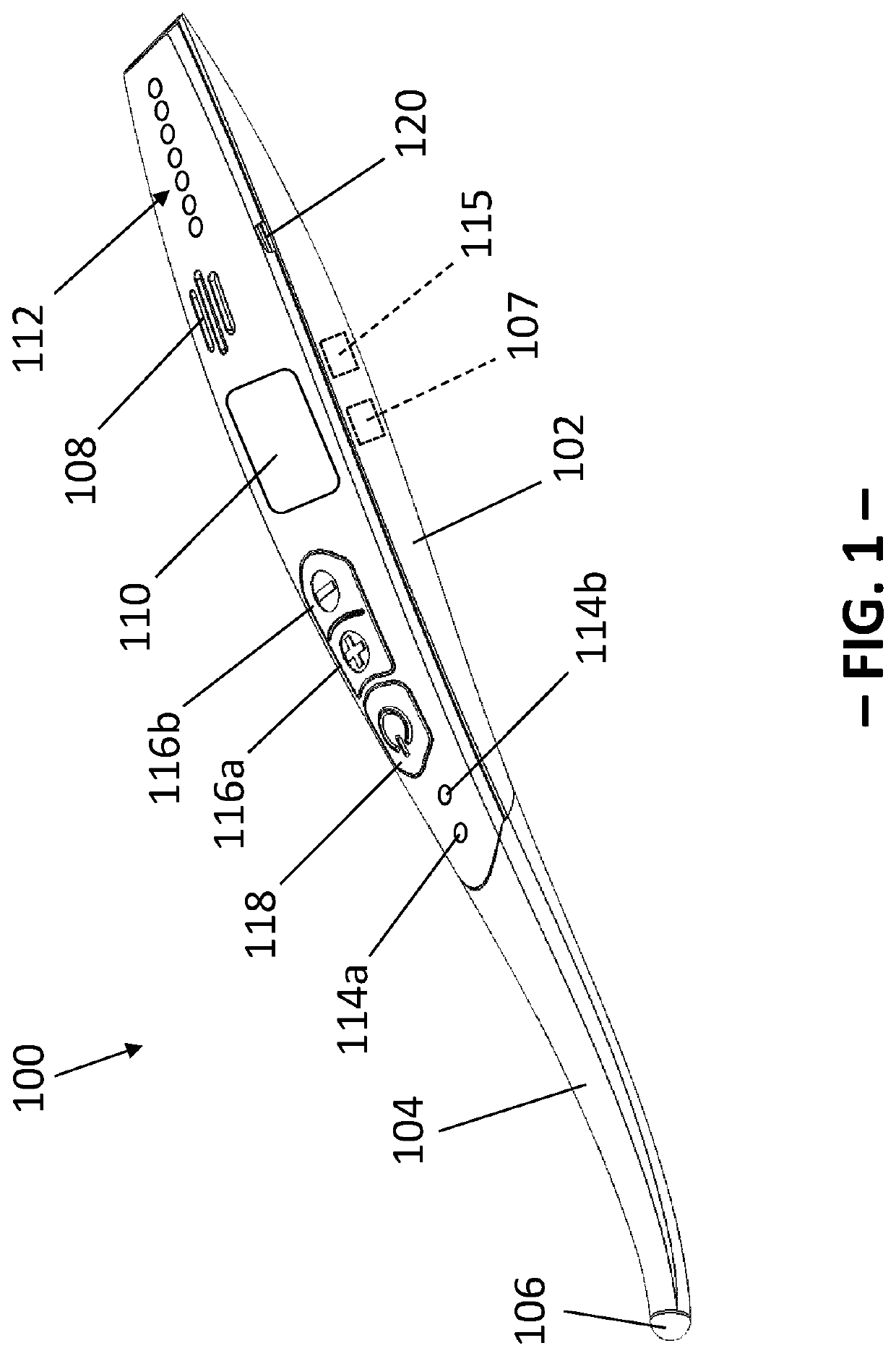

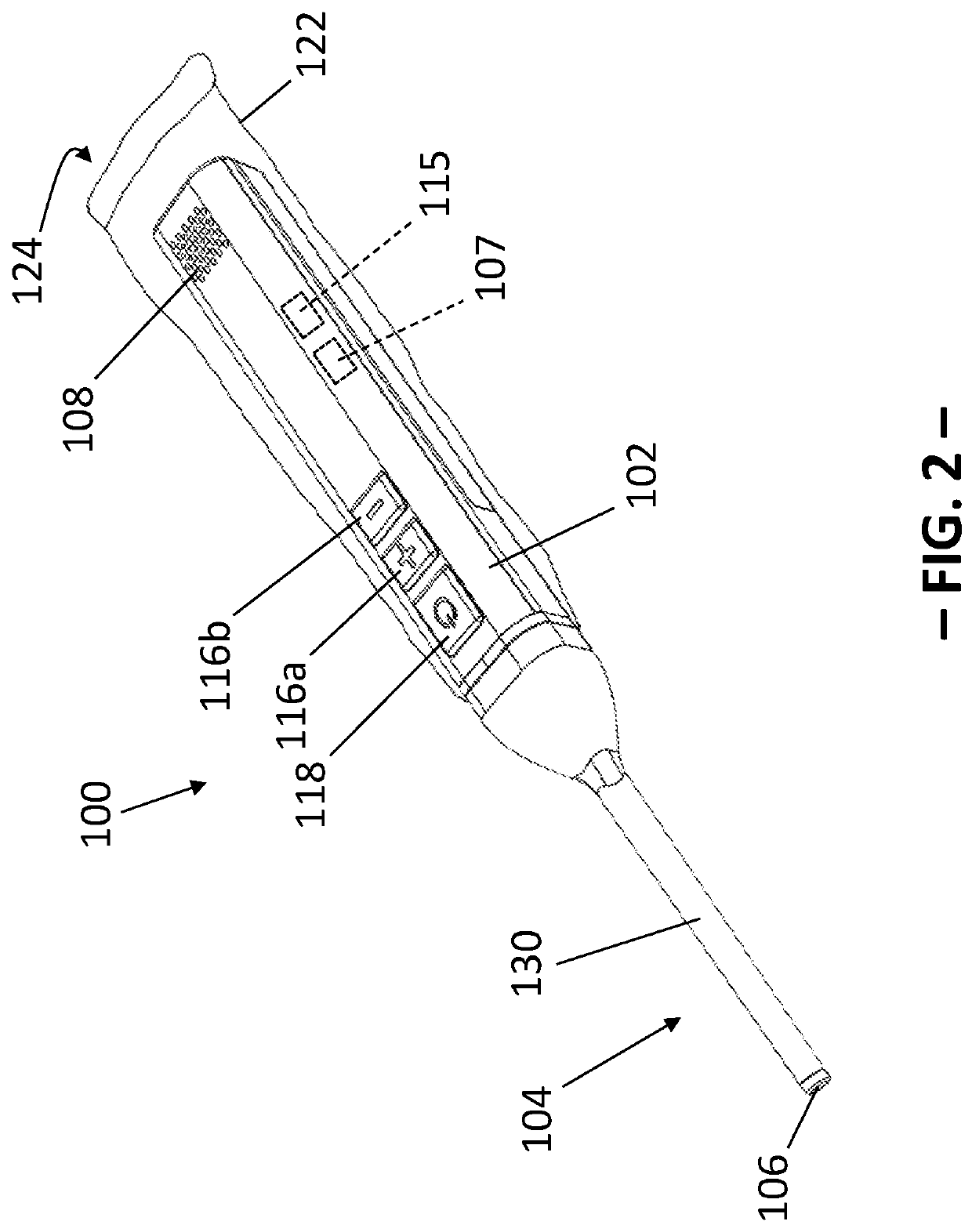

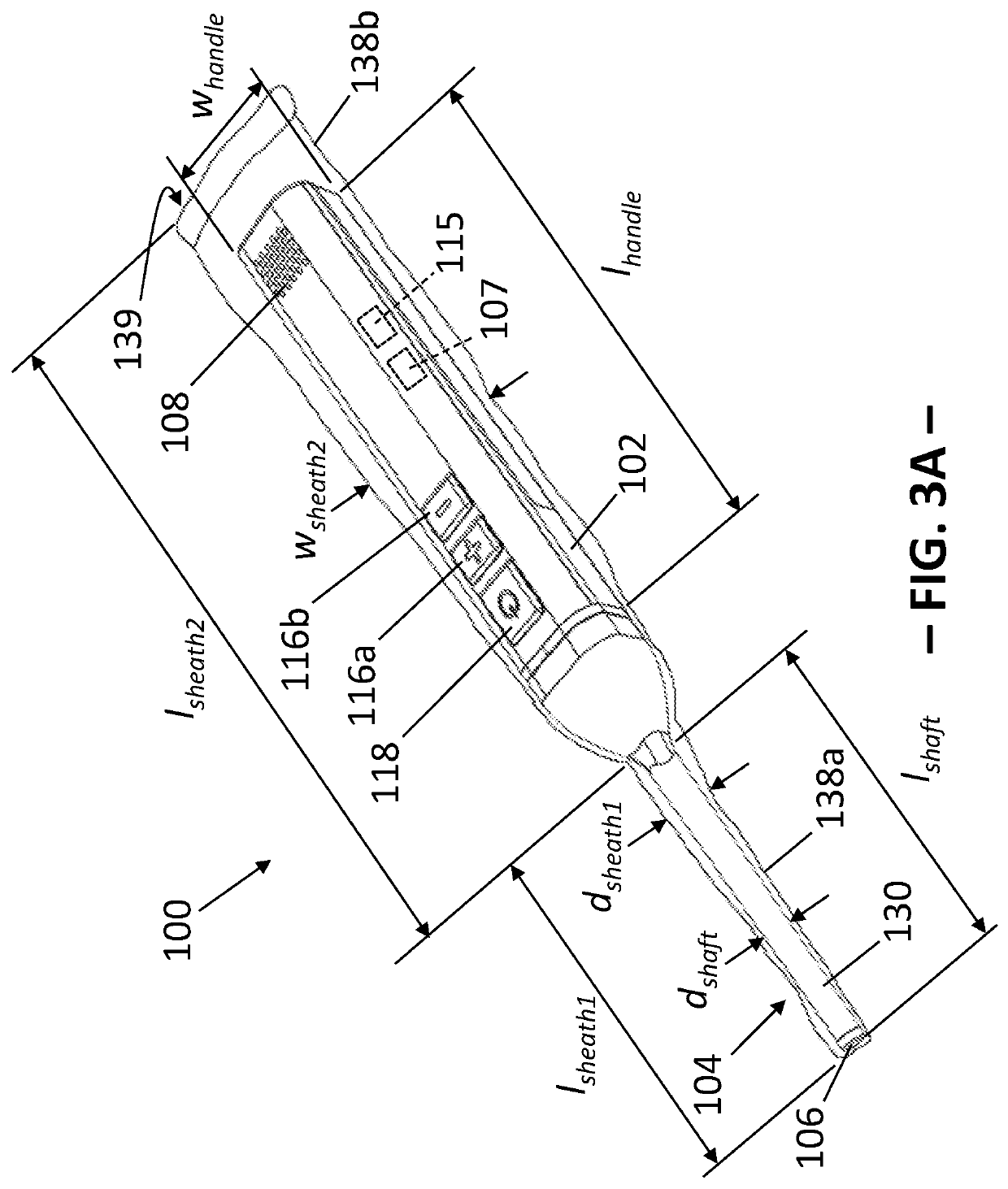

Handheld Ultrasound Device and Replaceable Tips Therefor

PendingUS20190374199A1Blood flow measurement devicesInfrasonic diagnosticsMedicineHandheld ultrasound

Handheld ultrasound devices and replaceable tips for such devices are provided. For example, a handheld ultrasound device comprises a handle and a tip that includes a sensor for transmitting and receiving ultrasound waves. The handle and the tip may be a single, integral, unit or the tip may be separable from the handle. In either embodiment, the handle and tip together are a fully self-contained unit. Also provided are handheld ultrasound sterile assemblies, comprising a handheld ultrasound device and a sheath that fully covers the device to provide a sterile barrier for the device. Further, tips for handheld ultrasound devices are provided. The tips may be a replaceable component of the handheld ultrasound devices. For example, the tips may be configured for one-time use, and the tip rather than the entire handheld ultrasound device may be replaced between procedures such that a new tip is used in a subsequent procedure.

Owner:REMINGTON MEDICAL

Ultrasound device with attachable components

PendingCN114206440AUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyUltrasound deviceHandheld ultrasound

A handheld ultrasound device and corresponding method, including devices and methods for restoring a vulvovaginal region of a user. Generally, a handheld ultrasound device includes a device body coupled to an acoustic coupler and a handle. The device body further includes an internal component including an ultrasonic transducer, an energy delivery element, and circuitry for controlling the ultrasonic output. In a particular example, a method of using a handheld ultrasound device includes: engaging tissue in a vulvovaginal region and tissue around the vulvovaginal region with an energy delivery element; applying ultrasonic energy from the energy delivery element to vulvovaginal tissue through an acoustic coupler; and affecting measurable parameters associated with vulvovaginal reconstitution.

Owner:MADORRA INC

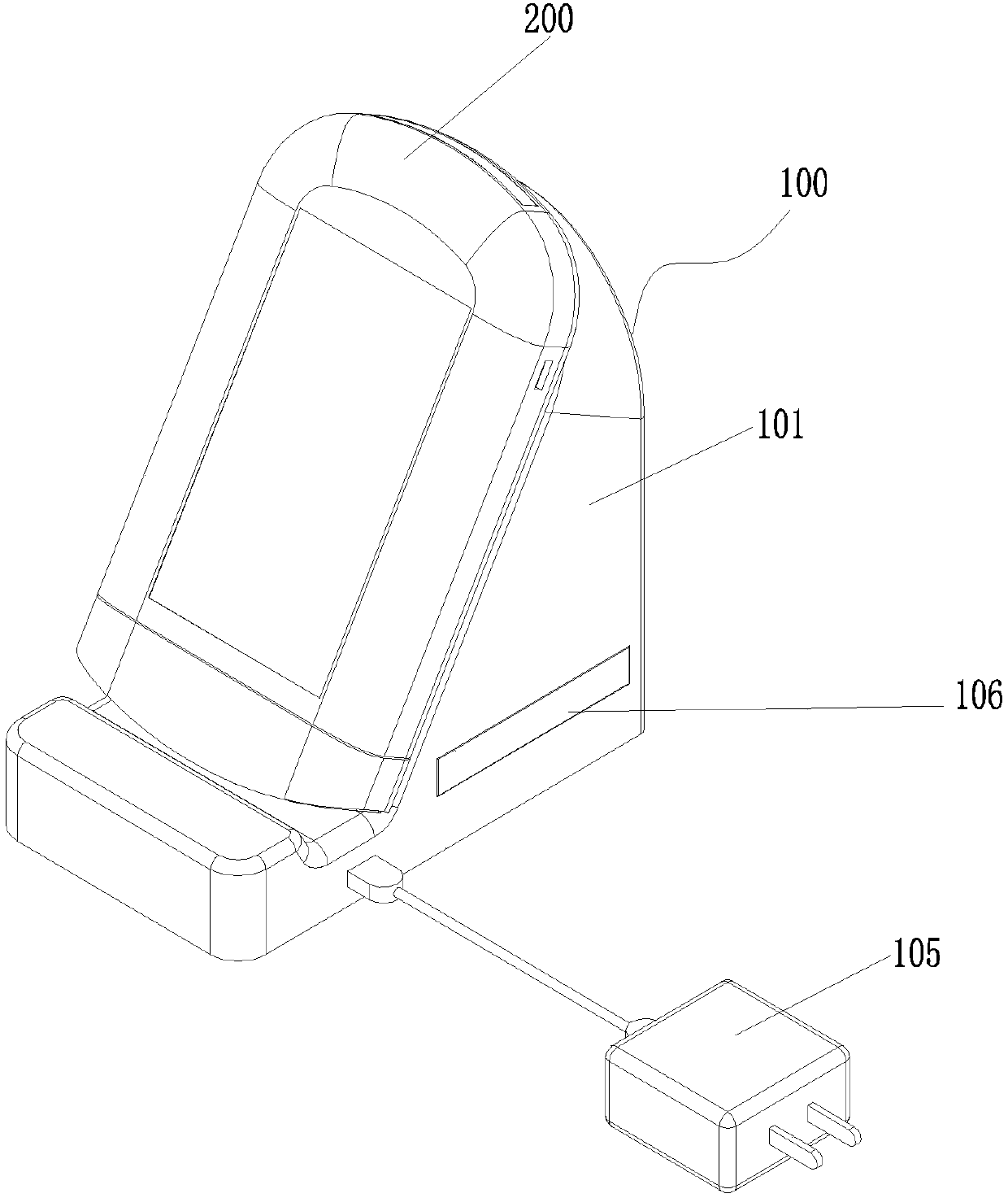

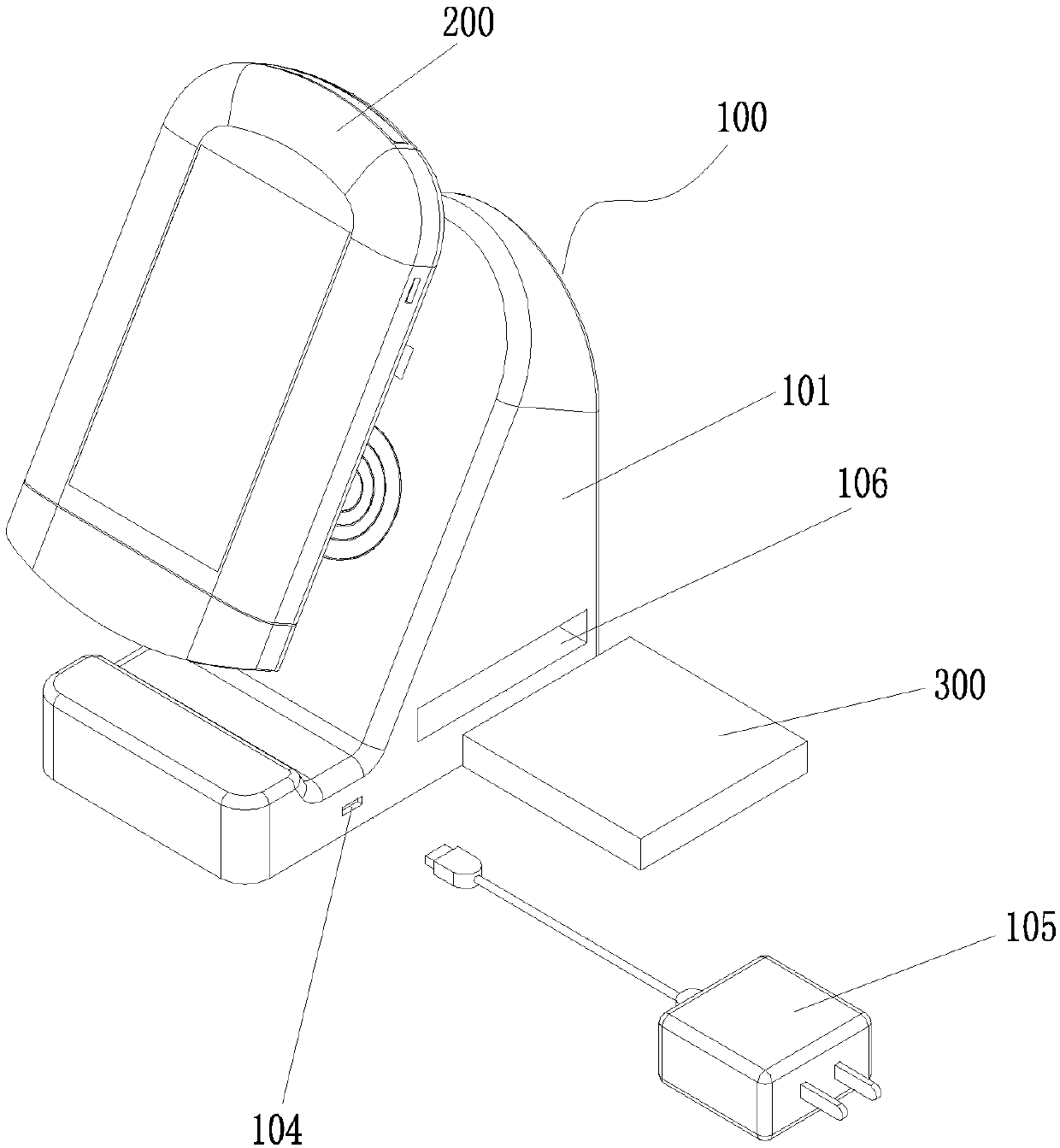

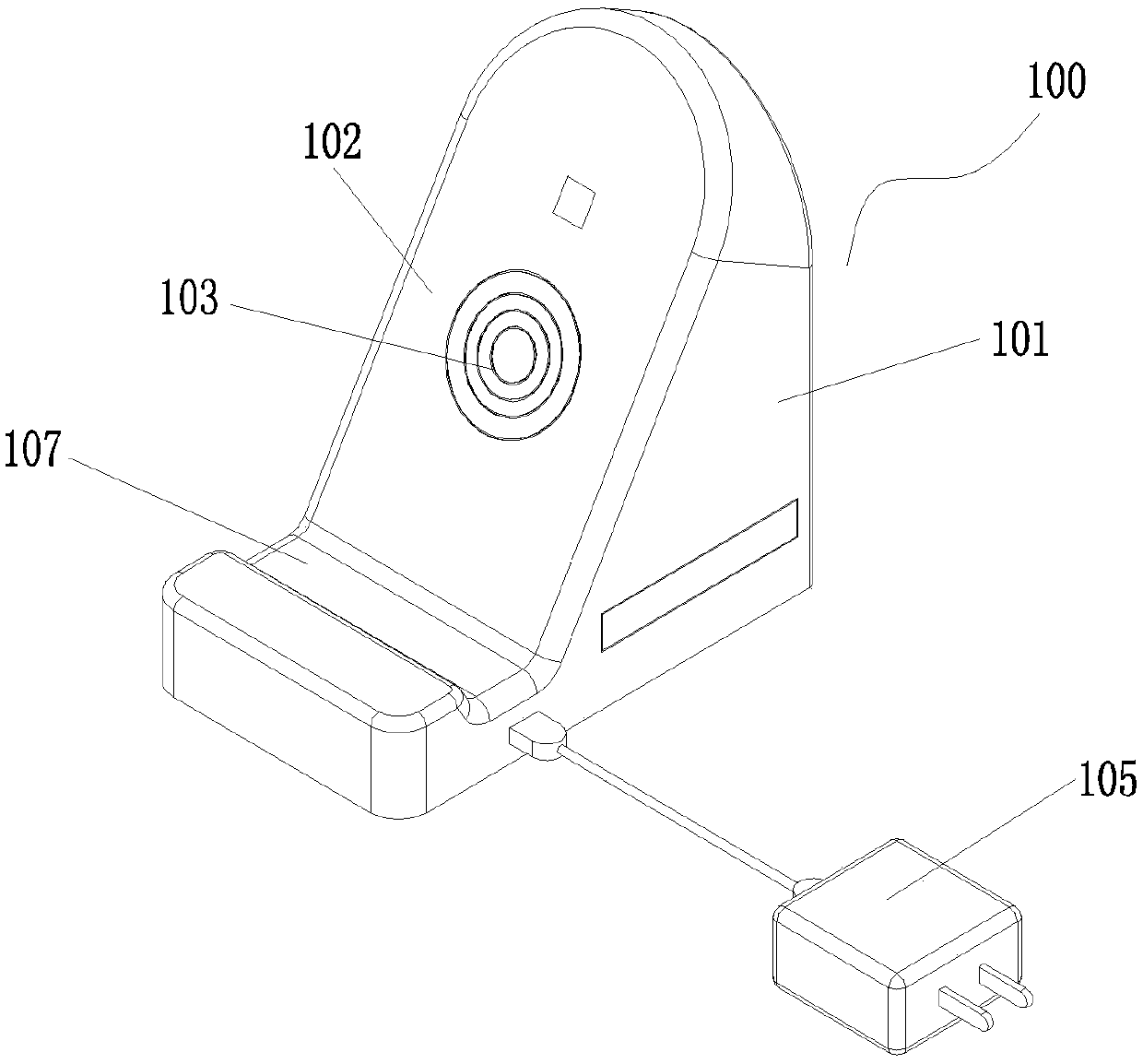

Handheld ultrasonic charging system and device

PendingCN107769336AEasy to useDoes not affect normal workBatteries circuit arrangementsElectric powerBattery chargeHandheld ultrasound

The invention relates to a handheld ultrasonic charging system and device. The handheld ultrasonic charging device comprises a charging support, and a charging interface used for providing a power interface is arranged on the charging support; a supporting surface used for holding handheld ultrasonic equipment is arranged on the charging support, and a charging position corresponding to a batteryarea of the handheld ultrasonic equipment is arranged on the supporting surface; the charging position is used for charging a battery contained in the handheld ultrasonic equipment in a wired or wireless mode. The handheld ultrasonic charging system can be used for charging the handheld ultrasonic equipment in the wired or wireless mode, and is convenient to use.

Owner:CHISON MEDICAL TECH CO LTD

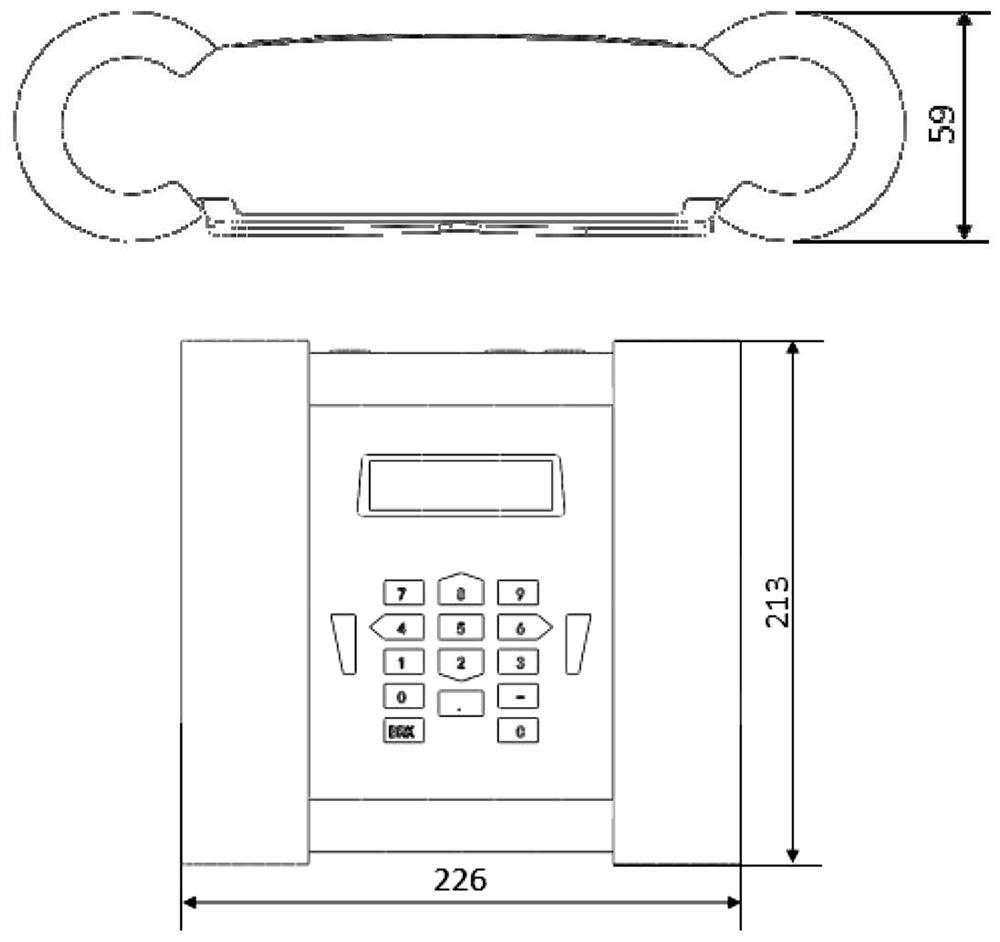

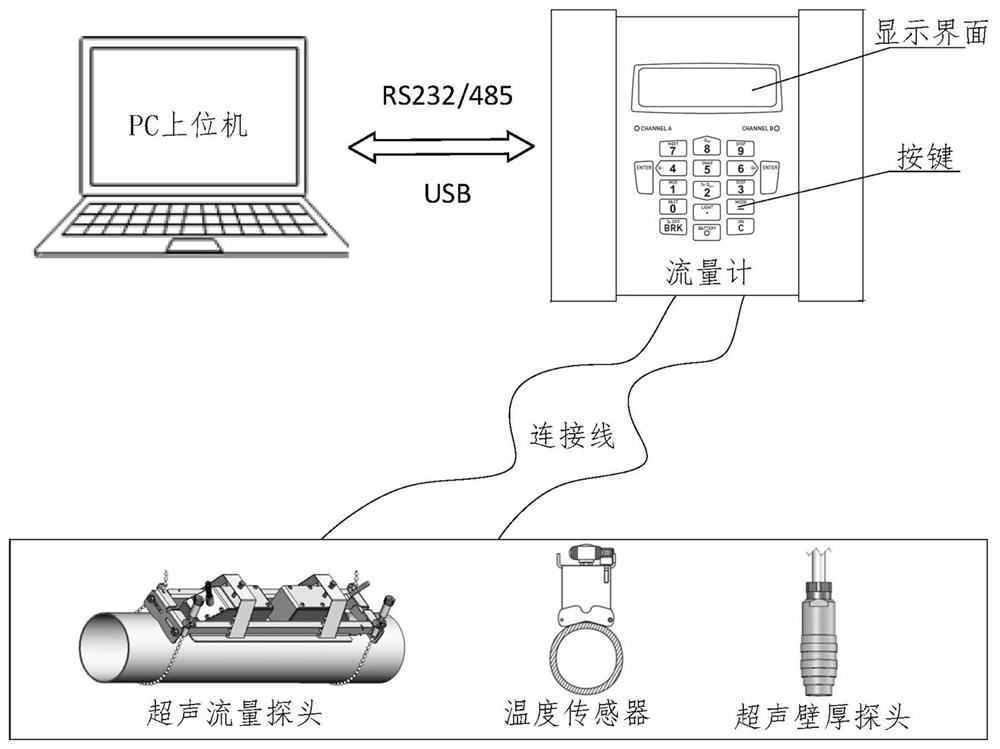

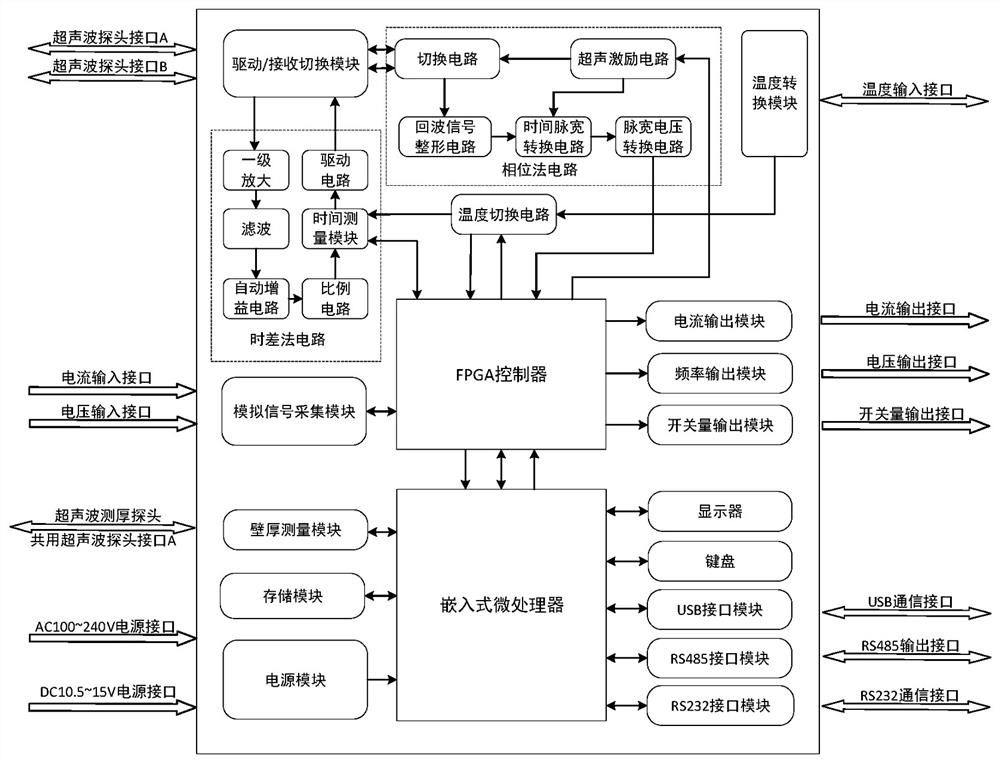

Intelligent ultrasonic measurement system and measurement method

The invention discloses an intelligent ultrasonic measurement system and a measurement method, and belongs to the field of measurement instruments in the industrial field. The measurement system is an instrument capable of measuring flow, temperature, wall thickness and the like in a pipeline in different field environments, the core of the measurement system is a handheld ultrasonic measuring instrument, and the handheld ultrasonic measuring instrument is a handheld intelligent flow measuring instrument with an embedded microprocessor as a control core. The whole measurement system is composed of an ultrasonic flow measuring instrument, an ultrasonic flow probe, a temperature sensor, an ultrasonic wall thickness probe, a fixing support, a clamp, a PC and the like, and achieves flow, temperature and wall thickness measurement. The system has the functions of key operation, test parameter setting, test result display and the like, can achieve flow measurement under different pipe diameters, different media and different environments, has the remarkable advantages of being wide in measurement range, high in environmental adaptability, high in precision and the like, and can meet the application requirements in the military and civil fields.

Owner:ZHONGBEI UNIV

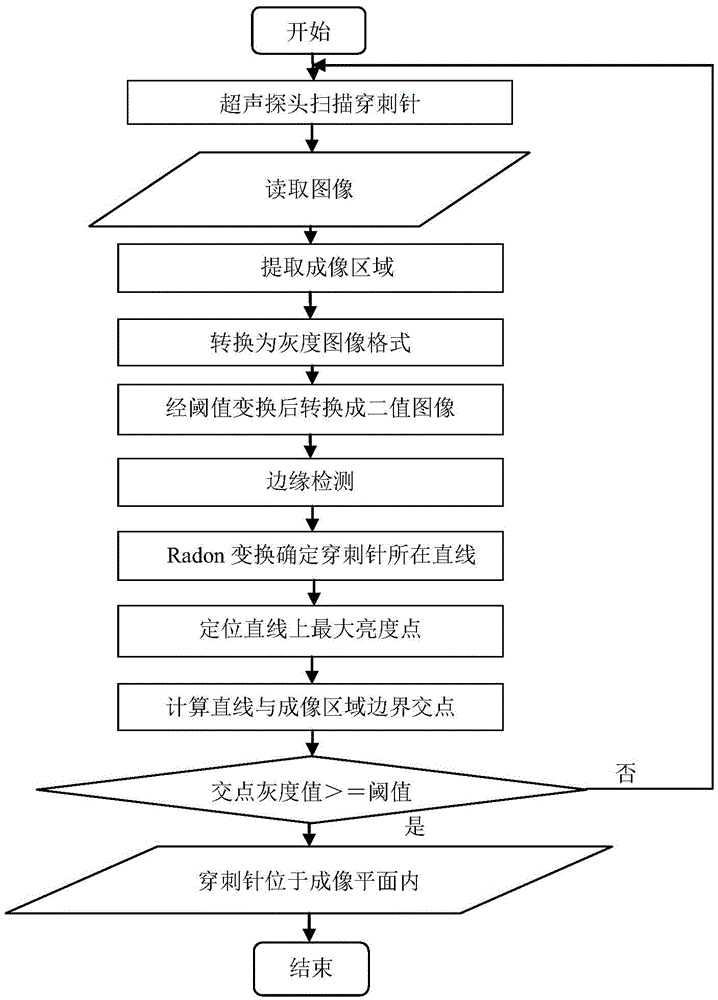

A method for judging coplanarity between two-dimensional ultrasound image and puncture needle

ActiveCN104248454BRealize TrackingRealize tracking and positioningUltrasonic/sonic/infrasonic diagnosticsSurgeryColor imageUltrasound imaging

The present invention relates to a method for judging the coplanarity between a two-dimensional ultrasonic image and a puncture needle. A hand-held ultrasonic probe scans the puncture needle in the tissue, and saves the ultrasonic image of the puncture needle in the tissue. It is characterized in that: step 1: extracting the imaging area on the ultrasonic image, Convert the color image to a grayscale image, and convert it into a binary image after threshold transformation; Step 2: Perform edge detection on the binary image obtained in Step 1, and determine the straight line where the puncture needle is located through Radon transformation; Step 3: Locate the puncture needle The position of the needle tip; step 4: determine whether the puncture needle is located in the imaging plane by judging whether the gray value of the intersection point of the straight line where the puncture needle is located and the boundary of the ultrasound imaging area is greater than a certain threshold.

Owner:HARBIN ENG UNIV

Handheld Ultrasound Device and Replaceable Tips Therefor

InactiveUS20190374201A1Blood flow measurement devicesOrgan movement/changes detectionMedicineHandheld ultrasound

Handheld ultrasound devices and replaceable tips for such devices are provided. For example, a handheld ultrasound device comprises a handle and a tip that includes a sensor for transmitting and receiving ultrasound waves. The handle and the tip may be a single, integral, unit or the tip may be separable from the handle. In either embodiment, the handle and tip together are a fully self-contained unit. Also provided are handheld ultrasound sterile assemblies, comprising a handheld ultrasound device and a sheath that fully covers the device to provide a sterile barrier for the device. Further, tips for handheld ultrasound devices are provided. The tips may be a replaceable component of the handheld ultrasound devices. For example, the tips may be configured for one-time use, and the tip rather than the entire handheld ultrasound device may be replaced between procedures such that a new tip is used in a subsequent procedure.

Owner:REMINGTON MEDICAL

Speckle and noise reduction in ultrasound images

InactiveUS20140358005A1Speckle reductionReduce time gain compression noiseOrgan movement/changes detectionMechanical vibrations separationUltrasound imagingSonification

An ultrasound imaging system includes features to reduce speckle and time gain compression noise. A handheld ultrasound system may include beam forming electronics and digital waveform generators to generate the transmitted pulses with fine grained apodization to improve coherence and reduce speckle. Speckle filtering may be included in the ultrasound system. Features to reduce quantization noise and improve the time gain compression response may be provided.

Owner:EAGLEYEMED

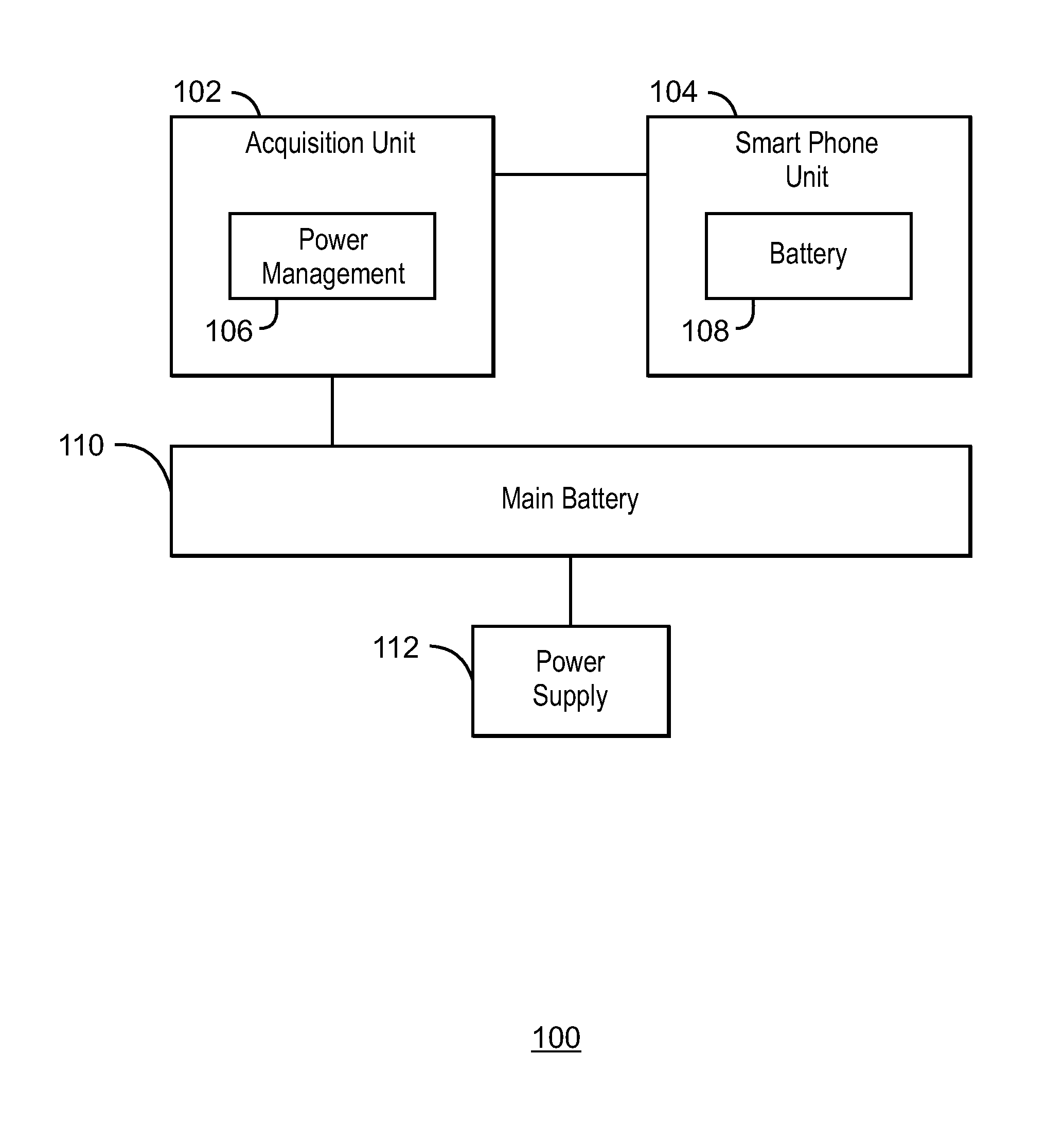

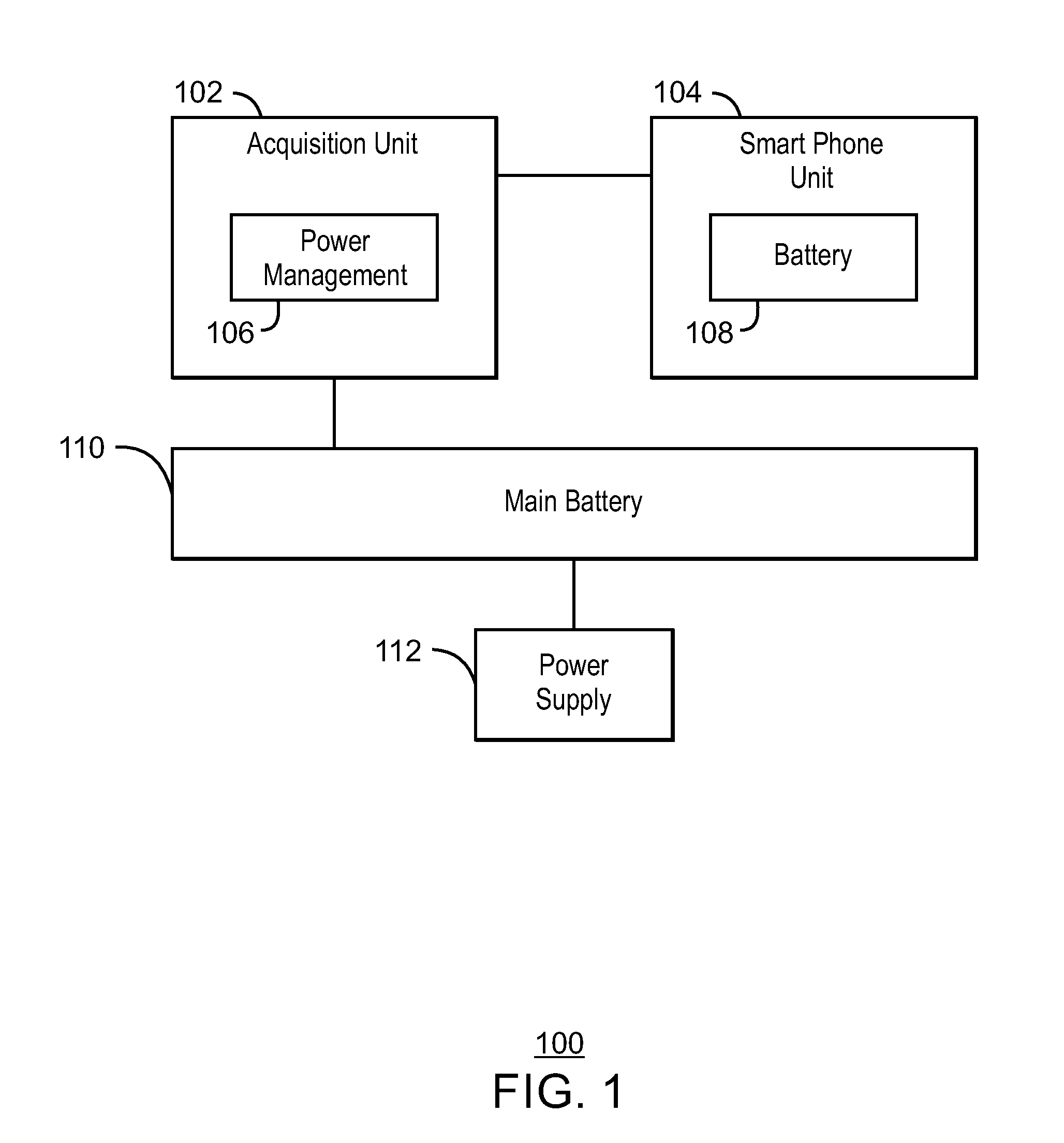

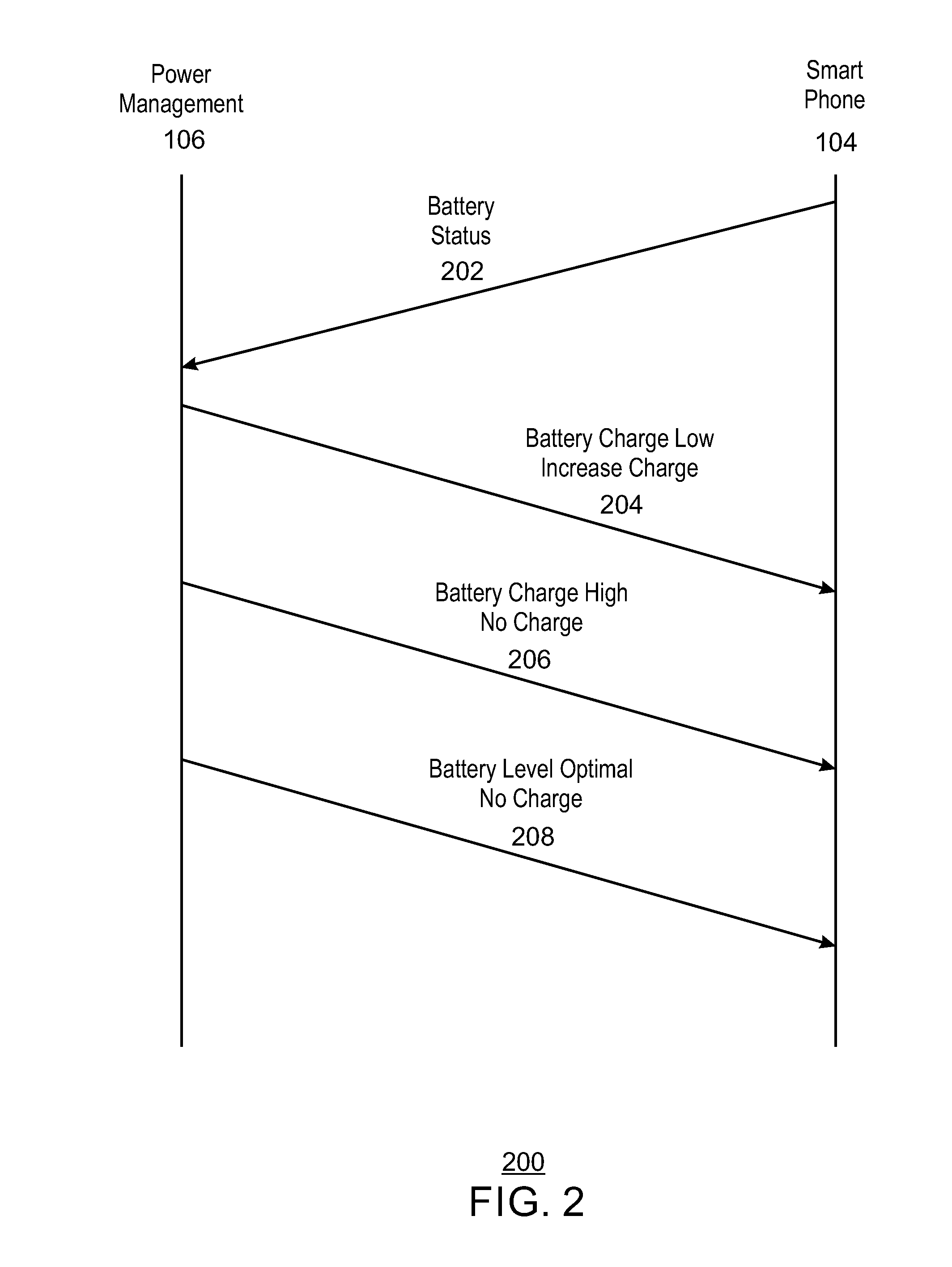

Optimization of a battery driven ultrasound device

InactiveUS20160190844A1Charge level is greatBatteries circuit arrangementsElectrical testingUltrasound deviceHandheld ultrasound

An apparatus is described herein. The apparatus includes a first battery and a main battery. The first battery is a phone battery. The main battery is a battery of a handheld ultrasound system and the main battery is to maintain a charge of the first battery at an optimal charge level.

Owner:GENERAL ELECTRIC CO

Ultrasound device for vulvovaginal rejuvenation

A handheld ultrasound device and corresponding methods used for rejuvenating the vulvovaginal area of the user. In general, the handheld ultrasound devices include a device body coupled to an acousticcoupler and a handle. The device body further includes internal components including an ultrasound transducer, an energy delivery element, and circuitry for controlling the ultrasound output. The methods of using the handheld ultrasound device include engaging the tissue in and around the vulvovaginal area with the energy delivery element, applying ultrasound energy to the vulvovaginal tissue from the energy delivery element and through the acoustic coupler, and affecting a measurable parameter associated with vulvovaginal rejuvenation.

Owner:MADORRA INC

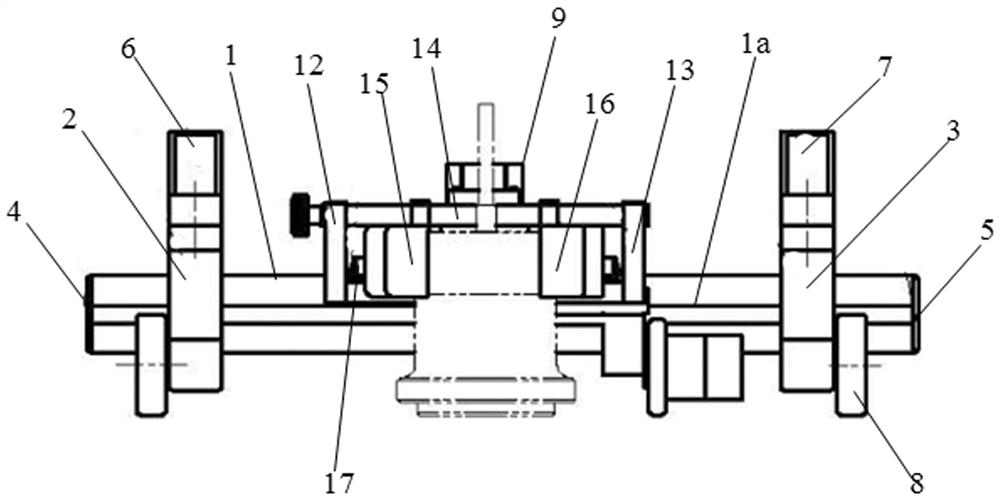

Steel plate handheld ultrasonic detection device

PendingCN113252786AAchieving Vertical AdjustmentRealize horizontal sliding adjustmentAnalysing solids using sonic/ultrasonic/infrasonic wavesSteelmakingHandheld ultrasound

The invention relates to a steel plate handheld ultrasonic detection device which comprises a left sliding support (2), a cross beam (1) and a right sliding support (3) which are matched with one another, a vertical displacement support (9), a vertical guide rail (10), a transverse moving support (11) and a scale ruler (18) are further sequentially arranged on the cross beam (1), and an adjusting lead screw (14) is connected between a left vertical plate (12) and a right vertical plate (13) at the two ends of the transverse moving support (11). A left probe clamping block (15) and a right probe clamping block (16) which are matched with each other are connected to the adjusting screw rod (14) and are connected with a transverse moving guide rail (17) connected to the transverse moving bracket (11). The device has the advantages of small detection blind area, strong resolution, high detection sensitivity and fast detection speed, optimizes the steel plate detection process, improves the production efficiency, enhances the quality control of the steel plate, and provides powerful guarantee for the quality improvement of steel binding and steelmaking.

Owner:NANJING IRON & STEEL CO LTD +1

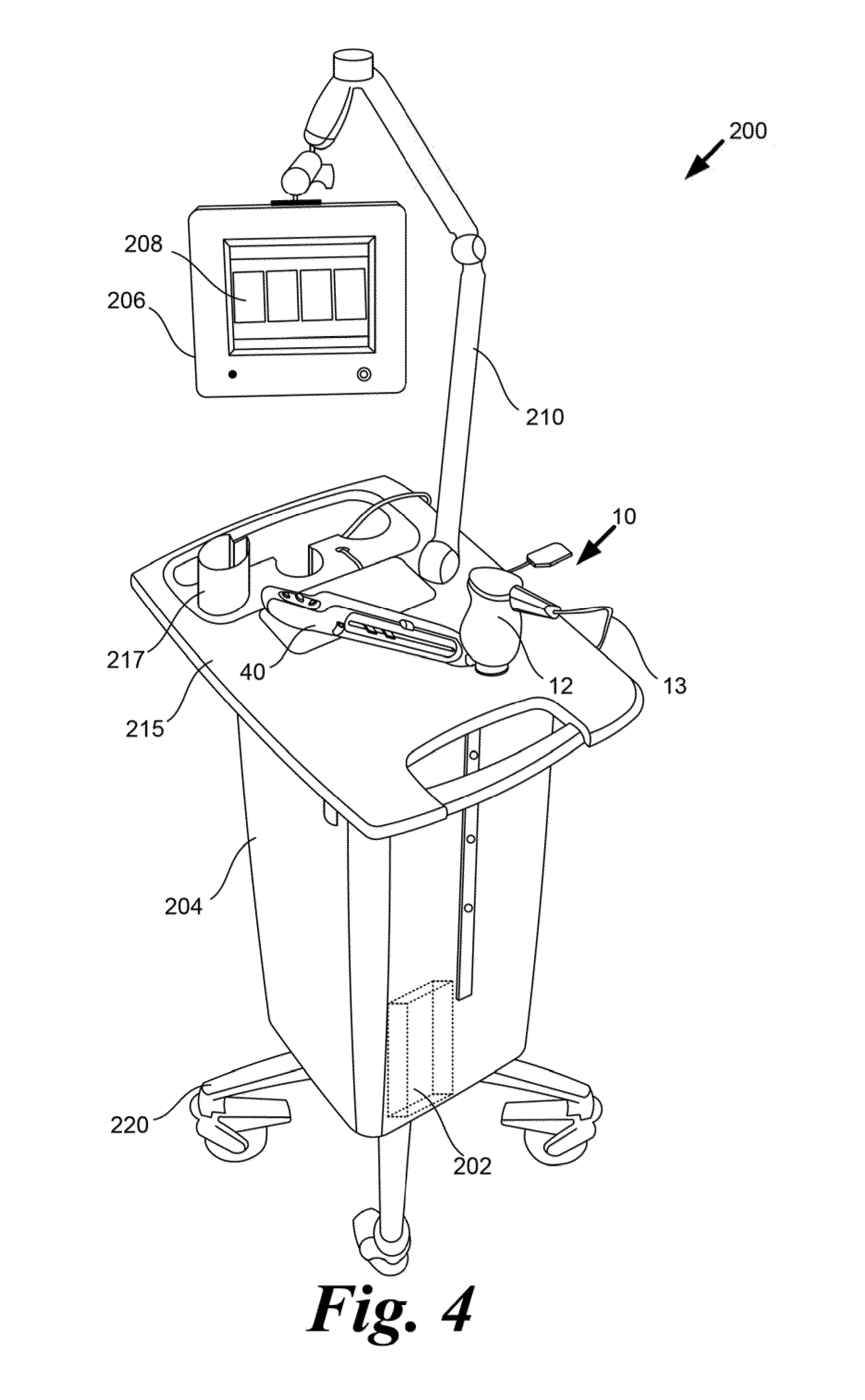

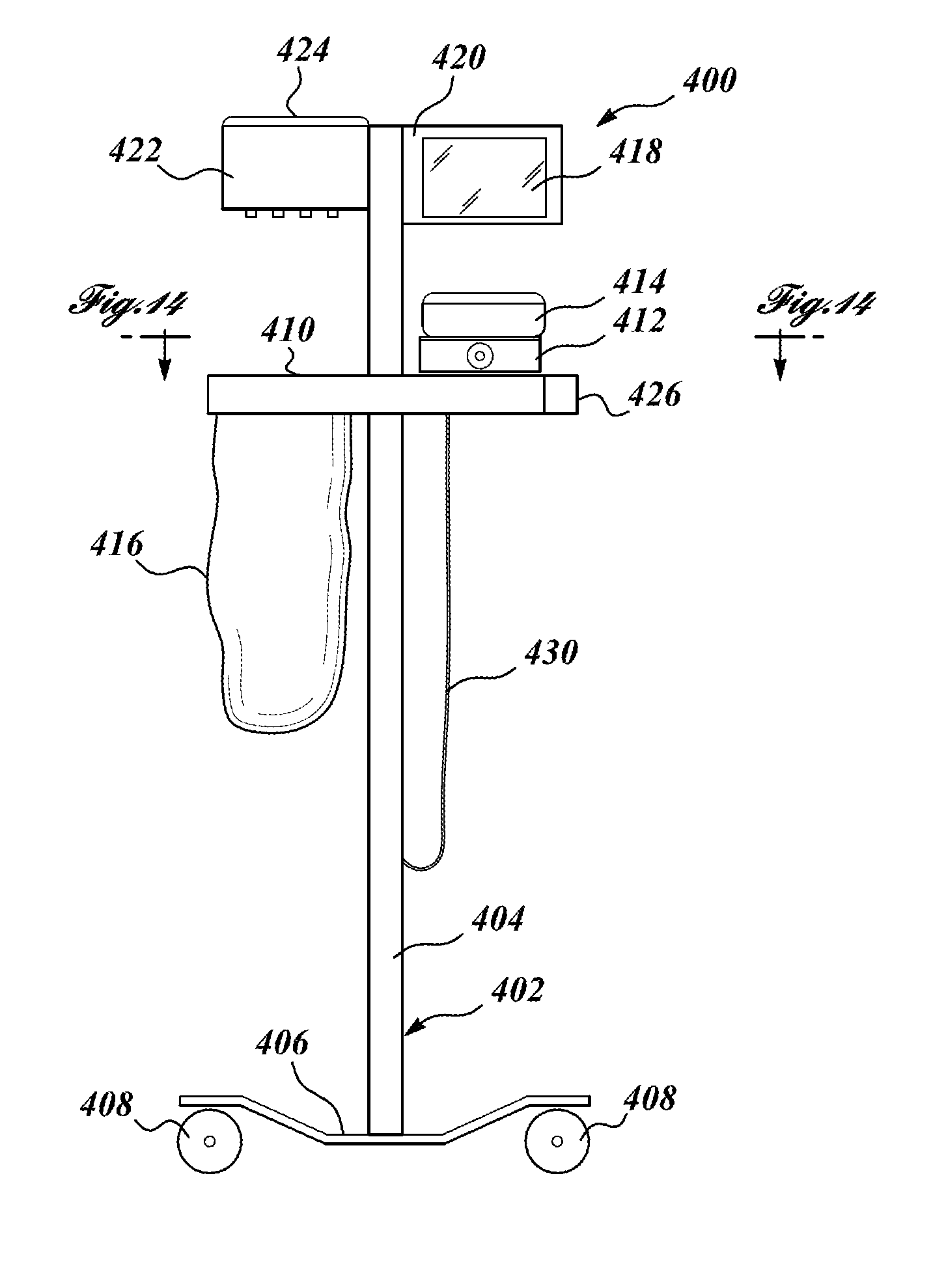

Ultrasound gel dispensing and probe sanitizing station

InactiveUS20150245810A1Improve experienceOvercome problemsMovable measuring chambersVolume measurement and fluid deliveryElectricityInsertion stent

A cart includes a power supply, a display unit, a holder having a primary coil positioned with respect to a compartment to be proximate a secondary coil of a handheld ultrasound probe when it is positioned in the compartment, a charging circuit that provides an alternating current to inductively couple the primary and the secondary coils, light sources operable to provide at least ultraviolet light, and a drive circuit electrically coupled to drive the light sources. The cart may include a dispenser with a container that can hold an ultrasound coupling medium, and a dispensing mechanism having a scoop with an elongated recess that is rotatably mounted with respect to the container to move between a first position in which the elongated recess is in fluid communication with the interior of the container and a second position in which the elongated recess is exposed to an exterior of the dispenser.

Owner:DBMEDX

Handheld ultrasonic spot welder and operation method

PendingCN111590905AHigh strengthHigh speed of soundMechanical vibrations separationFrequency changerRubber material

The invention relates to a handheld ultrasonic spot welder and an operation method. A host machine is of an integrated design comprising a probe and an ultrasonic vibration system; the ultrasonic vibration system comprises an electronic tracking frequency converter, an ultrasonic transducer and an amplitude-change pole; the amplitude-change pole is arranged at one end of the host machine; an aviation plug is arranged at one end, far way from the amplitude-change pole, of the host machine; a welding head is arranged at one end, far away from the host machine, of the amplitude-change pole; a bayonet and a connecting screw are connected to the outer side of the amplitude-change pole; a fastener device is arranged at one end close to the host machine; the amplitude-change pole and the fastenerdevice are in butt joint through a connecting screw; the fastener device is connected with a piezoelectric ceramic piece close to one end of the host machine; and the electrode plate is connected with the piezoelectric ceramic piece through a special fastening bolt for a high-strength transducer. According to the handheld ultrasonic spot welder, a cable wire at one end of the host machine is supported through a support sleeve made of an insulating rubber material, and through grooves distributed at equal intervals, the support sleeve can conveniently drive the cable wire to bend at a certaininclined angle, so that the cable wire is prevented from being wound with a hand part, and the handheld ultrasonic spot welder is convenient to use.

Owner:方需科技(上海)有限公司

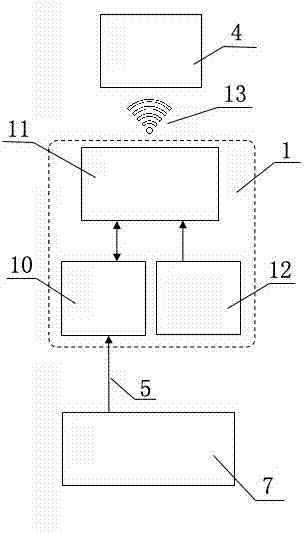

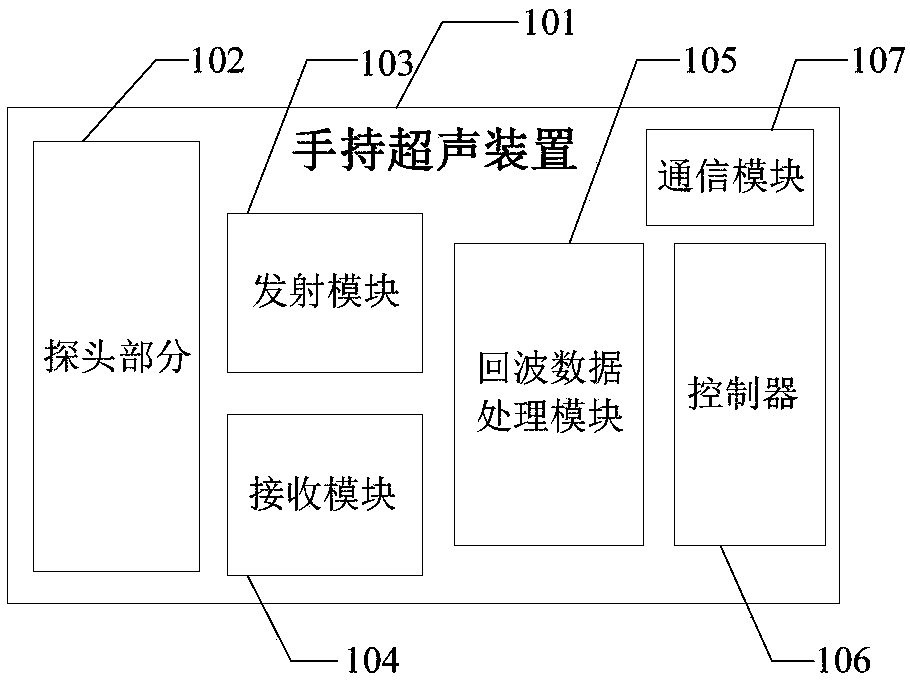

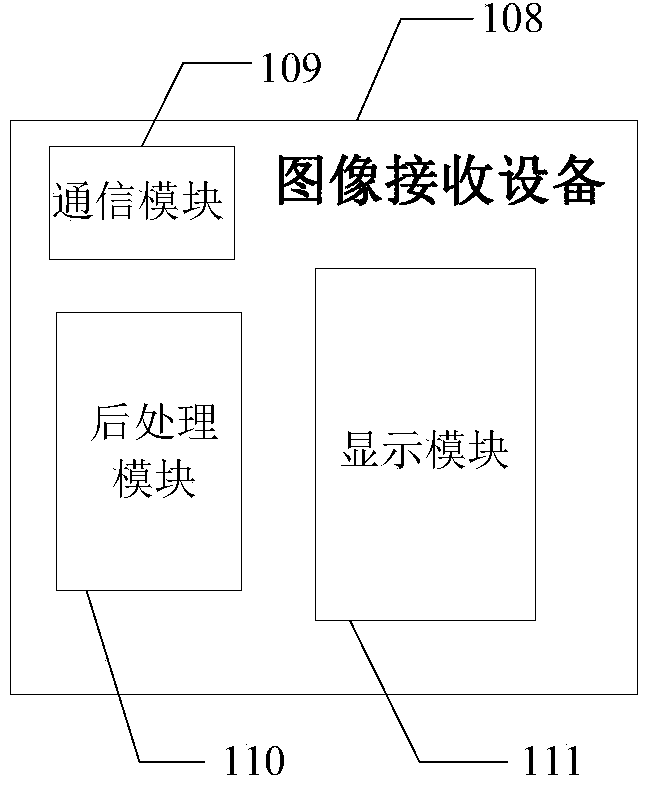

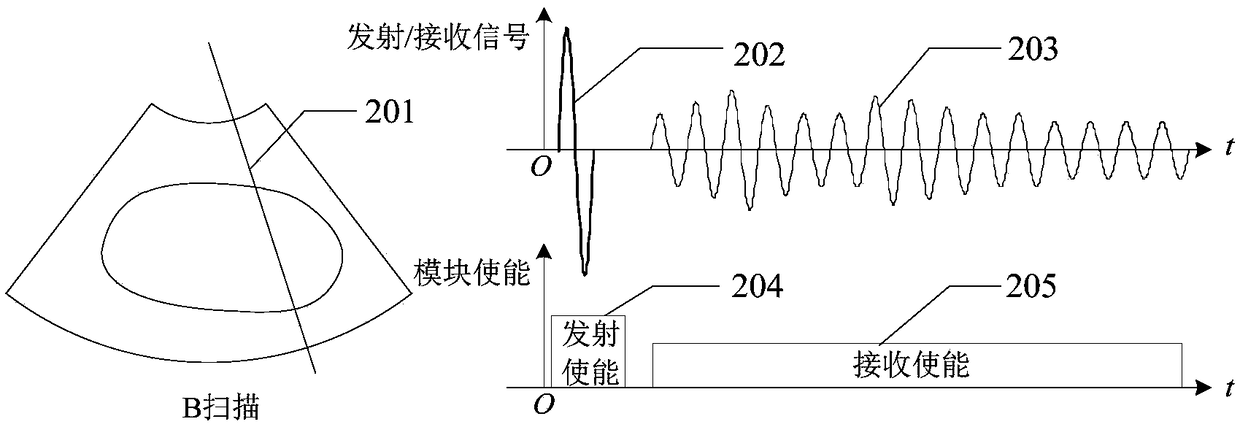

A handheld ultrasound device and imaging method

ActiveCN107822655BReduce power consumptionAvoid overall overheatingInfrasonic diagnosticsSonic diagnosticsSonificationHandheld ultrasound

The invention relates to a handheld ultrasonic device and an imaging method. The device comprises a probe part, a transmitting module, a receiving module, an echo data processing module, a controllerand a communication module; the controller controls the transmitting module to generate transmission pulses so that the probe part can be stimulated to transmit ultrasonic wave signals; the controllercontrols the receiving module to collect ultrasonic echo signals received by the probe part; the echo data processing module processes the ultrasonic echo signals collected by the receiving module and then sends the data to the communication module; the communication module communicates with external image receiving equipment in a wireless or wired mode; the controller conducts low-power-consumption scanning control on the transmitting module and the receiving module, wherein low-power-consumption scanning control comprises the steps that the transmitting module is controlled to conduct widening transmission, the receiving module is controlled to conduct widening receiving, it is controlled that low-power-consumption empty scanning is generated, the transmitting module is controlled to work during ultrasonic transmission, and the receiving module is controlled to work when receiving effective data. According to the device and the method, on the basis that the system performance is notdegraded, power consumption is reduced, probe overheating is prevented, and endurance time is prolonged.

Owner:武汉启佑生物医疗电子有限公司

Handheld Ultrasound Device and Replaceable Tips Therefor

PendingUS20190374200A1Blood flow measurement devicesInfrasonic diagnosticsMedicineHandheld ultrasound

Handheld ultrasound devices and replaceable tips for such devices are provided. For example, a handheld ultrasound device comprises a handle and a tip that includes a sensor for transmitting and receiving ultrasound waves. The handle and the tip may be a single, integral, unit or the tip may be separable from the handle. In either embodiment, the handle and tip together are a fully self-contained unit. Also provided are handheld ultrasound sterile assemblies, comprising a handheld ultrasound device and a sheath that fully covers the device to provide a sterile barrier for the device. Further, tips for handheld ultrasound devices are provided. The tips may be a replaceable component of the handheld ultrasound devices. For example, the tips may be configured for one-time use, and the tip rather than the entire handheld ultrasound device may be replaced between procedures such that a new tip is used in a subsequent procedure.

Owner:REMINGTON MEDICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com