Process for preparing fuel cell carbon-carried Pt-based catalyst

A fuel cell and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, battery electrodes, etc., can solve problems such as time-consuming, loss of precious metals, complicated and difficult-to-control operation steps, and achieve simple operation and excellent performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

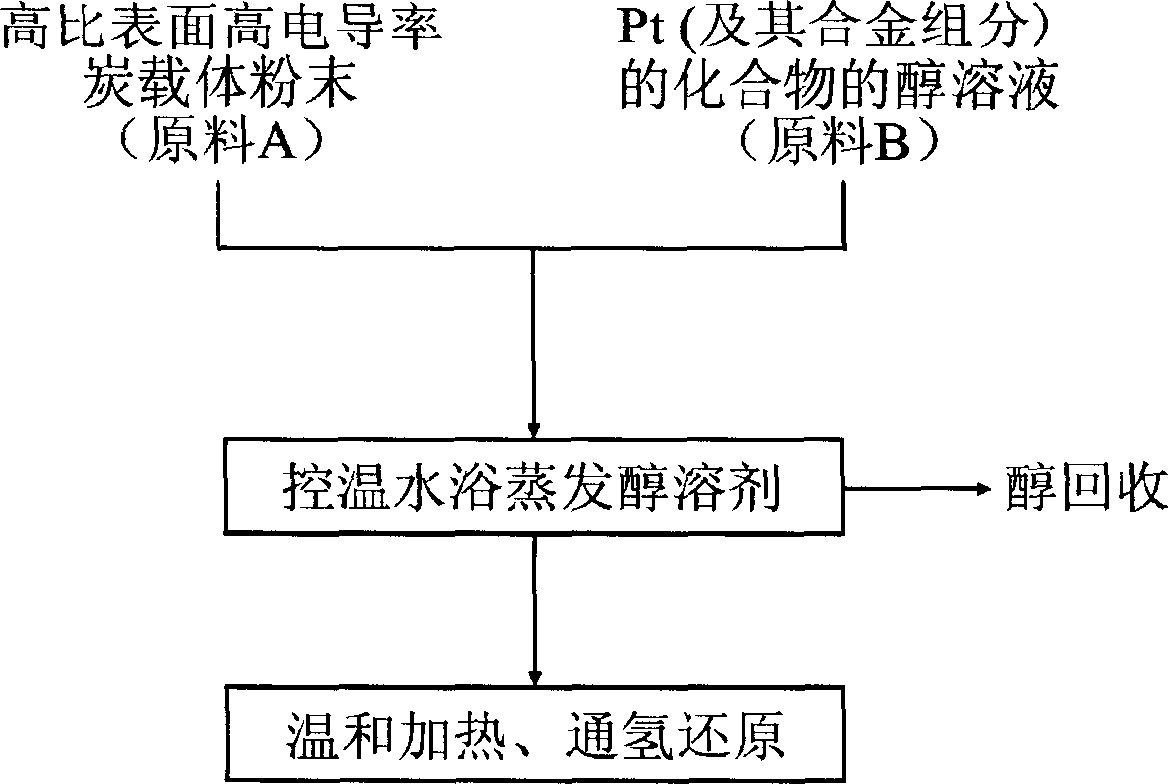

[0023] see figure 1 , the present invention adopts the following "two-step method" to prepare fuel cell carbon-supported platinum-based catalysts, the first step: the alcohol solution B (wherein the alcohol is methanol, ethanol, propanol or iso lower alcohols such as propanol) and carbon carrier A with high specific surface and high conductivity (such as VulcanXC-72 of Carbot Company) are stirred and mixed, and the alcohol solvent is slowly evaporated on a water bath at 40-100 ° C (the evaporated alcohol can be recovered ); the second step: the dry powder obtained in the previous step is used as a reducing agent at 100-300° C. to reduce the platinum or its alloy element compound on the carbon surface to a metal or alloy to obtain the desired carbon-supported platinum-based catalyst.

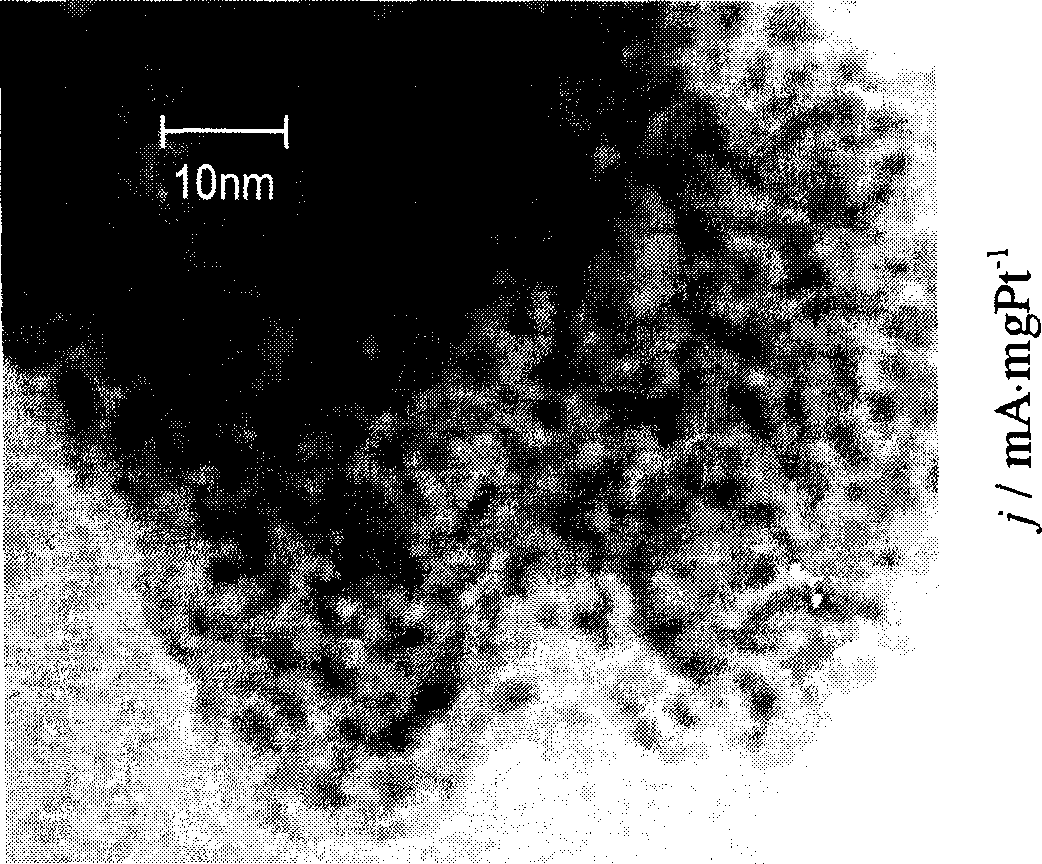

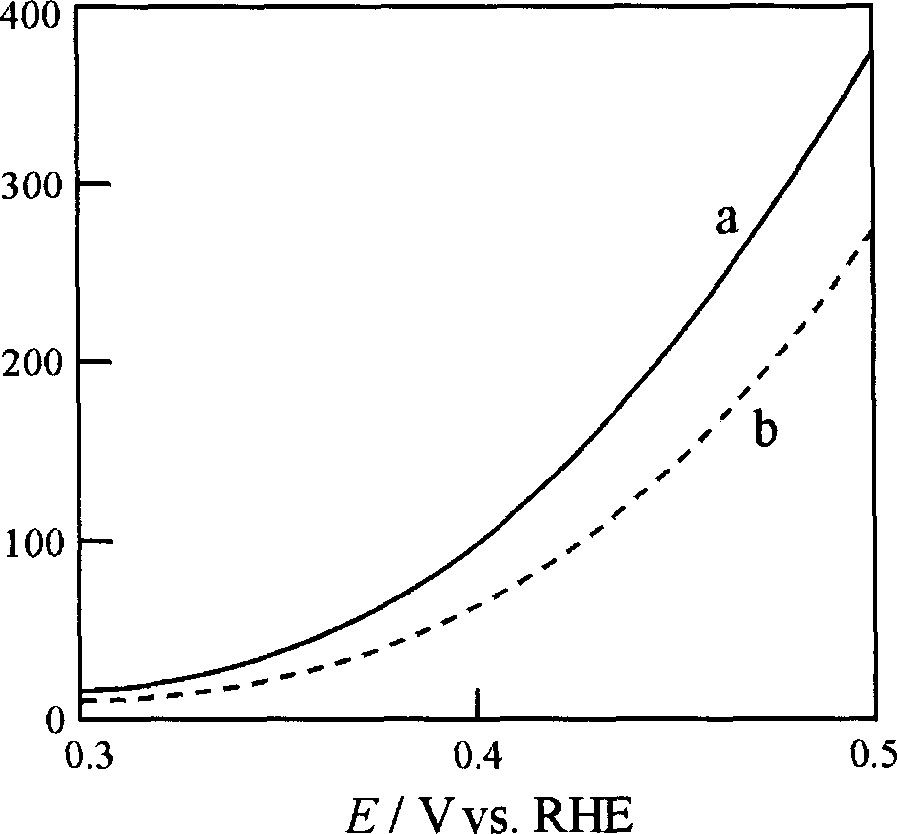

[0024] Taking the preparation of PtRu / C as an example, H 2 PtCl 6 with RuCl 3 Dissolve in ethanol, add carbon black (Vulcan XC-72 from Carbot Company) and stir well; evaporate ethanol in a wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com