Soft type polymeric compound lithium battery and preparation method thereof

A polymer and lithium battery technology, applied in the manufacture of electrolyte batteries, secondary batteries, non-aqueous electrolyte batteries, etc., can solve the problems of no relevant patents and achieve light weight, high energy density, and high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

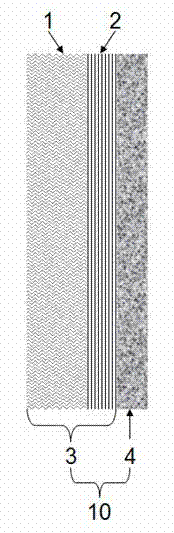

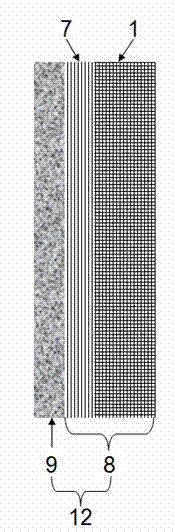

[0026] Preparation of positive electrode sheet

[0027] will be 90 wt .% LiMn 2 o 4 、6 wt .% PVDF and 4 wt .% Dissolve acetylene black in N-methylpyrrolidone, stir well until a viscous slurry is formed; then apply the slurry to the carbon fiber cloth 1 with a thickness of 0.3mm and the aluminum coating layer 2 with a thickness of 0.2μm 3 current collectors consisting of aluminized carbon fiber cloth, 120 o After C vacuum drying, the positive electrode sheet is obtained;

[0028] Preparation of negative electrode sheet

[0029] will be 90 wt .% Artificial graphite, 5 wt .% PVDF and 5 wt .% Dissolve acetylene black in N-methylpyrrolidone, stir well until a viscous slurry is formed; then apply the slurry to a fiber cloth with a thickness of 0.3mm and a copper plating layer with a thickness of 0.12μm Copper plated carbon fiber cloth current collector, 100 o After C vacuum drying, the negative electrode sheet is obtained.

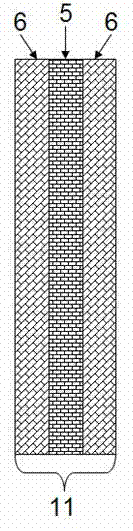

[0030] Preparation of composite po...

Embodiment 2

[0035] Preparation of positive electrode sheet

[0036] will be 85 wt .% Li(Ni0.333 mn 0.333 co 0.333 )O 2 、7 wt .% Hydroxypropyl Methyl Cellulose and 8 wt .% Dissolve nano-carbon fibers in N-methylpyrrolidone, stir well until a viscous slurry is formed; then apply the slurry to a carbon fiber cloth with a thickness of 1mm and an aluminum-coated layer with a thickness of 1.2μm. Aluminum carbon fiber cloth current collector, 100 o After C vacuum drying, the positive electrode sheet is obtained;

[0037] Preparation of negative electrode sheet

[0038] Will 93 wt .% Li 4 Ti 5 o 12 、5 wt .% hydroxypropyl methylcellulose and 2 wt .% Dissolve nano-carbon fibers in N-methylpyrrolidone, stir well until a viscous slurry is formed; then apply the slurry to a fiber cloth with a thickness of 1mm and a copper-plated layer with a thickness of 1.2μm. Copper Carbon Fiber Cloth Current Collector, 80 o After C vacuum drying, the negative electrode sheet is obtained.

...

Embodiment 3

[0044] Preparation of positive electrode sheet

[0045] Will 95 wt .% LiCoO 2 、3 wt .% hydroxybutadiene and 2 wt .% Dissolve carbon nanotubes in N-methylpyrrolidone, stir well until a viscous slurry is formed; then apply the slurry to a carbon fiber cloth with a thickness of 2mm and an aluminum layer with a thickness of 2.5μm Aluminized carbon fiber cloth collector, 80 o After C vacuum drying, the positive electrode sheet is obtained;

[0046] Preparation of negative electrode sheet

[0047] will be 87 wt .% Silicon carbon composite material, 8 wt .% hydroxybutadiene and 5 wt .% Dissolve carbon nanotubes in N-methylpyrrolidone, stir well until a viscous slurry is formed; then apply the slurry to a fiber cloth with a thickness of 2mm and a copper-plated layer with a thickness of 1.5μm Copper plated carbon fiber cloth collector, 120 o After C vacuum drying, the negative electrode sheet is obtained.

[0048] Preparation of composite polymer membranes

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com