Composite mesoporous silica (IL/SiO2) for encapsulating ionic liquid and preparation and application thereof

A mesoporous silica and ionic liquid technology, which is applied in secondary batteries, electrochemical generators, and final product manufacturing, can solve the problems of unstable electrochemical properties of electrolytes, and achieve improved mechanical properties and high conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0046] (1)IL / SiO 2 Preparation

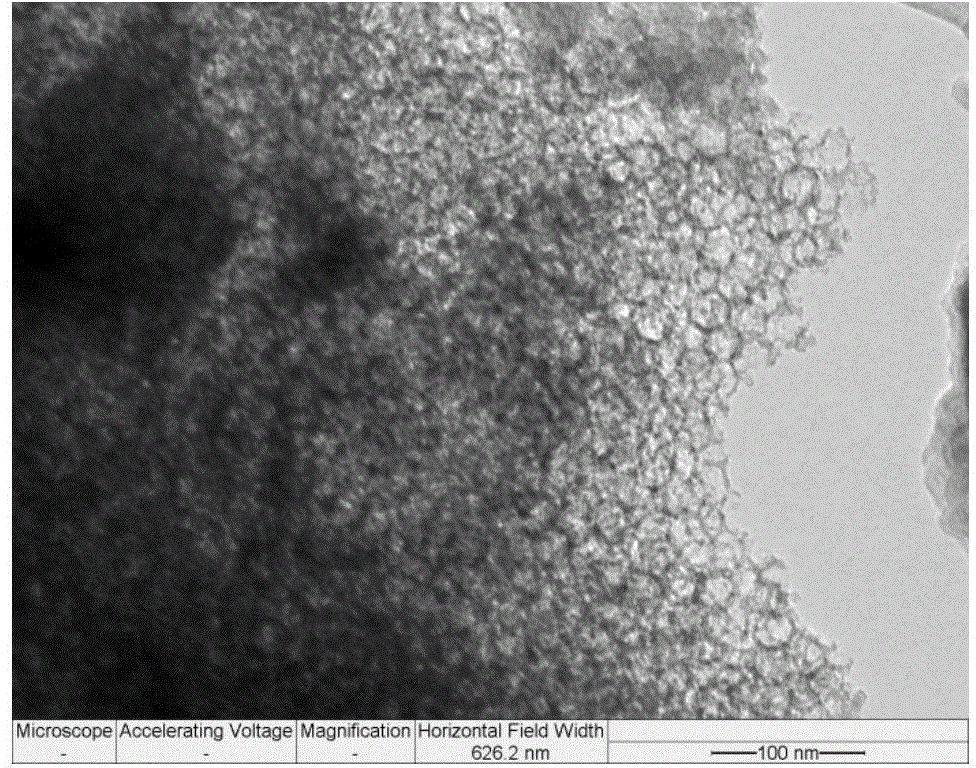

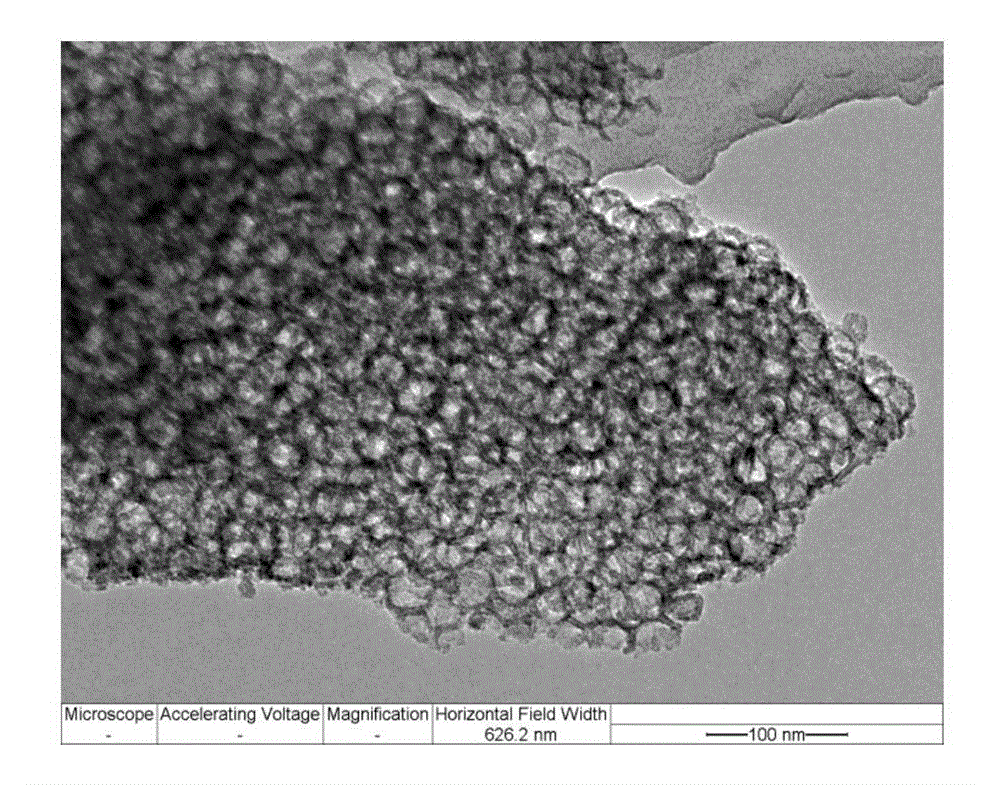

[0047] Add a certain proportion of polyoxyethylene-polyoxypropylene-polyoxyethylene block copolymer (P123), 12mol / L HCl aqueous solution, and deionized water into the flask, stir at 40℃ until P123 is completely dissolved, use 1,3 , 5-Trimethylbenzene (TMB) as a pore expander was added to the flask and stirred for 4 hours. Add ethyl orthosilicate to the flask, continue to stir for 24h, raise the temperature to 90℃, stop stirring, crystallize for 24h, separate by suction filtration, wash with deionized water and ethanol, and extract at 130℃ for 24h. The extracted powder was dried in a vacuum oven at 80℃ for 4h to obtain mesoporous SiO 2 .

[0048] Mesoporous SiO 2 Disperse in an acetone solvent for ultrasonic dispersion for 2 hours, dissolve the IL in an acetone solvent, mix the two, and stir the mixture under reflux at 80°C for 10 hours. After separation by suction filtration, wash with methanol several times, and place the extracted powder in a va...

Embodiment 4

[0075] A composite mesoporous silica for encapsulating ionic liquids. It is a compound formed by 1-carboxymethyl-3-methylimidazole bistrifluoromethanesulfonimide salt and mesoporous silica (IL / SiO 2 ),

[0076] The structural formula of 1-carboxymethyl-3-methylimidazole bistrifluoromethanesulfonimide salt is:

[0077]

[0078] Mesoporous silica is expanded by a pore expander, and the pore size is in the range of 10-15nm. The expansion of mesoporous silica uses the following steps:

[0079] (1) Stir the polyoxyethylene-polyoxypropylene-polyoxyethylene block copolymer (P123), 12mol / L HCl aqueous solution, and deionized water at 40℃ until P123 is completely dissolved, and add 1,3,5-tri Toluene is used as a pore expander, and stirring is continued for 4h;

[0080] (2) Add ethyl orthosilicate and continue stirring for 24h, increase the temperature to 90℃, stop stirring, crystallize for 24h, separate by suction and wash with deionized water and ethanol, the above-mentioned polyoxyethylene-p...

Embodiment 5

[0091] A composite mesoporous silica for encapsulating ionic liquids. It is a compound formed by 1-carboxymethyl-3-methylimidazole bistrifluoromethanesulfonimide salt and mesoporous silica (IL / SiO 2 ),

[0092] The structural formula of 1-carboxymethyl-3-methylimidazole bistrifluoromethanesulfonimide salt is:

[0093]

[0094] The mesoporous silica is expanded by a pore expander, and the pore diameter is in the range of 10-15nm. The expansion uses the following steps:

[0095] (1) Stir the polyoxyethylene-polyoxypropylene-polyoxyethylene block copolymer (P123), 12mol / L HCl aqueous solution, and deionized water at 40℃ until P123 is completely dissolved, and add 1,3,5-tri Toluene is used as a pore expander, and stirring is continued for 4h;

[0096] (2) Add ethyl orthosilicate and continue to stir for 24h, raise the temperature to 90℃, stop stirring, crystallize for 24h, separate by suction filtration, wash with deionized water and ethanol, extract at 130℃ for 24h, polyoxyethylene -The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com