Gel polymer electrolyte, preparation method for the same, super capacitor and application thereof

A gel polymer, supercapacitor technology, applied in the field of electrochemical power supply, can solve the problems of unsatisfactory effect, low battery yield, limited improvement in electrical conductivity, etc., to achieve high yield and efficiency, and improve the absorption of electrolytes. capacity, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

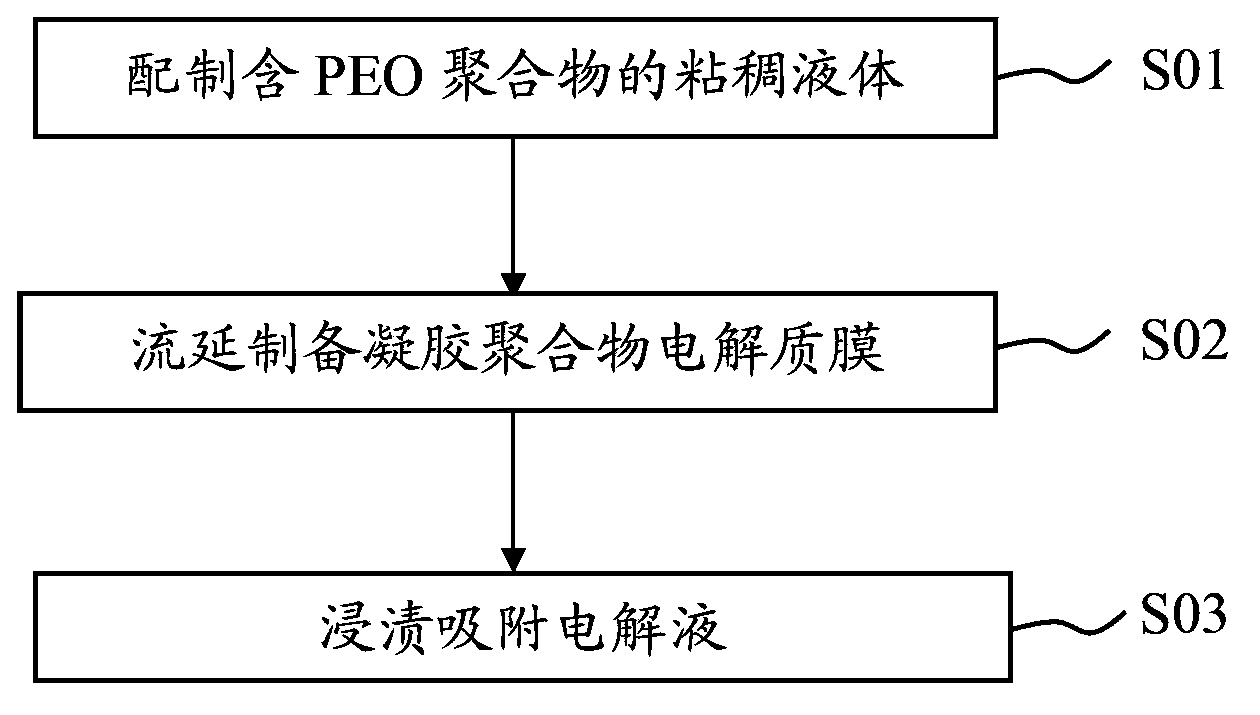

[0022] The embodiment of the present invention provides a method for preparing a gel polymer electrolyte with a simple process. The preparation method technological process of this gel polymer electrolyte is as follows figure 1 As shown, it includes the following steps:

[0023] Step S01. Prepare viscous liquid containing PEO polymer: prepare PEO polymer and organic plasticizer to form viscous liquid;

[0024] Step S02. Casting to prepare a gel polymer electrolyte membrane: coating the viscous liquid prepared in step S01 on the diaphragm, forming a film by casting, and drying in vacuum to obtain a gel polymer electrolyte membrane;

[0025] Step S03. Immersion and adsorption electrolyte: under the protection of an inert gas, the gel polymer electrolyte membrane is immersed in a quaternary ammonium salt ionic liquid electrolyte with a concentration of 0.5-2.0 mol / L for 5-60 minutes, and taken out to obtain The gel polymer electrolyte.

[0026] Specifically, the mass ratio of ...

Embodiment 1

[0044] Gel polymer electrolyte and preparation method thereof, the preparation method of the gel polymer electrolyte comprises the following steps:

[0045] Step 11. Prepare a viscous liquid containing PEO: add 10g of PEO and 120g of NMP to the flask respectively, and stir for 8 hours under the protection of an inert gas to mix evenly to obtain a uniform and transparent viscous liquid;

[0046] Step 12. Casting to prepare the gel polymer electrolyte membrane: cast the viscous prepared in step 11 on the three-layer PP / PE / PP separator to form a film, and naturally volatilize until the film becomes white, and the vacuum degree is 0.01 at 100°C MPa vacuum drying for 48 hours to obtain a three-layer PP / PE / PP diaphragm reinforced PEO polymer substrate gel film;

[0047] Step 13. Prepare a three-layer PP / PE / PP membrane-reinforced PEO polymer-based gel film: transfer the dried PEO-based gel film to an argon-filled glove box and immerse it in 1mol / L Et 4 NBF 4 / AN electrolyte for 30...

Embodiment 2

[0052] Gel polymer electrolyte and preparation method thereof, the preparation method of the gel polymer electrolyte comprises the following steps:

[0053] Step 21. Prepare a viscous liquid containing PEO: add 10g of PEO and 50g of AN to the flask respectively, and stir for 10 hours under the protection of an inert gas to mix evenly to obtain a uniform and transparent viscous liquid;

[0054] Step 22. Preparation of gel polymer electrolyte membrane by casting: cast the viscous prepared in step 21 on the three-layer PP / PE / PP diaphragm to form a film, and naturally volatilize until the film becomes white, and the vacuum degree is 0.01 at 60°C MPa vacuum drying for 24 hours to obtain a three-layer PP / PE / PP diaphragm reinforced PEO polymer substrate gel film;

[0055] Step 23. Prepare a three-layer PP / PE / PP membrane-reinforced PEO polymer-based gel film: transfer the dried PEO-based gel film to an argon-filled glove box and immerse it in 1mol / L MeEt 3 NBF 4 / PC electrolyte for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com