Organic inorganic composite polymer electrolyte and preparation method and application thereof

An inorganic composite, polymer technology, applied in the field of C, can solve the problems of ionic conductivity not meeting the requirements of the application, unsatisfactory mechanical properties, increased interface impedance, etc., to achieve good ionic conductivity and mechanical properties, and low cost. , the effect of inhibiting agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

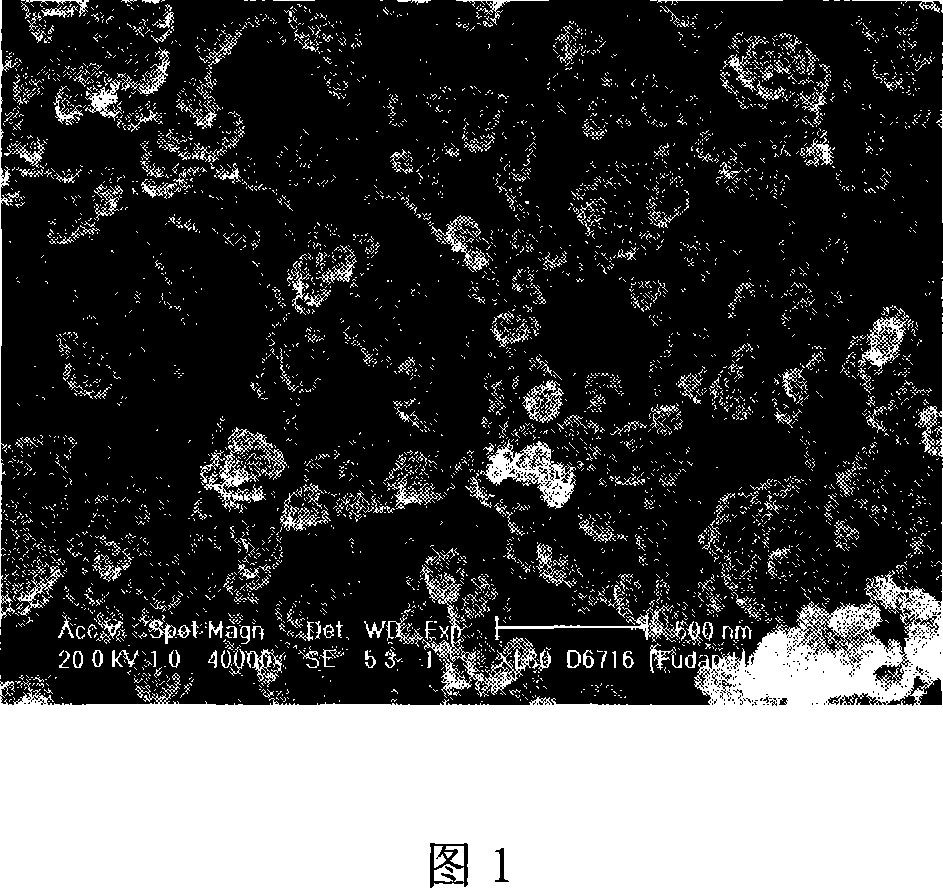

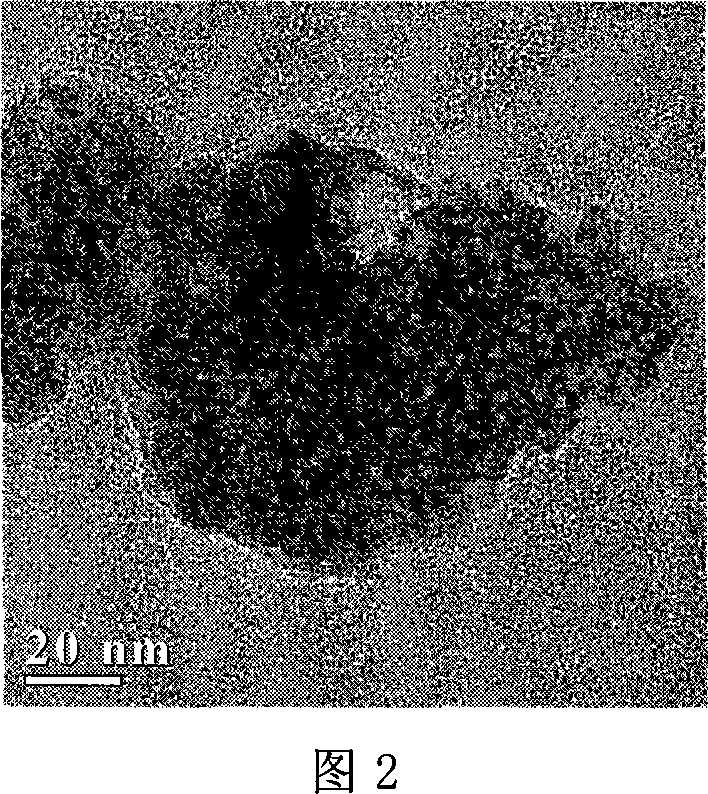

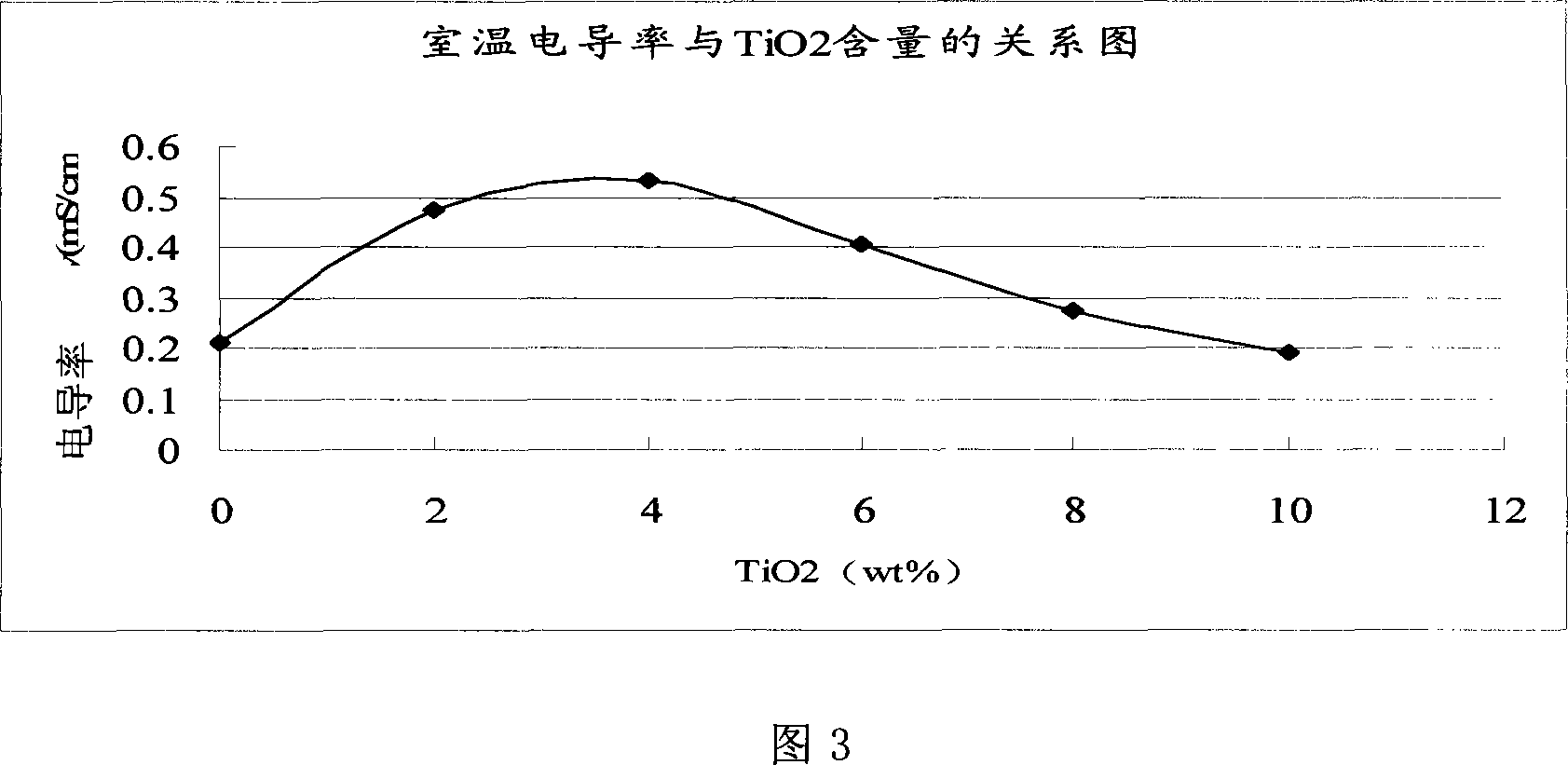

[0034] Add 1 gram of nano-titanium dioxide and 0.0090 gram of sodium dodecylsulfonate into 100 milliliters of deionized water, and ultrasonically disperse for 4 hours. Under mechanical stirring, the temperature was raised to 80°C, 0.0456 g of sodium bisulfite and 0.0150 g of ammonium persulfate were added, and 1.5 g of methyl acrylate was slowly added. React for 1 hour, cool to room temperature and add 36 g of sodium chloride to break the emulsion. Centrifuge to obtain solid particles, and bake at 60°C until constant weight. Accompanying drawing 1 is the scanning electron micrograph of the modified nano titanium dioxide that this method obtains, and accompanying drawing 2 is the transmission electron micrograph of the modified nano titanium dioxide that this method obtains. Take 0.0900 grams of the above-mentioned nanoparticles, 2.205 grams of acrylonitrile, 2.205 grams of methyl acrylate and 0.0441 grams of azobisisobutyronitrile and join them in a 50-milliliter three-necked...

Embodiment 2

[0036] Add 1 gram of nano-titanium dioxide and 0.0090 gram of sodium dodecylsulfonate into 100 milliliters of deionized water, and ultrasonically disperse for 4 hours. Under mechanical stirring, the temperature was raised to 80°C, 0.0456 g of sodium bisulfite and 0.0150 g of ammonium persulfate were added, and 1.5 g of methyl acrylate was slowly added. React for 1 hour, cool to room temperature and add 36 g of sodium chloride to break the emulsion. Centrifuge to obtain solid particles, and bake at 60°C until constant weight. Take 0.1800 grams of the above-mentioned nanoparticles, 2.160 grams of acrylonitrile, 2.160 grams of methyl acrylate and 0.0432 grams of azobisisobutyronitrile and join them in a 50-milliliter three-necked bottle equipped with a nitrogen protection device, a reflux condenser, and a thermometer. After one hour, the temperature was raised to 60° C., stirred for 18 hours, 0.648 g of polyethylene glycol diacrylate and 0.0065 g of azobisisobutyronitrile were a...

Embodiment 3

[0038] Add 1 gram of nano-titanium dioxide and 0.0090 gram of sodium dodecylsulfonate into 100 milliliters of deionized water, and ultrasonically disperse for 4 hours. Under mechanical stirring, the temperature was raised to 80°C, 0.0456 g of sodium bisulfite and 0.0150 g of ammonium persulfate were added, and 1.5 g of methyl acrylate was slowly added. React for 1 hour, cool to room temperature and add 36 g of sodium chloride to break the emulsion. Centrifuge to obtain solid particles, and bake at 60°C until constant weight. Take 0.2700 grams of the above-mentioned nanoparticles, 2.115 grams of acrylonitrile, 2.115 grams of methyl acrylate and 0.0423 grams of azobisisobutyronitrile and join them in a 50-milliliter three-necked bottle equipped with a nitrogen protection device, a reflux condenser, and a thermometer. After one hour, the temperature was raised to 60° C., stirred for 18 hours, 0.6345 g of polyethylene glycol diacrylate and 0.0063 g of azobisisobutyronitrile were ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com