Flexible polymer dielectric material for electrical condenser and preparation thereof

A flexible polymer and dielectric material technology, applied in the direction of fixed capacitor dielectrics and components of fixed capacitors, can solve problems such as poor mechanical properties and poor combination of two-phase interfaces, and achieve good mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

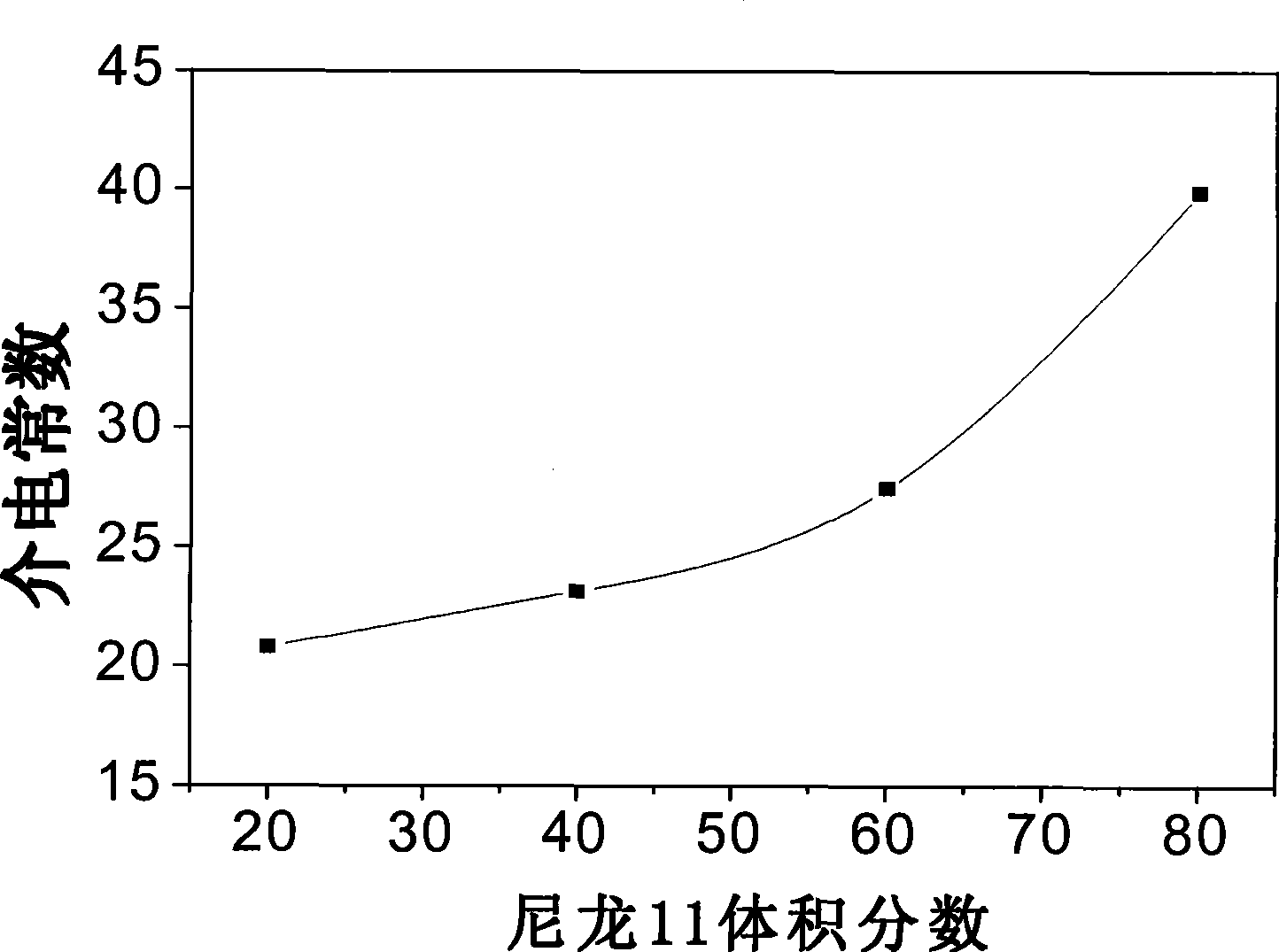

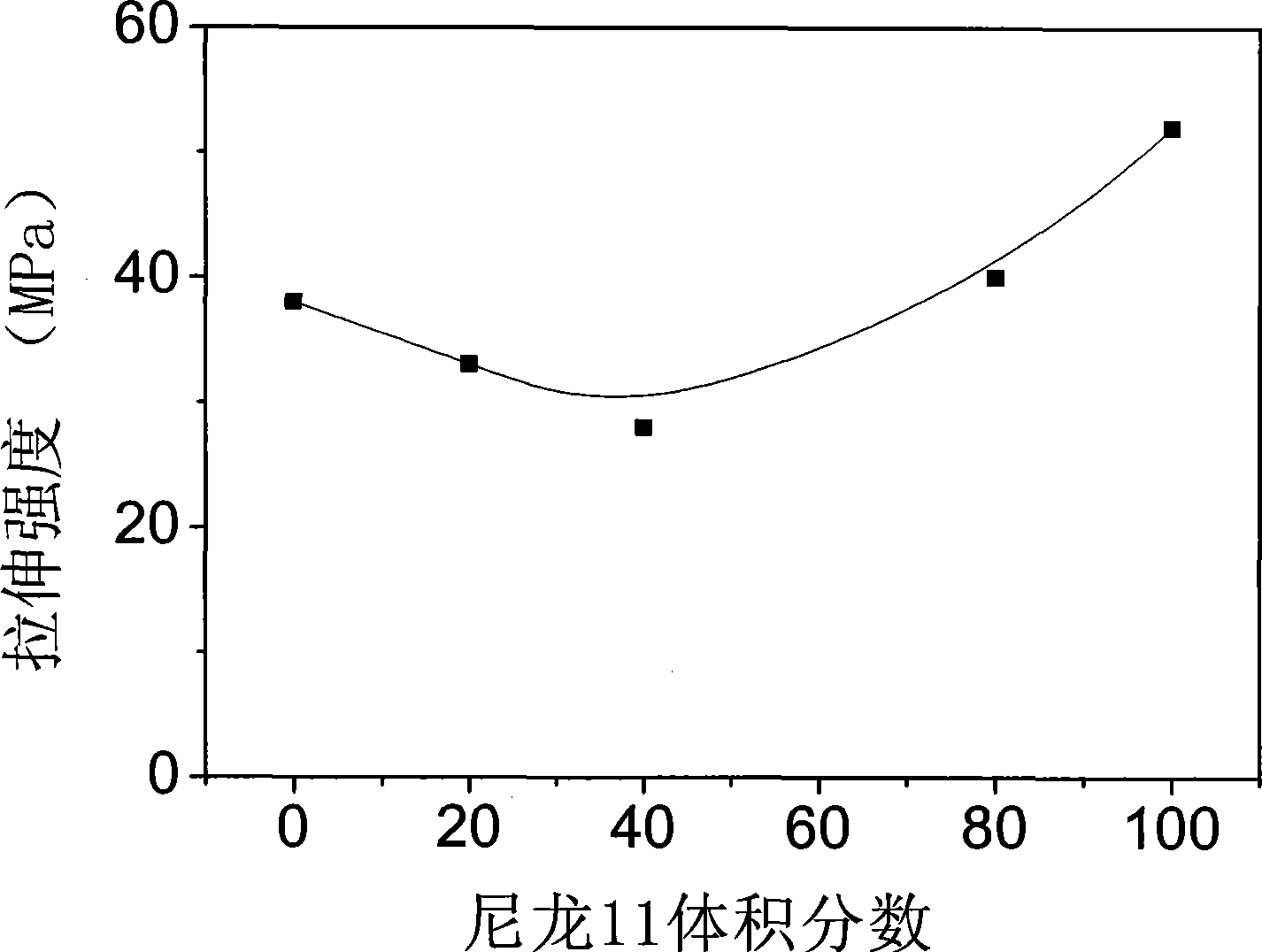

[0019] Example 1: Mix 20% PA11 and 80% PVDF powders according to the volume ratio in an internal mixer at 180-190°C and 15-20r / min; Molding at ~15MPa for 30 minutes, and then cooling under pressure, the PA11 / PVDF alloy material is prepared, and the dielectric constant of the alloy can reach 30.

Embodiment 2

[0020] Example 2: Mix 40% PA9 and 60% PVDF powder according to the volume ratio in an internal mixer at 180-200°C and a speed of 40-50r / min; Molding at 10-15MPa for 30 minutes, and then cooling under pressure, the PA9 / PVDF alloy material was prepared, and the dielectric constant of the alloy could reach 27.

Embodiment 3

[0021] Example 3: Mix 90% PA7 and 10% PVDF pellets according to the volume ratio in an internal mixer at 200-220°C and a rotating speed of 15-30r / min; , Molded under 20MPa for 20min, and then cooled under pressure, the PA7 / PVDF alloy material was prepared, and the dielectric constant of the alloy could reach 35.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com