Aluminum particle/PVDF polymer dielectric medium and preparation method thereof

A technology of aluminum particles and polymers, applied in the field of aluminum particles/PVDF polymer dielectric and its preparation, can solve the problems of no obvious increase in thermal conductivity, loss of electrical breakdown strength, sudden change in dielectric properties, etc., and achieve processing performance Good, improved thermal breakdown voltage, stable dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

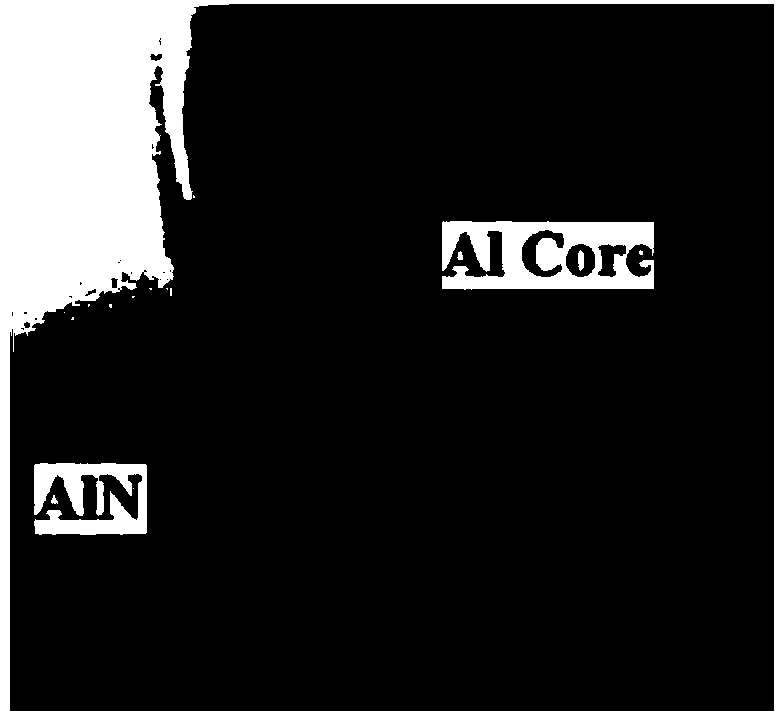

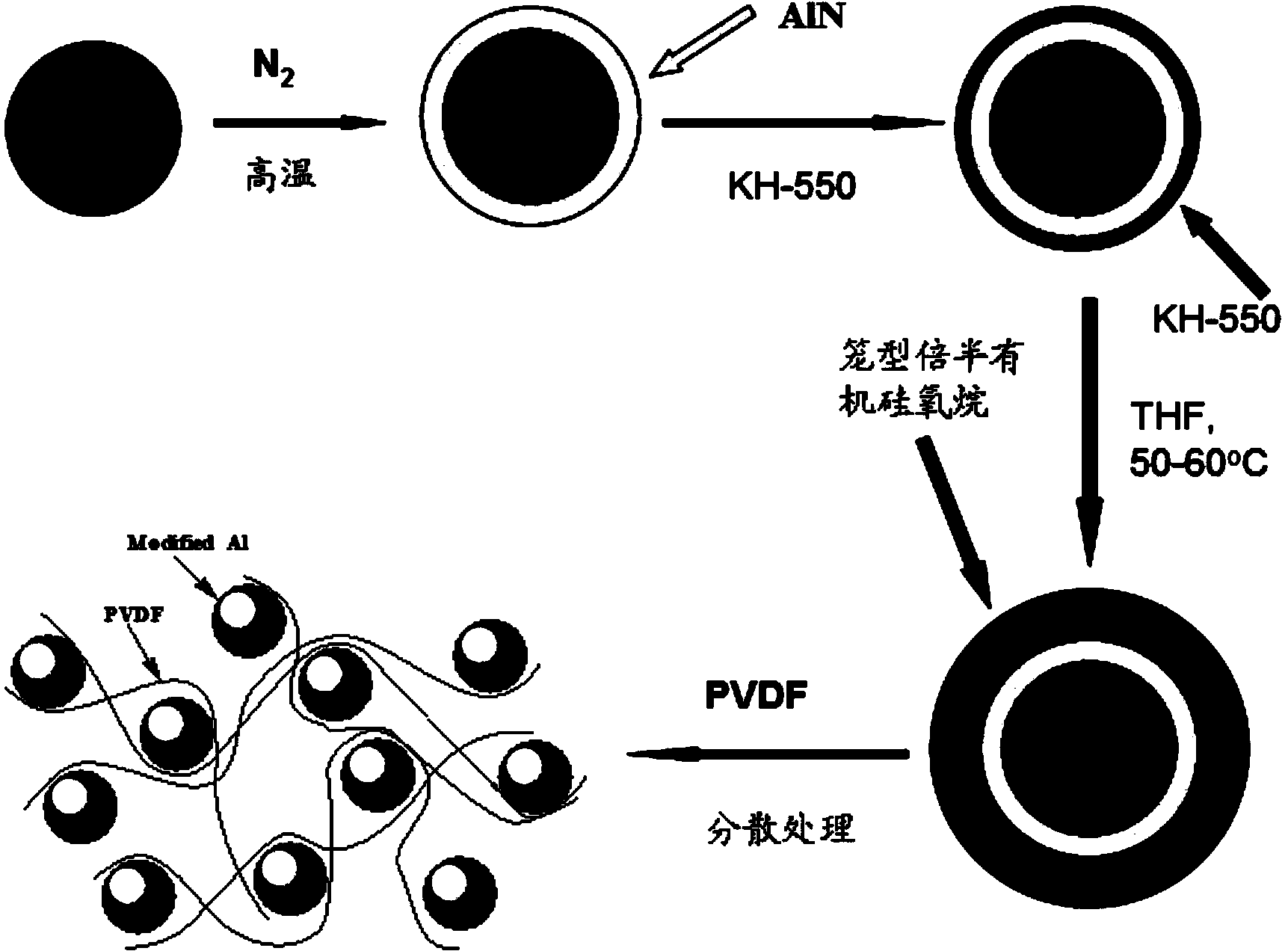

[0036] see figure 2 , The preparation method of the present invention has the following three steps, which are divided into three parts: preparation of aluminum particles with a composite structure, surface modification, and compounding with PVDF resin.

[0037] (1) Preparation of aluminum particles with composite structure:

[0038] Take 50g of aluminum particles and put them into several porcelain boats, put the porcelain boats into a high-temperature heating furnace, continuously feed high-purity nitrogen, and remove the air for 30 minutes. After the air is removed, turn on the heating device and raise the temperature to 500°C under a nitrogen atmosphere. , lasted 0.2h. Turn off the heating switch, cool down to room temperature under a nitrogen atmosphere, take out the sample, and set aside.

[0039] (2) Surface modification of aluminum particles with composite structure:

[0040] Weigh 20g of composite structure aluminum particles and put them into a 200mL three-necked...

Embodiment 2

[0046] see figure 2 , a method for preparing an aluminum particle / PVD polymer electrolyte, comprising the following steps:

[0047] 1) Preparation of aluminum particles with composite structure:

[0048] Aluminum particles with a particle size of 70-80nm are heated at 520°C in a nitrogen atmosphere for 0.3h and cooled down to room temperature in a nitrogen atmosphere to obtain aluminum particles with a composite structure;

[0049] 2) Surface modification of aluminum particles with composite structure:

[0050] Mix the aluminum particles with composite structure and xylene and obtain a reaction solution after ultrasonication for 5 minutes, add KH-560 silane coupling agent which accounts for 4% of the mass of aluminum particles with composite structure dropwise to the reaction solution, and reflux at 83°C for 9.5 hours , then reflux at 125°C for 2.5h, then filter and dry at 110°C for 6h to obtain modified composite structure aluminum particles; wherein, the ratio of composit...

Embodiment 3

[0055] 1) Preparation of aluminum particles with composite structure:

[0056] Aluminum particles with a particle size of 70-80nm are heated at 580°C in a nitrogen atmosphere for 0.3h and cooled down to room temperature in a nitrogen atmosphere to obtain aluminum particles with a composite structure;

[0057] 2) Surface modification of aluminum particles with composite structure:

[0058] Mix the aluminum particles with composite structure and xylene and obtain a reaction solution after ultrasonication for 7 minutes, add KH-560 silane coupling agent which accounts for 3.5% of the mass of aluminum particles with composite structure dropwise to the reaction solution, and reflux at 87°C for 9 hours. Then reflux at 120°C for 3 hours, then filter and dry at 114°C for 5.5 hours to obtain modified aluminum particles with composite structure; wherein, the ratio of aluminum particles with composite structure to xylene is 20g:75mL;

[0059] Ultrasonic dispersion of modified aluminum pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com