Surface modified medical metal material and preparation method thereof

A metal material and surface modification technology, applied in the field of surface-modified medical metal materials and their preparation, can solve the problem of weak bonding strength between hydroxyapatite coating and titanium-based metal materials, shortening of implant life, and implantation. The failure of bulk materials, etc., to achieve the effect of good biocompatibility and activity, low production cost and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

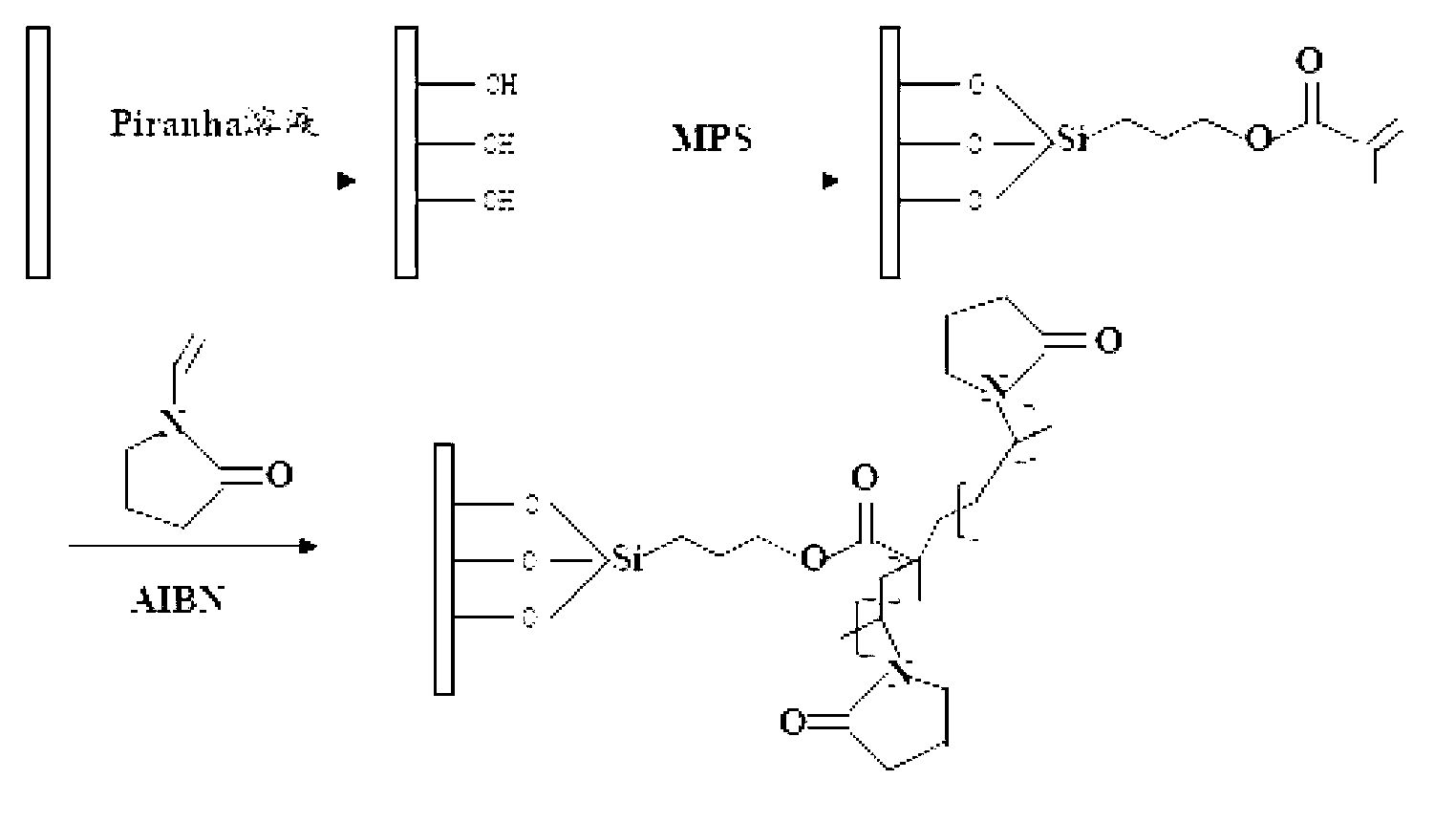

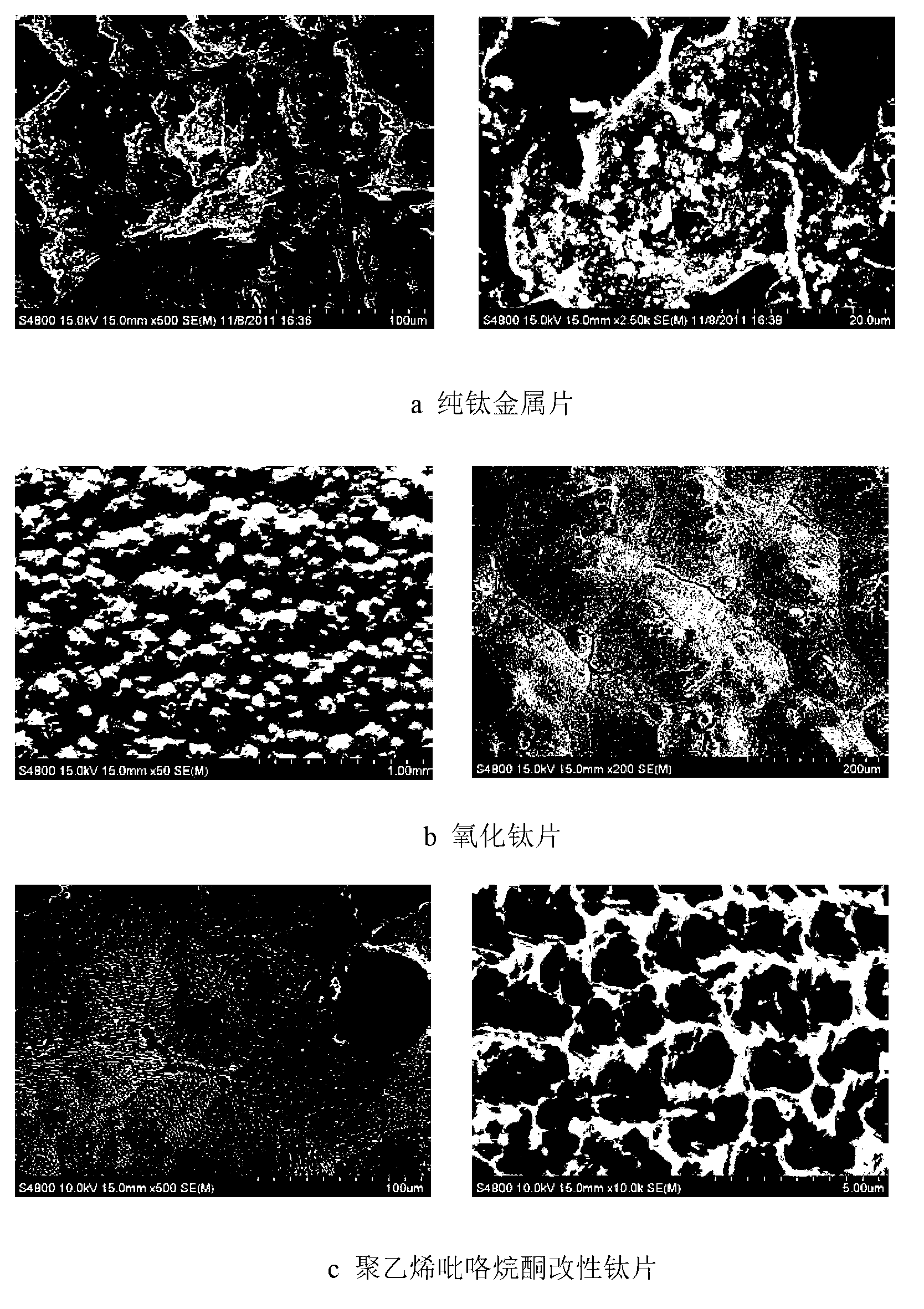

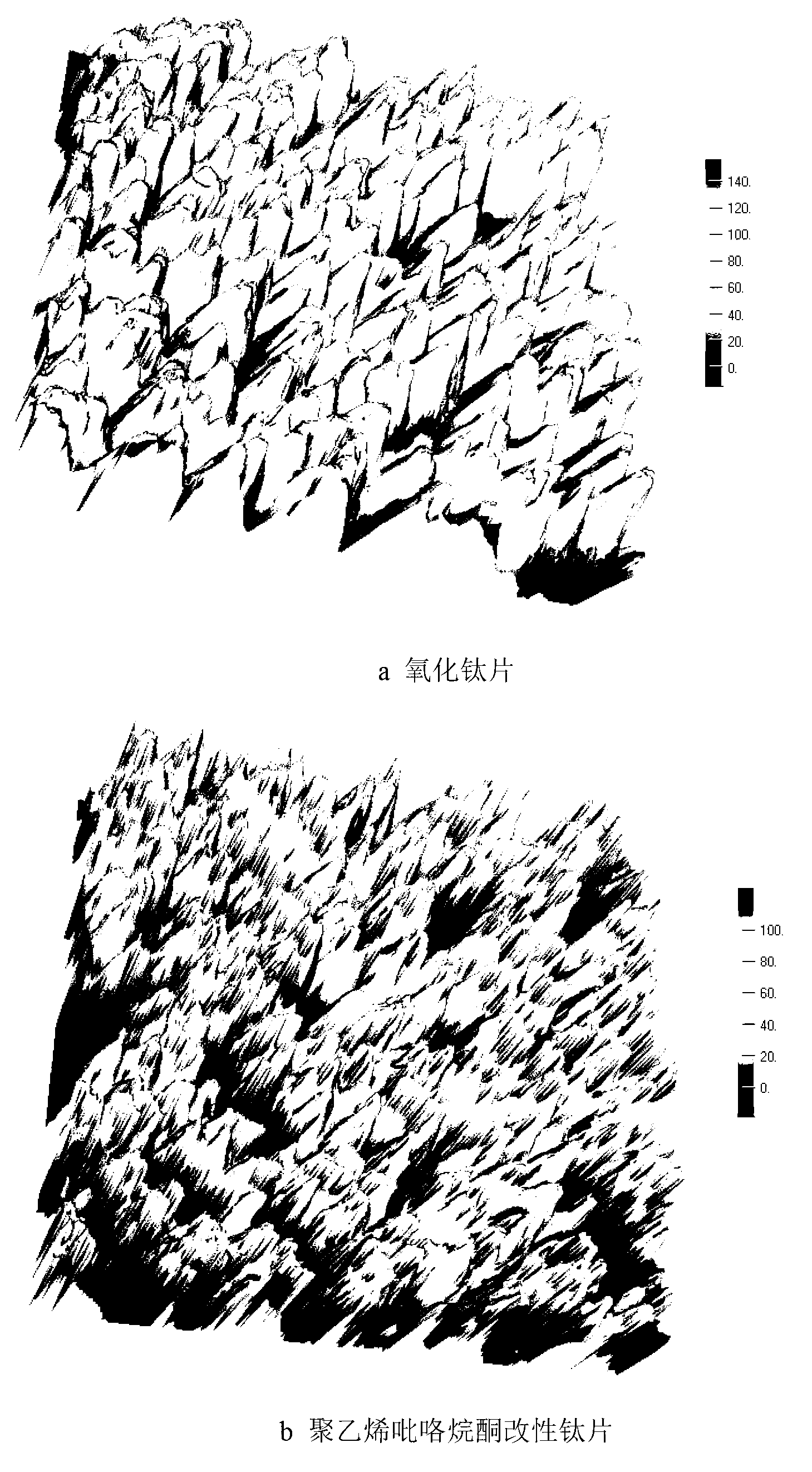

[0031](1) Place a 10mm×10mm×1mm pure titanium sheet in acetone, ethanol, and deionized water for 10 minutes to obtain a pure titanium sheet with a clean surface; control the temperature of the piranha solution at 95°C, and add the pure titanium sheet with a clean surface sheet, oxidized for 20min to obtain surface oxidized titanium sheet;

[0032] (2) Put the above surface oxidized titanium sheet in 1000mL of toluene, add 2mL of silane coupling agent γ-methacryloxypropyltrimethoxysilane, stop the reaction after refluxing for 15h, take out the titanium sheet, and let it dry naturally Dry to obtain γ-methacryloxypropyltrimethoxysilane-coupled titanium sheets;

[0033] (3) Then put the pure titanium sheet coupled with γ-methacryloxypropyltrimethoxysilane in 250mL of methanol, and add 50mL of vinylpyrrolidone, 1g of azobisisobutyl Nitrile, stop the reaction after reflux reaction for 15 hours, take out the titanium sheet, and dry naturally; the medical titanium metal material graf...

Embodiment 2

[0035] (1) Place a 10mm×10mm×1mm pure titanium sheet in acetone, ethanol, and deionized water for 10 minutes to obtain a pure titanium sheet with a clean surface; control the temperature of the piranha solution at 80°C, and add the pure titanium sheet with a clean surface sheet, oxidized for 40min to obtain surface oxidized titanium sheet;

[0036] (2) Put the above surface oxidized titanium sheet in 1000mL of toluene, add 2mL of silane coupling agent γ-methacryloxypropyltrimethoxysilane, stop the reaction after refluxing for 15h, take out the titanium sheet, and let it dry naturally Dry to obtain γ-methacryloxypropyltrimethoxysilane-coupled titanium sheets;

[0037] (3) Then put the titanium plate coupled with γ-methacryloxypropyltrimethoxysilane in 250mL of methanol, and add 30mL of vinylpyrrolidone and 1g of azobisisobutyronitrile in sequence under nitrogen atmosphere , stop the reaction after 15 hours of reflux reaction, take out the pure titanium sheet, and let it dry na...

Embodiment 3

[0039] (1) Place a 10mm×10mm×1mm pure titanium sheet in acetone, ethanol, and deionized water for 10 minutes in order to obtain a pure titanium sheet with a clean surface; control the temperature of the piranha solution at 90°C, and add the pure titanium sheet with a clean surface sheet, oxidized for 20min to obtain surface oxidized titanium sheet;

[0040] (2) Put the above surface oxidized titanium sheet in 1000mL of toluene, add 2mL of silane coupling agent γ-methacryloxypropyltrimethoxysilane, stop the reaction after refluxing for 15h, take out the titanium sheet, and let it dry naturally Dry to obtain γ-methacryloxypropyltrimethoxysilane-coupled titanium sheets;

[0041] (3) Then put the titanium plate coupled with γ-methacryloxypropyltrimethoxysilane in 250mL of methanol, and add 50mL of vinylpyrrolidone and 1g of azobisisobutyronitrile in sequence under nitrogen atmosphere , stop the reaction after reflux reaction for 15 hours, take out the titanium sheet, and dry natu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com