Preparation method for silicon-based negative electrode material with secondary cluster structure and used for lithium ion battery

A technology for silicon-based negative electrode materials and lithium-ion batteries, which can be used in battery electrodes, secondary batteries, structural parts, etc., can solve the problems of high energy consumption, weak binding force, and high production costs in high-temperature processing, and achieve good rate performance and improved The effect of combining force and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

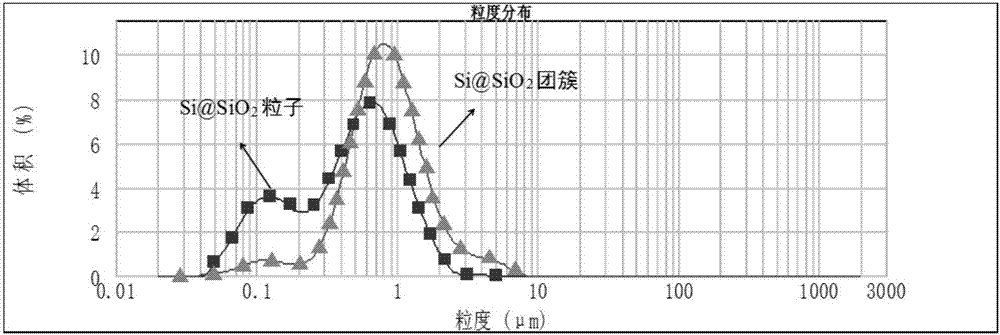

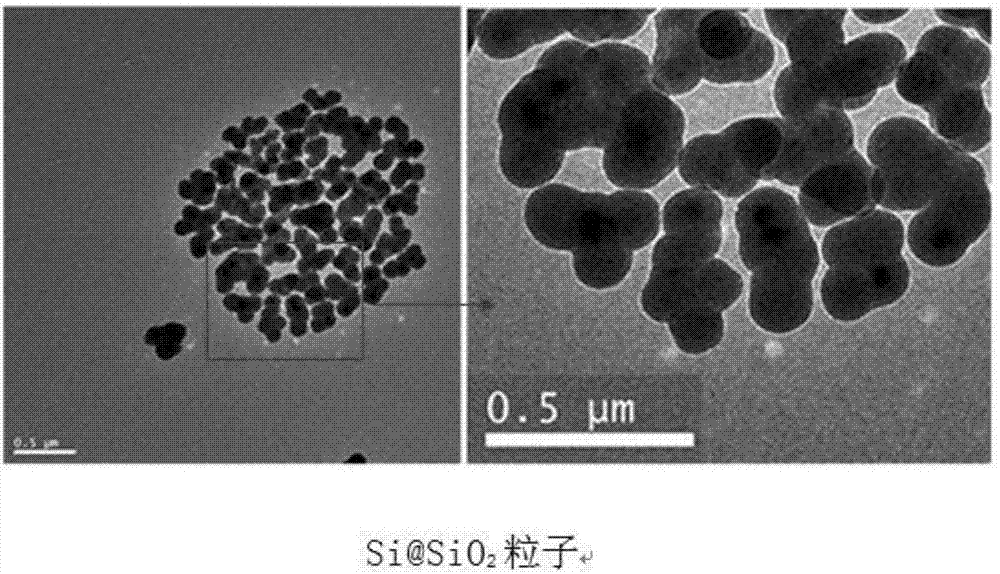

[0032] (1) Disperse 0.2g of silicon particles with a particle size of 30-50nm in a mixed solution containing 50mL of water and 200mL of ethanol, then add 2.5mL (0.0335mol) of ammonia water with a mass fraction of 25%, and add positive Ethyl silicate 2.0mL, stirred for 12h, centrifuged, dried to obtain Si@SiO 2 particle.

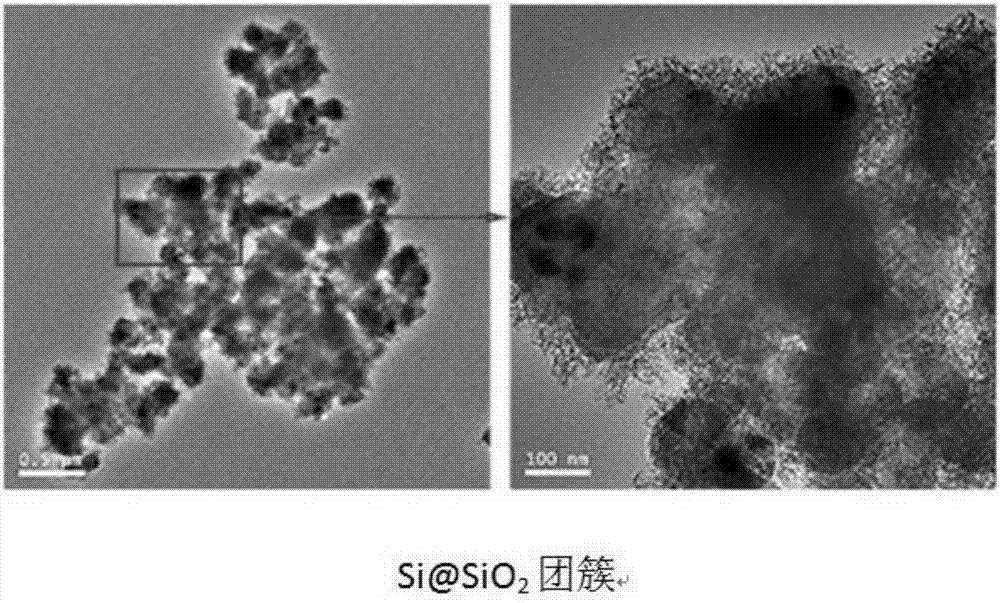

[0033] (2) Si@SiO prepared in (1) 2Take 0.3g of particles, disperse in 18mL of ethylene glycol, add 0.5mL of water, add 0.126g (1mmol) of manganese chloride, 67μL (1mmol) of ethylenediamine, ultrasonically disperse evenly, put it in a hydrothermal kettle, and heat it at 200°C After reacting for 6h, centrifuging and drying, Si@SiO 2 clusters.

[0034] (3) Take the Si@SiO prepared in (2) 2 Cluster 0.2g, disperse in 60mL water, ultrasonically disperse evenly, add 0.2mL (0.00268mol) of ammonia water with a mass fraction of 25%, 0.0182g (0.05mmol) of cetyltrimethylammonium bromide, stir for 1h, add Resorcinol 0.048g, mass fraction 36.5% formaldehyde aqueous s...

Embodiment 2

[0039] (1) Disperse 0.2g of silicon particles with a particle size of 30-50nm in a mixed solution containing 50mL of water and 200mL of ethanol, then add 2.5mL (0.0335mol) of ammonia water with a mass fraction of 25%, and add positive Ethyl silicate 2.0mL, stirred for 12h, centrifuged, dried to obtain Si@SiO 2 particle.

[0040] (2) Si@SiO prepared in (1) 2 Take 0.3g of particles, disperse them in 18mL of ethylene glycol, add 0.5mL of water, add 0.173g (1mmol) of manganese acetate, 67μL (1mmol) of ethylenediamine, ultrasonically disperse evenly, put them in a hydrothermal kettle, and heat them at 200°C React for 6h, centrifuge and dry to get Si@SiO 2 clusters.

[0041] (3) Take the Si@SiO prepared in (2) 2 Cluster 0.2g, disperse in 60mL water, ultrasonically disperse evenly, add 0.2mL (0.00268mol) of ammonia water with a mass fraction of 25%, 0.0182g (0.05mmol) of cetyltrimethylammonium bromide, stir for 1h, add Resorcinol 0.048g, mass fraction 36.5% formaldehyde aqueous ...

Embodiment 3

[0043] (1) Disperse 0.2g of silicon particles with a particle size of 30-50nm in a mixed solution containing 50mL of water and 200mL of ethanol, then add 2.5mL (0.0335mol) of ammonia water with a mass fraction of 25%, and add positive Ethyl silicate 2.0mL, stirred for 12h, centrifuged, dried to obtain Si@SiO 2 particle.

[0044] (2) Si@SiO prepared in (1) 2 Take 0.3g of particles, disperse in 18mL of ethylene glycol, add 0.5mL of water, add 0.13g (1mmol) of cobalt chloride, 67μL (1mmol) of ethylenediamine, ultrasonically disperse evenly, put it in a hydrothermal kettle, and heat it at 200°C After reacting for 6h, centrifuging and drying, Si@SiO 2 clusters.

[0045] (3) Take the Si@SiO prepared in (2) 2 Cluster 0.2g, disperse in 60mL water, ultrasonically disperse evenly, add 0.2mL (0.00268mol) of ammonia water with a mass fraction of 25%, 0.0182g (0.05mmol) of cetyltrimethylammonium bromide, stir for 1h, add Resorcinol 0.048g, mass fraction 36.5% formaldehyde aqueous solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Volume usage | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com