Preparation method of attapulgite/fluorinated polyurethane nanocomposite

A technology of nanocomposite materials and attapulgite, applied in the field of materials science, can solve the problems of poor thermal stability and mechanical properties, and achieve the effect of convenient and simple product processing, low cost and easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

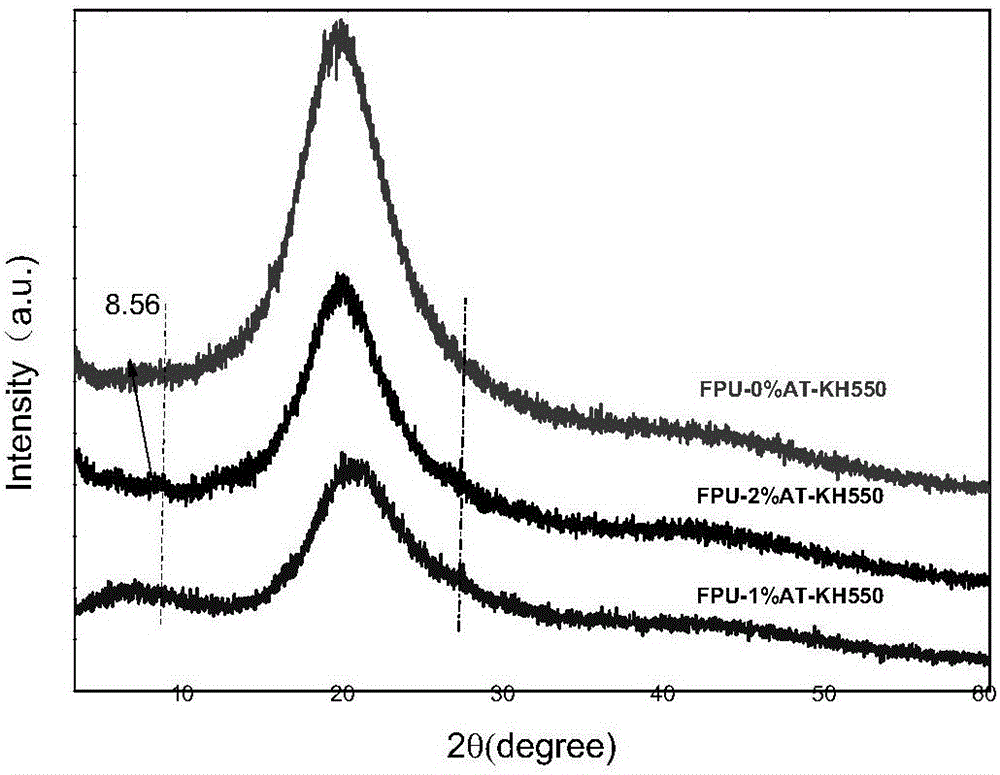

Embodiment 1

[0022] A preparation method of attapulgite / fluorine-containing polyurethane composite material, comprising the steps of:

[0023] (1) Pretreatment of attapulgite

[0024] Purification and acidification treatment: Disperse 10g of attapulgite in deionized water, then add 0.5g of dispersant sodium hexametaphosphate, stir the mixed system at room temperature for 4 hours, discard the bottom residue, centrifuge the upper suspension, and dry And grind. Afterwards, acidify the purified attapulgite, disperse 5g of attapulgite in 50mL of 1mol / L HCl solution, stir the mixed system for one hour at room temperature, then centrifugally dry the mixed solution, grind and sieve.

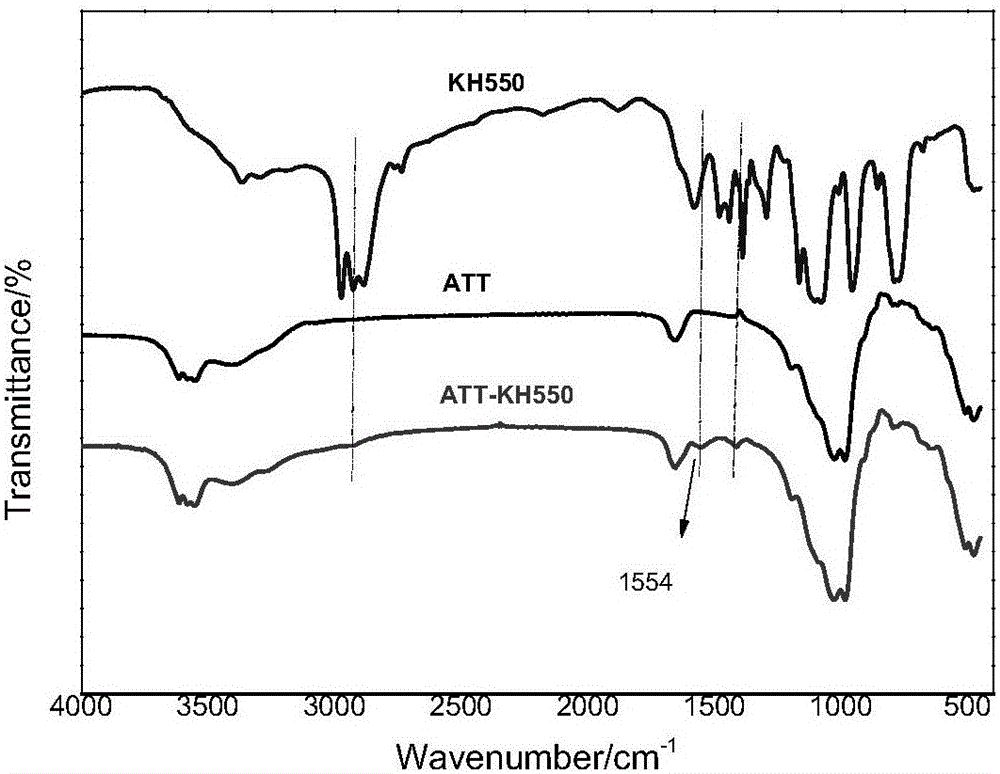

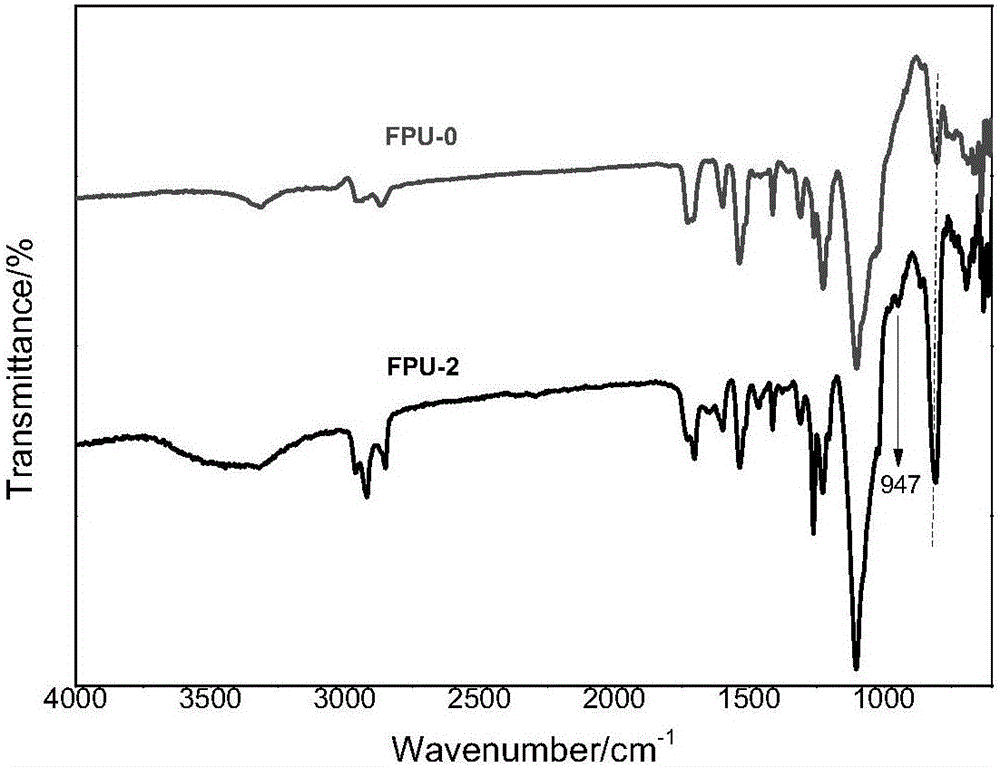

[0025] (2) Organic modification of attapulgite

[0026] Modification of silane coupling agent KH550: first, hydrolyze the silane coupling agent, the solution system is ethanol, H2O, KH550 (volume ratio is 72:8:20), after stirring the system for 2 hours, adjust the pH value of the solution to 4-5. Add 50ml of ethan...

Embodiment 2

[0033] A preparation method of attapulgite / fluorine-containing polyurethane nanocomposite material, comprising the steps of:

[0034] (1) Pretreatment of attapulgite

[0035] Purification and acidification treatment: Disperse 10g of attapulgite in deionized water, then add 0.5g of dispersant sodium hexametaphosphate, stir the mixed system at room temperature for 4 hours, discard the bottom residue, centrifuge the upper suspension, and dry And grind. Afterwards, acidify the purified attapulgite, disperse 5 g of attapulgite in 50 mL of 1 mol / L HCl solution, stir the mixed system at room temperature for one hour, wash it alternately with acetone and deionized water until neutral, and mix The liquid was dried by centrifugation and ground and sieved.

[0036] (2) Organic modification of attapulgite

[0037] Modification of silane coupling agent KH550: first, hydrolyze the silane coupling agent, the solution system is ethanol, H2O, KH550 (72 / 8 / 20), after the system is stirred for...

Embodiment 3

[0041] A preparation method of a novel attapulgite / fluorine-containing polyurethane nanocomposite material, comprising the steps of:

[0042] (1) Pretreatment of attapulgite

[0043] Purification and acidification treatment: Disperse 10g of attapulgite in deionized water, then add 0.5g of dispersant sodium hexametaphosphate, stir the mixed system at room temperature for 4 hours, discard the bottom residue, centrifuge the upper suspension, and dry And grind. Afterwards, acidify the purified attapulgite, disperse 5 g of attapulgite in 50 mL of 1 mol / L HCl solution, stir the mixed system at room temperature for one hour, wash it alternately with acetone and deionized water until neutral, and mix The liquid was dried by centrifugation and ground and sieved.

[0044] (2) Organic modification of attapulgite

[0045] Modification of silane coupling agent KH550: first, hydrolyze the silane coupling agent, the solution system is ethanol, H2O, KH550 (72 / 8 / 20), after the system is sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com