Impervious cement mortar

A cement mortar and cement technology, applied in the field of impermeable cement mortar, can solve problems such as fluffing, cracking, hollowing, etc., and achieve the effects of strong permeability, simple operation method and strong activation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

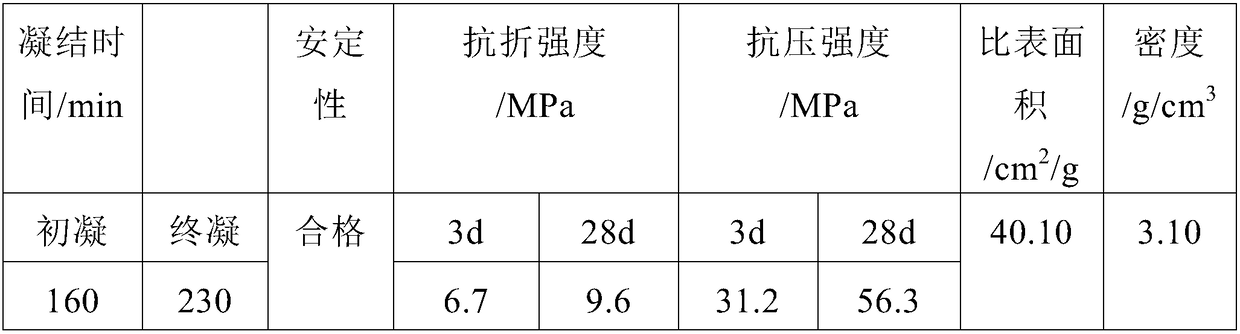

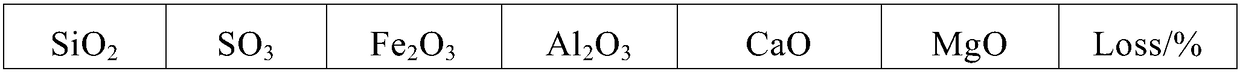

Embodiment 1

[0043] The impermeable cement mortar is composed of the following raw materials in parts by weight: 300 parts by weight of cement, 900 parts by weight of sand, 350 parts by weight of water, 900 parts by weight of recycled aggregate, and 5 parts by weight of water reducing agent.

Embodiment 2

[0045] The impermeable cement mortar is composed of the following raw materials in parts by weight: 300 parts by weight of cement, 900 parts by weight of sand, 350 parts by weight of water, 900 parts by weight of reinforced recycled aggregate, and 5 parts by weight of water reducing agent.

[0046] The strengthened recycled aggregate is prepared by the following method: spraying the nano-calcium carbonate composite polymer strengthening solution on the surface of the recycled aggregate, the weight ratio of the nano-calcium carbonate composite polymer strengthening solution to the recycled aggregate is 1:0.06, and at the same time Stir continuously, and after stirring at 200 rpm for 50 minutes, place it in a ventilated environment at 20°C for 72 hours to obtain reinforced recycled aggregate.

[0047] The nano-calcium carbonate composite polymer strengthening solution is obtained in the following manner: take an aqueous solution of calcium nitrate with a molar concentration of 0....

Embodiment 3

[0050] The impermeable cement mortar is composed of the following raw materials in parts by weight: 300 parts by weight of cement, 900 parts by weight of sand, 350 parts by weight of water, 900 parts by weight of reinforced recycled aggregate, and 5 parts by weight of water reducing agent.

[0051] The strengthened recycled aggregate is prepared by the following method: spraying the nano-calcium carbonate composite polymer strengthening solution on the surface of the recycled aggregate, the weight ratio of the nano-calcium carbonate composite polymer strengthening solution to the recycled aggregate is 1:0.06, and at the same time Stir continuously, and after stirring at 200 rpm for 50 minutes, place it in a ventilated environment at 20°C for 72 hours to obtain reinforced recycled aggregate.

[0052] The nano-calcium carbonate composite polymer strengthening solution is obtained in the following manner: take an aqueous solution of calcium nitrate with a molar concentration of 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com