Polycarboxylate superplasticizer with high water retention and preparation method thereof

A technology of water polycarboxylate and water reducer, which is applied in the field of high water retention polycarboxylate water reducer and its preparation, to achieve the effects of improving workability, reducing the amount of use, and small polymerization steric hindrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

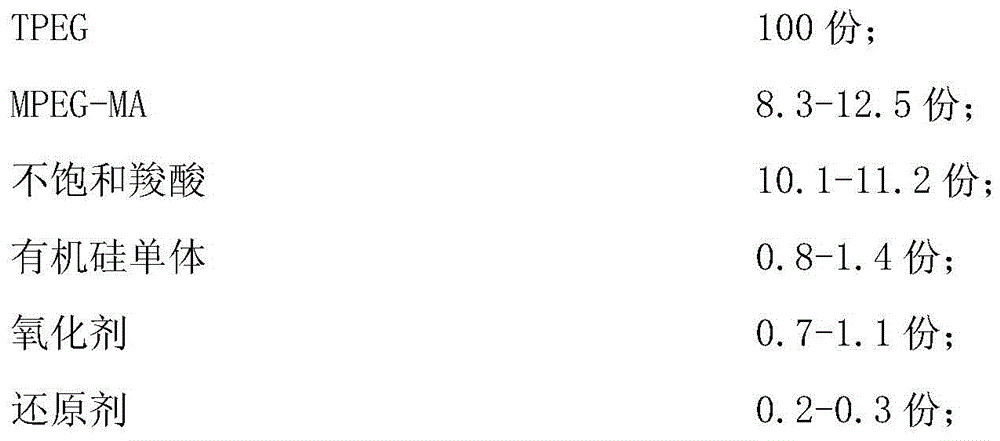

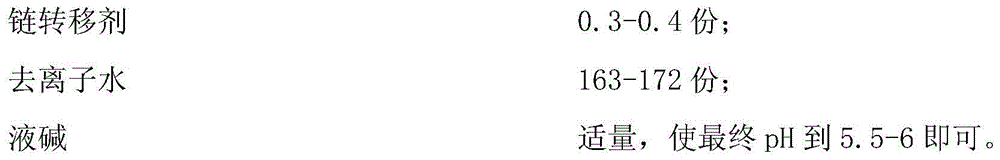

Method used

Image

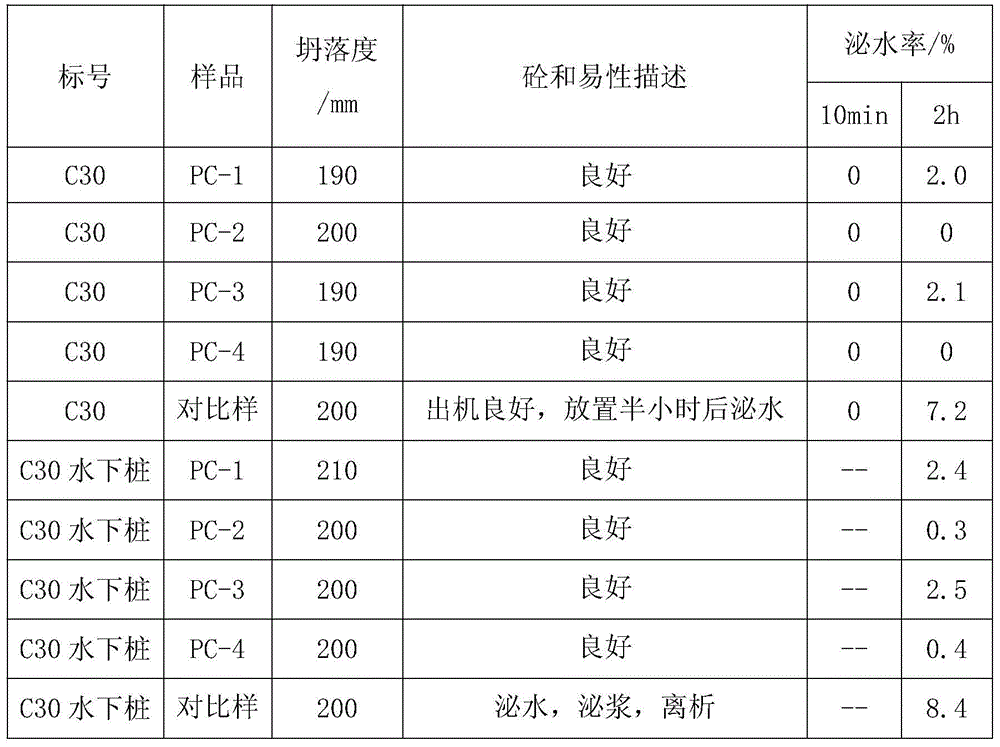

Examples

Embodiment 1

[0022] Embodiment 1: High water retention polycarboxylate superplasticizer

[0023] 100 parts of TPEG and 132.8 parts of deionized water were added to the reactor. Under constant stirring, add 0.8 parts of ammonium persulfate at one time. Then, 8.8 parts of acrylic acid, 2 parts of methacrylic acid, 12.5 parts of MPEG-MA, 0.4 parts of thioglycolic acid, 0.3 parts of aseptic acid, 0.8 parts of γ-methacryloxypropyltrimethoxysilane and 33.2 parts were added dropwise. Parts of mixed solution of deionized water, control the drop in 1 to 4 hours. After dropping, stir at room temperature for 1 hour. Finally, add liquid caustic soda into the reaction kettle and adjust the final pH to 5.5-6 to obtain a new type of high water retention polycarboxylate superplasticizer, and record the sample as PC-1.

Embodiment 2

[0024] Embodiment 2: High water retention polycarboxylate superplasticizer

[0025] 100 parts of TPEG and 130.4 parts of deionized water were added to the reactor. Under constant stirring, add 0.8 parts of ammonium persulfate at one time. Then, 8.8 parts of acrylic acid, 2 parts of methacrylic acid, 12.5 parts of MPEG-MA, 0.4 parts of thioglycolic acid, 0.3 parts of aseptic acid, 1.4 parts of γ-methacryloxypropyltrimethoxysilane and 32.6 parts were added dropwise. Parts of deionized water mixed solution, control dripping in 1 to 4 hours. After dropping, stir at room temperature for 1 hour. Finally, add liquid caustic soda into the reaction kettle and adjust the final pH to 5.5-6 to obtain a new type of high water retention polycarboxylate superplasticizer, and record the sample as PC-2.

Embodiment 3

[0026] Embodiment 3: High water retention polycarboxylate superplasticizer

[0027] 100 parts of TPEG and 131.2 parts of deionized water were added to the reactor. Under constant stirring, 0.7 parts of ammonium persulfate was added in one go. Then, 8.8 parts of acrylic acid, 1.3 parts of methacrylic acid, 8.3 parts of MPEG-MA, 0.3 parts of thioglycolic acid, 0.2 parts of aseptic acid, 1 part of γ-methacryloxypropyl trimethoxysilane and 32.8 parts were added dropwise. The mixed solution of deionized water is controlled to drop in 1 to 4 hours. After dropping, stir at room temperature for 1 hour. Finally, add liquid caustic soda into the reaction kettle and adjust the final pH to 5.5-6 to obtain a new type of high water retention polycarboxylate superplasticizer, and record the sample as PC-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| sand rate | aaaaa | aaaaa |

| sand rate | aaaaa | aaaaa |

| bleeding rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com