Patents

Literature

30results about How to "Easy to copolymerize" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acryloxyalkoxysilicane modified acrylic acid ester polymerization emulsion and its preparation method and application

InactiveCN101121771AGood weather resistanceHigh reactivityOrganic detergent compounding agentsOther chemical processesMethacrylatePolymer science

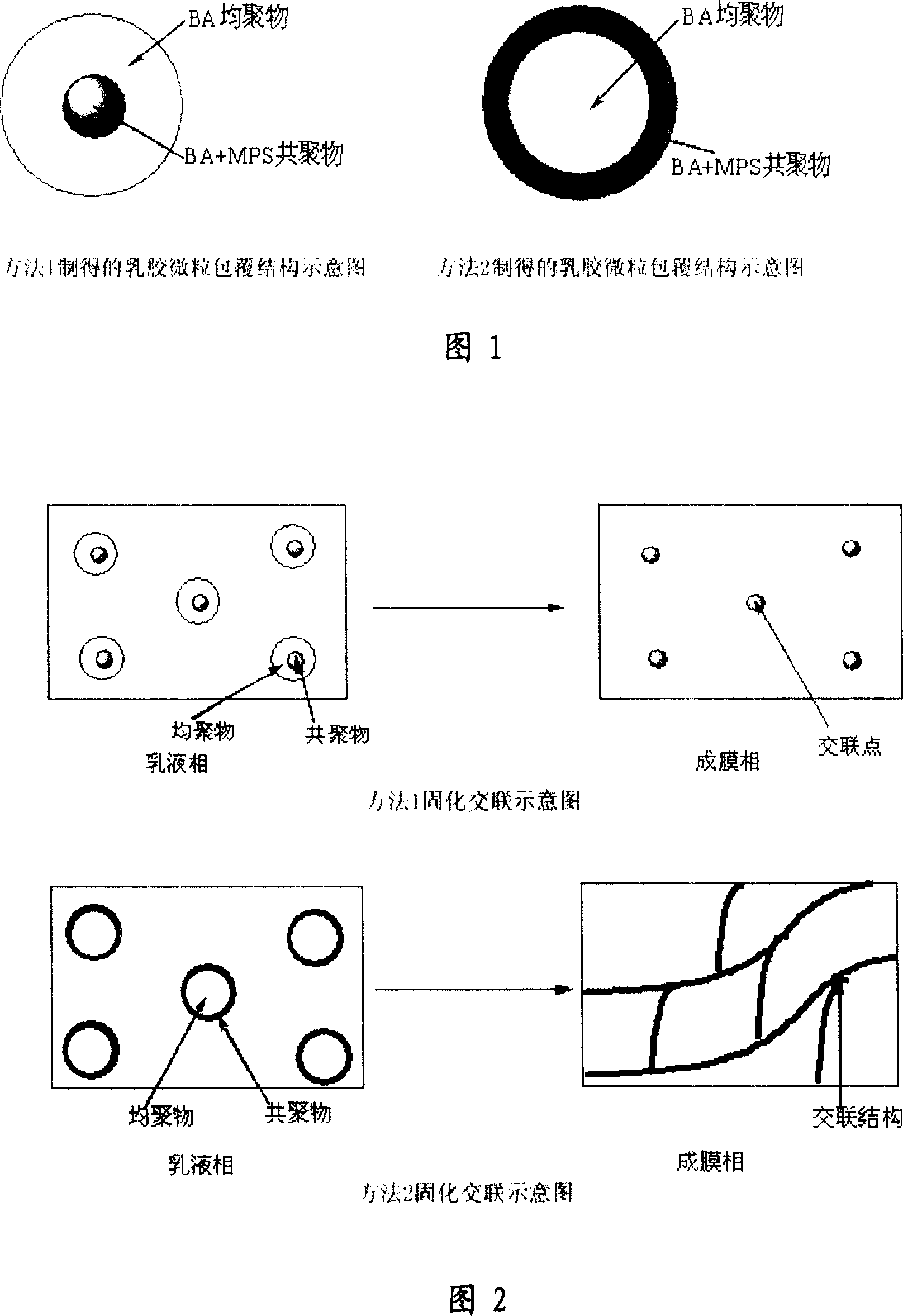

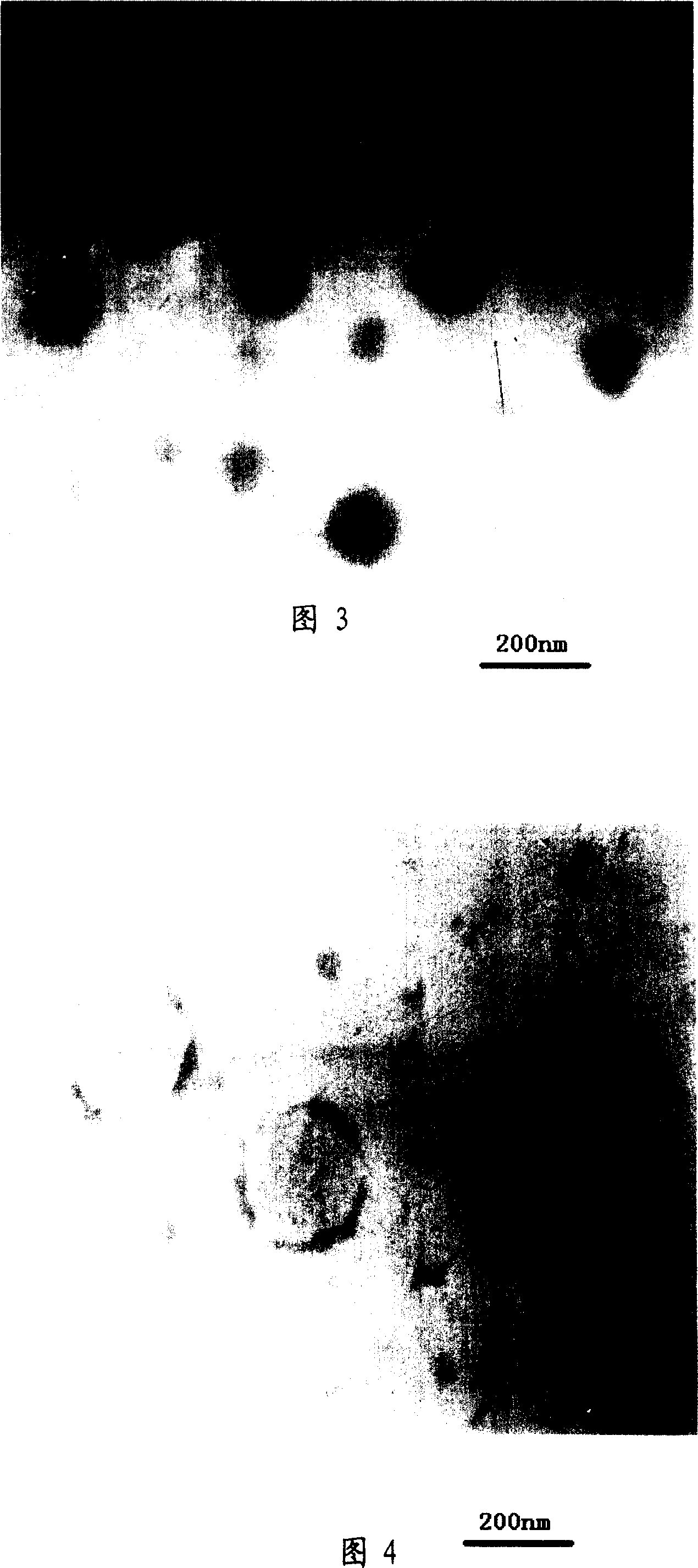

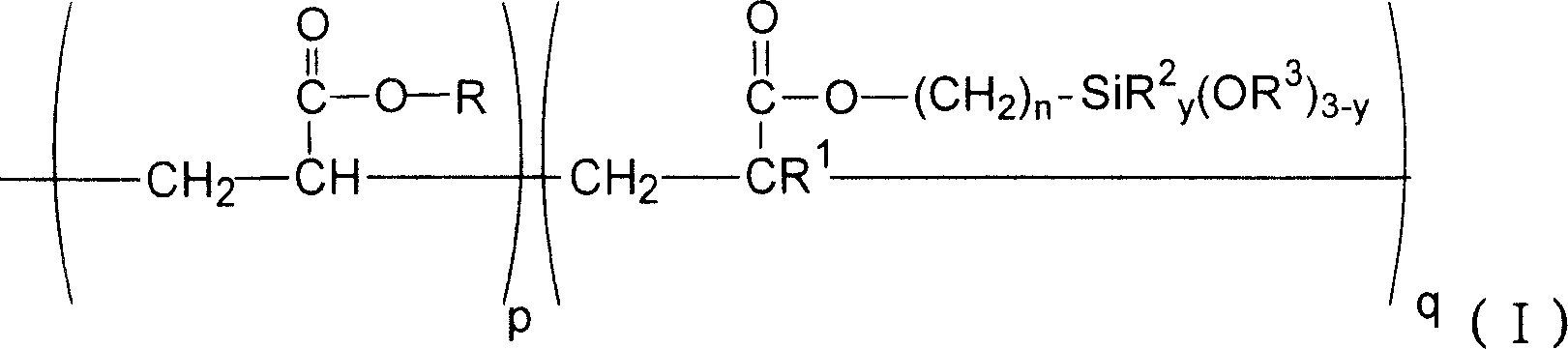

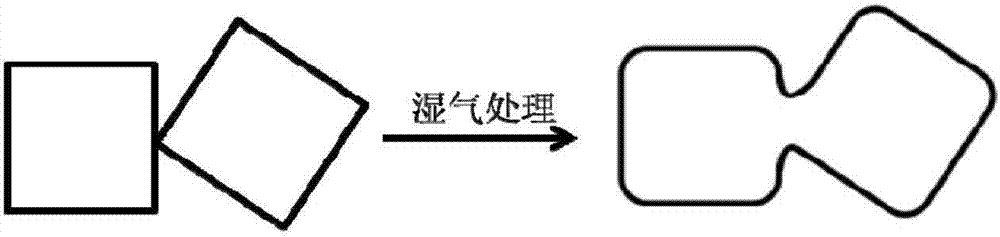

Disclosed are an acrylate emulsion modified by one or more acryloxyalkoxysilanes with a controllable latex particle shape, and a preparation method and application thereof. The emulsion of the present invention is obtained by the emulsion copolymerization of (meth)acryloyloxyalkoxysilane and acrylic acid hydrocarbyl ester, and it is not necessary to use methacrylate monomers with high volatility and toxicity, styrene and unsaturated acids. other types of unsaturated monomers. Using the relationship of the reactivity ratio in the reaction kinetics, by controlling the entry of the reaction raw materials, copolymers with different latex particle morphological structures can be obtained through emulsion polymerization. The copolymerization method is simple in operation, low in cost and environmentally friendly. The polymer product thus obtained has significantly improved certain mechanical properties. The emulsions can be used in buffer coatings, adhesives, sealants, gaskets, inks, and cleaning agents. The sealant made with this emulsion has good stability and can be placed stably for more than one year at room temperature. It can be widely used in sealing, coating and bonding of automobiles, building materials, daily products, etc.

Owner:汉高股份两合公司

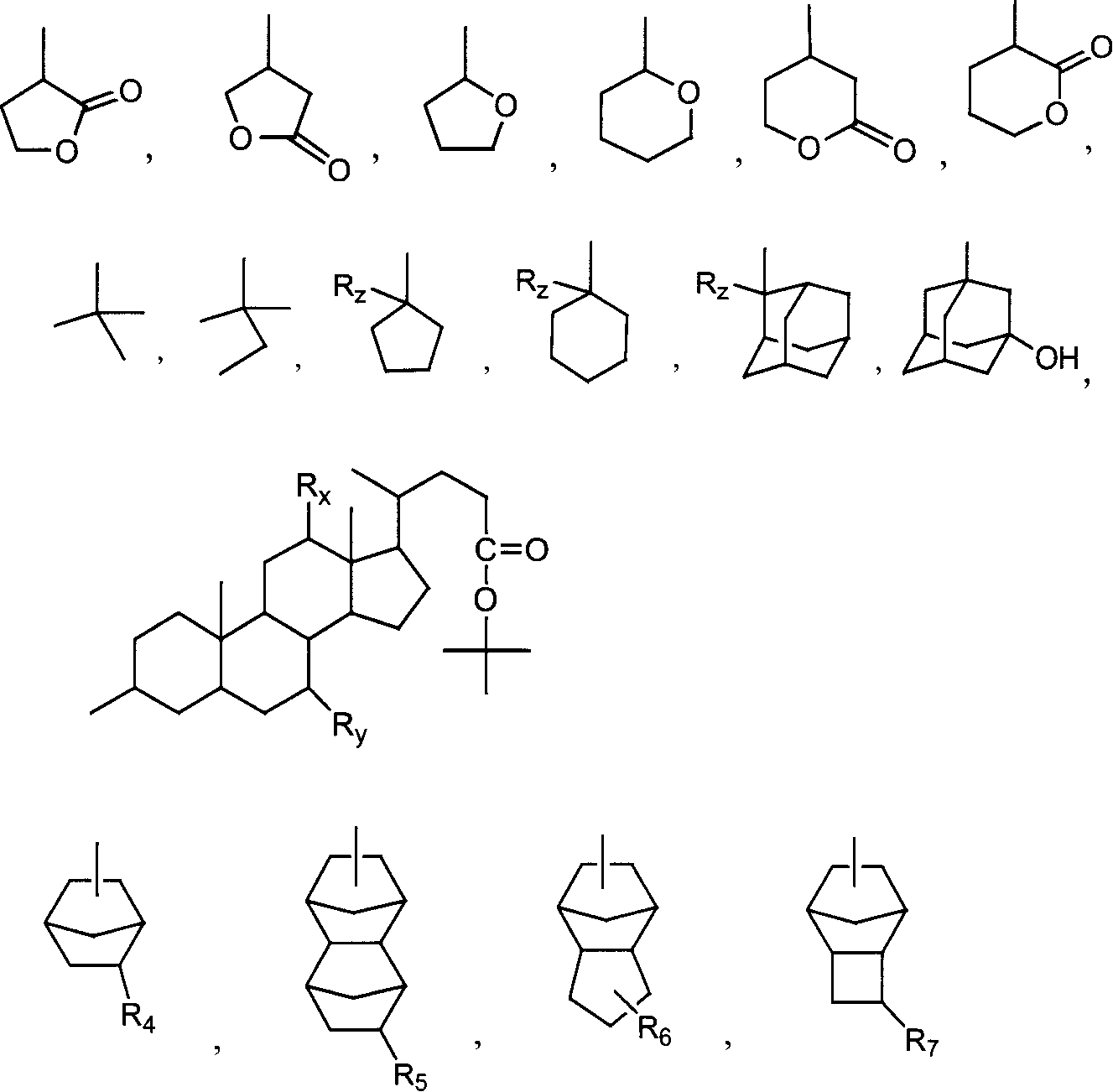

193nm photoresist containing silicon coupling agent and its filming resin

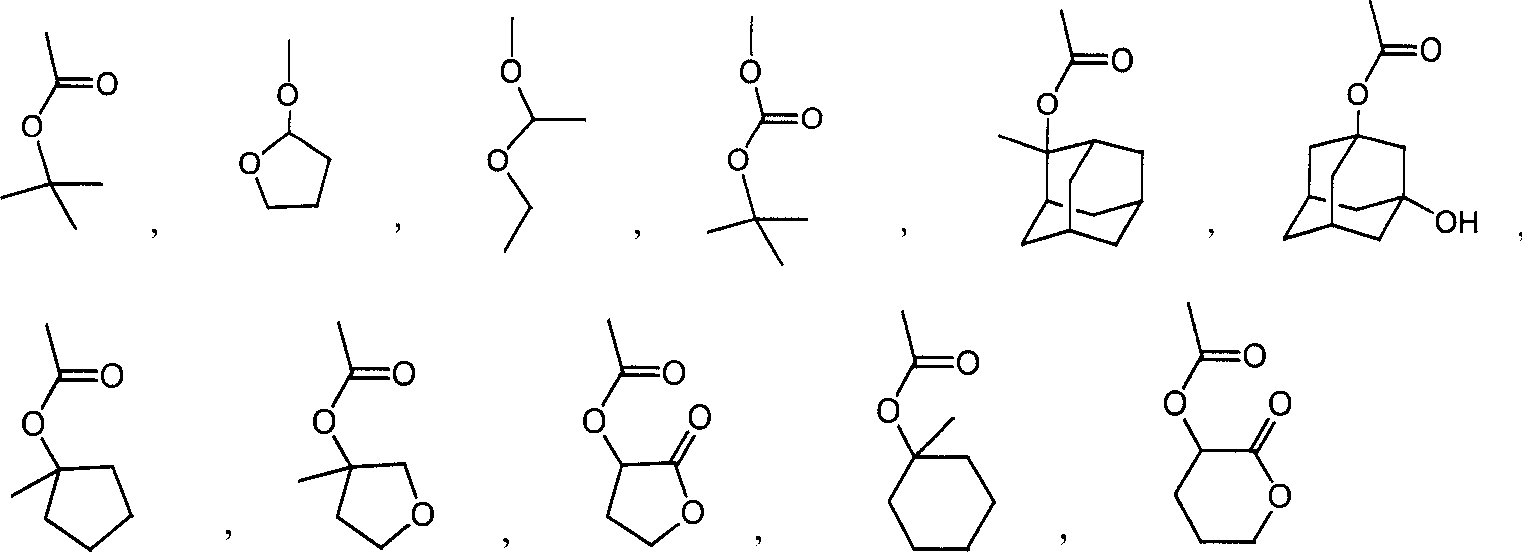

InactiveCN1828418AWeak absorptionImprove adhesionPhotosensitive materials for photomechanical apparatusChemistryPhotoresist

Wherein, it selects the copolymer with silicon-contained acrylic ester and acrylic ester or naphthenic hydrocarbon. This invention improves photoresist adherence and anti-drying etching performance, increases the resolvability by Si-OR group, and enhances the contrast of exposure area and non-exposure area to obtain more clear photo-etching figure.

Owner:苏州市成技新材料开发有限公司

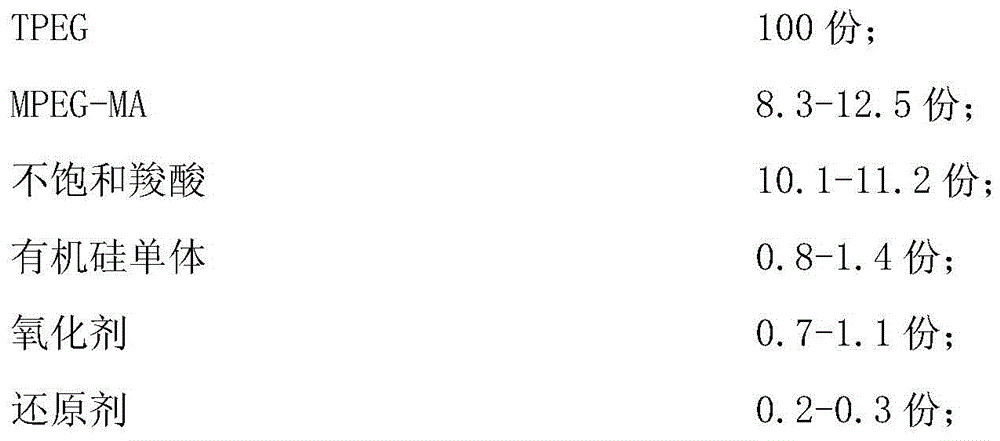

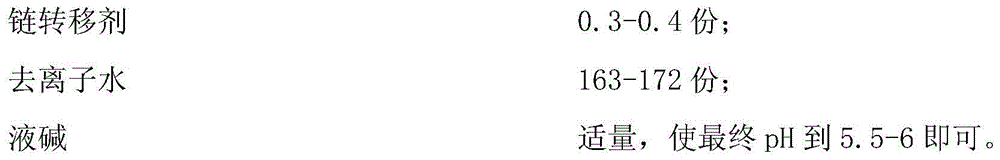

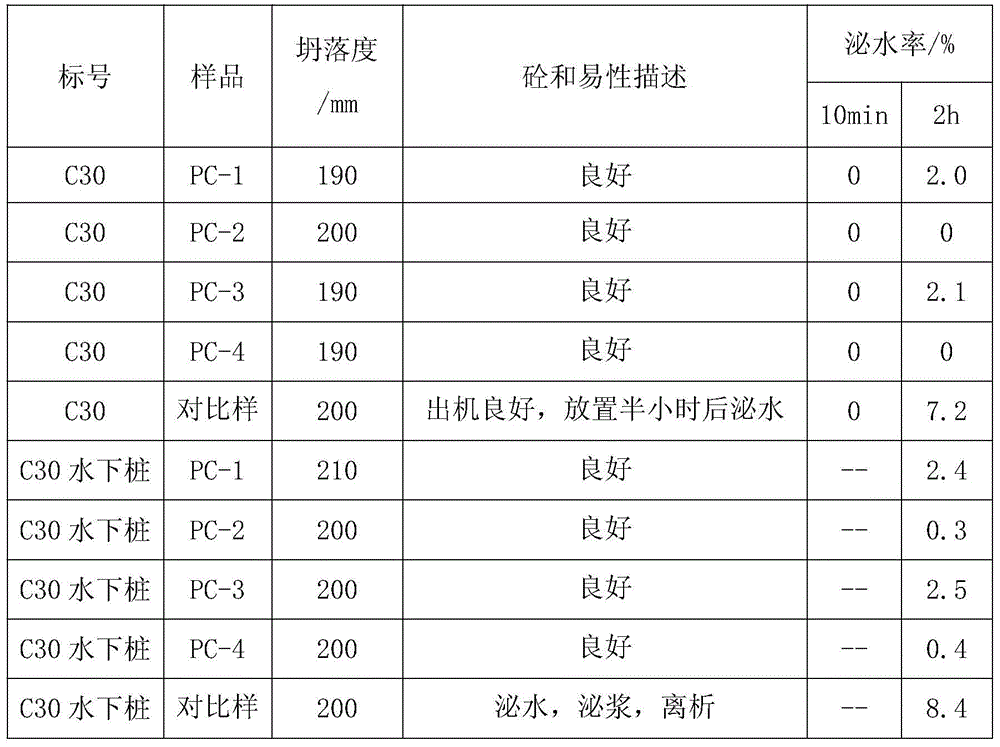

Polycarboxylate superplasticizer with high water retention and preparation method thereof

The invention discloses a polycarboxylate superplasticizer with high water retention and a preparation method thereof. The polycarboxylate superplasticizer with high water retention is prepared from, by weight, 100 parts of TPEG, 8.3-12.5 parts of MPEG-MA, 10.1-11.2 parts of unsaturated carboxylic acid, 0.8-1.4 parts of organosilicone monomer, 0.7-1.1 parts of an oxidizing agent, 0.2-0.3 part of a reducing agent, 0.3-0.4 part of a chain transfer agent, 163-172 parts of deionized water and liquid alkali for making pH to 5.5-6. The polycarboxylate superplasticizer with high water retention has high slump under the condition of low dosage, workability of concrete can be improved, and water-retention and tackifying effects are achieved. Meanwhile, reaction condition is suitable, the reaction is normal-temperature reaction without heat source, and the technology is concise, environmentally friendly and highly efficient and is suitable for a large-scale industrial production method.

Owner:厦门路桥翔通建材科技有限公司

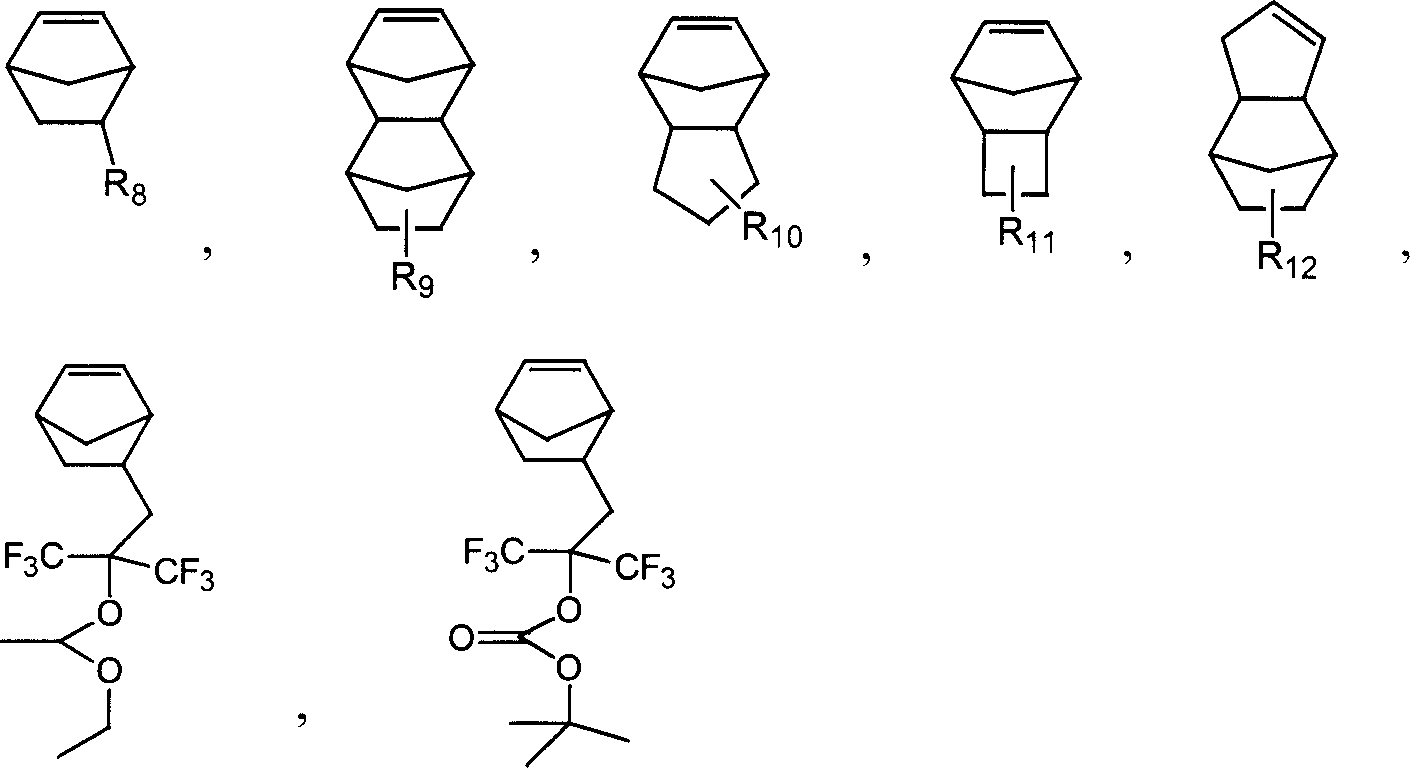

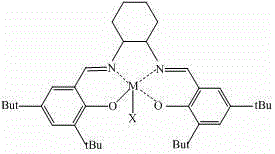

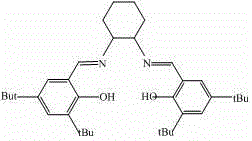

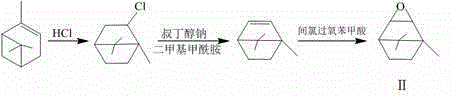

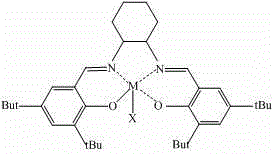

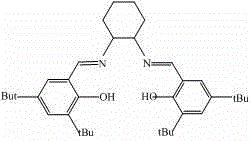

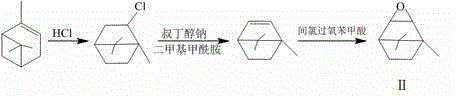

Method for preparing polycarbonate by copolymerizing carbon dioxide and alpha-pinene derivatives

The invention discloses a method for preparing polycarbonate by copolymerizing carbon dioxide and alpha-pinene derivatives, and belongs to the field of high molecular materials. The polycarbonate material with an alternate structure is prepared by copolymerizing two alpha-pinene derivatives and the carbon dioxide under a catalytic system and under the condition that the carbon dioxide pressure is 2.0 to 5.0 MPa, wherein the catalytic system consists of tetradentate schiff base metal complexes SalenMX as a main catalyst and bi(triphenylphosphine) ammonium chloride or 4-dimethylamino-pyridine or the like as a cocatalyst. By adoption of the method, the process is simple, and the raw material alpha-pinene is cheap, easily available and renewable. The method has the advantages of high catalytic efficiency, large molecular weight of copolymers, narrow distribution and the like. The polycarbonate obtained by polymerization has the characteristics of excellent biodegradability, excellent biocompatibility and the like, and can be applied to industries such as agriculture, biomedicine and the like.

Owner:KUNMING UNIV OF SCI & TECH

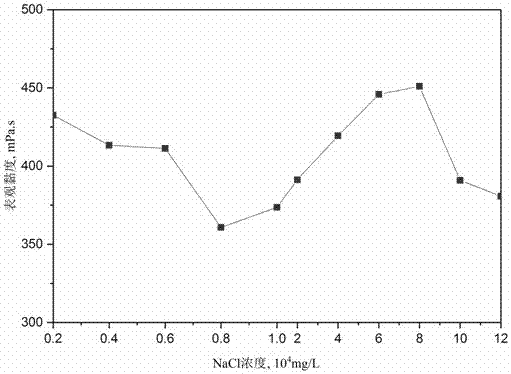

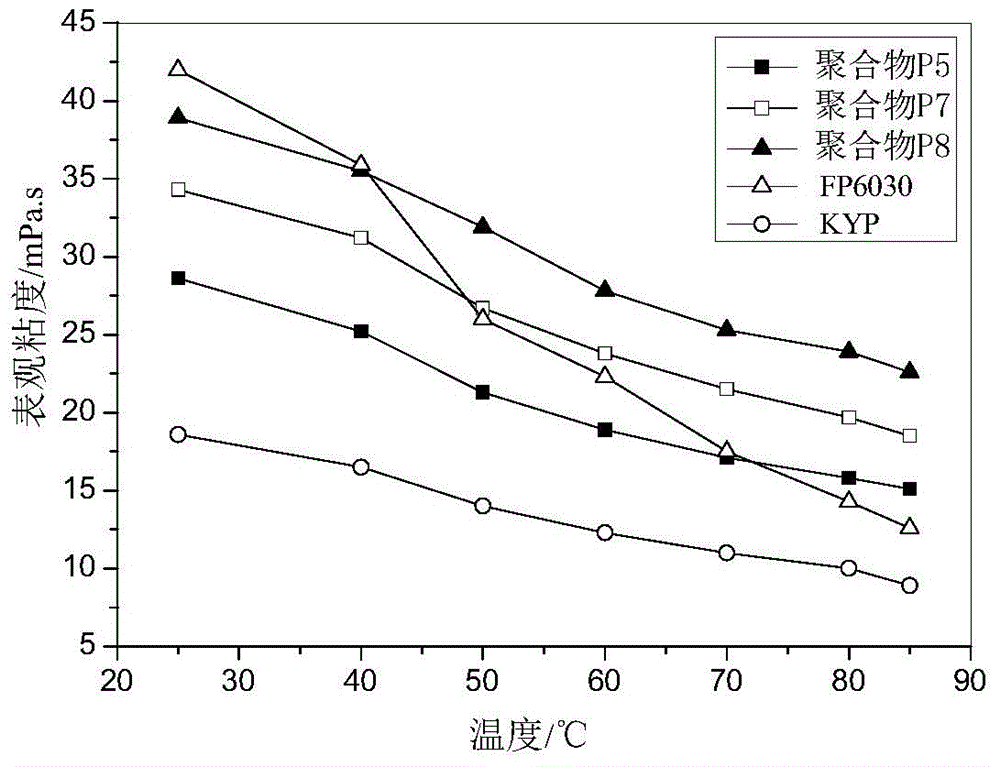

Surface-active two-tailed hydrophobic associated polymer and preparation method thereof

ActiveCN107033293AAvoid hydrolysisImprove rigidityDrilling compositionPolymer scienceTemperature resistance

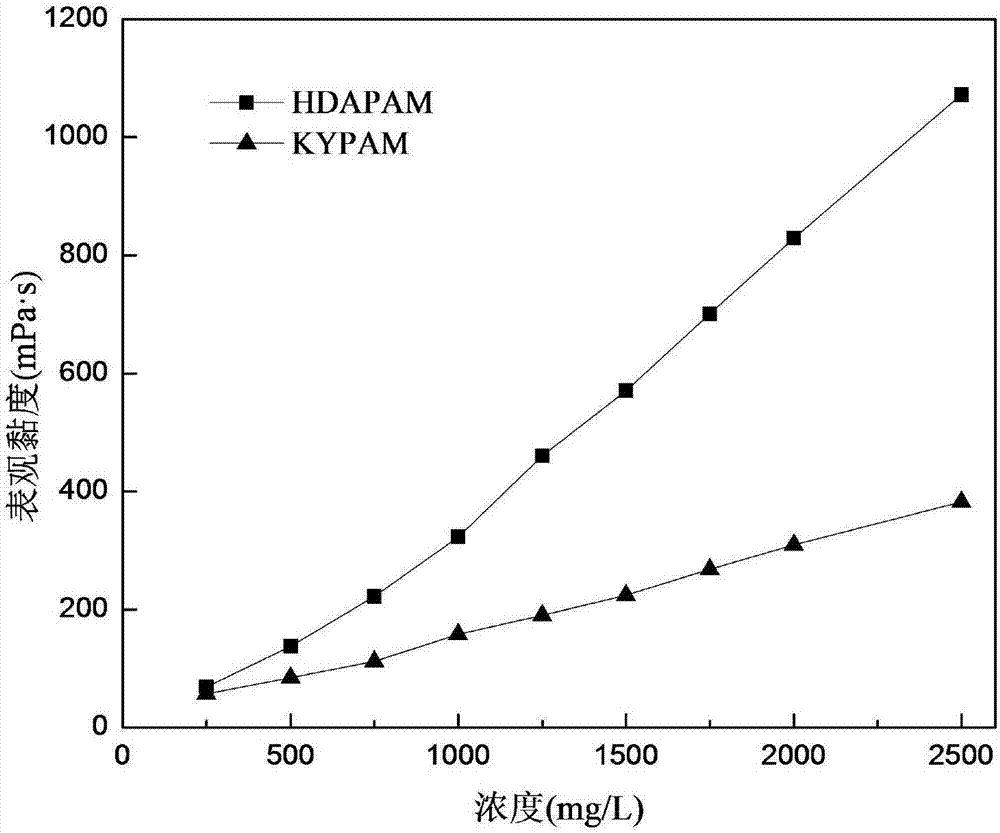

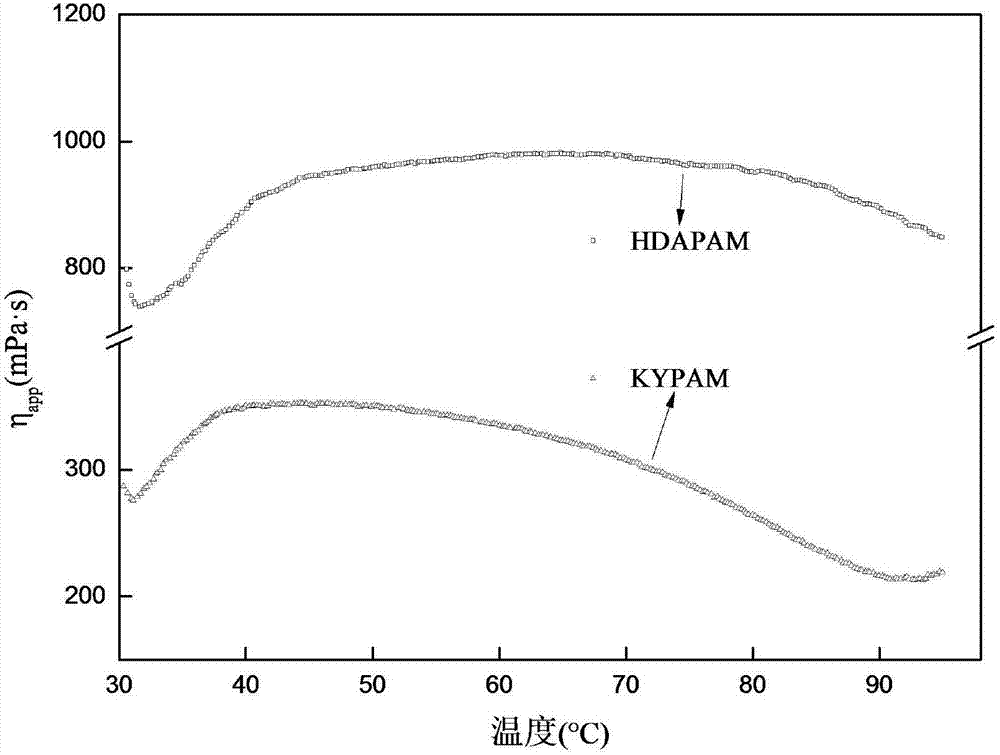

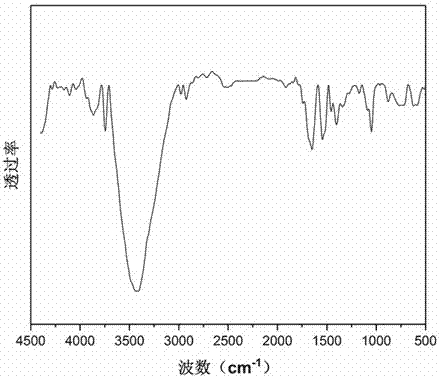

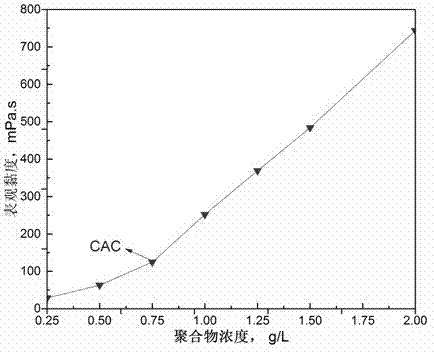

The invention discloses a surface-active two-tailed hydrophobic associated polymer and a preparation method thereof; the surface-active two-tailed hydrophobic associated polymer is prepared via micellar free radical copolymerization: adding a surfactant, sodium lauryl sulfate, and a hydrophobic monomer, N-phenethyl-N-alkyl (methyl) acrylamide or N-benzyl-N-alkyl (methyl) acrylamide into the aqueous solution of acrylamide, acrylic acid, 2-acrylamide-2-methylpropanesulfonic acid, and surface-active macromonomer polyoxyethylene lauryl ether (methyl) acrylate, using the surfactant to solubilize the hydrophobic monomer in the formed micelle, using sodium hydroxide to adjust pH to 6-8, and copolymerizing the hydrophobic monomer and a water-soluble monomer by means of photo-initiation. The properties, such as tackifying performance, temperature resistance, salt resistance and hydrolysis resistance, of the polymer can be effectively improved, the preparation method and principle of the polymer are reliable, and the preparation method is simple to perform and has a promising application prospect.

Owner:SOUTHWEST PETROLEUM UNIV

Supramolecular polymer based on multiple intermolecular acting forces and preparation method thereof

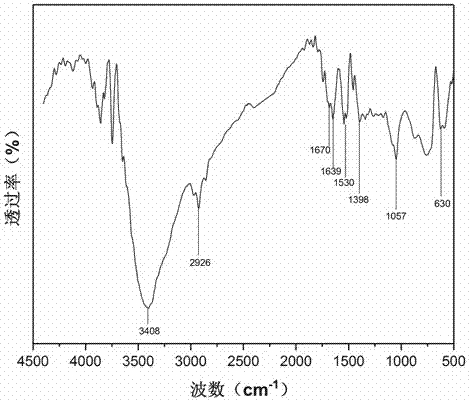

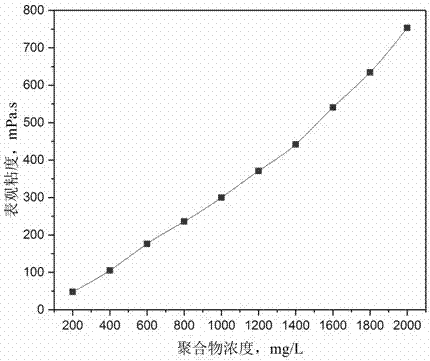

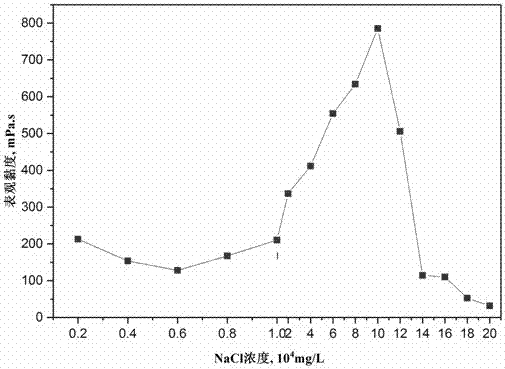

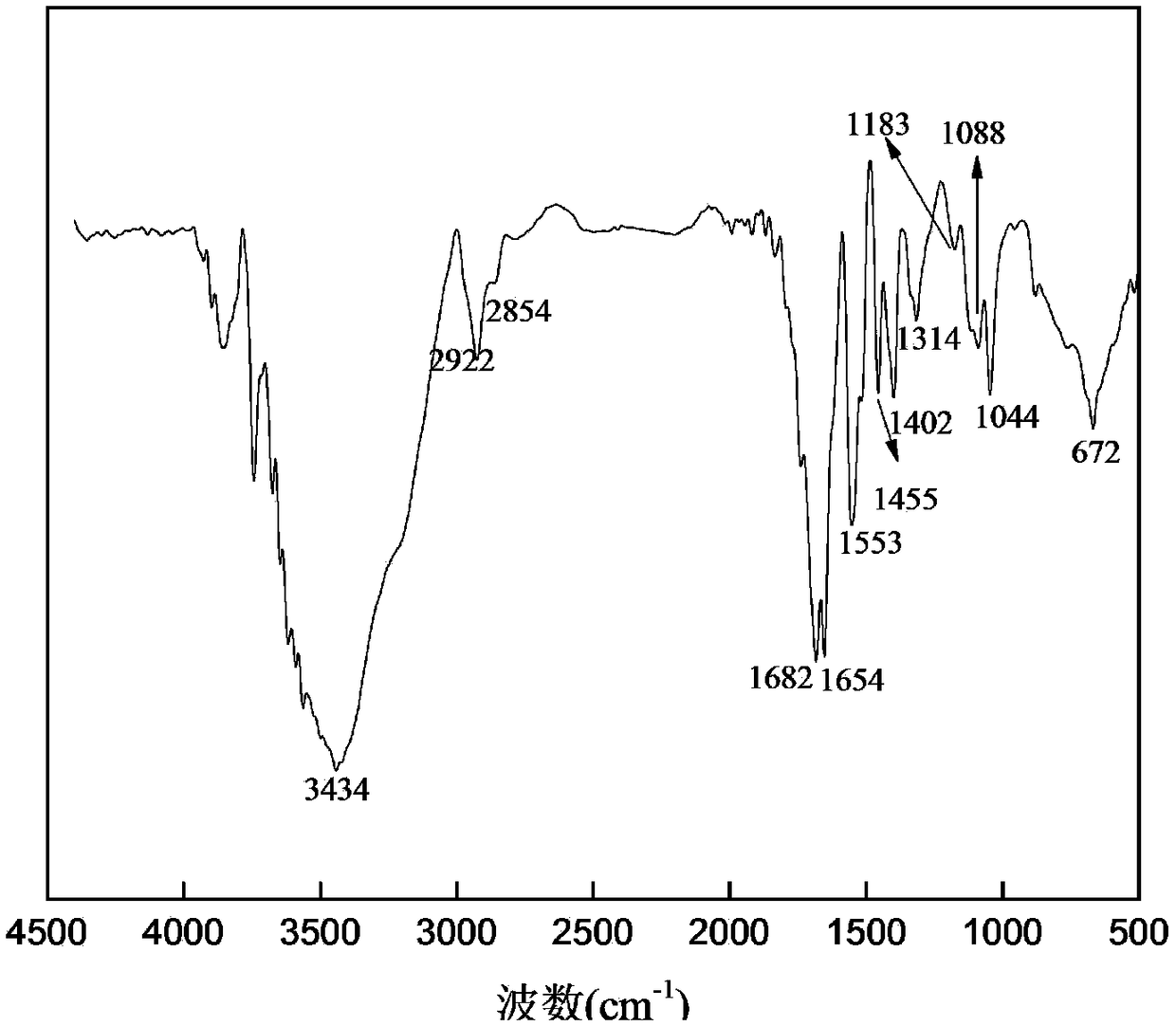

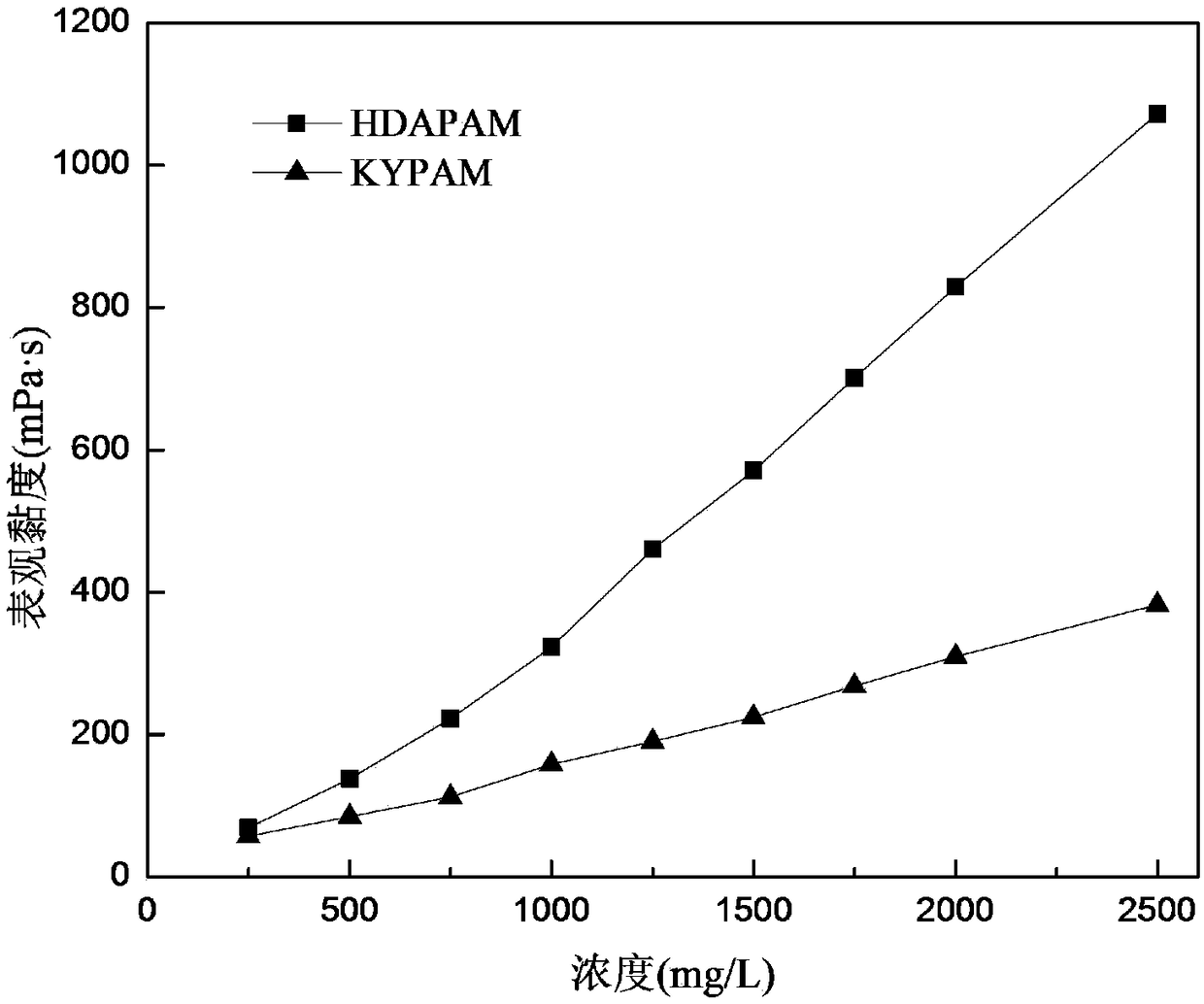

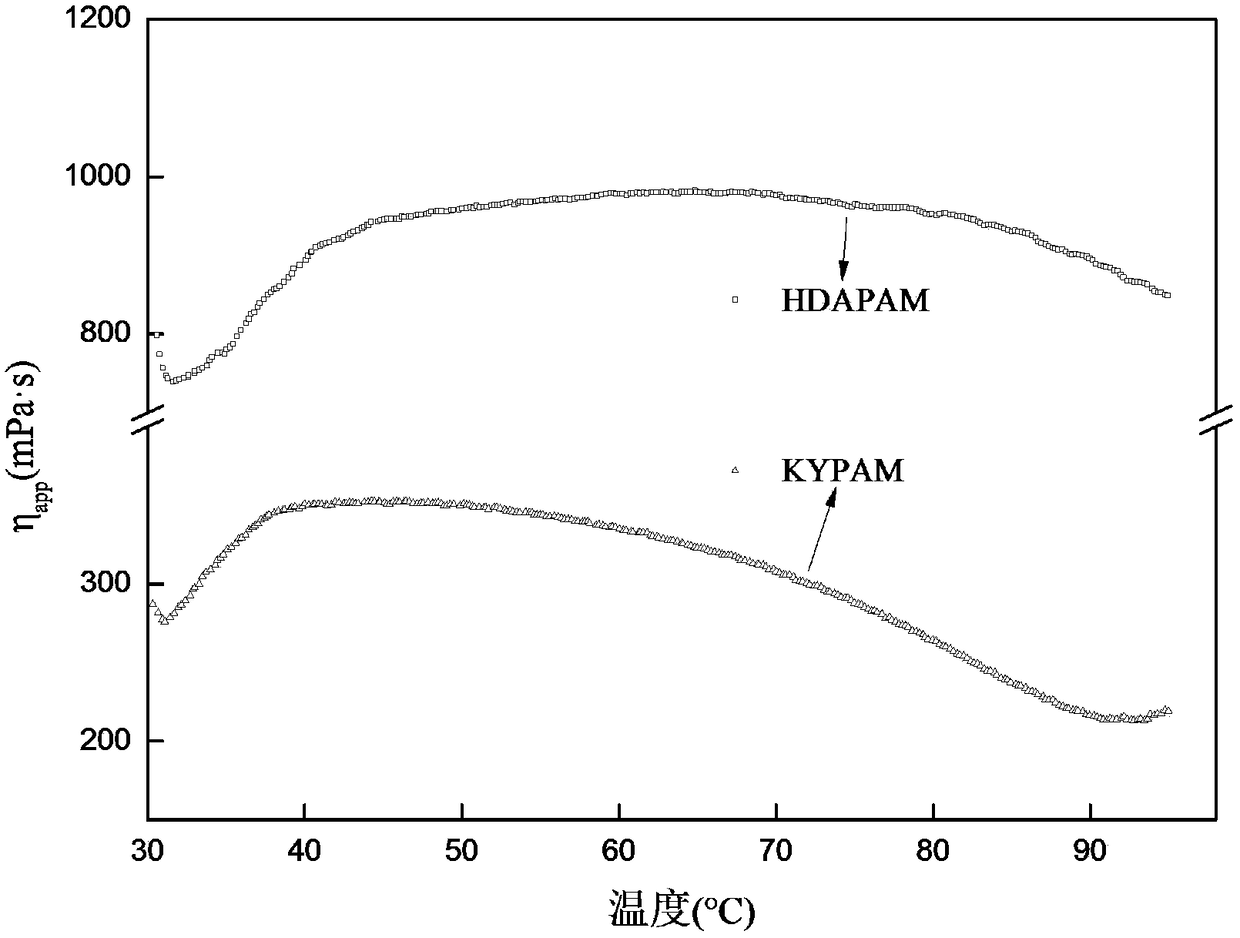

ActiveCN107459604AGood temperature and salt resistanceEasy to copolymerizeDrilling compositionPolymer adhesivePersulfate

The invention discloses a supramolecular polymer based on multiple intermolecular acting forces. The supramolecular polymer is prepared by a reaction monomer acrylamide, crylic acid, maleic anhydride modified beta-cyclodextrin and methylacryloyl chloride modified alkylphenol polyoxyethylene ether through polymerization reaction. The preparation method comprises the steps that 1, the acrylamide, the crylic acid, the maleic anhydride modified beta-cyclodextrin and the methylacryloyl chloride modified alkylphenol polyoxyethylene ether are added into deionized water, the pH value of a system is regulated to 6-8 after even stirring; 2, nitrogen is introduced to the solution obtained in the step 1 for 30 minutes to remove oxygen, a redox initiation system prepared from persulfate and sodium hydrogen sulfite is added, heating is performed to 30-50 DEG C, and reaction is performed for 4-7 hours to obtain a polymer colloid, namely the supramolecular polymer. The supramolecular polymer is used for oil field displacement, the viscosity, heat resistance and salt tolerance properties and shear restoration of the supramolecular polymer are remarkably improved, and the supramolecular polymer has a higher use value.

Owner:SOUTHWEST PETROLEUM UNIV

Sulfonate lycine type hydrophobic associated polymer and preparation method thereof

ActiveCN107022050AIncrease viscosityImprove temperature resistanceDrilling compositionPolymer scienceNitrogen gas

The invention discloses a sulfonate lycine type hydrophobic associated polymer and a preparation method thereof. A preparation process of the sulfonate lycine type hydrophobic associated polymer comprises the following steps that firstly, acrylamide and acrylic acid are mixed in an aqueous solution, and the pH of a system is regulated to be around 6 to 8; secondly, 3-(dimethylamino propyl methacrylamide)propanesulfonate, N-aryl-N-alkyl(methyl)acrylamide and lauryl sodium sulfate are added and stirred until the solution is clear; and thirdly, after nitrogen is led in for deoxidization, a photoinitiator azobis(isobutylamidine hydrochloride) is added for polymerization under photoinitiation conditions. Since advantages of a double-tail hydrophobic associated polymer and advantages of a lycine type polymer are combined, the viscosifying capability, the temperature endurance, the salt resistance and the hydrolysis resistance of the sulfonate lycine type hydrophobic associated polymer are remarkably improved, the sulfonate lycine type hydrophobic associated polymer can be used for an oil-displacing agent or an acidizing and fracturing thickener used for increasing a crude oil recovery rate in oilfield development, and the preparation method of the sulfonate lycine type hydrophobic associated polymer has the advantages of reliable principle, easiness in operation and wide market prospect.

Owner:SOUTHWEST PETROLEUM UNIV

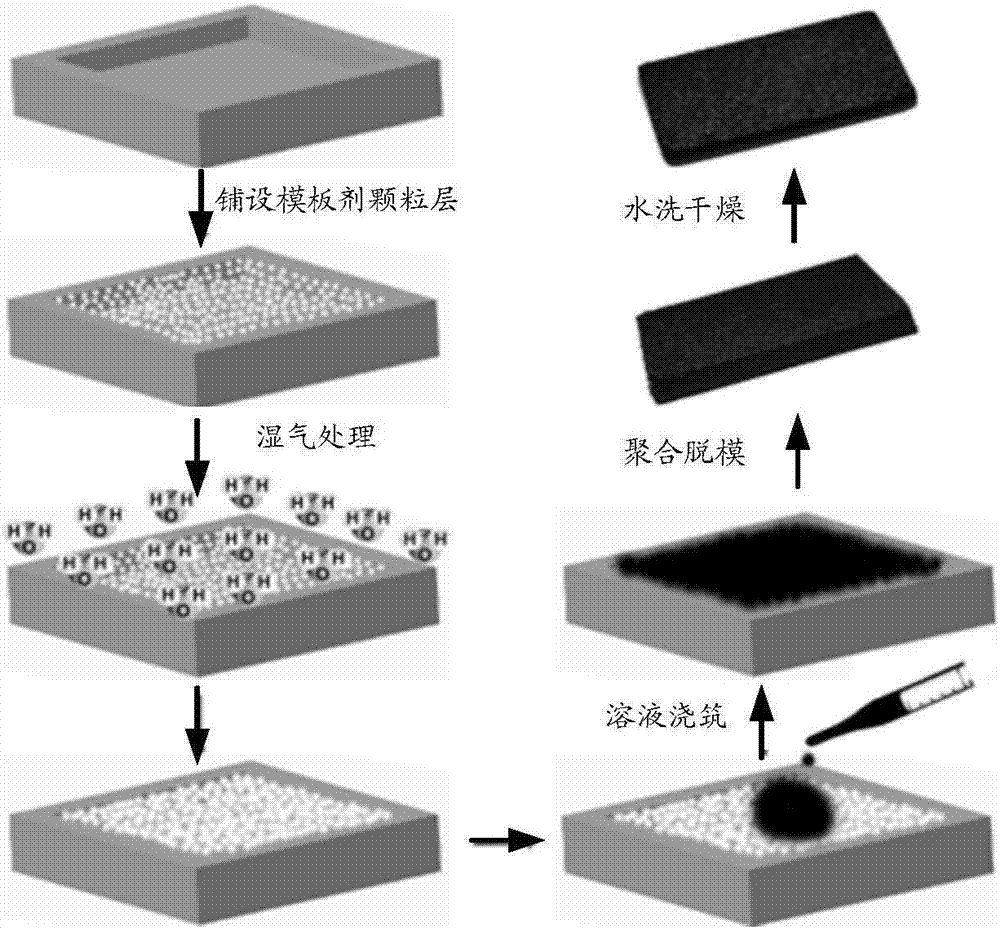

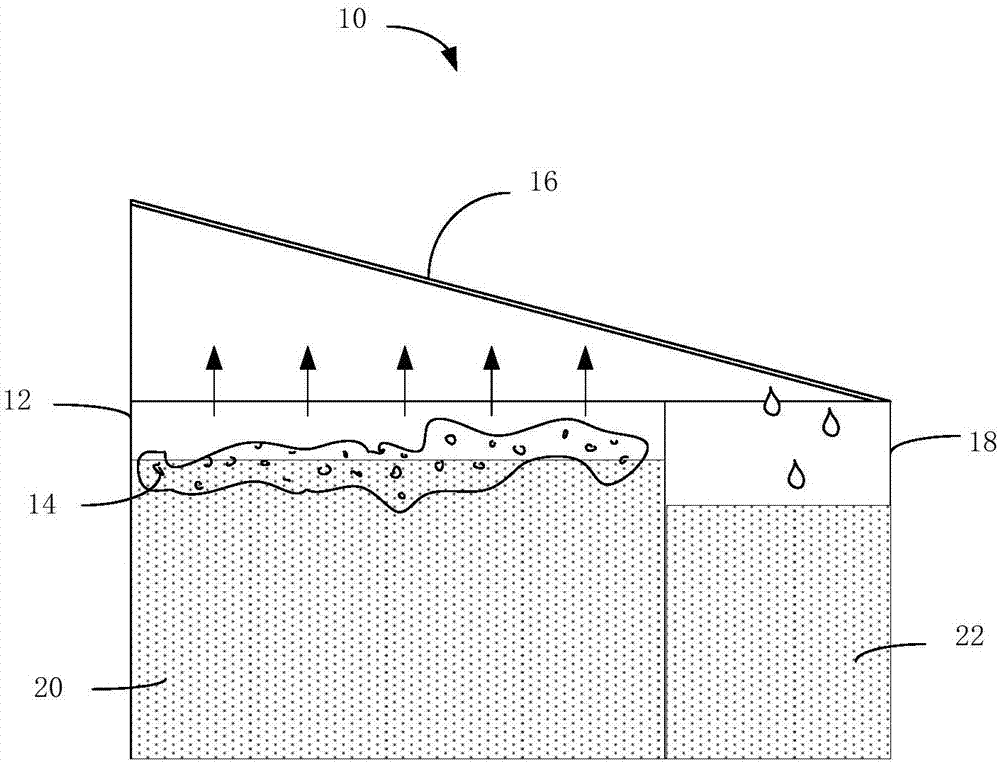

Synthetic method of graphene reverse osmosis composite membrane

ActiveCN106178977AImprove qualityGuaranteed decentralizationWater contaminantsWater/sewage treatment bu osmosis/dialysisReverse osmosisSolvent

The invention discloses a synthetic method of a graphene reverse osmosis composite membrane, and belongs to the technical field of materials. The method comprises the following steps: firstly preparing amido graphene , then mixing the amido graphene with a solvent, carrying out ultrasonic dispersion, adding unsaturated acyl chloride and triethylamine in sequence, stirring and heating to react; filtering, and washing to obtain an intermediate; adding monomers into a mixture of the intermediate and the solvent, stirring uniformly, then adding an initiator, heating and stirring to form the membrane. According to the reverse osmosis composite membrane prepared by the method, polymers are dispersed among layers, the polymers maintain the dispersion of the layers while the mechanical strength of the membrane is improved, and the reverse osmosis performance of graphene is also retained. The reverse osmosis composite membrane is good in performance, and fundamentally overcomes the defect such as small graphene specific surface area caused by excessive stacking of the layers in the graphene synthesis process. The synthetic graphene reverse osmosis composite membrane can be used for water treatment in the fields of electrons, information, energy resources, materials, biological medicine and the like.

Owner:XINXIANG UNIV

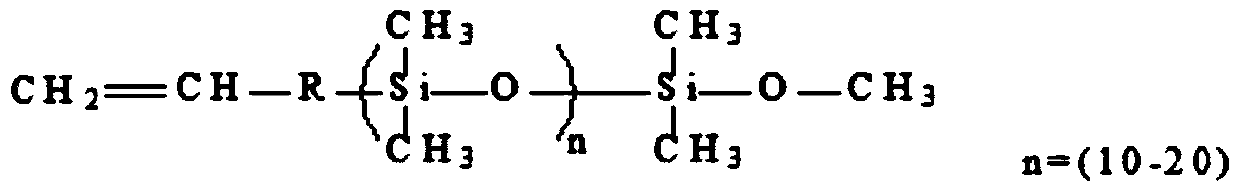

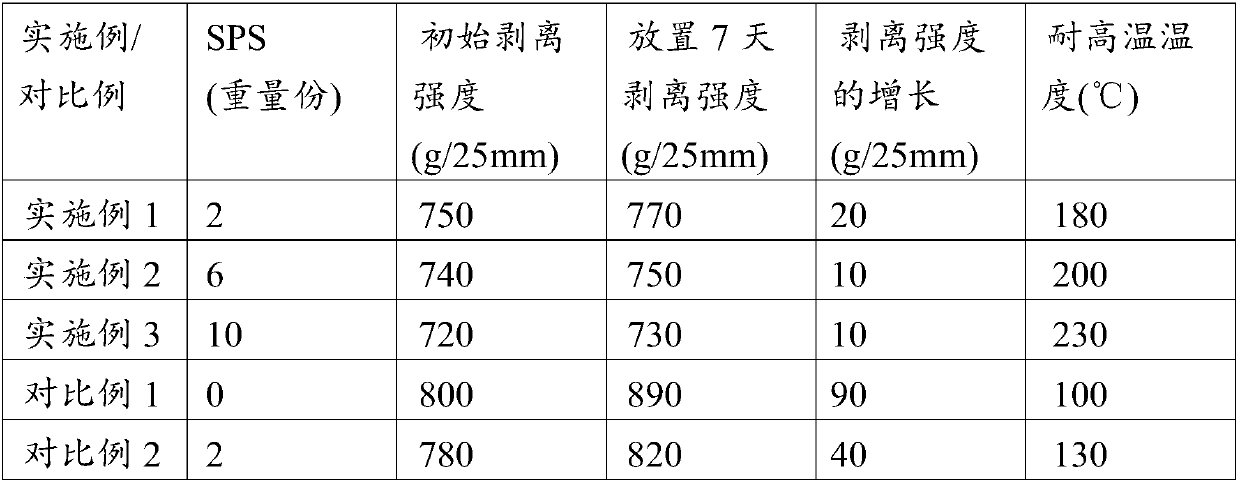

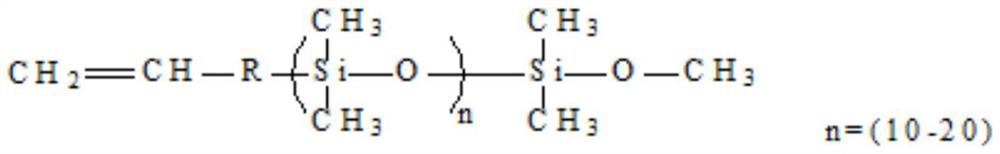

Preparation method of organosilicon modified polyacrylate pressure-sensitive adhesive and obtained pressure-sensitive adhesive

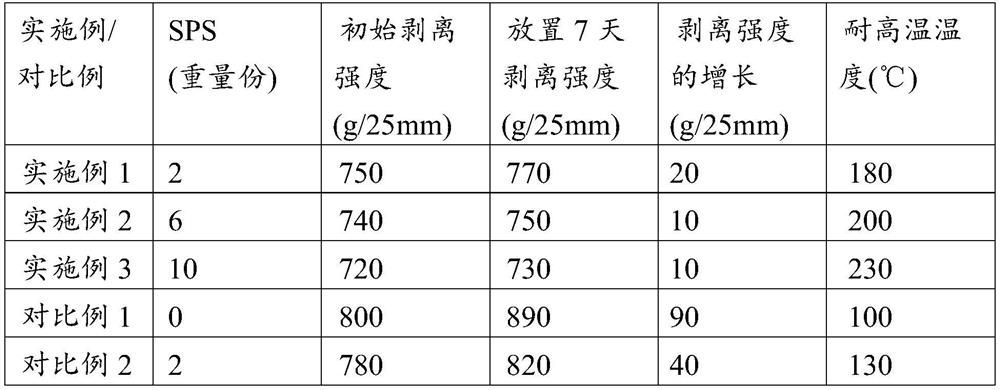

ActiveCN109536085AGood adhesionStrong cohesionEster polymer adhesivesPolymer scienceFunctional monomer

The invention relates to a preparation method of an organosilicon modified polyacrylate pressure-sensitive adhesive. The method includes: continuously adding a mixture of a single end double-bond terminated organosilicon polymer (SPS), 2-ethylhexyl acrylate and butyl acrylate that serve as acrylic soft monomers, an acrylic functional monomer and a part of an initiator dropwise for reaction, then adding methyl methacrylate serving as an acrylic hard monomer into a reaction kettle at one time, and then adding the remaining initiator into the reaction kettle at one time for further reaction. As the method provided by the invention adopts SPS, and employs the technology of first dropwise adding reaction and then adding of methyl methacrylate and the remaining initiator at one time for reaction, the prepared organosilicon modified polyacrylate pressure-sensitive adhesive can ensure certain peeling strength and reduce the peeling strength increase, and also has high temperature resistance.

Owner:深圳市益达兴科技股份有限公司

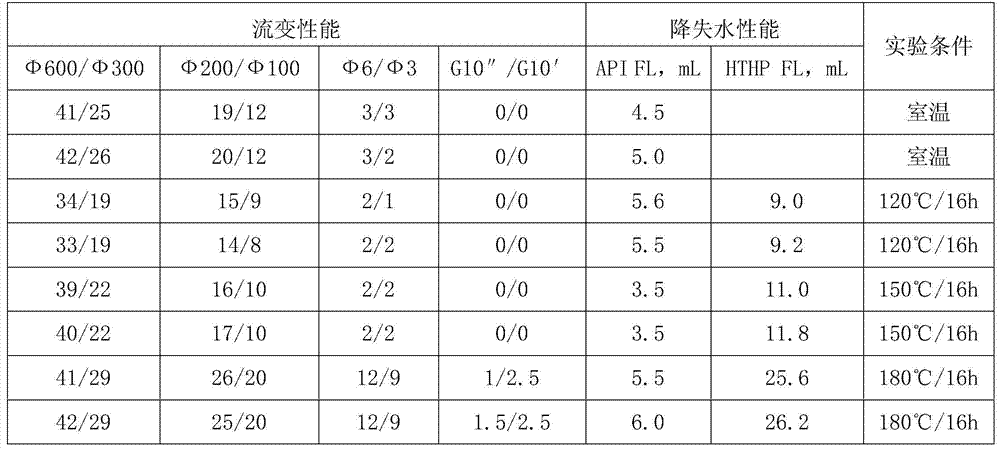

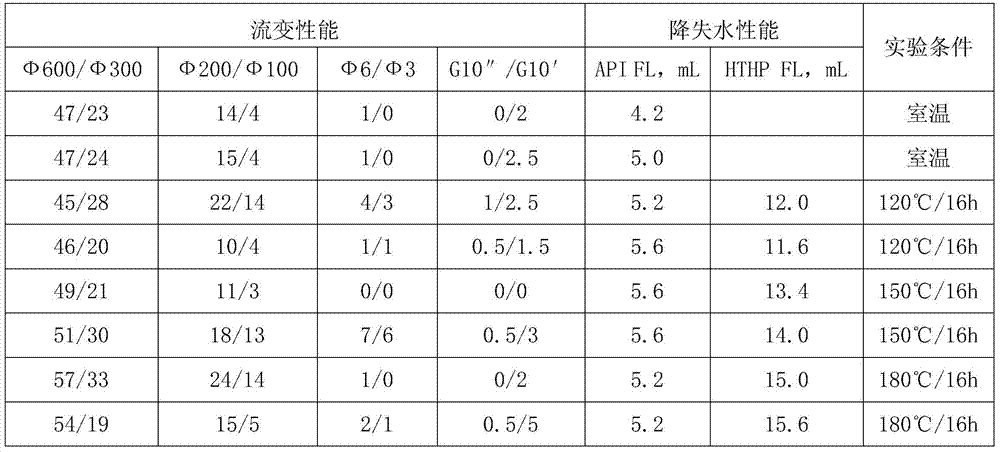

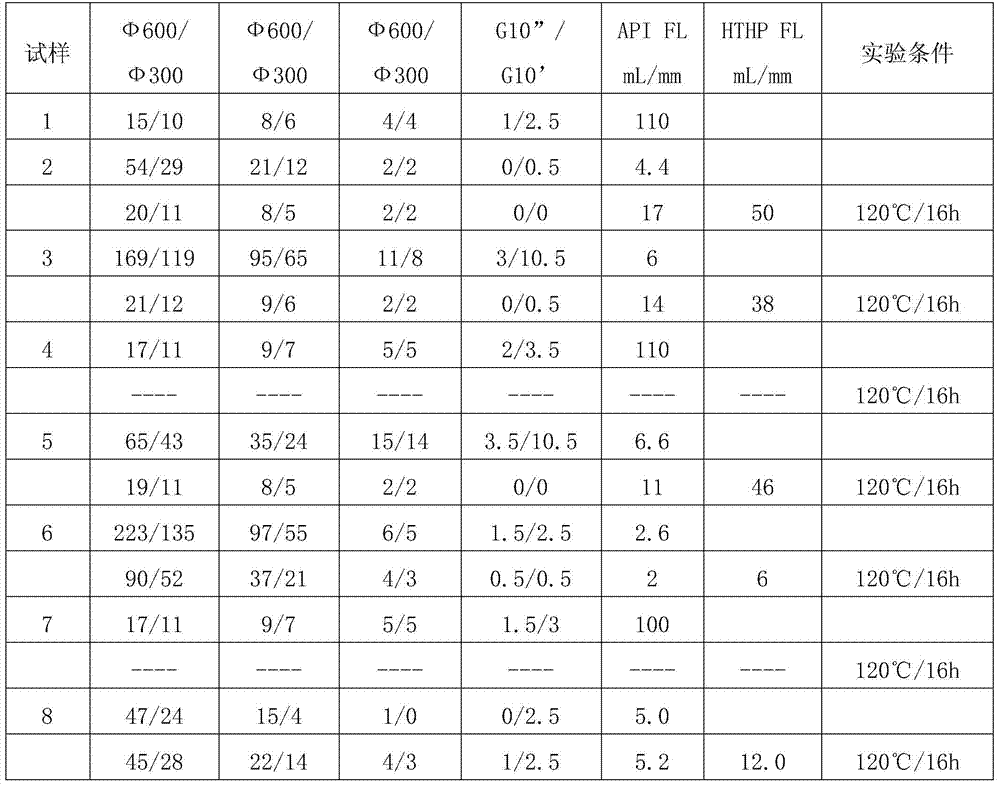

Anti-salt and anti-calcium fluid loss reducer for drilling fluid and preparation method thereof

ActiveCN104497995BGood filter loss reduction effectImprove salt resistanceDrilling compositionCalcium EDTAPollution

The invention discloses a salt-resistant and calcium-resistant filtrate reducer applied to a drilling fluid and a preparation method of the filtrate reducer. The filtrate reducer is prepared from raw materials and water, wherein the raw materials comprise 2-acrylamide-2-methyl propane sulfonic acid, acrylic acid, acrylamide and dimethyl diallyl ammonium chloride; the ratio of m(2-acrylamide-2-methyl propane sulfonic acid) to m(acrylic acid) to m(acrylamide) to m(dimethyl diallyl ammonium chloride) to m(initiator) to m(molecular weight control agent) is (40-60) to (6-10) to (30-40) to (5-9) to (1-2) to (0.1-0.5). The molecular weight of the salt-resistant and calcium-resistant filtrate reducer applied to the drilling fluid and prepared by the preparation method is greatly improved; the coating property, the inhibition property, the heat stability and the salt-resistant and calcium-resistant pollution capacity of the filtrate reducer are greatly improved; by virtue of the salt-resistant and calcium-resistant filtrate reducer applied to the drilling fluid, the rheological property of the drilling fluid can be greatly improved; the salt-resistant and calcium-resistant filtrate reducer applied to the drilling fluid also has a high temperature-resistant effect at 150-180 DEG C.

Owner:北京奥凯立科技发展股份有限公司

Photothermal conversion component, and applications of aniline oligomer and derivatives thereof

ActiveCN106947042AEasy to copolymerizeFacilitate blendingSolar heating energyGeneral water supply conservationThermal energyOligomer

The invention provides a photothermal conversion component which includes at least one of an aniline oligomer and derivatives of the aniline oligomer and is used for convert sunlight into thermal energy. Herein, the derivatives of the aniline oligomer have an aniline oligomer group. The invention also provides applications of the aniline oligomer or the derivatives thereof.

Owner:TSINGHUA UNIV

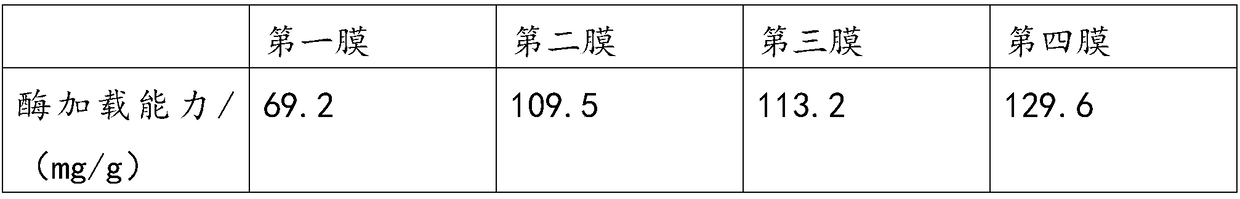

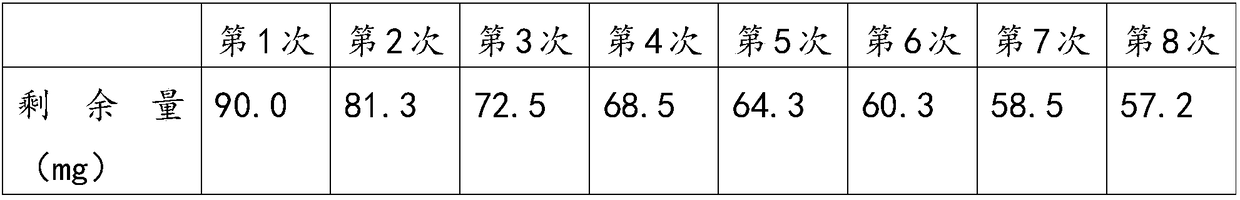

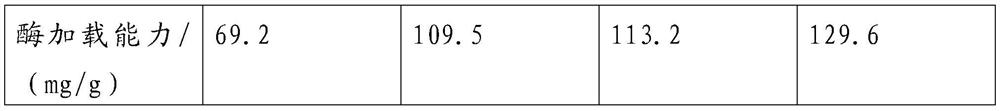

Preparation method of composite nanofiber membrane, composite nanofiber membrane, application of composite nanofiber membrane to enzyme immobilization and immobilized enzyme

ActiveCN108754871AImprove the nano effectGood enzyme loading capacityElectro-spinningOn/in organic carrierComposite nanofibersNanofiber

The invention belongs to the field of nanofiber membranes, and particularly relates to a preparation method of a composite nanofiber membrane, the composite nanofiber membrane, application of the composite nanofiber membrane to enzyme immobilization and an immobilized enzyme. An electrostatic spinning solution containing chitosan is adopted for preparing the nanofiber membrane, and the membrane has a good film-forming property and an enzyme-immobilizing function; meanwhile, polypeptide nanofibers are adopted and loaded onto the membrane, in this way, the property of the membrane is further improved, and the enzyme-immobilizing property of the membrane is improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

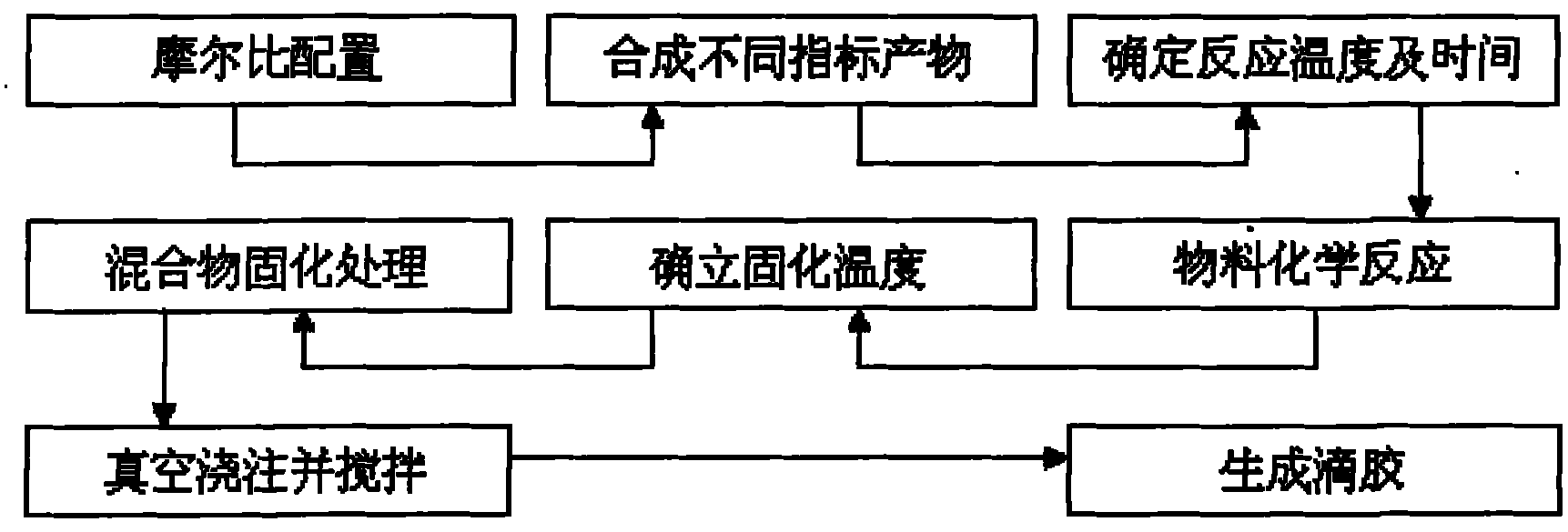

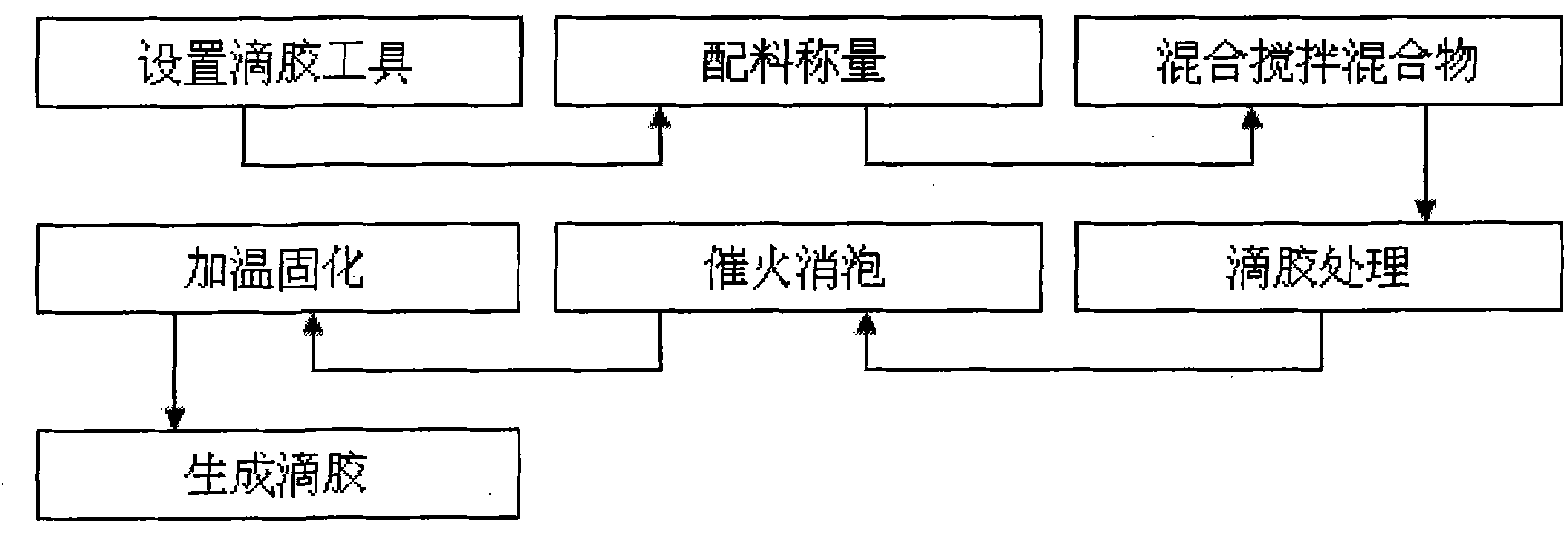

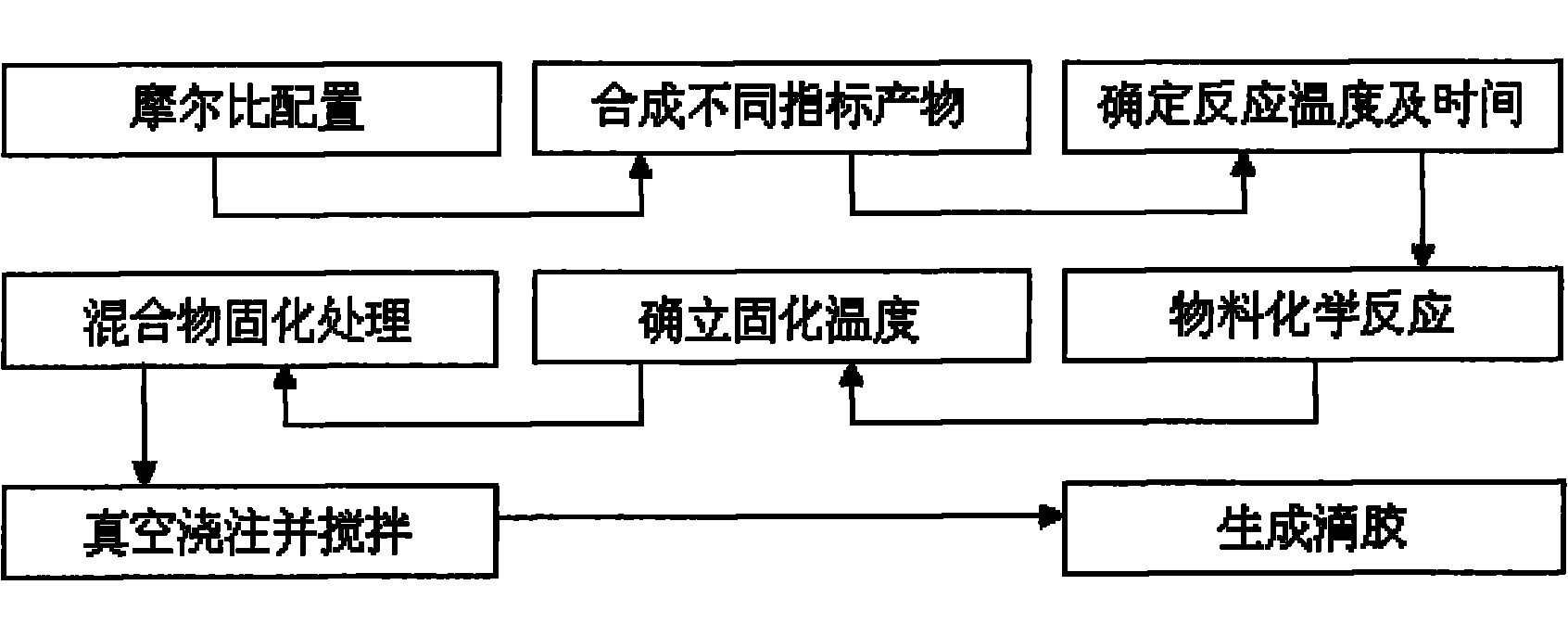

High adhesive force dipping-adhesive manufacturing process

InactiveCN102140323AIncrease crosslink densityIncrease internal stressEpoxy resin adhesivesCross-linkHeat resistance

The invention discloses a high adhesive force dipping-adhesive manufacturing process which comprises the steps of: synthesizing products with different indexes according to different amine values, viscosities and proportions of materials with different solid contents; controlling reaction time and temperature; determining the chemical infrastructure of materials to be fully reacted; carrying out the curing process so as to obtain a mixture with balanced viscosity and solids after the reactant is reacted; repeatedly stirring and putting the mixture into a vacuum tank; and obtaining finished products after reducing air gaps in a poured product and bubbles. The dipping-adhesive resin has high cross-linking density and big internal stress; as network structures contain a large quantity of hydroxide groups absorbing water easily, the dipping-adhesive resin has the defects of high moisture absorption, bad size stability and dielectric performances, low toughness and bad moist head stability and the like, and phenomena such as adhesive failure, air holes, water waves and the like of products appear in the processing process. By improving the formulation, performances such as heat resistance, moisture absorption, dielectric properties, impact toughness, consolidation and the like are improved. Phenomena such as adhesive failure, air holes, water waves and the like of the produced products are avoided.

Owner:DONGGUAN GUANHUI HARDWARE

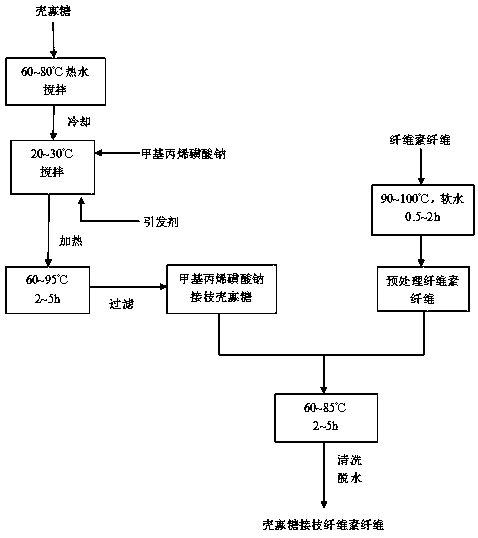

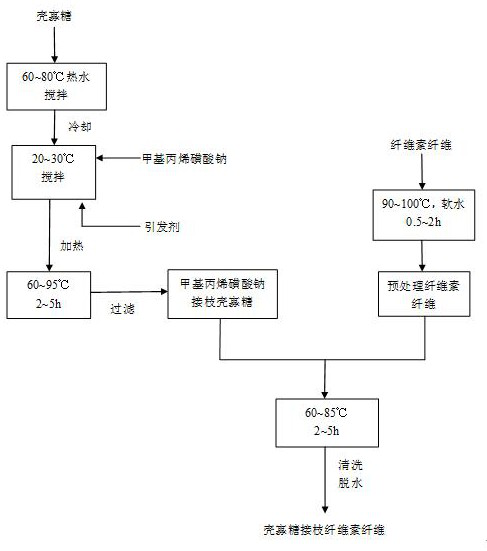

Preparation method of chitosan oligosaccharide grafted cellulose fiber

ActiveCN109112830AHigh amino contentReact SafeBiochemical fibre treatmentVegetal fibresPotassium persulfateSulfonate

The invention relates to a preparation method of chitosan oligosaccharide grafted cellulose fiber. The preparation method comprises following steps: A, preparation of sodium methallyl sulfonate-chitosan, wherein chitosan oligosaccharide is added into hot water to prepare a chitosan oligosaccharide aqueous solution, the chitosan oligosaccharide aqueous solution is cooled to room temperature, sodiummethallyl sulfonate is added into the chitosan oligosaccharide aqueous solution, an obtained mixture is subjected to stirring and heating, and potassium persulfate is added so as to obtain the sodiummethallyl sulfonate-chitosan oligosaccharide solution; B, cellulose fiber pretreatment, wherein cellulose fiber and soft water are introduced into a pretreatment tank, heating, stirring, water discharging, dehydration, and drying are carried out so as to obtain pretreated cellulose fiber; and C, preparation of chitosan oligosaccharide grafted cellulose fiber, wherein the cellulose fiber obtainedin step B is introduced into a reaction vessel, the sodium methallyl sulfonate-chitosan oligosaccharide solution obtained in step A is added, water is added, and stirring, heating, and centrifugal dewatering are carried out so as to obtain the chitosan oligosaccharide grafted cellulose fiber.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN

Method for preparing polycarbonate by copolymerizing carbon dioxide and alpha-pinene derivatives

The invention discloses a method for preparing polycarbonate by copolymerizing carbon dioxide and alpha-pinene derivatives, and belongs to the field of high molecular materials. The polycarbonate material with an alternate structure is prepared by copolymerizing two alpha-pinene derivatives and the carbon dioxide under a catalytic system and under the condition that the carbon dioxide pressure is 2.0 to 5.0 MPa, wherein the catalytic system consists of tetradentate schiff base metal complexes SalenMX as a main catalyst and bi(triphenylphosphine) ammonium chloride or 4-dimethylamino-pyridine or the like as a cocatalyst. By adoption of the method, the process is simple, and the raw material alpha-pinene is cheap, easily available and renewable. The method has the advantages of high catalytic efficiency, large molecular weight of copolymers, narrow distribution and the like. The polycarbonate obtained by polymerization has the characteristics of excellent biodegradability, excellent biocompatibility and the like, and can be applied to industries such as agriculture, biomedicine and the like.

Owner:KUNMING UNIV OF SCI & TECH

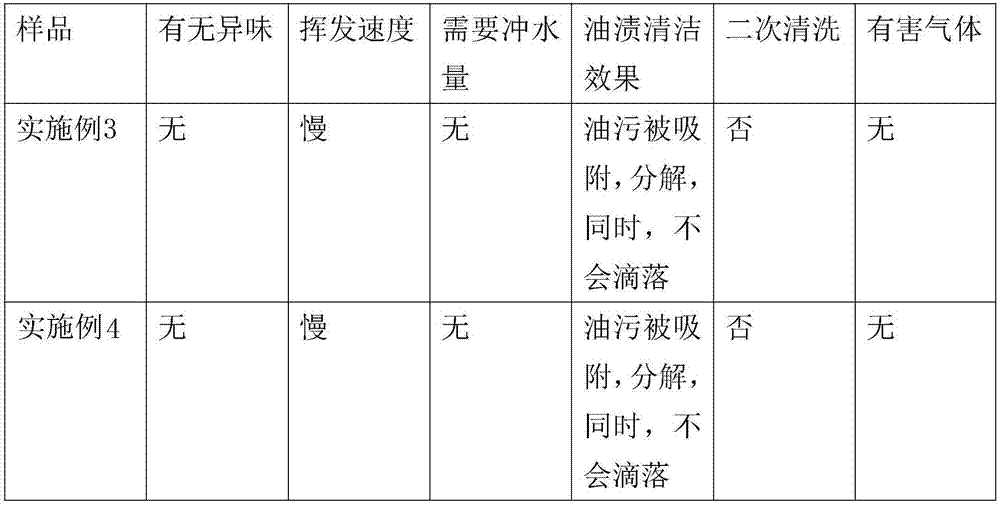

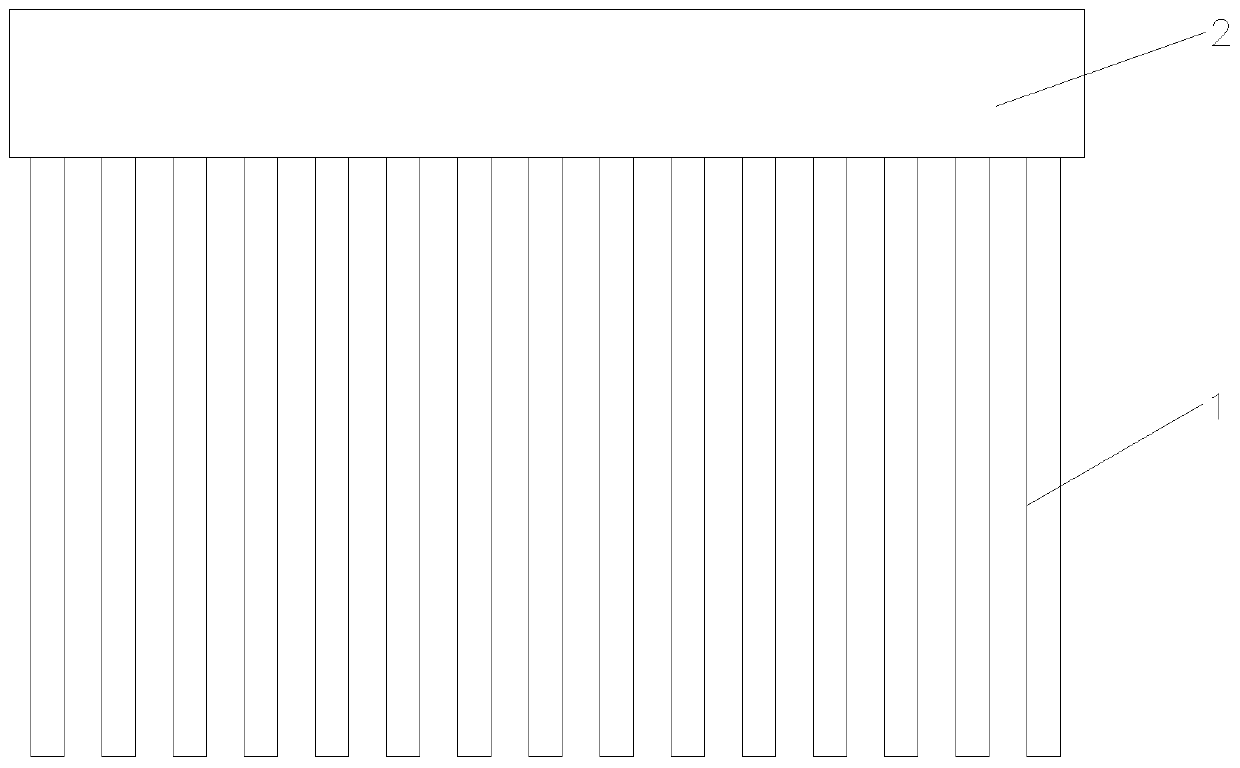

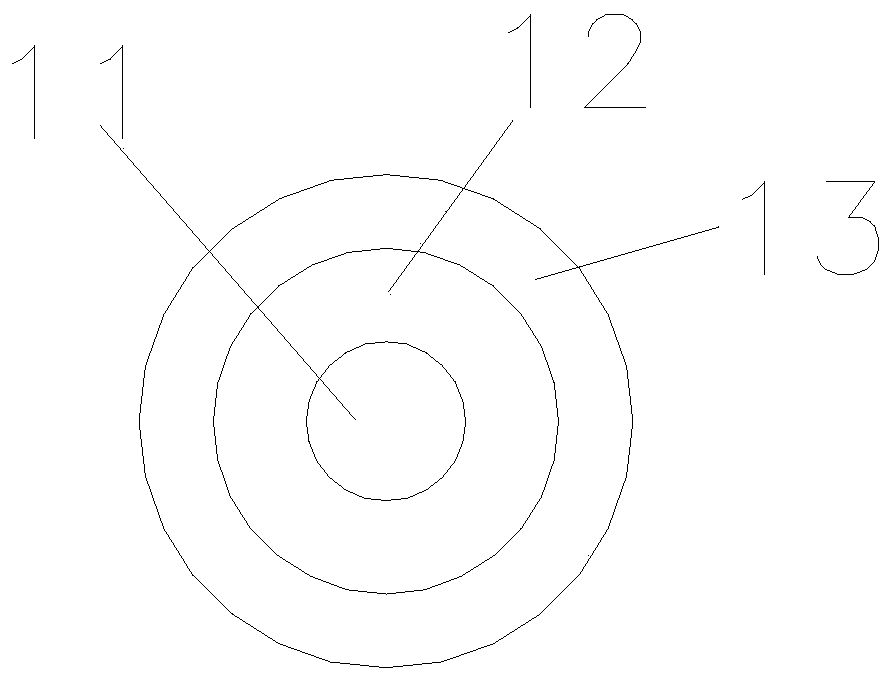

Multi-layer oil stain adsorption cleaning tool

ActiveCN107969785AEasy to cleanCause secondary pollutionBristleCoatingsMicrocrystalline waxVegetable oil

The invention provides a multi-layer oil stain adsorption cleaning tool. A brush is of three-layer structure, the three layers are in nesting, wherein an inner layer is an anti-corrosion and high-tenacity rubber bar, a middle layer is soluble soft wax, and an outer layer is sponge. The multi-layer oil stain adsorption cleaning tool has the beneficial effects that the inner layer is the anti-corrosion and high-tenacity rubber bar, due to adding of toughening polyvinyl chloride resin, to-and-fro bending can be realized, the service life is long, acrylic polymers adopt double bonds, auto-agglutination can be realized easily, copolymerization also can be realized easily, aggregation is realized rapidly, the tenacity is increased, the middle layer is soluble soft wax, microcrystalline wax is adopted as the main body, vegetable oil is matched for forming the inner layer, the outer layer is coated with wax prepared by adopting oil gel, after adsorbing oil stains, the wax is dissolved and diluted with the oil stains, so that the oil stains are effectively cleaned, the sponge on the outer layer adsorbs the oil stains, the oil stains permeate to the surface of wax through the sponge, are dissolved with the wax, and are left on the sponge, so that no secondary pollution is caused to glass.

Owner:ANHUI KECHANG MACHINERY MFG

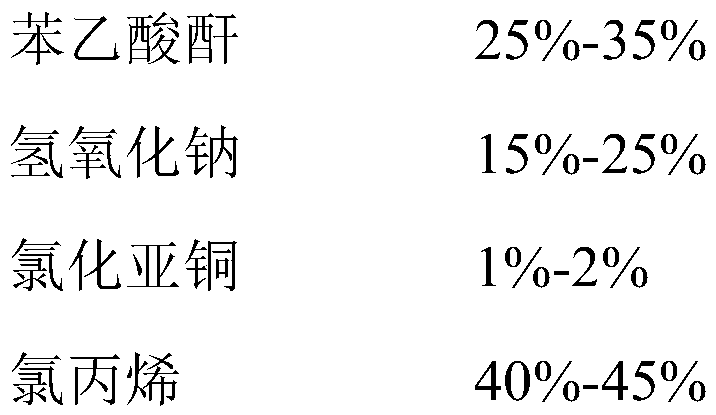

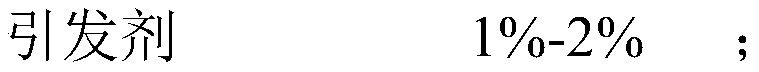

A method of using single-entry type ceramic wood

ActiveCN108789705BStable network structureImprove thermal stabilityWood treatment detailsPressure impregnationFiberSodium acetate

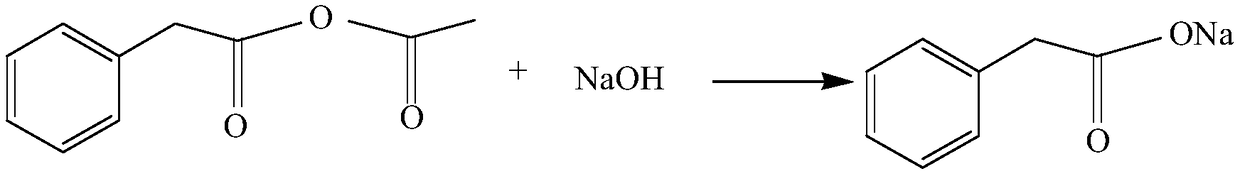

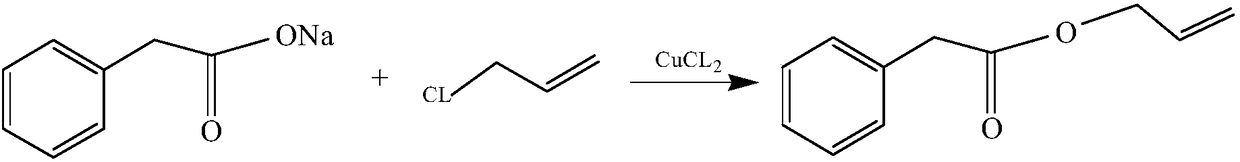

The invention discloses an application method of single body entry type ceramic wood. During ceramic wood preparing, sodium phenylacetate and chloropropene prepared through the reaction of phenylacetic acid and sodium hydroxide enters wood, allyl phenylacetate is generated, then, a high-molecular polymer is generated, and a net-shaped structure is formed by the high-molecular polymer and wood fiber. The interior-exterior structure, rigidity and strength of the ceramic wood can be consistent, and the interior and exterior waterproof performance, corrosion resisting performance, mothproof performance, anti-mold performance, safety performance and size stability of the ceramic wood are guaranteed, and therefore the ceramic wood can be directly used on the premise that coating of a coat is notconducted; and when the surface of the ceramic wood is old-fashioned, the performance of the ceramic wood is not influenced after grinding.

Owner:中吉亚(山东)新材料有限公司

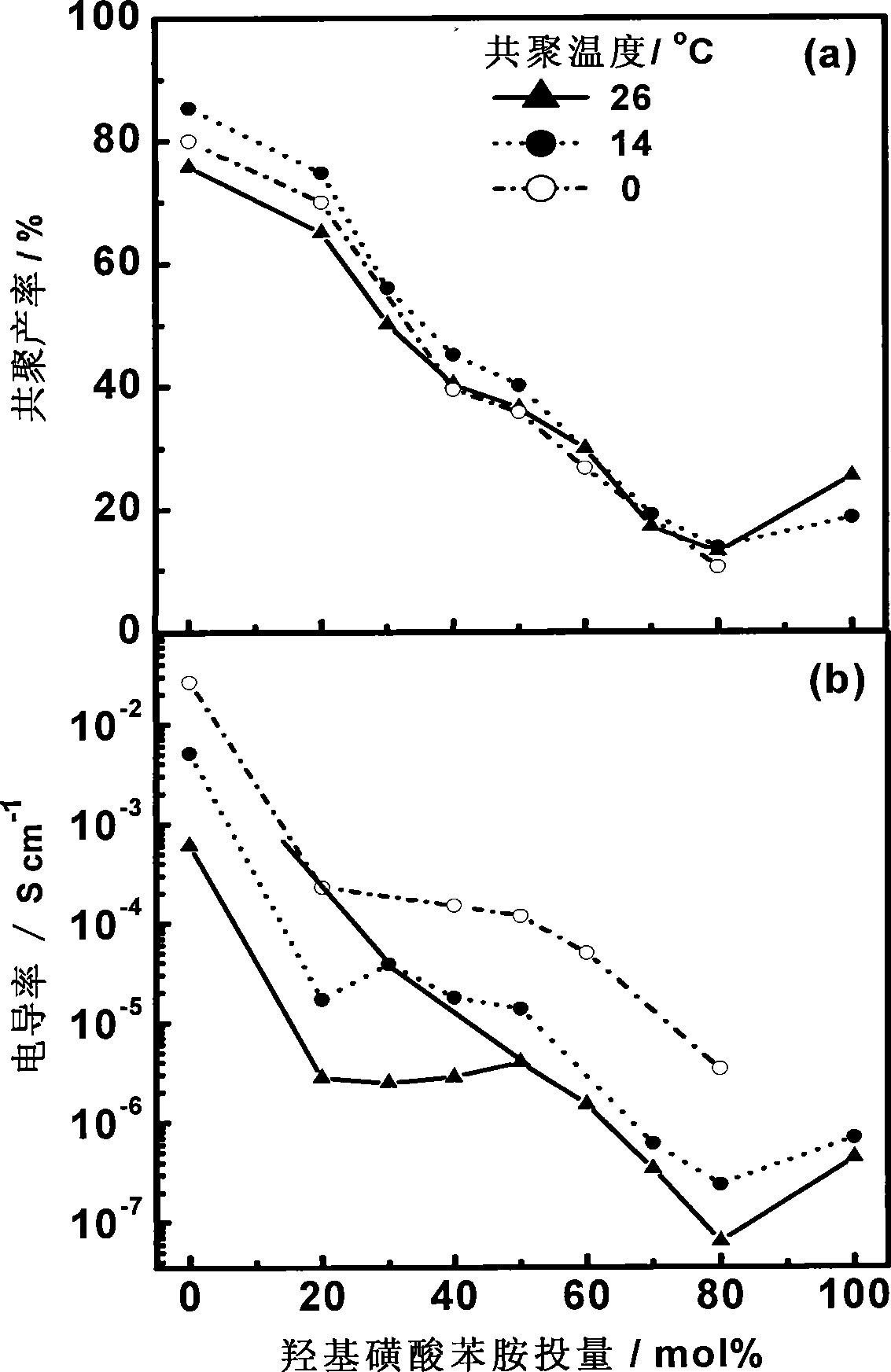

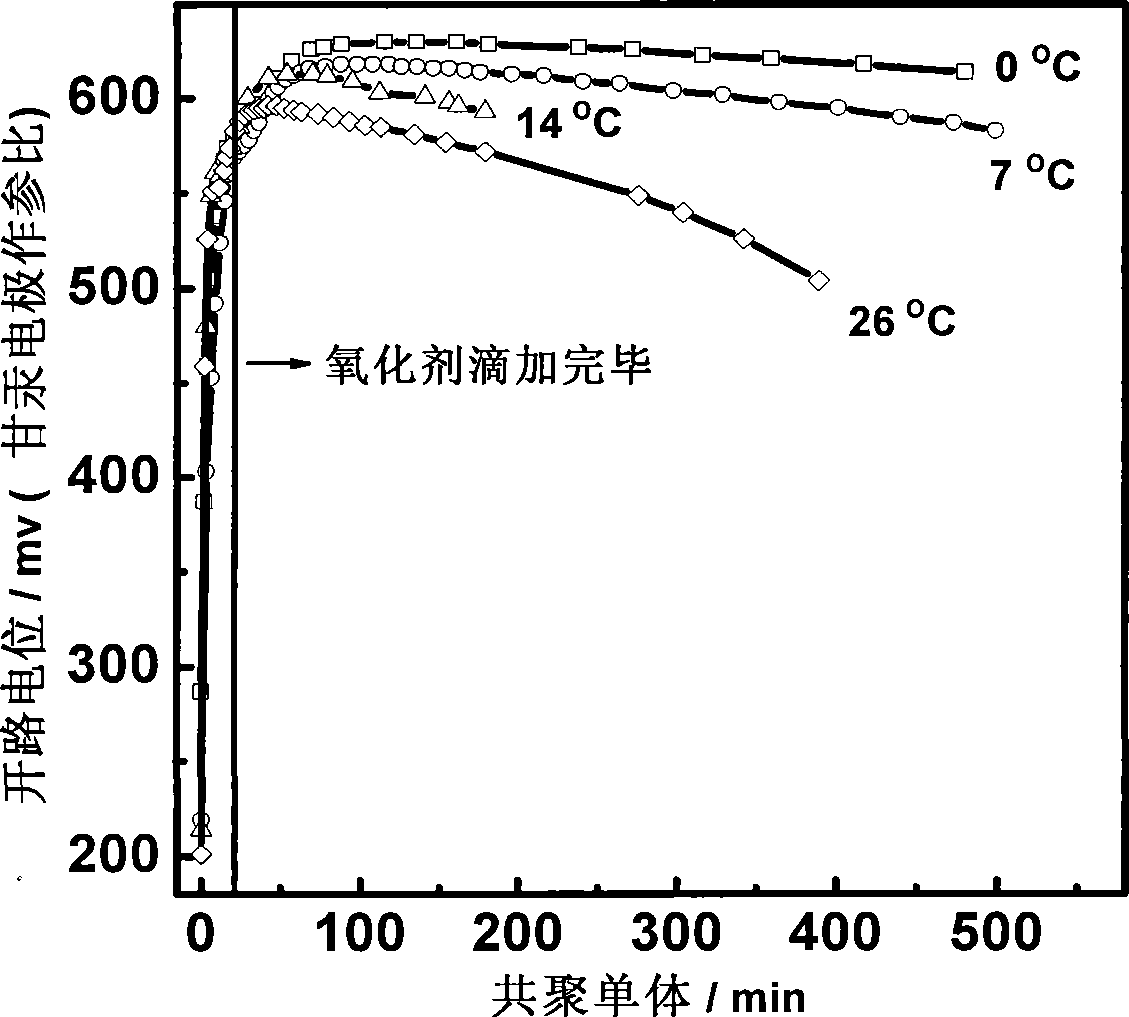

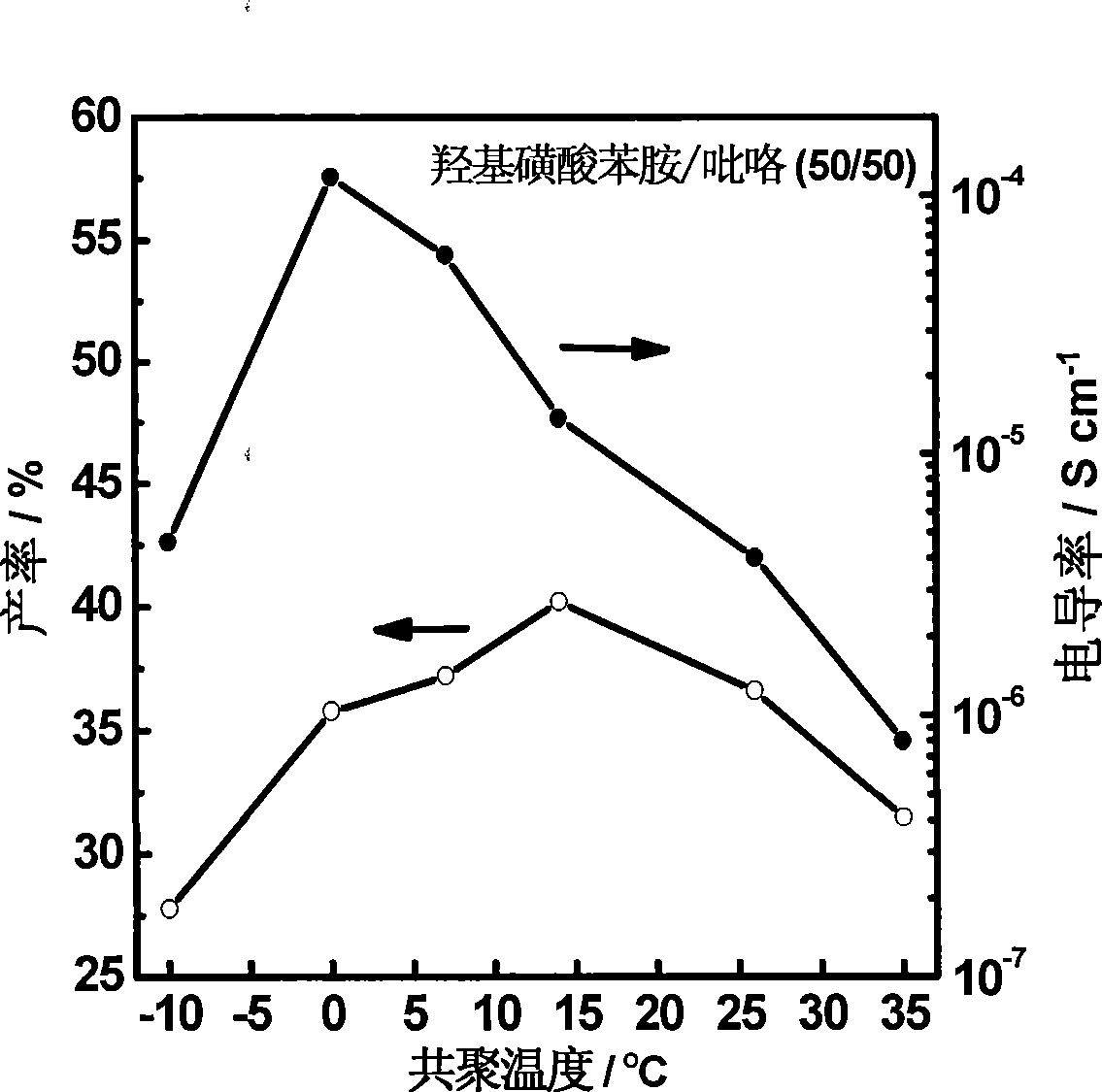

Method for preparing nano-polymers of hydroxyl sulfoacid phenylamine and pyrrole

The invention discloses a preparation method for nano-polymer of hydroxyl acid aniline and pyrrole, which is characterized in that hydroxyl sulfonic aniline and pyrrole dissolve in acid solution are added with oxidizers to totally react and then the nano-polymer of hydroxyl sulfonic aniline and pyrrole is obtained. The preparation method has the advantages that the sulfonic aniline monomer and the pyrrole are adopted to carry out the simple chemical oxidation copolymerization, and the electrostatic repulsion effect of the sulfonic groups is utilized to obtain conductive pyrrole copolymer nano-particles; the method does not additionally need stabilizing agents, so the post treatment process is very simple, and the obtained nano-particles have clean surfaces and good self stability; at the same time, the functional groups are introduced into the copolymer molecules.

Owner:TONGJI UNIV

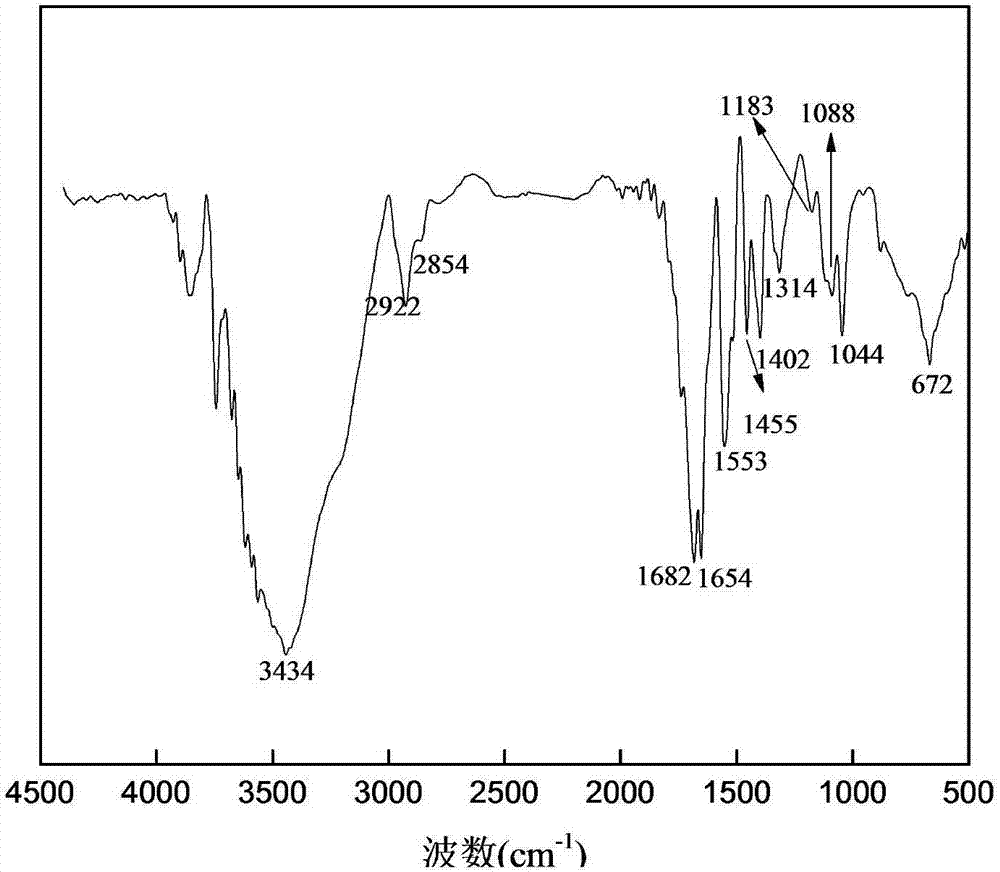

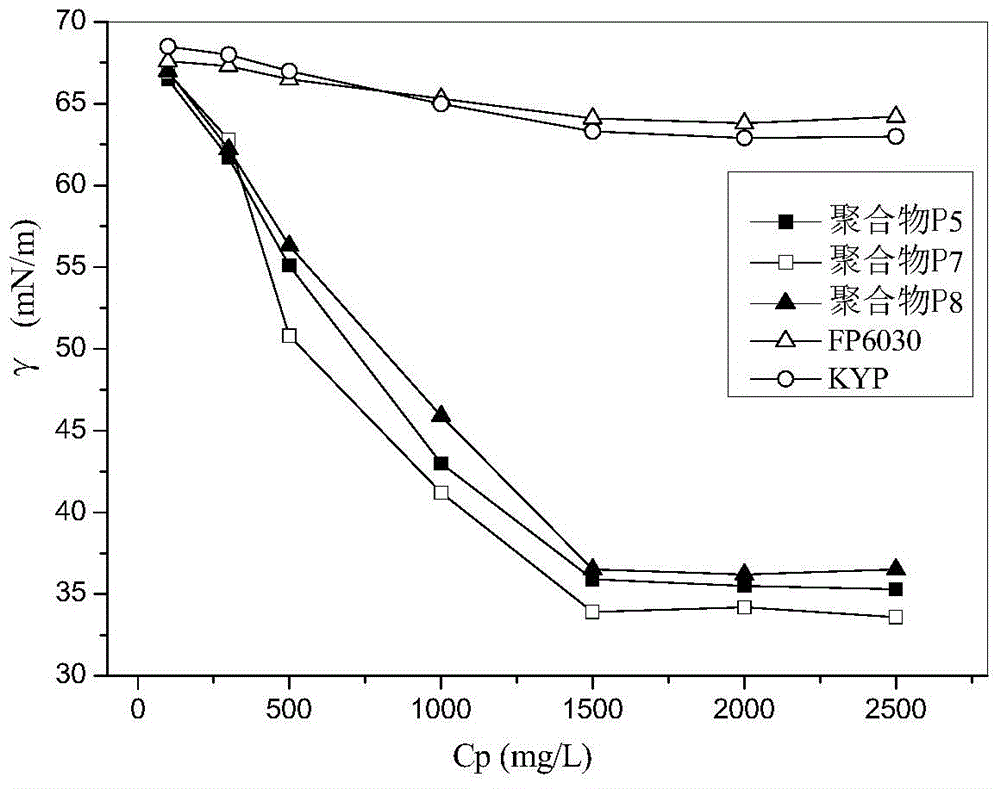

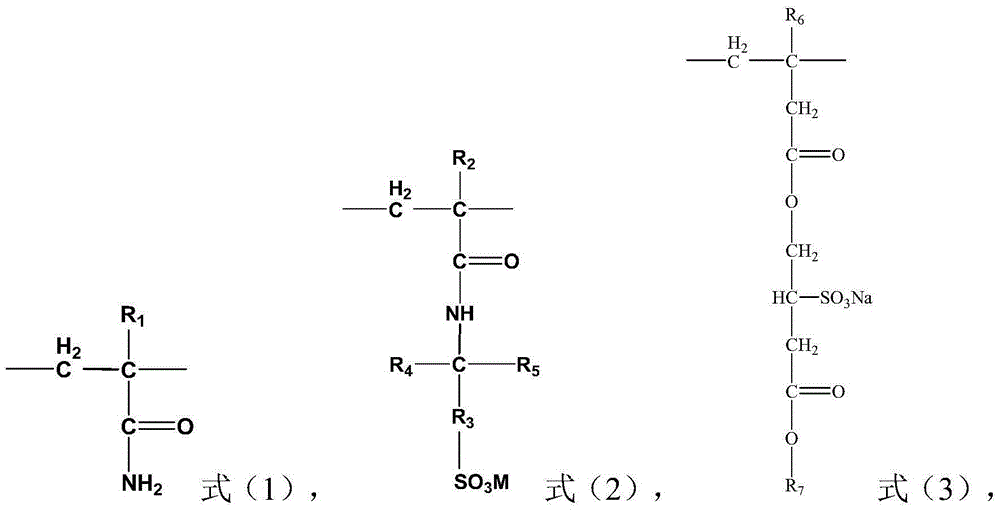

Polymer with surface activity function and preparation method and application thereof

InactiveCN106478868AImprove surface activityEasy to copolymerizeDrilling compositionPolymer scienceHeat resistance

The invention relates to the field of polymers, and discloses a polymer with surface activity function and a preparation method and application thereof. The polymer comprises structural unit A, structural unit B and structural unit C, wherein the structural unit A is a structural unit with structure shown in formula (1); the structural unit B is a structural unit with structure shown in formula (2); and the structural unit C is a structural unit with structure shown in formula (3). The polymer with surface activity function has good surface activity, aqueous medium thickening ability, and heat resistance and salt tolerance.

Owner:CHINA PETROLEUM & CHEM CORP +1

A preparation method of composite nanofiber membrane, composite nanofiber membrane and its application in enzyme immobilization and immobilized enzyme

ActiveCN108754871BLarge specific surface areaHigh chemical activityElectro-spinningOn/in organic carrierPolymer scienceComposite nanofibers

The invention belongs to the field of nanofiber membranes, and particularly relates to a preparation method of a composite nanofiber membrane, the composite nanofiber membrane, application of the composite nanofiber membrane to enzyme immobilization and an immobilized enzyme. An electrostatic spinning solution containing chitosan is adopted for preparing the nanofiber membrane, and the membrane has a good film-forming property and an enzyme-immobilizing function; meanwhile, polypeptide nanofibers are adopted and loaded onto the membrane, in this way, the property of the membrane is further improved, and the enzyme-immobilizing property of the membrane is improved.

Owner:ANHUI POLYTECHNIC UNIV

A kind of sulfonate betaine type hydrophobic association polymer and preparation method thereof

Owner:SOUTHWEST PETROLEUM UNIV

A new type of brush for cleaning glass oil stains

The invention discloses a novel glass oil stain cleaning hairbrush. The hairbrush is of a three-layer structure, wherein the three layers are mutually nested; the inner layer is a corrosion-resistinghigh-tenacity rubber strip; the middle layer is soluble soft wax; and the outer layer is a sponge. The hairbrush has the beneficial effects that the inner layer, which is the corrosion-resisting high-tenacity rubber strip, can be bent forth and back due to the addition of toughened polyvinyl chloride, so that service life in practical use is prolonged; through acrylate polymer double bonds, self-polymerization and co-polymerization are promoted, agglomeration is accelerated, and tenacity is enhanced; the middle layer, which is soluble soft wax, takes micro-crystalline wax as a main body, and the middle layer is defined in cooperation with the micro-crystalline wax and vegetable oil; the outer layer is covered by wax which is prepared from an oil gel, and the wax can get thinned as being dissolved together with oil stains which are adsorbed, so that the oil stains can be effectively cleaned; the oil stains are adsorbed by virtue of the sponge of the outer layer; and the oil stains can penetrate to the surface of the wax via the sponge, get dissolved together with the wax and remain on the sponge, so that secondary pollution to glass is prevented.

Owner:江门市意奇高工贸有限公司

A preparation method of organosilicon-modified polyacrylate pressure-sensitive adhesive and the obtained pressure-sensitive adhesive

ActiveCN109536085BGood adhesionStrong cohesionEster polymer adhesivesPolymer scienceFunctional monomer

This application relates to a preparation method of silicone-modified polyacrylate pressure-sensitive adhesive. The mixture of butyl ester, acrylic acid functional monomer and a part of the initiator is continuously added dropwise for reaction. After the drop is completed, methyl methacrylate as acrylic acid hard monomer is added to the reactor at one time, and then the remaining part of the initiator is added to the reactor at one time. , continue the reaction. Since the present invention adopts SPS, and adopts the process of adding dropwise reaction first and then adding methyl methacrylate and the remaining initiator to react, the prepared silicone modified polyacrylate pressure-sensitive adhesive can guarantee a certain degree of peeling Strength while reducing the growth of peel strength, and has high temperature resistance.

Owner:深圳市益达兴科技股份有限公司

A kind of preparation technology of chitosan oligosaccharide grafted cellulose fiber

ActiveCN109112830BHigh amino contentReact SafeBiochemical fibre treatmentVegetal fibresPotassium persulfateSulfonate

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN

A multi-layer oil stain adsorption cleaning tool

ActiveCN107969785BEasy to cleanCause secondary pollutionBristleCoatingsPolymer scienceMicrocrystalline wax

The invention provides a multi-layer oil stain adsorption cleaning tool. A brush is of three-layer structure, the three layers are in nesting, wherein an inner layer is an anti-corrosion and high-tenacity rubber bar, a middle layer is soluble soft wax, and an outer layer is sponge. The multi-layer oil stain adsorption cleaning tool has the beneficial effects that the inner layer is the anti-corrosion and high-tenacity rubber bar, due to adding of toughening polyvinyl chloride resin, to-and-fro bending can be realized, the service life is long, acrylic polymers adopt double bonds, auto-agglutination can be realized easily, copolymerization also can be realized easily, aggregation is realized rapidly, the tenacity is increased, the middle layer is soluble soft wax, microcrystalline wax is adopted as the main body, vegetable oil is matched for forming the inner layer, the outer layer is coated with wax prepared by adopting oil gel, after adsorbing oil stains, the wax is dissolved and diluted with the oil stains, so that the oil stains are effectively cleaned, the sponge on the outer layer adsorbs the oil stains, the oil stains permeate to the surface of wax through the sponge, are dissolved with the wax, and are left on the sponge, so that no secondary pollution is caused to glass.

Owner:ANHUI KECHANG MACHINERY MFG

A kind of supramolecular polymer based on multiple intermolecular forces and preparation method thereof

ActiveCN107459604BGood temperature and salt resistanceEasy to copolymerizeDrilling compositionPersulfateAlkylphenol

Owner:SOUTHWEST PETROLEUM UNIV

A kind of synthetic method of graphene reverse osmosis composite membrane

ActiveCN106178977BEasy to copolymerizeImprove qualityWater contaminantsReverse osmosisSynthesis methodsReverse osmosis

Owner:XINXIANG UNIV

A kind of double tail hydrophobic association polymer with surface activity and preparation method thereof

Owner:SOUTHWEST PETROLEUM UNIV

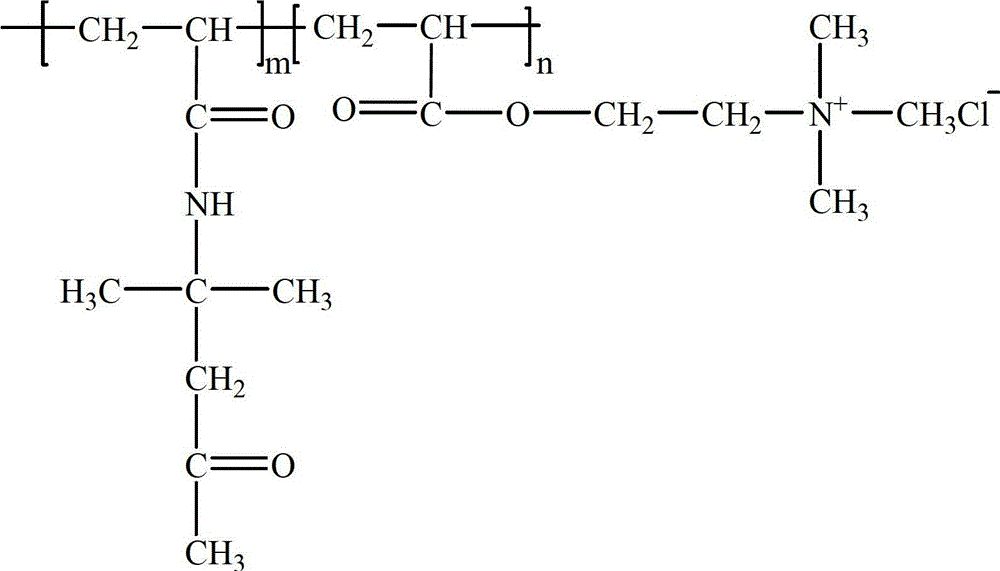

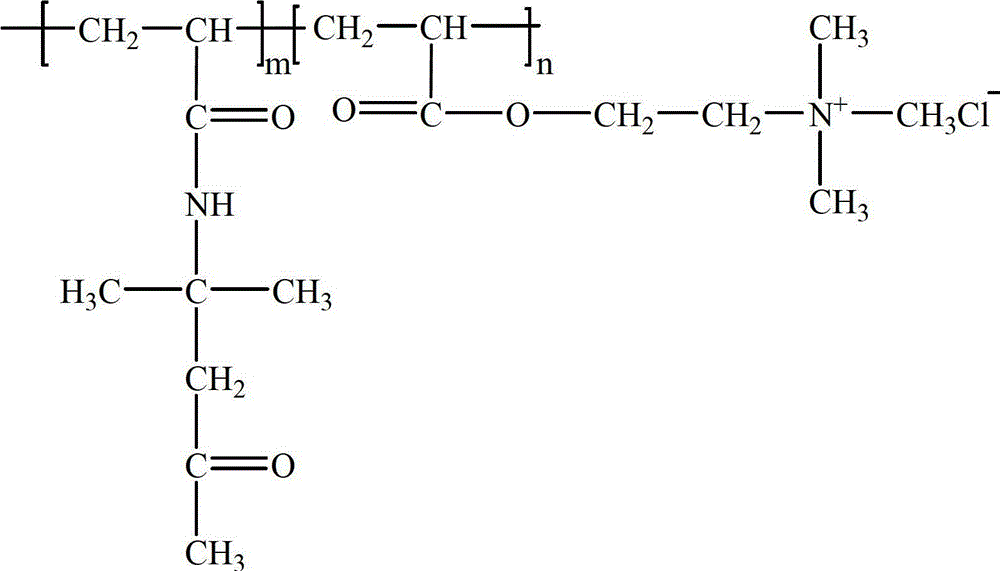

A kind of diacetone acrylamide-acryloyloxyethyltrimethylammonium chloride copolymer and preparation method thereof

ActiveCN103044617BImprove adsorption capacityGuaranteed adsorption effectWater/sewage treatment by flocculation/precipitationPotassium peroxodisulfateWaste treatment

Owner:SHAANXI UNIV OF SCI & TECH

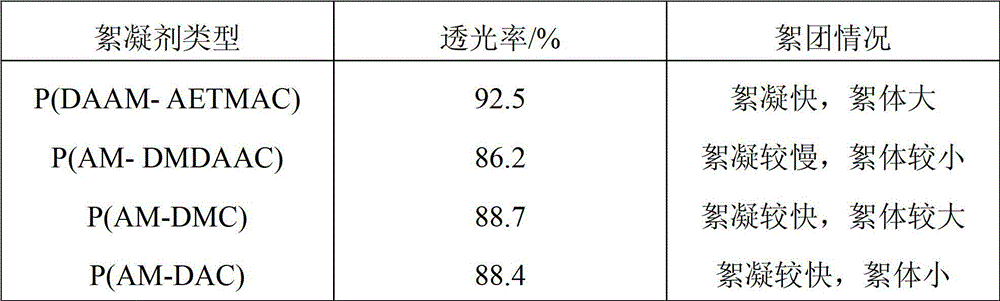

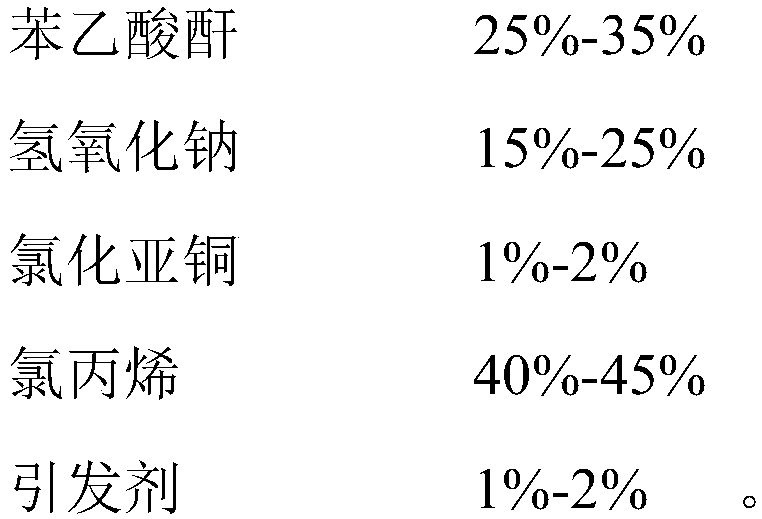

Application method of single body entry type ceramic wood

ActiveCN108789705AStable network structureImprove thermal stabilityWood treatment detailsPressure impregnationFiberBenzene

The invention discloses an application method of single body entry type ceramic wood. During ceramic wood preparing, sodium phenylacetate and chloropropene prepared through the reaction of phenylacetic acid and sodium hydroxide enters wood, allyl phenylacetate is generated, then, a high-molecular polymer is generated, and a net-shaped structure is formed by the high-molecular polymer and wood fiber. The interior-exterior structure, rigidity and strength of the ceramic wood can be consistent, and the interior and exterior waterproof performance, corrosion resisting performance, mothproof performance, anti-mold performance, safety performance and size stability of the ceramic wood are guaranteed, and therefore the ceramic wood can be directly used on the premise that coating of a coat is notconducted; and when the surface of the ceramic wood is old-fashioned, the performance of the ceramic wood is not influenced after grinding.

Owner:中吉亚(山东)新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com