Photothermal conversion component, and applications of aniline oligomer and derivatives thereof

A light-to-heat conversion and oligomer technology, applied in the field of light-to-heat conversion, can solve problems such as low heat conversion ability, high cost, and difficult preparation, and achieve low raw material cost, excellent light-to-heat conversion performance, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

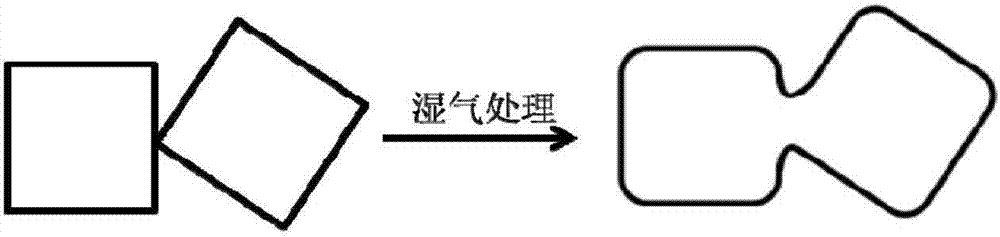

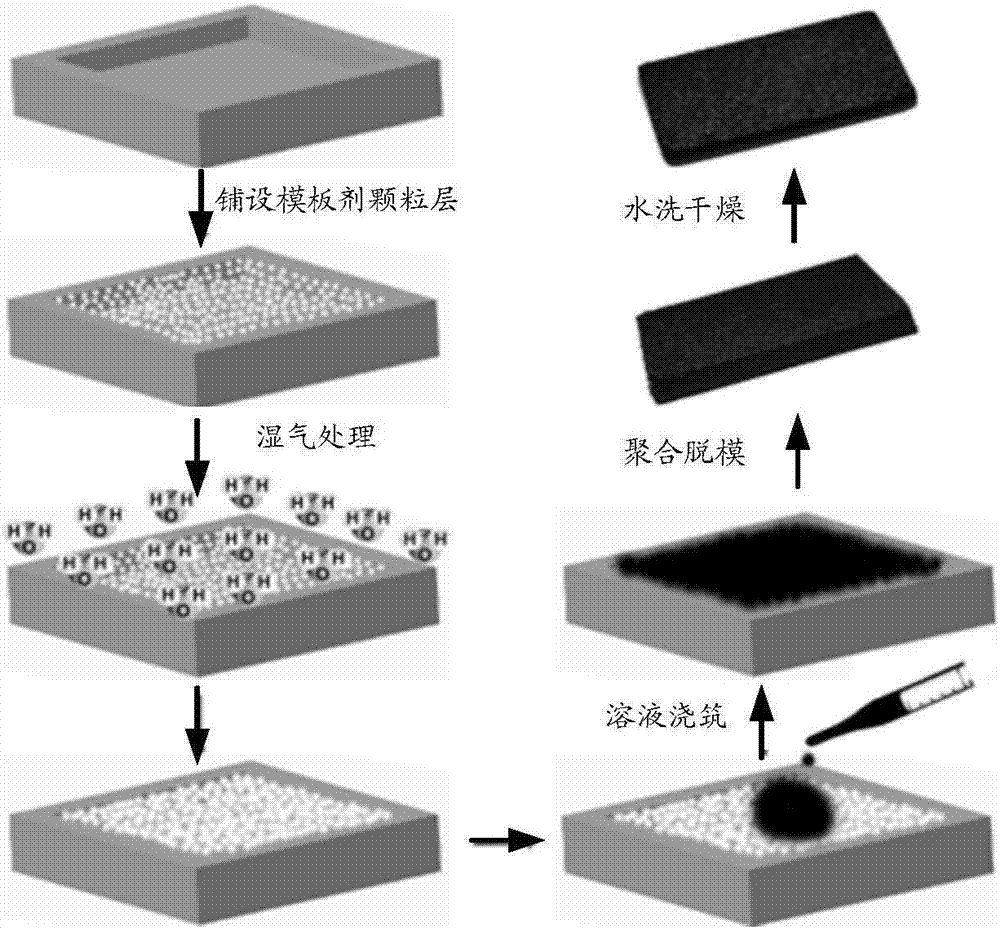

[0059] Sodium chloride crystals are laid into a mold, treated with water vapor and then dried to obtain a porous template formed by connecting multiple sodium chloride particles. The humidity of the water vapor is 95%, and the treatment time is 4 hours. At room temperature, 1 mmol of amino-terminated aniline trimer, 2.5 mmol of paraformaldehyde and 4 ml of nitrogen-methylpyrrolidone were mixed and ultrasonically dispersed to obtain a mixed solution. The mixed solution was stirred and pre-polymerized in an oil bath at 50°C for 30 minutes, and the pre-polymerized solution was poured onto the porous template, heated and cured at 50°C for 4 hours, and then heated to 200°C for 1 hour to synthesize the polymer in situ on the surface of the porous template. The polymer is released from the mold, and the porous template is washed away with distilled water to obtain a porous polymer having the following structural formula (I).

[0060]

[0061] The resulting porous polymer has a de...

Embodiment 2

[0066] Mix 0.55mmol of terephthalaldehyde, 0.4mmol of amino-terminated aniline trimer and 2ml of N,N-dimethylformamide by ultrasonic mixing, then add 0.1mmol of diethylenetriamine, heat and stir at 50°C for 30 minutes , the mixed solution was moved to the mold, reacted at 75°C for 30 minutes, 85°C for 30 minutes, and 120°C for 1 hour, and the obtained aniline-based polymer was a dynamic Schiff base system polymer with photothermal conversion effect. Due to the existence of Schiff base dynamic bonds, the system can reshape, self-heal and bond at high temperature. Moreover, the type and content of each component of the system can be adjusted according to demand.

Embodiment 3

[0068] 3.3 mmol of bisphenol A diglycidyl ether, 0.3 mmol of amino-terminated aniline trimer, 2.7 mmol of sebacic acid and 10 ml of N,N-dimethylformamide were ultrasonically mixed, and heated and stirred at 120°C for 1 hour. Then add 4g of silica gel (100-200 mesh), ultrasonic for 30 minutes, continue heating and stirring at 120°C for 1 hour, move the mixture to a mold, react at 120°C for 2 hours, 140°C for 2 hours, and 160°C for 30 minutes to obtain Photothermal conversion effect of silica-epoxy composite particles. The type and content of each component of the system can be adjusted according to demand.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| photothermal conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com